Page 1

Technical Information

Series 42 4T Axial Piston Tandem Pumps

Size 41/51

www.danfoss.com

Page 2

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Revision history Table of revisions

Date Changed Rev

November 2020 Minor update in Hydraulic Fluid Parameters 0302

July 2020 Changed document number from 'BC00000036' to 'BC152886482857' 0301

December 2018 Corrected technical data in System Parameters 0201

June 2016 converted to new layout 0101

May 2015 Converted to DITA CMS BA

February 2008 Corrections-Drawings AB

January 2008 First edition AA

2 | © Danfoss | November 2020 BC152886482857en-000302

Page 3

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Contents

Series 42 warehouse

General Description

Basic Design........................................................................................................................................................................................6

System Diagram................................................................................................................................................................................7

System Schematic............................................................................................................................................................................ 8

Technical Specifications

System Specifications...................................................................................................................................................................10

System Parameters........................................................................................................................................................................10

Hydraulic Fluid Parameters........................................................................................................................................................ 11

Operating Parameters

System Requirements...................................................................................................................................................................12

System Parameters........................................................................................................................................................................12

Hydraulic Fluid Parameters........................................................................................................................................................ 13

Sizing Equations............................................................................................................................................................................. 14

System Design Parameters

Fluid and Filtration........................................................................................................................................................................ 15

Filtration Configuration...............................................................................................................................................................15

Mounting Flange Loads...............................................................................................................................................................16

Estimating Overhung Load Moment.................................................................................................................................16

Case Drain.........................................................................................................................................................................................17

External Shaft Load and Bearing Life......................................................................................................................................17

Hydraulic Unit Life......................................................................................................................................................................... 18

Efficiency Graphs............................................................................................................................................................................19

Features and Options

Charge Pump...................................................................................................................................................................................20

Charge Pump Sizing Example:.............................................................................................................................................20

Charge Relief Valve........................................................................................................................................................................20

Overpressure Protection............................................................................................................................................................. 21

Bypass Valve.....................................................................................................................................................................................22

Displacement Limiters................................................................................................................................................................. 22

Shaft Options...................................................................................................................................................................................22

Auxiliary Mounting Pads............................................................................................................................................................. 23

Center Coupling............................................................................................................................................................................. 24

Control Selection............................................................................................................................................................................24

Manual Displacement Control (MDC).....................................................................................................................................26

Features and Benefit of MDC................................................................................................................................................26

Control Input Signal.................................................................................................................................................................27

Response Time...........................................................................................................................................................................27

Control Handles.........................................................................................................................................................................28

Electric Solenoid Override to Neutral................................................................................................................................28

Emergency Override to Neutral with Port for Brake Pressure Release..................................................................29

Neutral Start Switch (NSS)..................................................................................................................................................... 30

NSS with Back-up Alarm (BUA) Switch..............................................................................................................................30

Connectors..................................................................................................................................................................................30

Non-Feedback, Proportional Hydraulic (NFPH) Control.................................................................................................. 32

Features and Benefits of the NFPH control..................................................................................................................... 33

Connectors and Port locations............................................................................................................................................ 33

Installation Drawings

Manual Displacement Control (MDC).....................................................................................................................................34

Port Description........................................................................................................................................................................ 34

Dimensions................................................................................................................................................................................. 36

Non-Feedback, Proportional Hydraulic (NFPH).................................................................................................................. 39

Port Description........................................................................................................................................................................ 39

Dimensions................................................................................................................................................................................. 41

Shaft Options...................................................................................................................................................................................44

Displacement Limiter................................................................................................................................................................... 45

©

Danfoss | November 2020 BC152886482857en-000302 | 3

Page 4

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Contents

By-pass Valve...................................................................................................................................................................................46

Control Modules.............................................................................................................................................................................46

Auxiliary Mounting Pads............................................................................................................................................................. 48

Model Code

Model Code: A, Y, Z........................................................................................................................................................................50

Model Code: FD, FX, RD, RX........................................................................................................................................................51

Model Code: FE, RE........................................................................................................................................................................ 52

Model Code: FT, RT, FH, RH, FJ, RJ, FK, RK..............................................................................................................................53

Model Code: FL, RL, FM. RM........................................................................................................................................................54

Model Code: C, F, S........................................................................................................................................................................ 56

Model Code: U, G, V.......................................................................................................................................................................57

Model Code: N, P............................................................................................................................................................................58

4 | © Danfoss | November 2020 BC152886482857en-000302

Page 5

Piston centering spring

Servo piston

P100412E

P400169

M4

M5

L2

X2 X1

D

i

s

p

l

a

c

e

m

e

n

t

100%

100%

15 18

6

6

1518

P001628E

Signal Dp (bar)

