Page 1

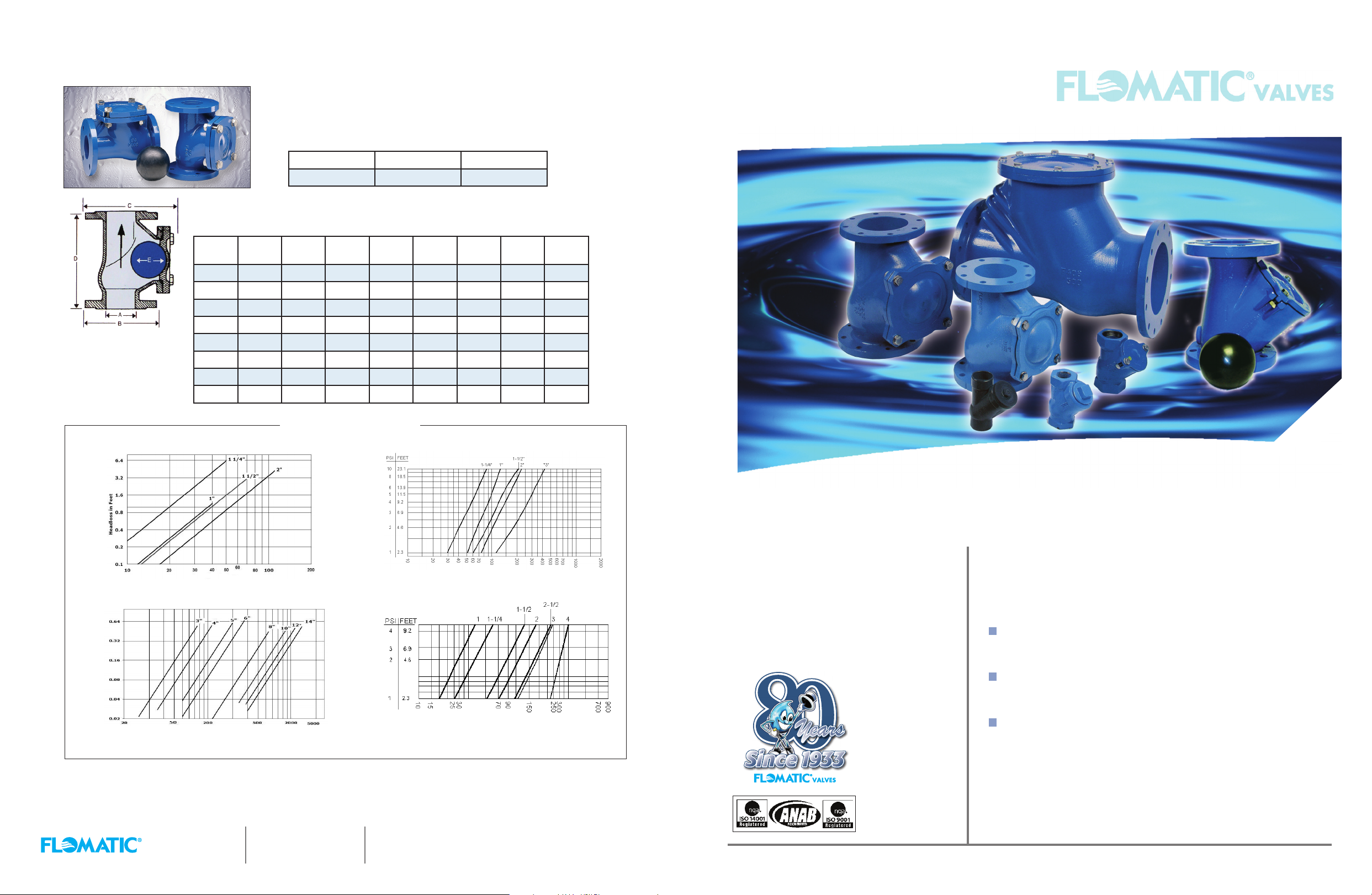

Ball Check Valves

Storm Water and Wastewater Applications

Threaded Model 208, 208B, 208T

Flanged Model 408, 408

2

Threaded/Flanged Model 508

Model 408, 4082 & 408FB

Size Range: 3”- 14”

A favorite and proven valve Model in the submersible water and wastewater

industry for decades. The 408 features a clean-out port permitting access to the

inside of the valve without removal from the pipe line. Flanged ANSI 125

connections. Model 408FB is equipped with a “floating” rather than a “sinking”

ball to prevent backflow from drains.

