Page 1

Data sheet

Anti-Drip Spray Nozzles Type 4023

Application

Many nozzles are satisfactory for spraying liquids,

but for a positive cut-o ask for the Hago type

4023 nozzle. Our exclusive design produces a

precisely controlled ow rate and spray angle

and includes a liquid cut-o near the orice. Fluid

cut-o near the orice can be very important in

situations where excessive after drip can damage

or destroy things located beneath the nozzle.

Chemicals, insecticides, and even plain water,

if allowed to drip, can foul the environment

or injure livestock, seedlings and industrial

materials.

With the type 4023 anti-drip nozzles, operators

can achieve fluid cut-off near the orifice while

maintaining pressure within the nozzle supply

system.

The type 4023 nozzle emits a finely atomized

spray mist suitable for nearly all humidifying,

light wetting and evaporative cooling

application. This nozzle has become a nozzle of

choice for the insect spray system industry.

Application and Features

• Insect control

• Odor control chemicals

• Green houses

• Agriculture, farms, livestock, barns

• Environmentally hazardous chemicals

• Reduces undesirable nozzle after-drip

• Field proven performance for over 40 years

• Accurate, flow rate and spray angle

• Produces a finely atomized mist

Availability

• Standard ow rate: 0.75 GPH at 160 psi

(11bar), water.

• Spray angle: 70 Degrees at 160 psi, water.

• Spray pattern: Semi solid cone.

Available Accessories

• Adapters

Identification The nozzles are marked with the following

information:

4023

Stampe d on the flats

4023 Anti-Drip spray nozzle

HP High Pressure

NSB Nickel Silver tip and Brass disc

© Danfoss | 03/2018 VDDZH322 | 1

NSBHP

12345

Batch code for internal use

Page 2

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Anti-Drip Spray Nozzles Type 4023

Technical Data

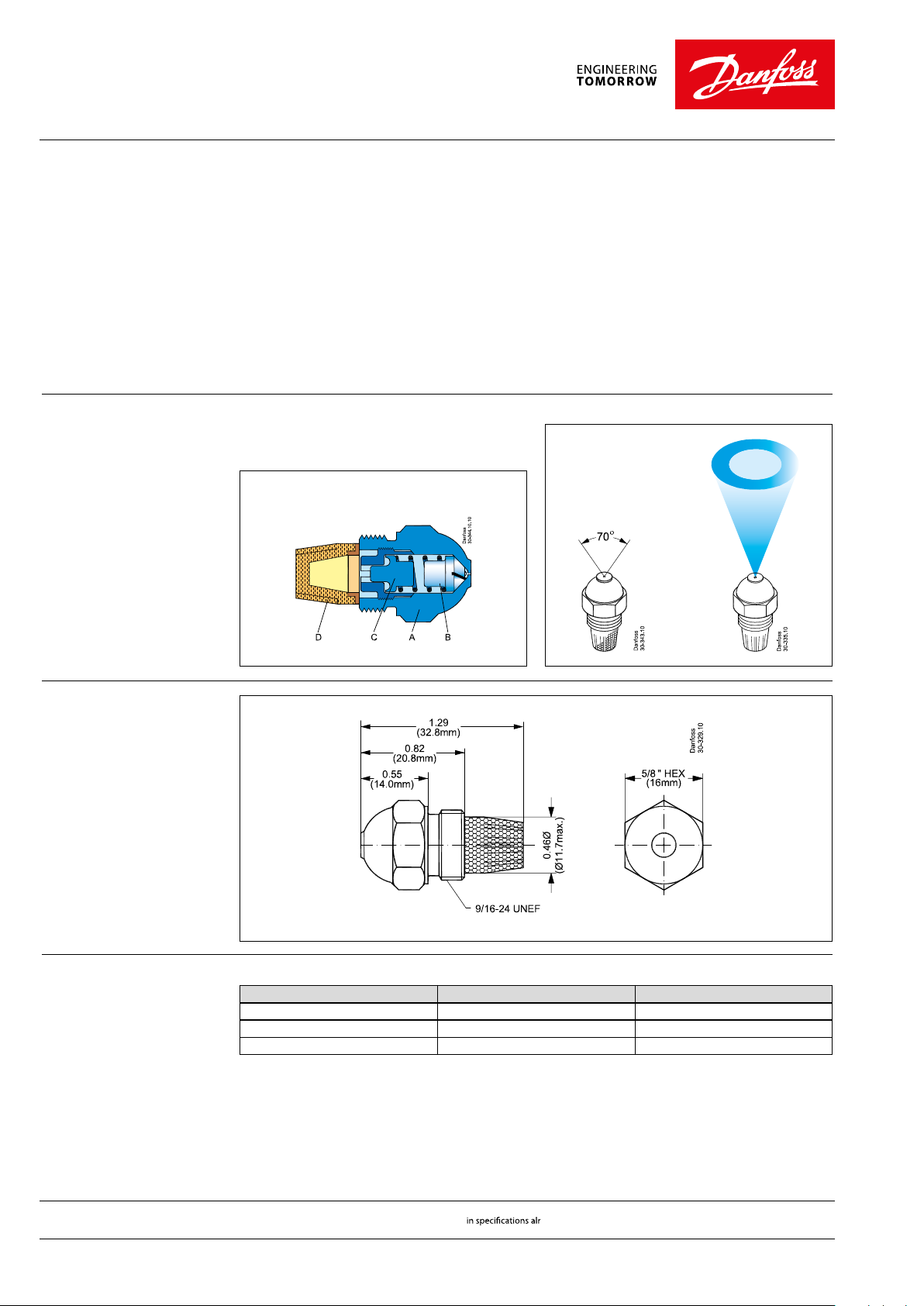

Design

Material and construction

Our nozzle with nickel silver tip and brass disc

is our most popular and corrosion resistant

offering for water applications. Nickel Silver is

a trade name for a non-magnetic copper nickel

alloy. This also includes a stainless steel spring.

Performance

Minimum recommended operation pressure is

160 psi (11 bar).

The nozzle is rated 0.75 gph (water) at 160 psi

(11bar) where it delivers a semi solid spray

pattern.

A: Tip

B: Disc

C: Cut-off valve

D: Sintered filter

Cut off valve

The cut off valve has a closing pressure between

40-70 psi (~3 to 5 bar)

Filtration

30-40 μm sintered bronze filter

Recommended tightening torque

130 to 180 in-lbs (15 to 20 Nm).

Maximum tightening torque

180 in-lbs (20 Nm).

Spray angle and pattern

Dimensions

Dimensions for reference only.

Program

Standard flow rate Semi Solid Remarks

Usgal/h 70° -

0.75 030L4501 -

0.75 030L4502 With O-ring

Danfoss

Toronto, ON/Baltimore, MD

Toll Free: 888-DANFOSS (326-3677) Option #3 for Heating

heating.danfoss.us

heating.cs.na@danfoss.com

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 03/20182 | VDDZH322

Loading...

Loading...