Dp system=345bar

Dp system=345bar

Dp system=35bar

Dp system=35bar

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Series 42 warehouse

Series 42 warehouse

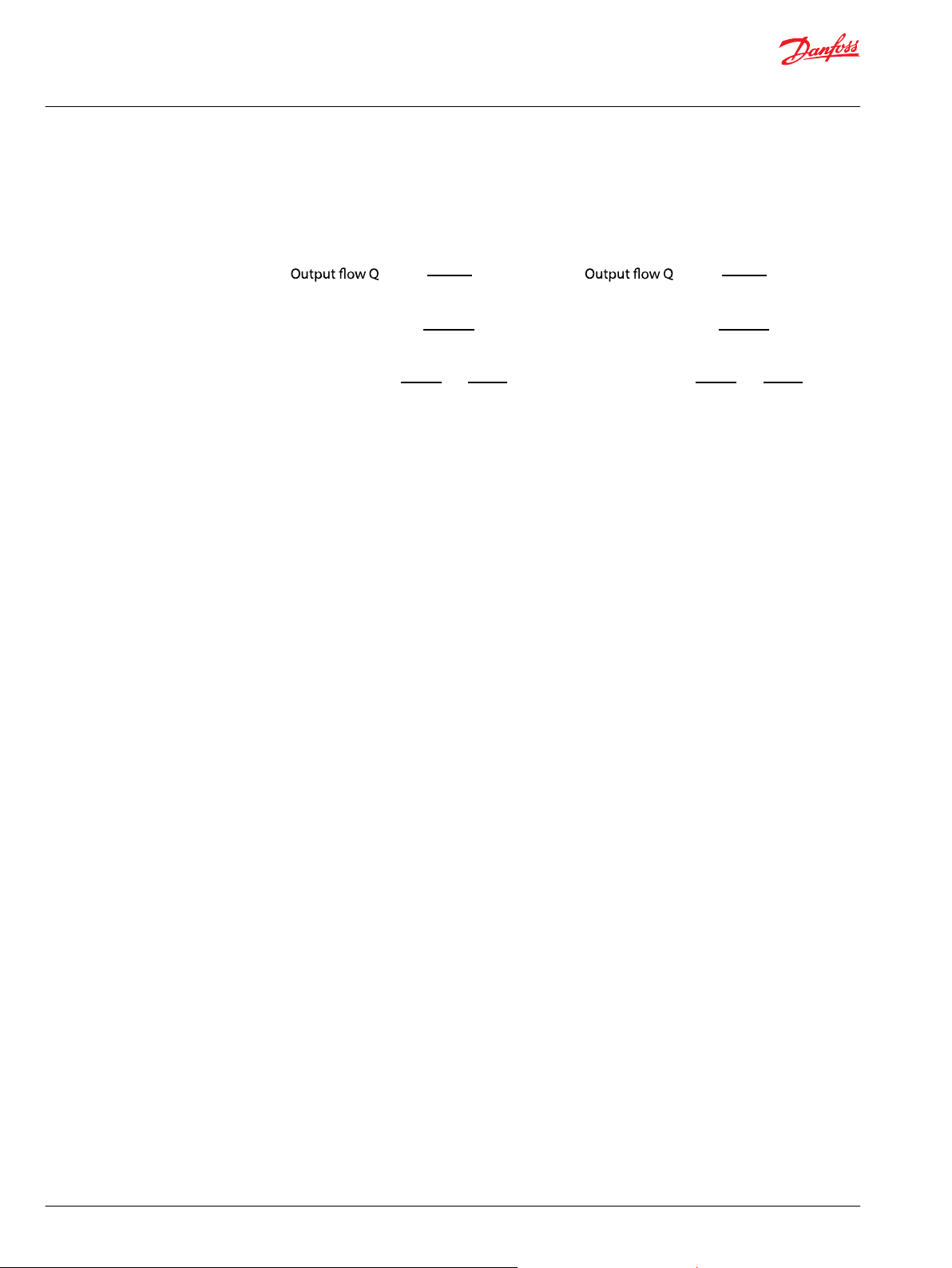

Pump displacement versus signal pressure

NFPH pump displacement to Input signal

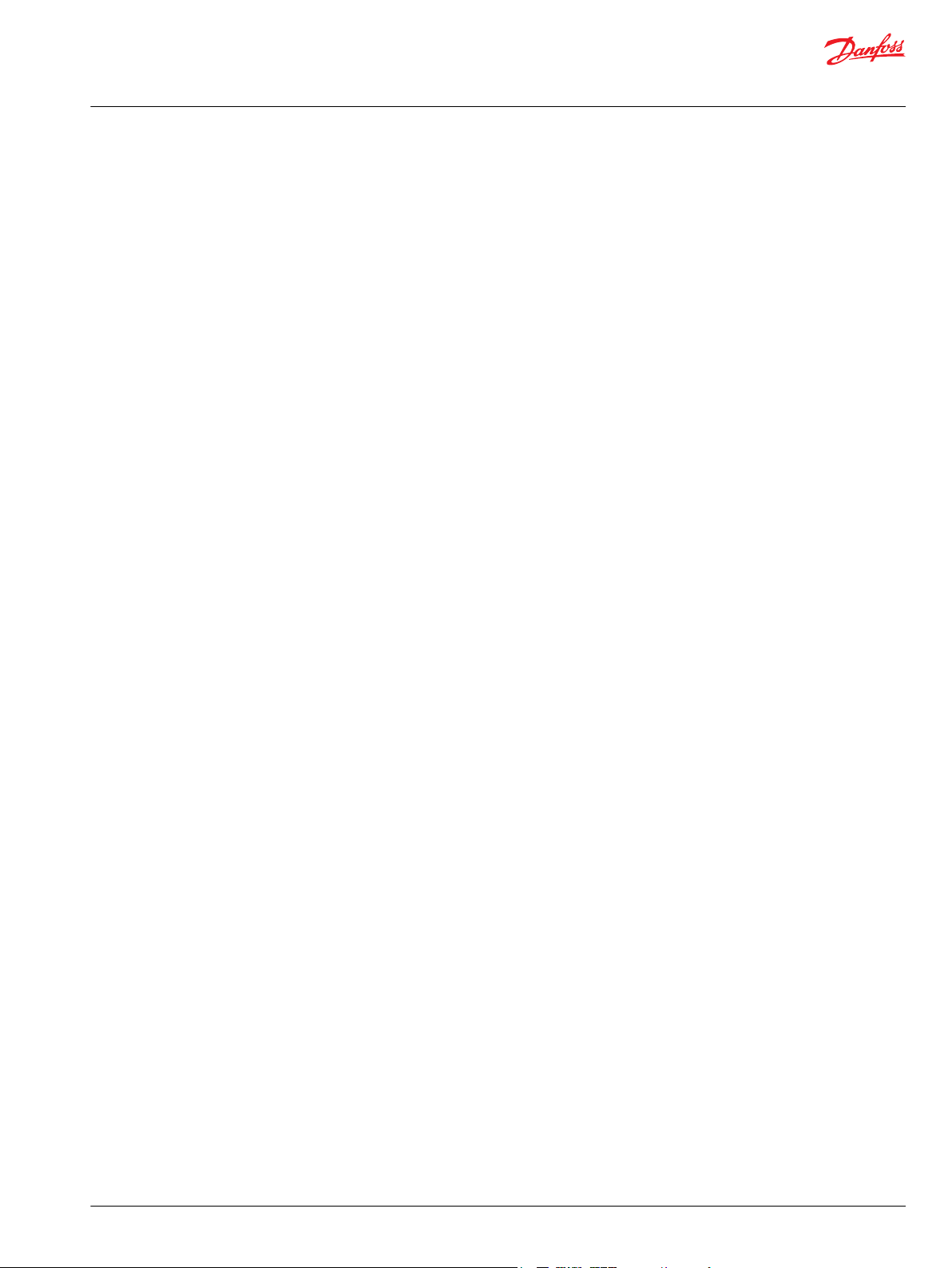

Non-feedback proportional hydraulic control

schematic

©

Danfoss | November 2020 BC152886482857en-000302 | 5

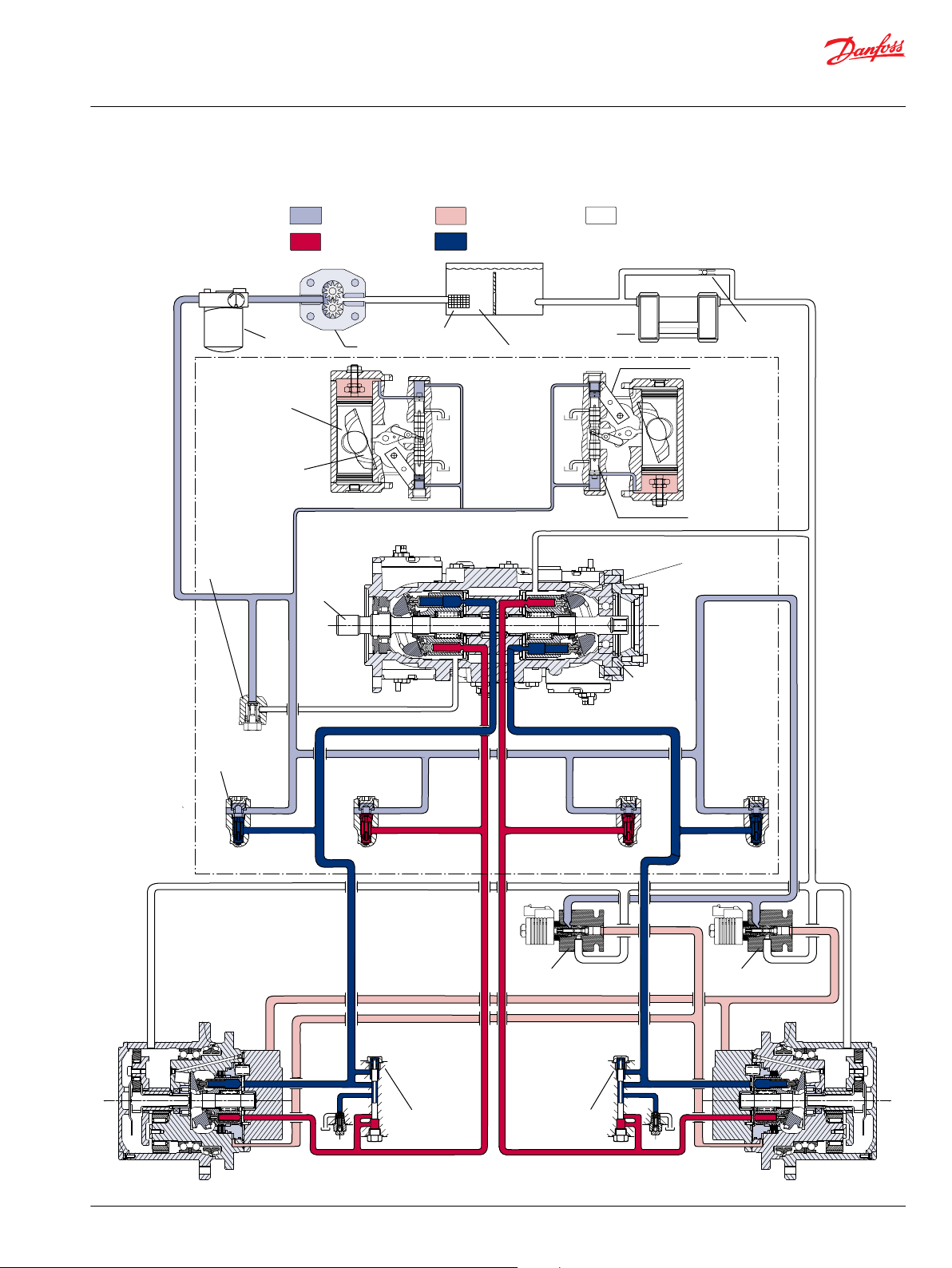

Page 6

Piston Swashplate

Roller bearing

Valve plate

Ball bearing

P400160

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

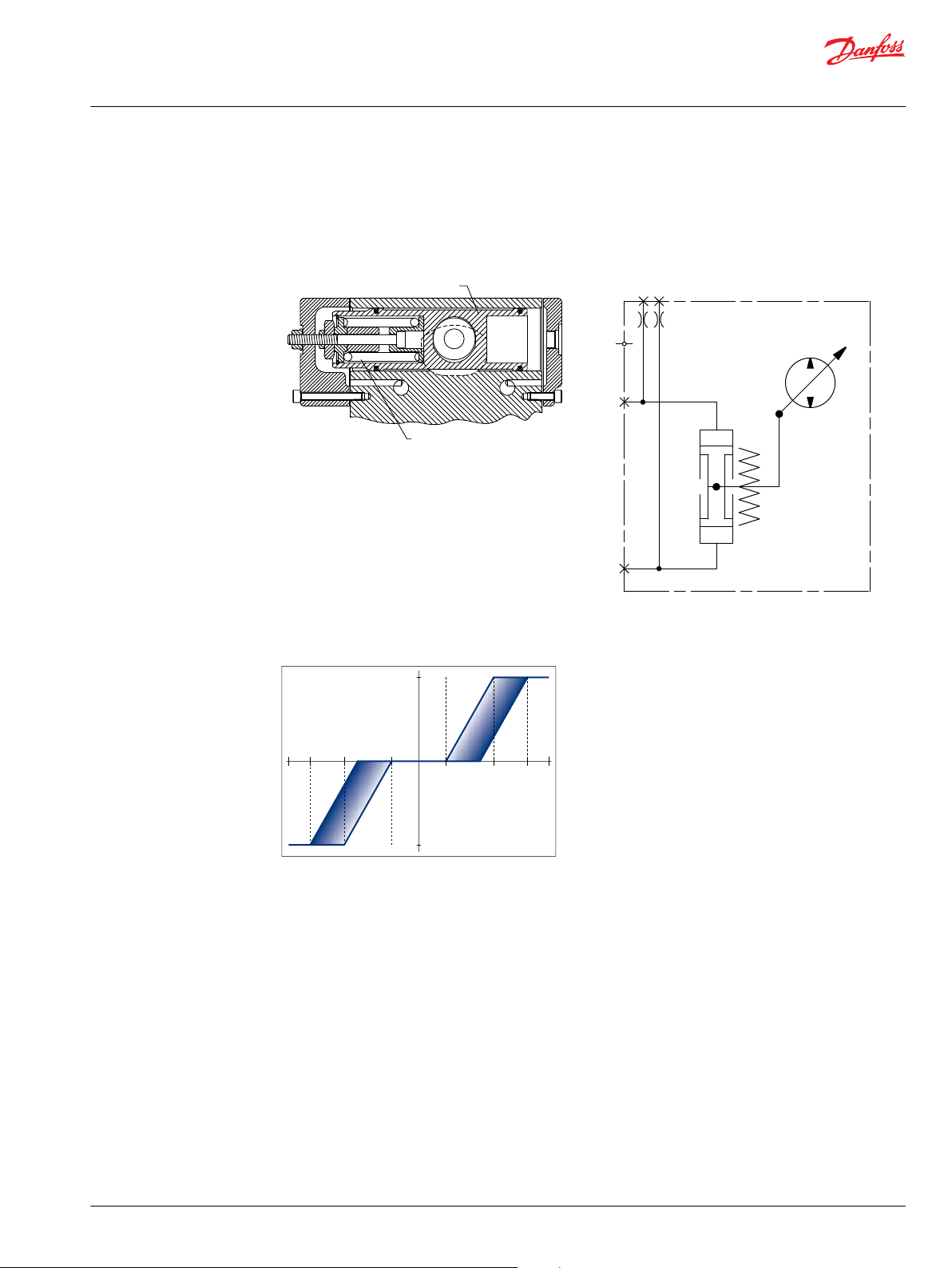

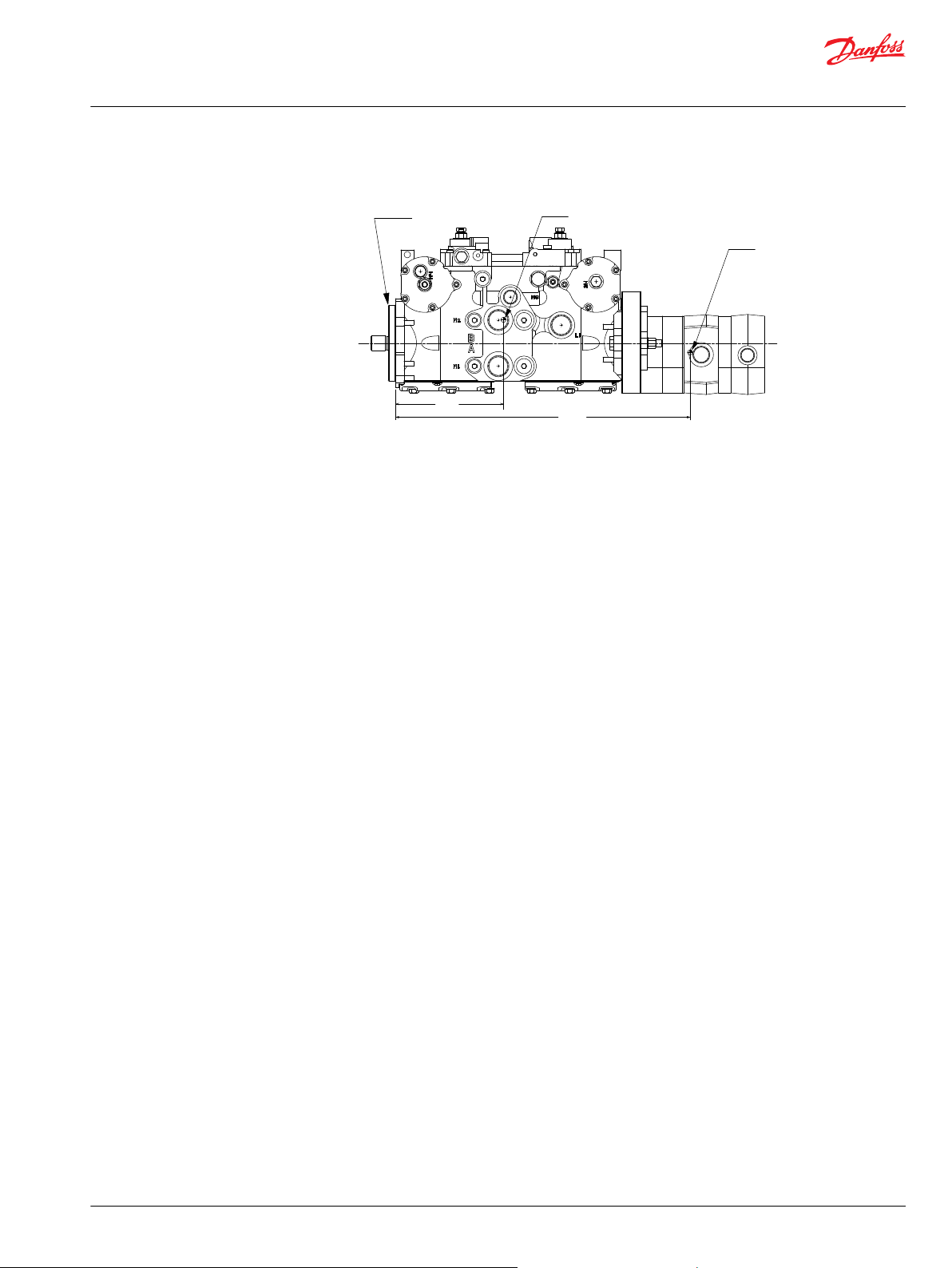

General Description

Basic Design

S42 Integrated Tandem Pumps (4T) are advanced hydrostatic units for medium power applications with

maximum loads of 415 Bar [6020 psi] (41 cm3) and 350 Bar [5075 psi] (51 cm3). You can combine these

pumps with a suitable Danfoss motor or other products in a system to transfer and control hydraulic

power.

The 4T axial piston pump is a compact, high power density unit, using the parallel axial piston/slipper

concept in conjunction with tiltable swashplates to vary the pumps’ displacements.

Reversing the angle of the swashplate reverses the flow of fluid from the pump, and reversing the

direction of rotation of the motor output. 4T axial piston pumps provide an infinitely variable speed

range between zero and maximum in both forward and reverse.

4T axial piston pumps use a cradle swashplate design with a hydraulic servo control cylinder. Control is

provided through a compact servo control system. Two types of servo controls are available. These

include mechanical hydraulic actuated feedback controls, and hydraulic proportional control. These

controls feature low hysteresis and responsive performance.