On special request, Flomatic offers optional high temperature and chemical resistance

Model 408SS, an all stainless steel valve body with Nitrile coated metal ball or solid

glass filled Teflon Ball.

Model 408/4082/408FB are available in eight

different sizes: 3”,4”, 5”, 6”, 8”, 10”,12” and 14”.

Model Max. Temperture Max. Pressure

408 and 408FB

180oF

150 PSI

SPECIAL ADAPTATION:

All Model 408 valves can

be equipped with optional

Prox Switch. Optional

corrosion resistant coatings

are available.

HEADLOSS CHARTS

MODEL 208

MODEL 408

Warranty: LIMITED ONE YEAR WARRANTY: The Flomatic Corporation warrants that its Ball Check Valves in all sizes are free from defects in materials and workmanship.

Flomatic will replace any valve covered by this warranty found to be defective within one year from time of sale. This warranty will be void if the product has been modified in

any way by the purchaser, or is subject to unreasonable use.

PRESSURE LOSS

PRESSURE LOSS

PRESSURE LOSS

PRESSURE LOSS

FLOW IN GALLONS PER MINUTE

FLOW IN GALLONS PER MINUTE

FLOW IN GALLONS PER MINUTE

FLOW IN GALLONS PER MINUTE

A

Nominal

Size

Part

Number

C

Maximum

Width

D

Length

E

Ball

Diameter

Bolt

Circle

Diameter

Bolt

Hole

Diameter

Number

of

Bolts

Weight

(Pounds)

3”* 2144-2 10

1

/4”

9

1

/2”

3

15

/16”

6” 3/4” 4 45

4”* 2145-2 11

3

/4”

11

1

/2”

4

23

/32”

7

1

/2

” 3/4” 8 72

5” 2143 13

1

/8”

13

25

/32”

6

1

/64”

8

1

/2

” 7/8” 8 85

6” 2146 14

27

/32”

16

1

/16”

7

1

/4”

9

1

/2

” 7/8” 8 132

8” 2147 18

5

/8”

19

11

/16”

9

21

/32”

11

3

/4”

7/8” 8 218

10” 2148 22

59

/64”

23

5

/8”

11

13

/16”

14

1

/4”

1” 12 272

12” 2149 28

25

/64”

27

35

/64”

14

13

/32”

17” 1” 12 541

14” 2150 32

9

/32”

34

29

/64”

16

35

/64”

18

3

/4”

1

1

/8

” 12 790

Flomatic Corporation

15 Pruyn’s Island Drive

Glens Falls, NY 12801-4421

Telephone: 1-(800)-833-2040 Direct Telephone: 1-(518)-761-9797

Fax: 1-(800)-314-3155 Direct Fax: 1-(518)-761-9798

www.flomatic.com

Flomatic Valves

High Quality Valves Built to Last...