Cross-sectional view

6 | © Danfoss | November 2020 BC152886482857en-000302

Page 7

Reservoir

Suction

Screen

Charge Pressure

Relief Valve

Servo Control

Cylinder

Swash Plate

Bypass Check

Heat Exchanger

Control Handle

Displacement

Control Spool

Cylinder Block

Assembly

Valiable

Displacement

Pump

Charge Pump

System Pressure

Control Pressure

Low Loop Pressure

Suction/Case Drain/

System Return

Charge Pressure

P106 147E

Loop

Flushing

Valve

Motor Gear boxMotorGear box

Loop

Flushing

Valve

Input

Shaft

Charge check/

HPRV valve

Brake release

control valve

Motor displacement

control valve

Filter

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

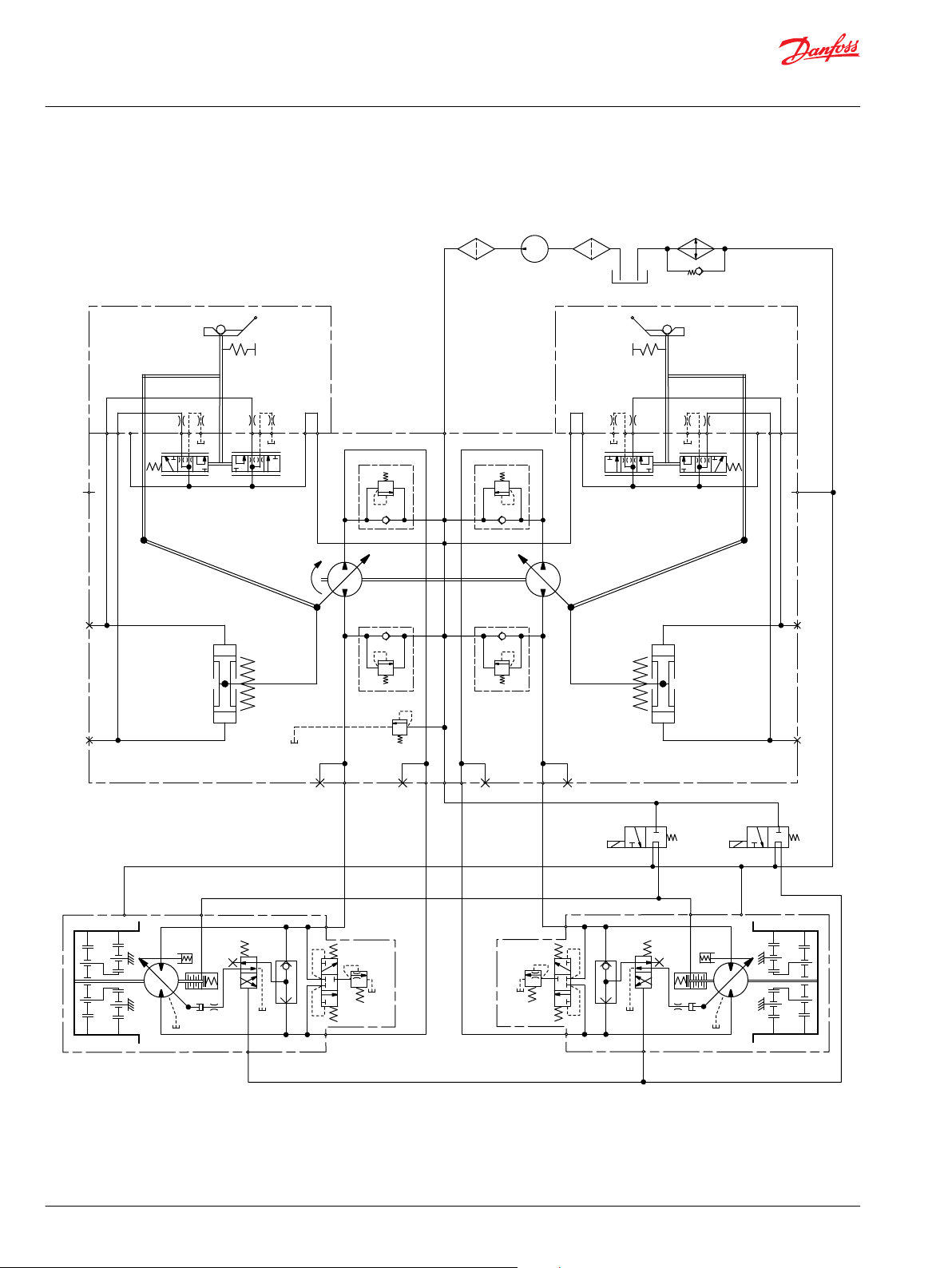

General Description

System Diagram

©

Danfoss | November 2020 BC152886482857en-000302 | 7

Page 8

P400161

M4

M2

M1M1 M2

M6

B C DA

M5

L2

M6

Front Rear

M5

GearboxGearbox MotorMotor

M4

L1

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

General Description

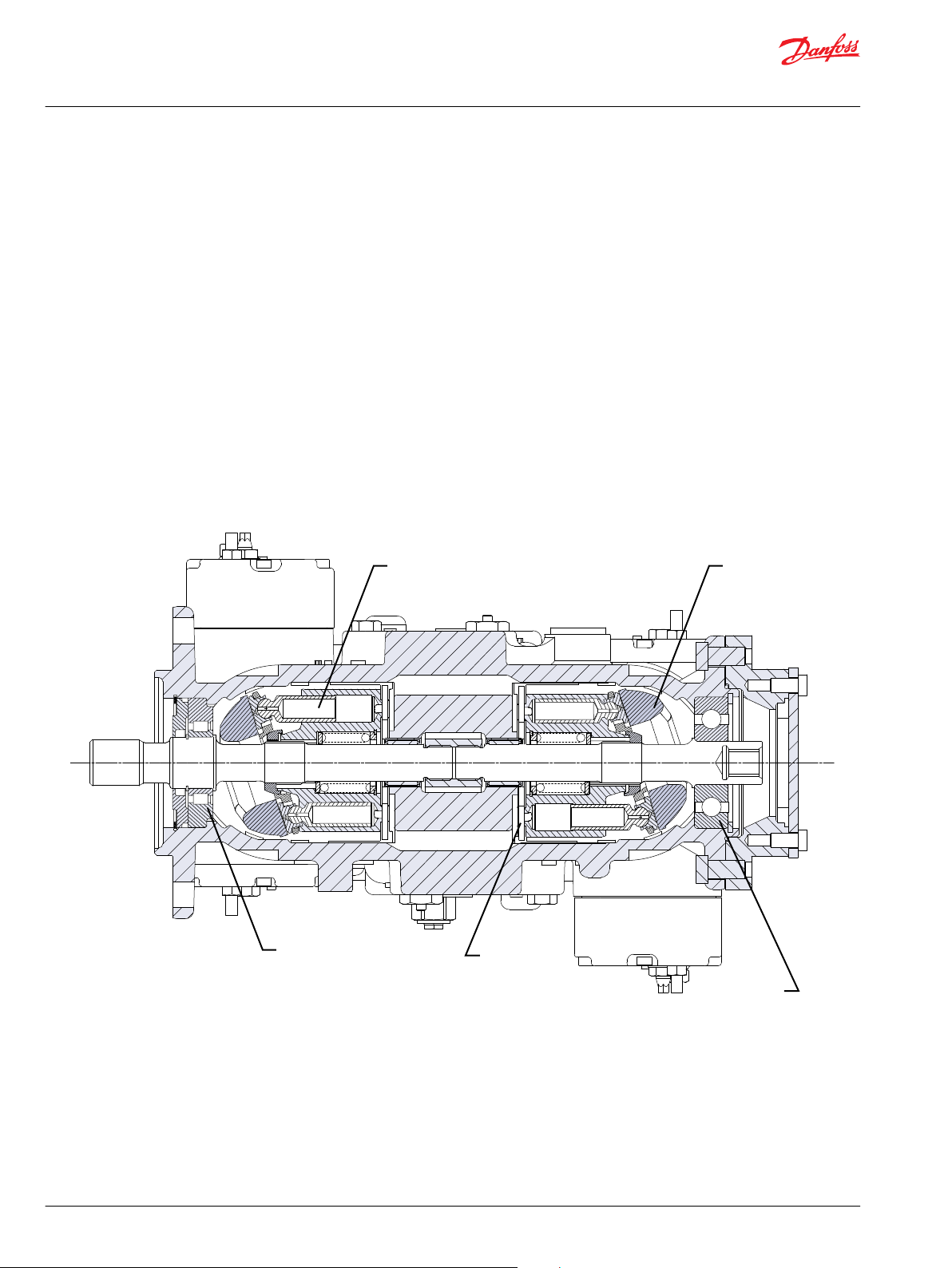

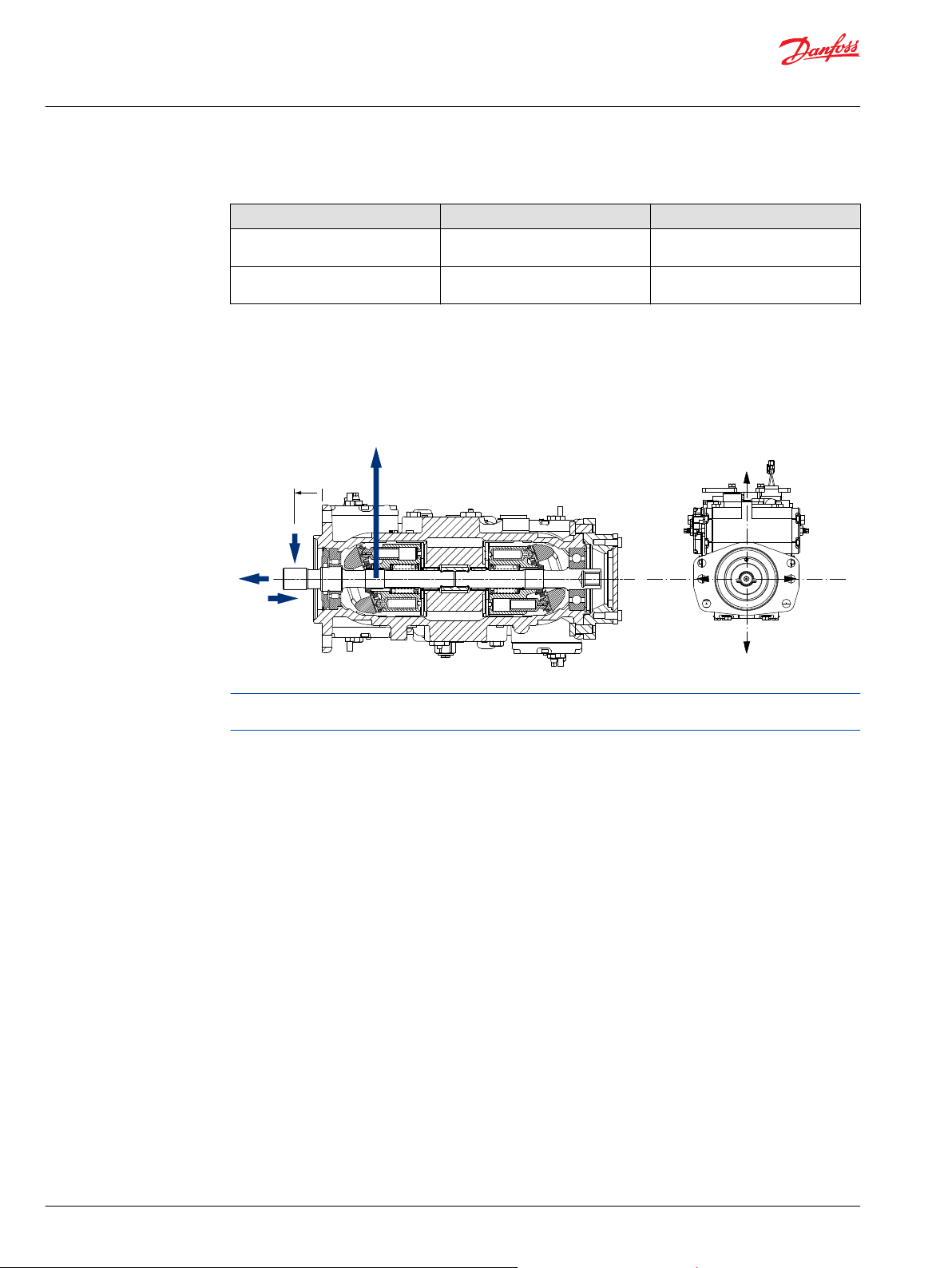

System Schematic

4T Axial Piston Pump

The illustration above shows a schematic of a 4T axial piston pump. System ports A, C and B, D connect to

the high pressure work lines. Return fluid is received from its inlet port and discharged through the outlet

port. Flow direction is determined by swashplate position. You can read system port pressure through

ports M1 and M2. The pump has two case drains (L1 and L2) to ensure there is lubricating fluid in the

8 | © Danfoss | November 2020 BC152886482857en-000302

Page 9

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

General Description

system. This schematic includes a manual displacement control. For other control schematics see the

related control section: Manual Displacement Control (MDC) on page 26, Non-Feedback, Proportional

Hydraulic (NFPH) Control on page 32

©

Danfoss | November 2020 BC152886482857en-000302 | 9

Page 10

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

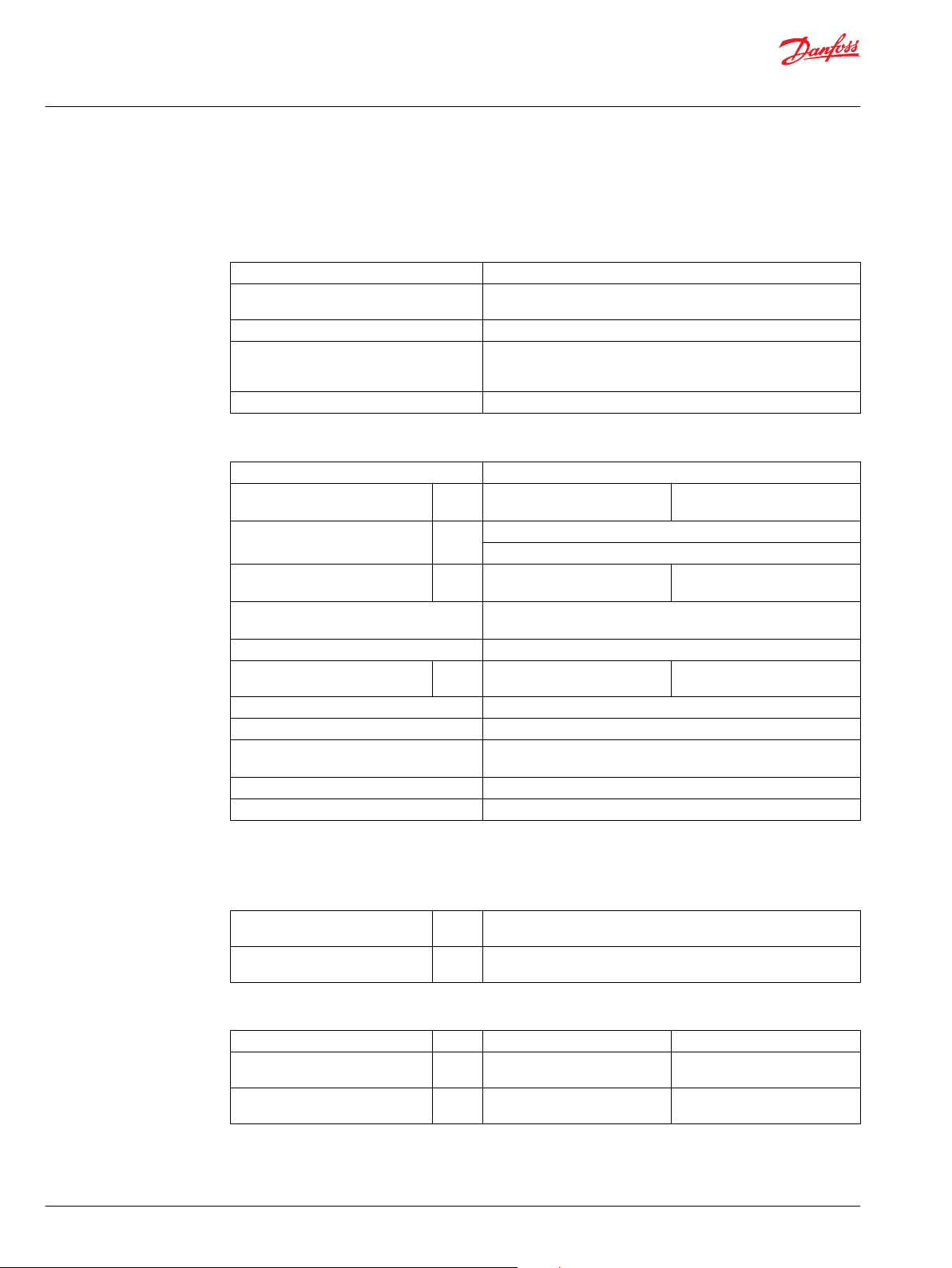

Technical Specifications

System Specifications

General Specifications

Feature Series 42 4T

Pump type

Direction of input rotation Clockwise or counterclockwise

Recommended installation position

Other system requirements Independent braking system, suitable reservoir and heat exchanger.

Hardware Features

Pump configuration Single variable pump

Displacement

Weight

Mass moment of inertia

Type of front mounting flange

(SAE flange size per SAE J744)

Port connections SAE-twin ports, radial, opposite side ports

System pressure regulation

Displacement limiters Option

Input shaft options Splined

Auxiliary mounting pad

(SAE pad per SAE J744)

Control options MDC, NFPH

Loop flushing None

3

cm

[in3]

kgf

[lbf]

kg•m

[lbf•ft2]

bar

[psi]

In-line, axial piston, positive displacement pumps including cradle

swashplate and servo control

Pump installation recommended with control position on the top or

side. Consult Danfoss for non conformance guidelines. The housing

must always be filled with hydraulic fluid.

40.9 [2.50] x 2 51 [3.11] x 2

MDC: 76 [168]

NFPH: 72 [158]

2

0.0072 [0.0054] 0.0076 [0.0056]

2 Bolt SAE C (4 additional bolt holes available)

210-415 [3045-6020] 210-325 [3045-4715]

SAE A (9 tooth, 11 tooth and 13 tooth)

SAE B (13 tooth)

System Parameters

Case pressure

Continuous pressure

Maximum pressure (cold start)

bar

[psi]

bar

[psi]

3 [44]

10.3 [150]

Pressure Limits

bar

[psi]

bar

[psi]

3

41 51

350 [5075] 325 [4713]

450 [6265] 400 [5800]

Displacement cm

Rated pressure

Maximum pressure

10 | © Danfoss | November 2020 BC152886482857en-000302

Page 11

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Technical Specifications

Speed Limits

Frame size cm

Minimum speed

Rated speed at maximum

displacement

Maximum speed at maximum

displacement

Charge Pump Displacement and Setting Pressure

Frame size cm

Internal -

Charge relief

valve settings

Theoretical Flow

Frame size cm

Theoretical flow at rated speed

Standard

Optional 14-24 [203-340]

3

-1

min

(rpm)

-1

min

(rpm)

-1

min

(rpm)

3

cm3/rev

[in3/rev]

bar

[psi]

3

l/min

[US gal/

min]

41 51

500

3200 2900

3450 3400

41 51

none none

20 [290]

41 51

131 [34.6] 148 [39.1]

Hydraulic Fluid Parameters

Check/high Pressure Relief Valve

Options

Setting —

bar

[psi]

No relief valve /check only Relief valve / check

210-415 [3045-6020] or by setting available

210, 250, 280, 300, 325, 345, 360, 385, 415

Fluid temperature range

Minimum -40 °C [-40 °F] Intermittent, cold start

Maximum continuous 104 °C [220 °F] -

Maximum 115 °C [240 °F] Intermittent

Fluid cleanliness level

Required fluid cleanliness level ISO 4406 Class 22/18/13

Fluid viscosity

Minimum 7.0 mm2/s (cSt) Intermittent

Recommended operating range 12-60 mm2/s (cSt) Maximum 1600 mm2/s (cSt) Intermittent, cold start

©

Danfoss | November 2020 BC152886482857en-000302 | 11

Page 12

W

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Operating Parameters

System Requirements

Independent braking system

Warning

Unintended vehicle or machine movement hazard. The loss of hydrostatic drive line power, in any

mode of operation (forward, neutral, or reverse) may cause the system to lose hydrostatic braking

capacity. You must provide a braking system, redundant to the hydrostatic transmission, sufficient to

stop and hold the vehicle or machine in the event of hydrostatic drive power loss.

Reservoir

Design the system to accommodate maximum volume changes during all system operating modes and

to promote de-aeration of the fluid as it passes through the tank. Minimum reservoir volume is 5/8 of the

maximum charge pump flow per minute with a minimum fluid volume equal to 1/2 of the maximum

charge pump flow per minute. At the maximum return flow, this allows 30 seconds fluid dwell for

removing entrained air. This is adequate for a closed reservoir (no breather) in most applications. Position

the reservoir outlet (pump inlet) above the bottom of the reservoir to take advantage of gravity

separation and prevent large foreign particles from entering the charge inlet line. Use a 100 - 125 μm

screen over the outlet port. Position the reservoir inlet (fluid return) so that flow to the reservoir is

discharged below the normal fluid level, and directed into the interior of the reservoir for maximum dwell

and efficient de-aeration. Use a baffle (or baffles) between the inlet and outlet ports to promote deaeration and reduce surging of the fluid.

System Parameters

Speed limits

Rated speed is the speed limit we recommend at full power condition and is the highest value at which

you can expect normal life. Maximum speed is the highest operating speed we permit. You cannot

operate above this speed without risk of immediate failure and loss of drive line power and hydrostatic

braking capacity (which may create a hazard). In mobile applications, you must apply this pump with a

speed speed below the stated maximum. Consult Pressure and Speed Limits, BC152886484313, when

determining speed limits for a particular application.

Inlet pressure

Control charge pump inlet conditions to achieve expected life and performance. Ensure a continuous

inlet pressure of not less than 0.8 bar absolute (not more than 6 in Hg vacuum). Normal pressures less

than 0.7 bar absolute (greater than 9 in Hg vacuum) indicate inadequate inlet design or a restricted filter.

Pressures less than 0.7 bar absolute (greater than 9 in Hg vac) during cold start are possible, but should

improve quickly as the fluid warms. Never exceed the maximum inlet vacuum.

Theoretical output

The theoretical maximum flow at rated speed is a simple function of pump displacement and speed. This

is a good gauge for sizing a companion motor. This does not take into account losses due to leakage or

variations in displacement.

Case pressure

Under normal operating conditions, the rated case pressure must not be exceeded. During cold start

case pressure must be kept below maximum intermittent case pressure. Size drain plumbing accordingly.

12 | © Danfoss | November 2020 BC152886482857en-000302

Page 13

W

C

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Operating Parameters

System pressure

System pressure is the differential pressure between high pressure system ports. It is the dominant

operating variable affecting hydraulic unit life. High system pressure, which results from high load,

reduces expected life. Hydraulic unit life depends on the speed and normal operating, or weighted

average, pressure that can only be determined from a duty cycle analysis.

Application pressure - is the high pressure relief or pressure limiter setting normally defined within the

order code of the pump. This is the applied system pressure at which the driveline generates the

maximum calculated pull or torque in the application. Maximum Working Pressure - is the highest

recommended Application pressure.

Maximum working pressure is not intended to be a continuous pressure. Propel systems with

Application pressures at, or below, this pressure should yield satisfactory unit life given proper

component sizing.

Maximum pressure is the highest allowable Application pressure under any circumstance. Application

pressures above Maximum Working Pressure will only be considered with duty cycle analysis and factory

approval.

Minimum pressure must be maintained under all operating conditions to avoid cavitation.

Warning

Hydraulic Fluid Parameters

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

Hydraulic fluid

Ratings and data are based on operating with hydraulic fluids containing inhibitors to prevent oxidation,

rust, and foam. These fluids must possess good thermal and hydrolytic stability to prevent wear, erosion,

and corrosion of the internal components.

Caution

Never mix hydraulic fluids of different types.

Temperature and viscosity

Ensure the application satisfies temperature and viscosity requirements concurrently. The data shown in

the tables on Hydraulic Fluid Parameters on page 11, assume petroleum-based fluids.

High temperature limits apply at the hottest point in the transmission, which is normally the case drain.

Always run the pump at or below the continuous temperature. Never exceed maximum temperature.

Durability of transmission components is not affected by cold oil, but it may affect the ability of oil to flow

and transmit power. Keep temperatures 16 °C [30 °F] above the pour point of the hydraulic fluid. The

minimum temperature relates to physical properties of component materials.

For maximum unit efficiency and bearing life, keep fluid viscosity in the continuous viscosity range.