MODEL 508

MODEL 208T

MODEL 408 & 408

2

*Model 408

2

1M 5/16

High Quality Valves Built to Last…

Page 2

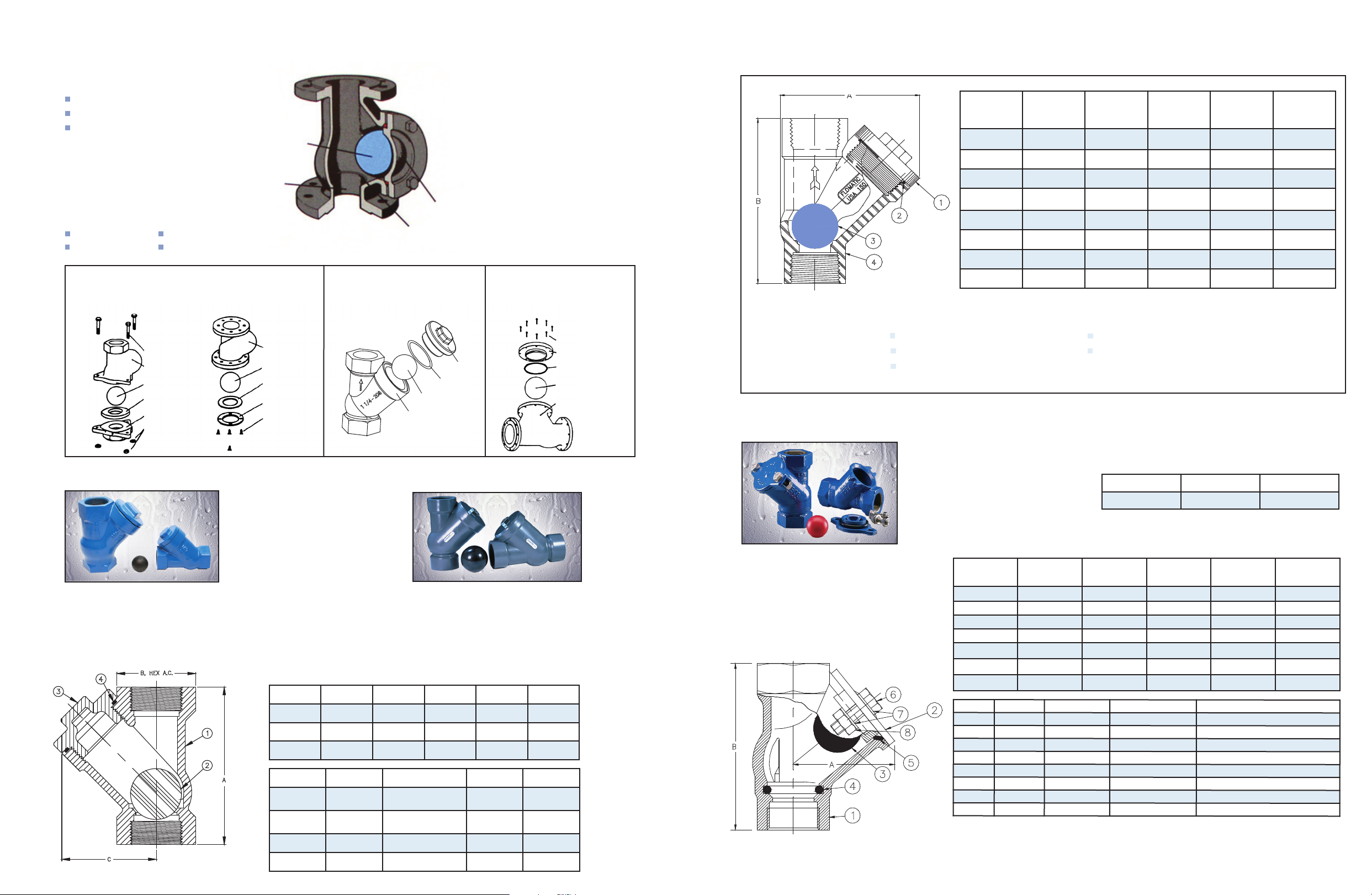

From America’s #1 Ball Check Valve Manufacturer...

Benefits & Features

Valves that end clogging

Flow Efficient

Low Maintenance Cost

Recommended for flow velocities of

3’ to 5’ per sec. Horizontal installation

requires 20’ static head for positive

sealing.

Available in:

Cast iron Ductile Iron

Stainless Steel PVC

*FLOATING BALL ALSO AVAILABLE, ADD “FB” TO PART NUMBER

FOR REFERENCES USE ONLY, SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

Model 208 Ball Check Valve - Cast Iron

Model 208T PVC Ball Check - Plastic

Size Range: 1”- 2”

Epoxy coated Cast Iron body Model

208 . Features NITRILE (Buna-N)

“Sinking Ball” or Floating Ball” (ad “FB”

to part number). E-Z access port for

cleaning or backflush.

Size Range: 1

1

/

4

”- 1

1

/

2

” 2”.

Temp Max: 180o (80C)

Epoxy coated Cast Iron body with

corrosion resistant phenolic ”Sinking Ball”

(floating optional Model 508FB. Simple

two bolt access cover for clean out.

Feature replaceable NITRILE (Buna-N)

valve seat.)

3” & 4” have no access cover

4” model is flanged.

Model 508/508FB are available in

seven different sizes: 1”, 1

1

/

4”, 1

1

/

2”, 2”, 2

1

/

2”, 3” and

4.”

Model 208T, corrosion resistant PVC body.

Threaded female x female connection.

Nitrile (Buna-N)seal. Also available with

PVC socket weld Model 208S.

Sizes: 1”, 1

1

/

4

”

, 1

1

/

2

”

, 2”. Temp Max: 150

o

(65C)

Not for ground burial.