During brief occasions of maximum ambient temperature and severe duty cycle operation, minimum

viscosity may occur. The system should encounter maximum viscosity only at cold start.

Size heat exchangers to keep the fluid temperature and viscosity within these limits. Test the system to

verify that these temperature limits are not exceeded.

©

Danfoss | November 2020 BC152886482857en-000302 | 13

Page 14

Based on SI units

= (l/min)

Input torque M = (N•m)

Input power P = = (kW)

Based on US units

= (US gal/min)

Input torque M = (lbf•in)

Input power P = = (hp)

Vg • n • η

v

1000

Vg • ∆p

20 • π • η

m

Q • ∆p

600 • η

t

M • n • π

30 000

Vg • n • η

v

231

Vg • ∆p

2 • π • η

m

Q • ∆p

1714 • η

t

M • n • π

198 000

Flow

Torque

Power

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Operating Parameters

Sizing Equations

Use these equations to help choose the right pump size and displacement for your application.

Variables

SI units [US units]

Vg= Displacement per revolution cm3/rev [in3/rev]

PO= Outlet pressure bar [psi]

Pi= Inlet pressure bar [psi]

∆p = pO - pi (system pressure) bar [psi]

n = Speed min-1 (rpm)

ηv= Volumetric efficiency

ηm= Mechanical efficiency

ηt= Overall efficiency (ηv • ηm)

14 | © Danfoss | November 2020 BC152886482857en-000302

Page 15

Reservoir

Filter

Charge

pum p

Charge

relief

valve

To pump case

Internal

To low pressur e

side of loop and

servo contro l

Strainer

P400162

P400163

Charge

Filter

pump

Charge

relief

valve

To pump case

Internal

To low pressure

side of loop and

servo control

Reservoir

Strainer

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

System Design Parameters

Fluid and Filtration

To prevent premature wear, use only new clean fluid. Use a filter capable of controlling fluid cleanliness

to ISO 4406 Class 22/18/13 (SAE J1165).

Locate the filter on the inlet (suction filtration) or discharge (charge pressure filtration) side of the charge

pump: 4T axial piston pumps are available with provisions for either configuration.

The selection of a filter depends on a number of factors including the contaminant ingression rate, the

generation of contaminants in the system, the required fluid cleanliness, and the desired maintenance

interval. Use filters that meet the above requirements of efficiency and capacity.

Filter efficiency can be measured with a Beta ratio (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter with a β-ratio within the

range of β

and closed circuits with cylinders being supplied from the same reservoir, a higher filter efficiency is

recommended. This also applies to systems with gears or clutches using a common reservoir. For these

systems, a charge pressure or return filtration system with a filter β-ratio in the range of β

10) or better is typically required.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness, BC152886482150, Technical

Information for more information.

= 75 (β10 ≥ 2) or better has been found to be satisfactory. For some open circuit systems,

35-45

= 75 (β10 ≥

15-20

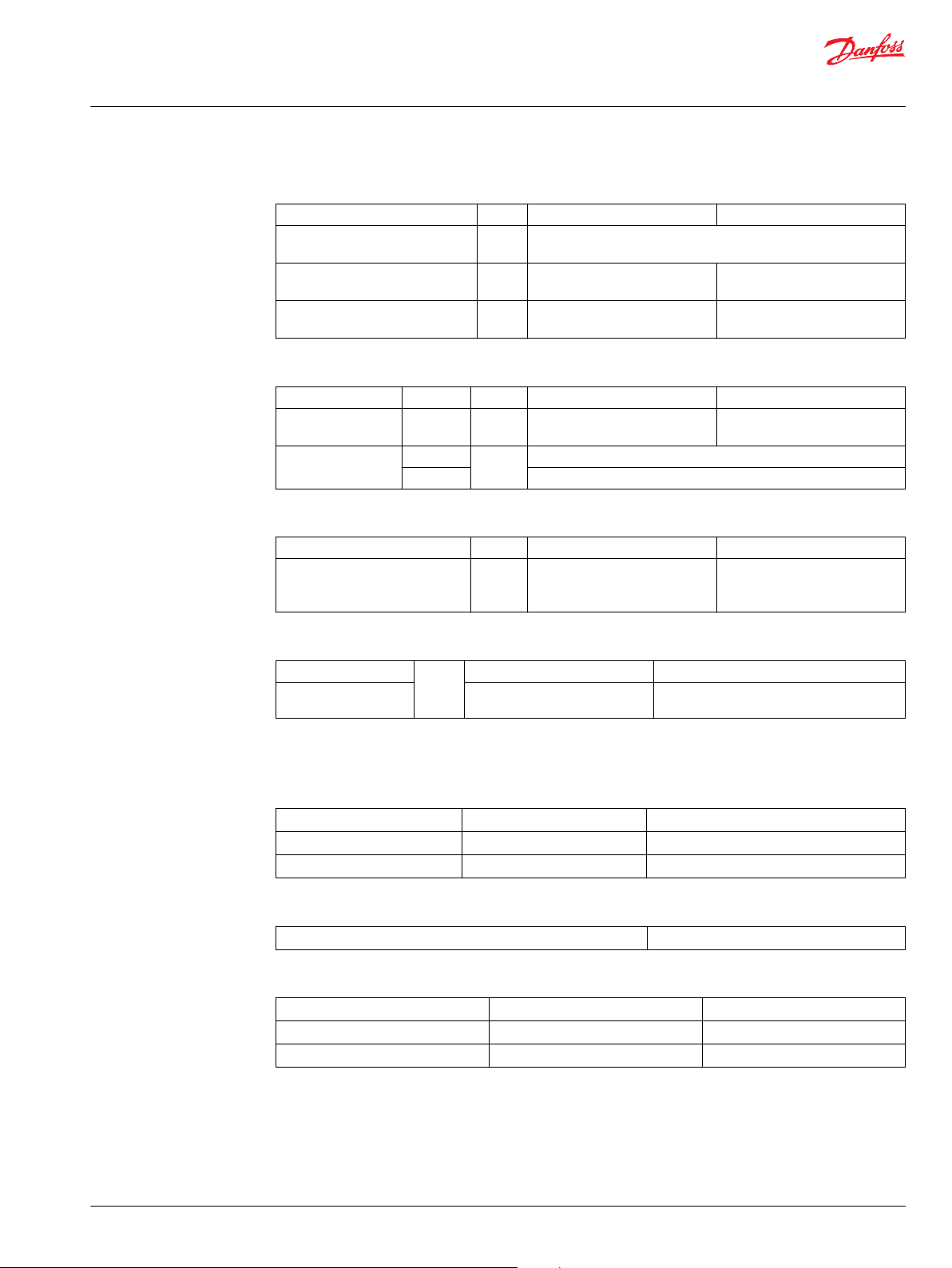

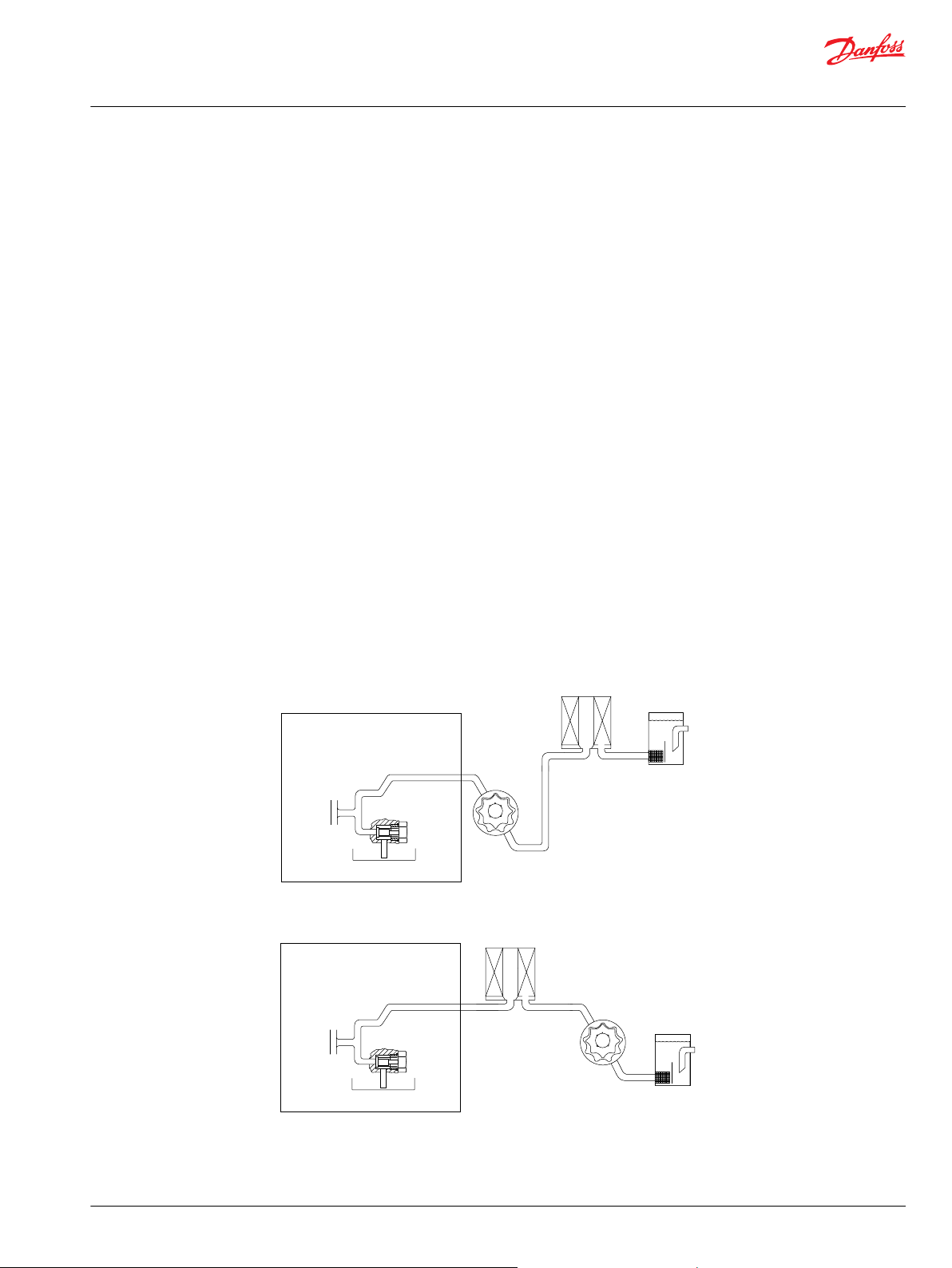

Filtration Configuration

Locate the filter on the inlet (Suction filtration) or discharge (Charge pressure filtration) side of the

external charge pump.

Suction filtration

Charge pressure filtration, full flow

©

Danfoss | November 2020 BC152886482857en-000302 | 15

Page 16

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

System Design Parameters

Mounting Flange Loads

Adding tandem mounted auxiliary pumps and/or subjecting pumps to high shock loads may result in

excessive loading of the mounting flange. Design pump applications to stay within the allowable shock

load and continuous load moments.

Shock load moment MS is the result of an instantaneous jolt to the system. Rated (continuous) load

moments MR are generated by the typical vibratory movement of the application.

Estimated maximum and continuous acceleration factors for some typical applications are shown in the

table.

Applications which experience extreme resonant vibrations may require additional pump support.

Exceeding the allowable overhung values listed below will require additional pump support.

G-factors for sample applications

Application Continuous (vibratory)

Skid steer loader 4 10

Trencher (rubber tires) 3 8

Asphalt paver 2 6

Windrower 2 5

Turf care vehicle 1.5 4

Vibratory roller 6 10

acceleration

(GR)

Maximum (shock) acceleration

(GS)

Allowable overhung load moments

Rated load moment (MR) Shock load moment (MS)

1441 N•m [12750 in•lbf] 3413 N•m [30200 in•lbf]

Estimating Overhung Load Moment

MR = GR (W1L1 + W2L2 + ... +WnLn)

MS = GS (W1L1 + W2L2 + ... +WnLn)

Where:

MRRated load moment N•m [lbf•in]

MSShock load moment N•m [lbf•in]

GRRated (vibratory) acceleration (G-factors: unitless)

GSMaximum shock acceleration (G-factors: unitless)

W Weight of the pump N [lbf]

L Distance from mounting flange to the center of gravity mm [in]

16 | © Danfoss | November 2020 BC152886482857en-000302

Page 17

Mounting flange

L2

Pump 1

Center of gravity

Pump 2

Center of gravity

P400164

L1

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

System Design Parameters

Overhung load moments

Case Drain

The front and rear pumps are connected by cast passages in the housing. The charge relief valve

discharges oil into the front housing. In order to provide positive housing flow thru both pumps, use of

rear case drain is required. The front case drain should only be used if the pumps are used as a common

drain manifold for the vehicle whereas external drain flow is brought into the rear case port and

discharged out the front.

External Shaft Load and Bearing Life

Bearing life is a function of speed, pressure, and swashplate angle, plus any external loads. Other factors

that affect life include fluid type, viscosity, and cleanliness.

In vehicle propulsion drives with no external loads—where the speed, pressure, and swashplate angle are

often changing—normal bearing B10 (90% survival) life exceeds the hydraulic unit life.

In non-propel drives, such as conveyors or fan drives, the operating speed and pressure may be nearly

constant leading to a distinctive duty cycle compared to that of a propulsion drive. In these types of

applications, we recommend a bearing life review. 4T axial piston pumps use bearings that can accept

some incidental external radial and thrust loads. However, any amount of external load reduces the

expected bearing life.

The allowable radial shaft loads are a function of the load position, orientation, and operating pressures

of the hydraulic unit. In applications where you cannot avoid external shaft loads, minimize the impact on

bearing life by orienting the load to the 0° or 180° position.

The maximum allowable radial load is calculated as: Re = Me / L

Where:

L Distance from mounting flange to point of load

M

e

R

e

T

out

F

B

Maximum external moment

Maximum radial side load

Thrust load

Load to cylinder block kit

©

Danfoss | November 2020 BC152886482857en-000302 | 17

Page 18

P400165

0 Re

180 Re

90 Re

270 Re

F

B

L

T

out

R

e

T

in

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

System Design Parameters

Allowable shaft loads

Displacement (cm3) 41 51

M

e

N•m [in•lbf]

T

OUT

N [lbf]

Avoid thrust loads in Tin direction.

If continuously applied external radial loads are 25% of the maximum allowable or more, or thrust loads

are known to occur, contact your Danfoss representative for an evaluation of unit bearing life.

Use clamp-type couplings where radial shaft side loads are present.

External shaft load orientation

111

[982]

1110

[250]

90

[800]

1110

[250]

Hydraulic Unit Life

Use the table and drawing to determine maximum allowable radial loads (Re), based on the maximum

external moment (Me) and the distance (L) from the mounting flange to the load.

Hydraulic unit life is the life expectancy of the hydraulic components. Hydraulic unit life is a function of

speed and system pressure. However, system pressure is the dominant operating variable. High pressure,

which results from high load, reduces expected life.

Design the hydraulic system to a projected machine duty cycle. Know the expected percentages of time

at various loads and speeds. Ask your Danfoss representative to calculate an appropriate pressure based

your hydraulic system design. If duty cycle data is not available, input power and pump displacement are

used to calculate system pressure.

All pressure limits are differential pressures (referenced to charge pressure) and assume normal charge

pressure.

4T axial piston pumps will meet satisfactory life expectancy if applied within the parameters specified in

this bulletin. For more detailed information on hydraulic unit life see BC152886484313, Pressure and

Speed Limits.

18 | © Danfoss | November 2020 BC152886482857en-000302

Page 19

100

80

95

90

85

Efficienc

y —

%

0

25 50

75

100

Speed,% of Rated Speed

V

o

l

u

m

e

t

r

i

c

E

f

f

i

c

i

e

n

c

y

1

b

2

5

0

0

ps

i

]

-

7

0

a

r [

V

o

l

u

m

e

t

r

i

c

E

f

f

i

c

i

e

n

c

y

b

5

0

0

0

ps

i

]

-

3

4

5

ar

[

O

v

e

r

a

l

l

E

f

f

i

c

5

0

0

p

s

i

]

i

e

n

c

y

-

1

7

0

b

a

r

[

2

O

v

e

r

a

l

l

E

f

f

i

c

i

e

n

c

y

-

3

4

5

b

a

r

[

5

0

0

0

p

s

i

]

P100401E

5000

0

4000

3000

2000

1000

System Pressur

e

0

25 50

75 100

Speed,% of Rated Speed

psi

350

bar

300

250

200

150

100

50

0

8

8

%

8

7

%

8

5

%

8

0

%

P100402E

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

System Design Parameters

Efficiency Graphs

The following performance map provides typical volumetric and overall efficiencies for 4T axial piston

pumps. These efficiencies apply for all 4T axial piston pumps at maximum displacement.

Pump performance as a function of operating speed at maximum displacement*

The following performance map provides typical pump overall efficiencies at various operating

parameters. These efficiencies also apply for all 4T axial piston pumps at maximum displacement.

Pump performance at select operating parameters at maximum displacement*

* Assumes viscosity in the continuous range

©

Danfoss | November 2020 BC152886482857en-000302 | 19

Page 20

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Charge Pump

An external charge pump is required on all 4T axial piston pumps units applied in closed circuit

installations to make up for internal leakage, to maintain positive pressure in the main circuit, and to

replace any leakage losses from external valving or auxiliary systems.

The total charge flow requirement is the sum of the charge flow requirement of each of the components

in the system. When initially sizing and selecting hydrostatic units for an applications, it is frequently not

possible to have all of the information necessary to accurately evaluate all aspects of charge pump size

selection. The following procedure will assist the designer in arriving at an initial charge pump selection

for a typical application.

In most 4T axial piston pump applications a general guideline is that the charge pump displacement

(CPG) should be equal to or greater than 10% of the total displacement (TD) of all axial piston units in the

system. This rule assumes that all units are of high speed, axial piston or bent axis design.

Particular application conditions may require a more detailed review of charge pump sizing. System

features and conditions that may invalidate the 10% of displacement rule include (but are not limited to):

•

Operation at low input speeds (below 1500 rpm)

•

Shock loadings

•

Excessively long system lines

•

Auxiliary flow requirements

•

Use of low speed, high torque motors

Charge Relief Valve

If a charge pump of sufficient displacement to meet the 10% of displacement rule is not available or if any

of the above conditions exist which could invalidate the 10% rule, contact your Danfoss representative.

A charge pump sizing worksheet can be found in BC157786484430, Selection of Driveline Components.

Charge Pump Sizing Example:

A system consists of 4T 41cc Pump driving two Series 40 -M35 Fixed Motors:

TD = 41 + 41 + 35 +35= 152 cm

•

CPD = 10 % x TD = 15.2 cm

•

This requires a charge pump displacement of 15.2 cm3 .

The charge relief valve maintains charge pressure at a designated level. 4T axial piston pumps come with

direct-acting poppet style charge relief valves. The valve setting is set at the factory. The setting is screw

adjustable.

The charge pressure settings are nominal values and are based on the charge flow across the charge

relief valve with a fluid viscosity of 28 mm2/s (cSt) [130 SUS] and a pump input speed of 1800 min-1(rpm).

Actual charge pressure differs slightly from the nominal setting when different input speeds are used.

The charge setting is a differential pressure (referenced to case pressure) and measured with the piston

pump at zero swashplate angle (neutral). Charge pressure drops slightly when the pump is in stroke due

to flow demands.

The charge pressure setting for pumps without an internal charge pump is set with an assumed charge

flow of 38 l/min (10 US gal/min). These units must have adequate charge flow supplied to the charge

inlet in order to maintain charge pressure at all times.

3

3

20 | © Danfoss | November 2020 BC152886482857en-000302

Page 21

From Charge

Pump

To Low Side

of Working

Loop & Servo

Control

To Case

P100392E

C

High pressure

side of working loop

Charge check and

high pressure

relief valve

Charge pressure

P100393E

C

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Charge Relief Valve

Caution

Incorrect charge pressure settings may result in the inability to build required system pressure, inability

to control pump, and/or inadequate loop flushing flows. Maintain correct charge pressure under all

operating conditions.

Overpressure Protection

4T axial piston pumps are available with a combination charge check and high pressure relief valve

assembly. High pressure relief valves come in a range of settings as shown in the model code. You may

specify individual port pressure settings. The high pressure relief valve settings are a differential pressure

(referenced to charge pressure) and are set at 3.8 l/min (1 US gal/min) of flow.

We can equip pumps with charge check valves only, if high pressure relief valve protection is not

necessary.

Charge Check and High Pressure Relief Valve

Caution

High pressure relief valves are for transient overpressure protection, not for continuous pressure control.

Operation over relief valves for extended periods of time results in severe heat build up. High flows over

relief valves may result in pressure levels exceeding the nominal valve setting and potential damage to

system components.

©

Danfoss | November 2020 BC152886482857en-000302 | 21

Page 22

Charge pressure

High pressure

side of working

loop

Charge check and

high pressure

relief valve

Bypass

plunger

FLOW

P100394E

C

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Bypass Valve

4T axial piston pumps are available with an optional bypass function for use when pump shaft rotation is

not possible. Use the bypass function to bypass fluid around the variable displacement pump. For

example: you may move a disabled vehicle to a service location or winch it onto a trailer without

operating the prime mover.

The bypass valve is integral to the charge check/high pressure relief valve assembly. Depress the

plungers located in the plugs of the valve assemblies to operate the bypass function. The valves remain

open until the prime mover is started. Charge pressure automatically closes them.

Charge Check and High Pressure Relief Valve with Bypass

Displacement Limiters

Caution

Damage to the hydraulic system may result from operating without charge flow. Bypass valves are for

moving a machine or vehicle for very short distances at very slow speeds. They are NOT tow valves.

4T axial piston pumps are available with adjustable mechanical displacement (stroke) limiters located in

the servo covers. The maximum displacement of the pump can be limited to any value from its maximum

displacement to zero in either direction. The limiters are factory set slightly beyond the maximum

displacement of the pump. Displacement limiters may not be suited to all applications.

Series 42 pump displacement limiters

Shaft Options

4T axial piston pumps are available with a variety of splined and tapered shaft ends. The accompanying

table shows available shaft sizes and torque ratings. Maximum torque ratings are based on shaft torsional

strength and assume a maximum of 200 000 load reversals.

22 | © Danfoss | November 2020 BC152886482857en-000302

Page 23

0

¯ -0.05P

(+.000)

(-.002)

Spline Engagement

for Torque

Em ax.

Mounting

Flange

Dm ax.

C

max.

B

max.

R 0.8 (.03)

max.

Coupling

F

min.

2.3 (.09)

Cutter clearance

With

Undercut

Without

Undercut

P001614E

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Use ANSI B92.1 Class 5 mating splines for splined output shafts. Danfoss external splines are modified

Class 5 fillet root side fit. The external spline major diameter and circular tooth thickness dimensions are

reduced in order to insure a clearance fit with the mating spline.

Shaft Availability and Torque Rating*

Shaft Max. torque Max. torque

15 tooth spline, 16/32 pitch 362 N•m [3200 in•lbf ] 192 N•m [1700 in•lbf ]

19 tooth spline, 16/32 pitch 734 N•m [6500 in•lbf ] 340 N•m [3000 in•lbf ]

* The limitations of these input shafts constrain the allowable auxiliary coupling torque.

Auxiliary Mounting Pads

Auxiliary mounting pads are available on all 4T axial piston pumps to mount auxiliary hydraulic pumps.

We include a sealed (oil tight) shipping cover as standard equipment. The shipping cover seals case

pressure and you can use it as a running cover if desired.

Since the auxiliary mounting pad operates under case pressure, you must use an O-ring to seal the

auxiliary pump to the pad. The drive coupling is lubricated with oil from the main pump case.

Spline specifications and torque ratings are shown in the accompanying table.

All mounting pads meet SAE J744 specifications.

•

The sum of main and auxiliary pump torque must not exceed stated maximum.

•

All torque values assume a 58 RC shaft spline hardness on mating pump shaft. Maximum torque is

•

based on maximum torsional strength and 200 000 load reversals.

Applications with severe vibratory or high G-force (shock) loading may require additional structural

•

support to prevent leaks or mounting flange damage. Refer to Mounting flange loads for additional

information.

Auxiliary Pad*

Pad size Spline Minimum spline length

(mm [in])

SAE A 9 tooth 16/32 pitch 13.5 [0.53] 107 [950]

SAE A special 11 tooth 16/32 pitch 13.5 [0.53] 147 [1300]

SAE A special 13 tooth 16/32 pitch 14.2 [0.56] 248 [2200]

SAE B 13 tooth 16/32 pitch 14.2 [0.56] 248 [2200]

Maximum torque (N•m

[lbf•in])

* Allowable Auxiliary coupling torque is subject to limitations of the input shaft.

This drawing provides the dimensions for the auxiliary pump mounting flange and shaft. Auxiliary pump

mounting flanges and shafts with these dimensions are compatible with the auxiliary mounting pads on

4T axial piston pumps. For auxiliary pad dimensions, see Auxiliary Mounting Pads on page 48.