Buna-N Vulcanized

Metal Ball

Unrestricted

Flow Way

Access port for in-line service.

Epoxy coated inside and out

Size Part Number

“A”

“B”

Width

Weight

(Pounds)

1” 3232

4

1

/

2

” 2

21

/

32

” 3

15

/

16

”

3.5

1

1

/

4

”

3233

5

13

/

64

” 3

7

/

64

” 4

1

/

4

”

4.5

1

1

/

2

”

3234

5

45

/

64

” 3

13

/

32

” 4

51

/

64

”

6

2”

3235

6

27

/32

” 4” 5

7

/

16

”

8

2

1

/

2

”

3236

7

7

/

8

” 4

29

/

32

” 6

1

/

4

”

11.5

3”

2044

9

19

/32

”

5” 8

9

/16

”

30

4”

2045

10

9

/16

”

6”

10

19

/32

”

45

Add “T ” after part number for NPT threads. Add “S” after part number for solvent weld.

Add “P ” after part number for BSPP threads. Not for ground burial.

New Vacuum Relief feature to reduce water hammer & noise in piple lines

*

Available NPT, BSPP or solvent weld connections. Valve can be used at temperatures up to 180

o

F (80oC).

1-PVC CAP

2-NITRILE “O” RING

3-NITRILE BALL

4-PVC BODY

Item

Quanity

Description

Material

ASTM

1

1

Body

(Epoxy Coated)

Cast Iron

A - 48

2

1

Cover

(Epoxy Coated)

Cast Iron

A - 48

3

1

*Ball

Phenolic

4

1

Seat Seal

Nitrile

5

1

Bonnet Seal

Nitrile

6

2

Bolt

Stainless Steel

304

7

4

Washer

Stainless Steel

304

8

2

Hex Nut

Stainless Steel

304

Models 208, 408, 4082 and 508

Flomatic Ball Check Valves

are especially designed for

demanding wastewater

and storm water pumping

applications.

Model 508

(Formally Model 50)

Model 208 Model 408 & 408

2

1

1

/

4

”

- 2” 3” - 14”

Stainless Steel Bolts

Stainless Steel Bolts

Cast Iron Body

Phenolic Ball

Seal

Threaded Brass Plate

Hex Nuts

Stainless Steel

Retaining Ring

Cast Iron Body

Ductile Iron

Access Plate Ductile Iron

Phenolic Ball

Seal

Rubber Covered

Hollow Iron Ball

Rubber Seal

Stainless Steel

Screws

Model 208

Model 208T

Model 508 and 508FB

Size Range: 1”- 4”

3” 4”

Model Max. Temperture Max. Pressure

508 and 508FB

180oF

150 PSI

Size (in.) Part # A B C WGT.(lbs.)

1

1

/

4

” 2141 5

1

/

16

” 2

1

/

2

” 3” 4 .5

1

1

/

2

” 2142-0 6

3

/

4

” 3

1

/

2

” 4

3

/

16

” 9.5

2 ” 2142 6

3

/

4

” 3

1

/

2

” 4

3

/

16

” 9

Item Qty. Description Material ASTM#

1 1

Valve Body

(EPOXY COATED)

Cast Iron A126 Class B

2 1

Ball

(SINKING)

Buna-N ---------

3 1 Cap Cast Iron A126 Class B

4 1 O-Ring Buna-N ---------

* Optional bosses for rail mounting available on the 208B model.

“A”- Size

Part

Number

A

Maximum

Width

B

Maximum

Ball

Diameter

Weight

(Pounds)

1

”

- NPT

2131T

6

27

/32”

4

1

/2”

1

1

/2”

1.0

1” -Socket

2131S 6

25

/32”

4

1

/2”

1

1

/2”

1.0

1

1

/4”

-NPT

2132T 5

21

/32”

4

1

/2”

1

1

/2”

1.0

1

1

/4”

Socket

2132S

5

5

/8”

4

1

/2”

1

1

/2”

1.0

1

1

/2”

-NPT

2133T 8

13

/64”

6

11

/32”

2

1

/2”

1.5

1

1

/2

”Socket

2133S 8

13

/64”

6

11

/32”

2

1

/2”

1.5

2”-NPT

2134T 7

1

/16”

6

11

/32”

2

1

/2”

1.5

2”-Socket

2134S 7

1

/16”

6

11

/32”

2

1

/2”

1.5

CAP

O'RING

BALL

BODY

Loading...

Loading...