©

Danfoss | November 2020 BC152886482857en-000302 | 23

Page 24

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Auxiliary pump mating dimensions

Pad Size P B C D E F

SAE A mm [in] 82.55 [3.250] 8.1 [0.32] 12.7 [0.500] 44 [1.73] 15 [0.59] 13.5 [0.53]

SAE B mm [in] 101.6 [4.000] 11.4 [0.45] 15.2 [0.60] 46 [1.81] 17.5 [0.69] 14.2 [0.56]

Center Coupling

The two pump shafts are connected with a center-section coupling that is a 22 tooth spline with a 24/48

pitch. The torque transmitted through the center coupling is the sum of the rear kit torque and the

auxiliary pump torque. The maximum torque rating of the auxiliary pad may be reduced from the values

in the above table due to center coupling limitations.

22 tooth Center-Section Coupling Torque Rating

Rating Torque in N•m [lbf•in] 22T

Maximum

Continuous

347 [3071]

243 [2151]

Control Selection

4T axial piston pumps use a servo control system with two types of control options. Manual Displacement

Controls (MDC) are feedback controls that provide and maintain a set displacement for a given input. The

MDC includes options for a Neutral Start Switch (NSS), backup alarm , and a solenoid override to neutral.

Non-Feedback Proportional Hydraulic controls (NFPH) is available to control the pump without

mechanical feedback.

All controls provide smooth, stepless positive control of the transmission in either direction. Optional

servo supply and drain orifices are available for special response needs.

Typical Control Applications

Machine Function MDC NFPH

Roller/compactor

Asphalt paver

Skid steer loader Propel

Articulated loader Propel

Utility tractor Propel

Windrower Propel

Trencher

Ag sprayer Propel

Specialized harvesters

(sod, fruit, nut, etc.)

Commercial mower Propel

Rock drill Propel

Drill rig

Sweeper

Propel

Vibratory drive

Propel

Propel

Chain drive

Propel

Auxiliary drive

Drill drive

Pull downe

Propel

Fan

24 | © Danfoss | November 2020 BC152886482857en-000302

Page 25

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Typical Control Applications (continued)

Machine Function MDC NFPH

Aerial lift Propel

Fork lift Propel

Brush / stump cutter

Airport vehicle Propel

Dumper Propel

Propel

Cutter drive

©

Danfoss | November 2020 BC152886482857en-000302 | 25

Page 26

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Manual Displacement Control (MDC)

The Manual Displacement Control (MDC) converts a mechanical input signal to a hydraulic signal. The

hydraulic signal positions the servo piston, tilting the swashplate to vary the pump’s displacement and

flow direction.

The position of the swashplate is proportional to the mechanical input signal. The control has mechanical

feedback that regulates the servo valve in relation to swashplate position to maintain displacement at

the commanded level regardless of changes in system pressure.

The full featured 4T axial piston pumps manual control consists of two manual displacement controls

with backup alarm swiches. One of the controls incorporate a neutral override (NOR) solenoid and brake

release port. The other control housing drains through the first control housing to provide neutral

override function.

Manual controls for use on one pump are also available and can be used in combination with another

type of control on the other pump. The servo control valve has variable geometry porting to regulate

swashplate response relative to input command. The control performs small displacement change

commands with maximum controllability throughout the entire stroking range of the pump. It completes

large displacement change commands with rapid swashplate response. Optional servo supply and drain

orifices are available for special response needs.

The control also has a full over-travel spool that allows input at a faster rate than swashplate movement

without damage to the control. Any swashplate position error is feed back to the servo valve for instant

correction.

Features and Benefit of MDC

The MDC is a high gain control: Small movements of the control handle move the servo valve to full

•

open position porting maximum flow to the servo cylinder.

The full over-travel spool design allows rapid changes in input signal without damaging the control

•

mechanism.

The MDC provides a fast response with low input force.

•

Precision parts provide repeatable and accurate displacement settings.

•

Mechanical feedback maintains pump displacement regardless of changes in system pressure.

•

The operator is isolated from swashplate vibration.

•

The swashplate and servo cylinder, as well as the control valve, are spring centered so the pump

•

returns quickly to neutral in the absence of control input.

The pump returns to neutral:

if the prime mover is shut down;

•

if the external control linkage fails at the control handle;

•

if there is a loss of charge pressure.

•

26 | © Danfoss | November 2020 BC152886482857en-000302

Page 27

-b -a

a b

100%

100%

P001015E

Displacement

M5

M4

P100404E

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Control Input Signal

The figure and table below relate the input electrical signal to pump displacement, (swashplate position),

for each coil configuration.

Pump displacement versus Electrical signal

Response Time

You can tailor the time to change from zero to maximum displacement using orifices incorporated in the

gasket between the control and pump housing. Using orifices you can match swashplate response to the

acceleration and deceleration requirements of your application. Verify proper orifice selection by testing.

MDC Response Time (Maximum to Maximum)

Frame size (cm3) Fast (no orifice) Medium Slow (standard)

41/51 0.6 sec 1.6 sec 2.5 sec

Neutral to maximum swashplate response is approximately 60% of the time for maximum to maximum

sawashplate travel. For other response times please contact your Danfoss representative.

MDC Schematic

©

Danfoss | November 2020 BC152886482857en-000302 | 27

Page 28

Charge Pressure

Servo Control

Valve

MDC Handle

Servo Piston

Feedback

Linkage

P100403E

P100407E

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Cross-section of MDC

Control Handles

Either straight or clevis (offset) style control handles are available for the MDC. The straight style handle

minimizes the overall height of the pump and control. The clevis style handle provides additional

clearance between the handle and control housing and works well for clevis style linkage installations.

Maximum allowable input torque at the control handle is 17 N•m (150 lbf•in). The maximum allowable

bending moment is 4 N•m (35 in•lbf ).

Pump Flow Direction with MDC

Input Shaft Rotation CW CCW

Handle of rotation CW CCW CW CCW

Port A flow Out In In Out

Port B flow In Out Out In

High pressure servo guage port M4 M5 M4 M5

MDC Handle Options

Electric Solenoid Override to Neutral

This normally open solenoid valve (C) shunts both ends of the servo piston. This prevents the pump from

stroking. When energized, the valve closes, allowing the pump to operate normally. This option is ideally

suited for operator presence or auto-resume functions without prime mover shut down. This solenoid is

available in 12 or 24 Vdc with 2 Amp. maximum current draw. It is available with DEUTSCH 2-way or with

a Packard Weather-Pack 2-way shroud connector.

28 | © Danfoss | November 2020 BC152886482857en-000302

Page 29

P400167

M4

M5

X7

C

L2

(from

charge pump)

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Emergency Override to Neutral with Port for Brake Pressure Release

This solenoid valve (C) operates as the override to neutral above, and drains a spring-applied,

hydraulically-released brake (port X7). Energizing the valve allows the pump to operate as normal, while

also charging port X7 to release the brake. This option is ideally suited for emergency stop functions

without prime mover shut down. The solenoid is available in 12 or 24 Vdc with 2 Amp. maximum current

draw. It is available with DEUTSCH 2-way or with a Packard Weather-Pack 2-way shroud connector.

Electric Override to Neutral Specifications

Solenoid State at Override Activation De-energized

Voltage 12 or 24 Vdc

Maximum Current 2 A

Hydraulic Schematic for MDC with Override Options

©

Danfoss | November 2020 BC152886482857en-000302 | 29

Page 30

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Neutral Start Switch (NSS)

This option provides an electrical switch contact that is closed when the control handle is in its neutral

(0°) position. The switch contact opens when the control handle rotates approximately 1.5° to 2°

clockwise (CW) or counterclockwise (CCW) from neutral.

The switch is rated for 5 Amp. inductive load at 12 or 24 Vdc. It is available with screw terminals (no

connector) or with a Packard Weather-Pack 2-way tower connector or DEUTSCH 2-way connector..

Wire the NSS in series with the engine starting circuit to ensure the pump is in neutral position before

allowing the engine to start.

Neutral Start Switch Specifications

Switch Neutral Position

Voltage

Current Rating

Neutral Play

NSS with Back-up Alarm (BUA) Switch

The BUA switch contact is open until the control handle rotates 2.6° to 3.75° from neutral. The BUA switch

closes when the control handle rotates either clockwise (CW) or counterclockwise (CCW) from neutral

(choose one direction only). The NSS function operates as described above.

The BUA contacts are rated for 2.5 Amp. resistive load at 12 or 24 Vdc. The NSS contacts are rated for 5

Amp. inductive load at 12 or 24 Vdc. This switch is available with screw terminals (no connector) or with a

Packard Weather-Pack 4-way tower connectoror Deutsch 2-way, 4-way connector..

Wire the NSS as described above. Wire the BUA switch in series with a back-up alarm to have the alarm

sound when the operator moves the pump control handle into reverse.

Closed

12 or 24 Vdc

5 A

± 2°

Backup alarm switch option

Switch Neutral Position

Voltage

Current Rating

Alarm Direction

Neutral Play

Open

12 or 24 Vdc

2.5 A

CW or CCW

± 2.6° to 3.75°

Connectors

For available connectors and dimensions, see outline drawings: Manual Displacement Control Options.

30 | © Danfoss | November 2020 BC152886482857en-000302

Page 31

M5

M4

X7

P100408E

D

A

B

C

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Hydraulic schematic for MDC with override options

and NSS

(A) = Backup alarm switch contacts (green wire)

(closed in reverse)

(B) = Neutral start switch w/ backup alarm

(C) = Electric solenoid override to neutral w/

brake release

(D) = Neutral start switch contacts (black wire)

(closed in neutral)

©

Danfoss | November 2020 BC152886482857en-000302 | 31

Page 32

Piston centering spring

Servo piston

P100412E

P400169

M4

M5

L2

X2 X1

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

Non-Feedback, Proportional Hydraulic (NFPH) Control

The Non-Feedback Proportional Hydraulic (NFPH) control is a hydraulic proportional control in which an

input pressure signal directly controls the pump servo piston to achieve pump displacement.

4T pumps with NFPH control have a special servo cylinder capable of providing proportional control with

a hydraulic input.

Swashplate position is proportional to the differential signal pressure at ports X1 and X2, but

displacement is also dependent on pump speed and system pressure. This characteristic of non-feedback

controls provides a natural power limiting function by reducing the pump swashplate angle as system

pressure increases. The accompanying graph shows typical operating characteristics.

The system may require tuning through the pump orifice combinations, control pressure supply line

sizing, actuation device output pressure and flow adjustments to achieve proper vehicle performance

characteristics.

Pump displacement versus signal pressure

Non-feedback proportional hydraulic control

schematic

Pump Flow Direction with NFPH control

Input Shaft Rotation

High pressure at port:

Port A flow

Port B flow

High servo gauge port

CW CCW

X1 X2 X1 X2

Out In In Out

In Out Out In

M4 M5 M4 M5

32 | © Danfoss | November 2020 BC152886482857en-000302

Page 33

D

i

s

p

l

a

c

e

m

e

n

t

100%

100%

15 18

6

6

1518

P001628E

Signal Dp (bar)

Dp system=345bar

Dp system=345bar

Dp system=35bar

Dp system=35bar

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Features and Options

NFPH pump displacement to Input signal

NFPH input signal pressure (bar)

Frame size a b c

28/32 5.5 13.7 17

38/45 5 12.75 16

The values provided in the table above are approximations at 1800 RPM and system delta pressures as

indicated in the graph provided. The values are dependent on input speed and delta pressure operating

conditions.

Features and Benefits of the NFPH control

Eliminates mechanical linkage for flexibility of control design

•

Power limiting characteristic reduces machine power requirements

•

Compatible with dual axis joysticks for dual path applications

•

Smooth operation

•

Connectors and Port locations

Refer to outline drawings.

©

Danfoss | November 2020 BC152886482857en-000302 | 33

Page 34

P400170

Z

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/

16

-18

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

System Port “B”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L1”

Port ISO 11926-1 – 1 5/

16

-12

System Port “A”

Port ISO 11926-1 – 1 5/

16

-12

System A Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System B Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Z

CCW

CW

P400171

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Manual Displacement Control (MDC)

Port Description

Port Description Sizes Port Description Sizes

A System port "A" 1 5/16 - 12 M2 System "A" pressure gauge port "M1"9/16 - 18

B System Port "B" 1 5/16 - 12 M1 System "C" pressure gauge port "M1"9/16 - 18

C System Port "C" 1 5/16 - 12 M2 System "D" pressure gauge port "M2"9/16 - 18

D System Port "D" 1 5/16 - 12 M4 x2 Servo pressure gauge port "M4"

L1 Case Drain Port "L1" 1 5/16 - 12 M5 x2 Servo pressure gauge port "M5"

34 | © Danfoss | November 2020 BC152886482857en-000302

9

/16 - 18

9

/16 - 18

Page 35

P400172

Servo Pressure Gauge Port “ M4”

Port ISO 11926-1 – 9/

16

-18

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

Servo Pressure Gauge Port “ M5”

Port ISO 11926-1 – 9/

16

-18

System Port “D”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L2”

Port ISO 11926-1 – 1 5/

16

-12

System Port “C”

Port ISO 11926-1 – 1 5/

16

-12

System C Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System D Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Port Description Sizes Port Description Sizes

L2 Case Drain Port "L2" 1 5/16 - 12 M6 x2 Charge inlet port "M6"

M1 System "A" pressure gauge port "M1"9/16 - 18

7

/8 - 14

©

Danfoss | November 2020 BC152886482857en-000302 | 35

Page 36

[4.72]

120

APPROXIMATE CENTER

AUXILIARY MOUNTING PAD

OPTION J, K, S

DISPLACEMENT LIMITER

OPTION 0, N

OF GRAVITY

G

G

F

F

[4.06]

103

[1.18]

30

[1.52]

38.5

[1.52]

38.5

[3.03]

77

[3.28]

83.2

41.6 [1.64]

131.7 [5.19]

171.7 [6.76]

180.34 [7.10]

192 [7.56]

277 [10.91]

335.4 [13.20]

421.3 [16.59]

433.4 [17.06]

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

System Port “B”

Port ISO 11926-1 – 1 5/

16

-12

P400173

Case Drain Port “L1”

Port ISO 11926-1 – 1 5/

16

-12

System Port “A”

Port ISO 11926-1 – 1 5/

16

-12

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Thru

System A Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System B Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Z

Ø10.8

±0.5

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/

16

-18

Neutral Adjust

17 mm HEX

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Dimensions

36 | © Danfoss | November 2020 BC152886482857en-000302

Page 37

P400174

Shaft

Center Line

Section F-F

Section G-G

[4.98]

126.5

[4.98]

126.5

[1.54]

39

APPROXIMATE

CENTER

OF GRAVITY

[3.56]

90.5

2X

[3.19]

81

2X

[5 ]

+0

-0.002

Ø127

+0

-0.05

[0.69 ±0.01]

Ø17.57

±0.30

THRU

6X

[1.97]

50

[10.87]

276.06

[1.26]

32

[4.31]

109.5

[3.24]

82.3

BOTH SIDES

SPOT FACE

(M5)

BOTH SIDES

SPOT FACE

(M4)

88

[3.46]

89

[3.50]

C

L

C

L

Z

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Adjustable displacement limiters

Shaft rotation CW CCW

Displacement limiter side 1 2 1 2

Limited flow through port B, C A, D A, D B, C

©

Danfoss | November 2020 BC152886482857en-000302 | 37

Determine rotation by viewing pump from the input shaft end. Contact your Danfoss representative for

specific installation drawings.

Page 38

P400175

[0.87]

22

2X

[0.55]

14

[0.5 ]

12.7

0

- 0.5

0

- 0.02

[14.23]

361.4

[4.31]

109.45

90°

±8°

BOTH

HANDLES

[4.49]

114

[1.15]

29.23

LIFTING BRACKET

LIFTING BRACKET

2XM 10X1.5-6H Thd

16 MIN Full Thd Depth

BOTH HANDS

[10.81]

274.55

[9.93]

Section E-E

E

E

252.3

[4.72]

120

[7.56]

192

[7.01]

178

[3.03]

77

[1.91]

48.6

[4.46]

113.3

[4.06]

103

[1.52]

38.5

[1.52]

38.5

[0.76]

19.2

[8.36]

212.3

[4.37]

111

[13.48]

342.4

88

[3.46]

C

L

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

System Port “D”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L2”

Port ISO 11926-1 – 1 5/

16

-12

System Port “C”

Port ISO 11926-1 – 1 5/

16

-12

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/

16

-18

System C Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System D Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Charge Relief Valve

12.5 mm External Hex

Neutral Adjust

17 mm HEX

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

38 | © Danfoss | November 2020 BC152886482857en-000302

Page 39

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/16-18

System Port “B”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L1”

Port ISO 11926-1 – 1 5/

16

-12

System Port “A”

Port ISO 11926-1 – 1 5/

16

-12

System A Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

P400176

System B Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Z

CCW CW

Z

P400177

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Non-Feedback, Proportional Hydraulic (NFPH)

Port Description

©

Danfoss | November 2020 BC152886482857en-000302 | 39

Port Description Sizes Port Description Sizes

A System port "A" 1 5/16 - 12 M1 System “C” pressure gauge port “M1”9/16 - 18

B System Port "B" 1 5/16 - 12 M2 System “D” pressure gauge port “M2”9/16 - 18

C System Port "C" 1 5/16 - 12 M4 x2 Servo pressure gauge port “M4”

D System Port "D" 1 5/16 - 12 M5 x2 Servo pressure gauge port “M5”

L1 Case Drain Port "L1" 1 5/16 - 12 M6 x2 Charge Inlet port “M6”

L2 Case Drain Port "L2" 1 5/16 - 12 X1 Control Port “X1”

9

/16 - 18

9

/16 - 18

7

/8 - 14

9

/

16

Page 40

P400178

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Charge Pressure Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/

16

-18

System Port “D”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L2”

Port ISO 11926-1 – 1 5/

16

-12

System Port “C”

Port ISO 11926-1 – 1 5/

16

-12

System C Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System D Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Control Port “X1”

Port ISO 11926-1 – 9/

16

-18

Control Port “X2”

Port ISO 11926-1 – 9/

16

-18

Control Port “X1”

Port ISO 11926-1 – 9/

16

-18

Control Port “X2”

Port ISO 11926-1 – 9/

16

-18

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Port Description Sizes Port Description Sizes

M1 System "A" pressure gauge port "M1"9/16 - 18 X2 Control Port “X2”

M2 System "B" pressure gauge port "M2"9/16 - 18

9

/

16

40 | © Danfoss | November 2020 BC152886482857en-000302

Page 41

P400179

[4.72]

120

APPROXIMATE CENTER

AUXILIARY MOUNTING PAD

OPTION J, K, S

DISPLACEMENT LIMITER

OPTION 0, N

OF GRAVITY

G

G

F

F

[4.06]

103

[1.18]

30

[1.52]

38.5

[1.52]

38.5

[3.03]

77

[3.28]

83.2

41.6 [1.64]

131.7 [5.19]

171.7 [6.76]

192 [7.56]

195.9 [7.71]

277 [10.91]

335.4 [13.20]

421.3 [16.59]

433.4 [17.06]

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

System Port “B”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L1”

Port ISO 11926-1 – 1 5/

16

-12

System Port “A”

Port ISO 11926-1 – 1 5/

16

-12

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/

16

-18

System A Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System B Pressure Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

Z

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Thru

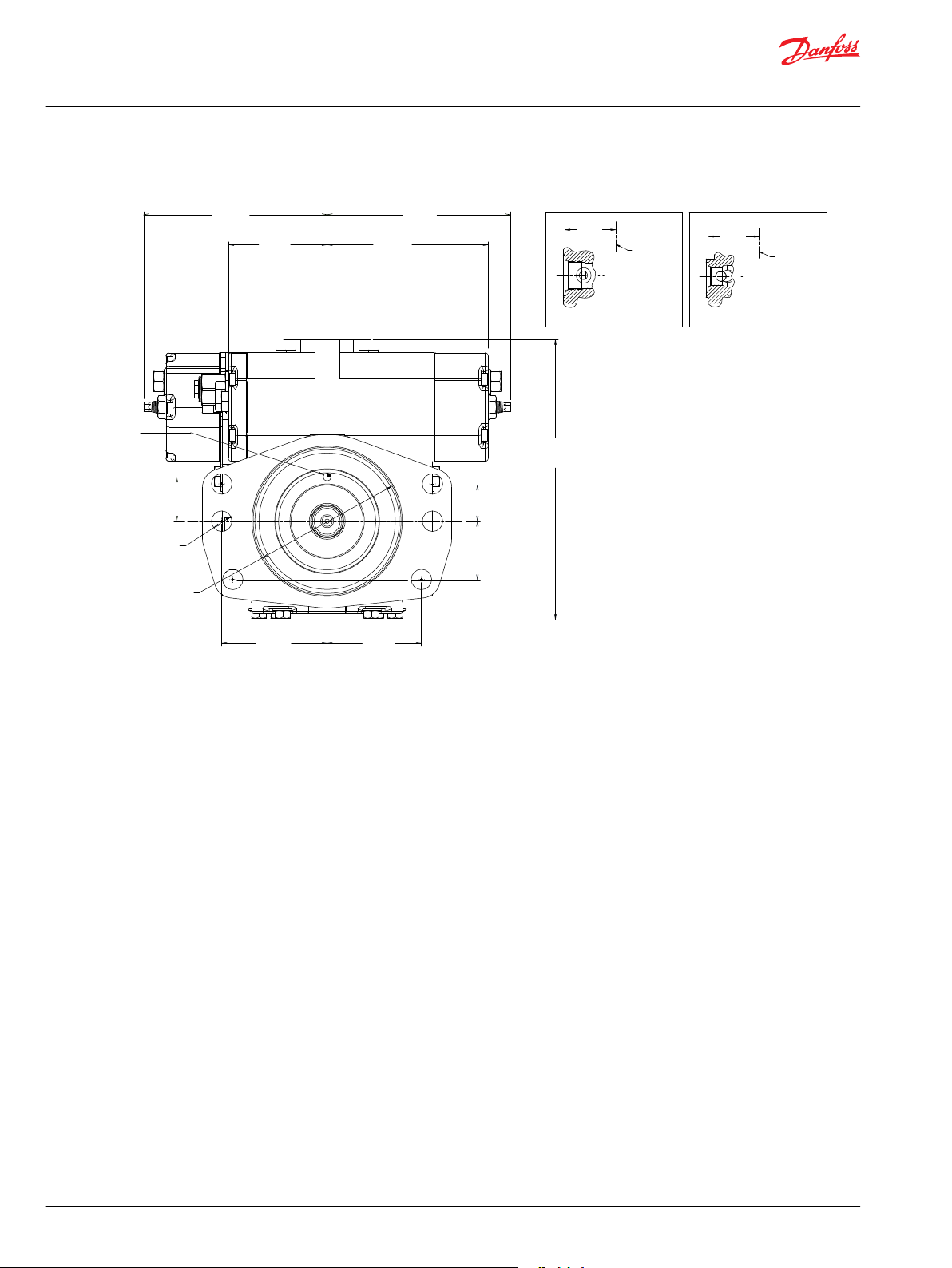

Ø10.8

±0.5

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

Dimensions

©

Danfoss | November 2020 BC152886482857en-000302 | 41

Page 42

Shaft

Center Line

Section F-F

Section G-G

[6.19]

157.3

[6.19]

157.3

[1.52]

38.7

APPROXIMATE

CENTER OF

GRAVITY

[3.56]

90.5

2X

[3.19]

81

2X

[5 ]

+0

-0.002

Ø127

+0

-0.05

[0.69 ±0.01]

Ø17.57

±0.30

THRU

6X

[1.97]

50

[9.42]

239.3

[1.26]

32

[5.56]

141.3

[3.24]

82.3

BOTH SIDES

SPOT FACE

(M5)

BOTH SIDES

SPOT FACE

(M4)

C

L

C

L

Z

88

[3.46]

89

[3.50]

P400180

Technical Information

Series 42 4T Axial Piston Tandem Pumps Size 41/51

Installation Drawings

42 | © Danfoss | November 2020 BC152886482857en-000302

Page 43

P400181

C

L

C

L

Servo Pressure Gauge Port “M4”

Port ISO 11926-1 – 9/

16

-18

Charge Inlet Port “M6”

Port ISO 11926-1 – 7/

8

-14

Servo Pressure Gauge Port “M5”

Port ISO 11926-1 – 9/

16

-18

Charge Relief Valve

12.5 mm External Hex

System Port “D”

Port ISO 11926-1 – 1 5/

16

-12

Case Drain Port “L2”

Port ISO 11926-1 – 1 5/

16

-12

System Port “C”

Port ISO 11926-1 – 1 5/

16

-12

System C Pressure Gauge Port “M1”

Port ISO 11926-1 – 9/

16

-18

System D Pressure

Gauge Port “M2”

Port ISO 11926-1 – 9/

16

-18

[4.49]

114