Page 1

VLT® 2800 Series

The multi purpose drive with a perfect match between price and performance

in a wide range of industrial applications.

18.5 kW

maximum motor size

Energy efficient control of a

wide range of applications,

with built-in brake chopper

and coated printed circuit

board as standard features.

The VLT® 2800 series is designed to t

the needs in a wide range of general

purpose drive applications up to

18.5 kW.

Power range

1/3 x 200 – 240 V ................ 0.37 – 3.7 kW

3 x 380 – 480 V ..................0.55 – 18.5 kW

With 160% overload torque (high

overload)

Over the years it has shown its value

to a large number of customers, resulting in a large base of installed drives

all over the world.

The VLT® 2800 is delivered with a factory tted brake chopper and coated

printed circuit boards for increased

protection as standard features.

Feature Benet

Easy to integrate and operate

Quick menu Easy start-up and fast parameter access

Automatic Motor Tuning

PID-controller Optimized process control

Fieldbus communication Control and surveillance from PLC or PC

Built-in brake chopper

Application dedication

Counter precise stop

Precise stop function

Dry run protection Protects the pump in dry run situations

Enhanced sleep mode

Pipe ll mode

Flexible and robust

Max. ambient temperature 45°C without

derating

Mounting with ventilated heat sink Flexible mounting incl. horizontal mounting

Side by side mounting Saves space in installations

Built-in RFI lter

Coated Printed Circuit Boards

Ensures optimal match and performance

increase between VLT 2800 and motor

Standard feature that increases exibility.

Eliminates need to decide up front if a brake

chopper is needed

The drive counts pulses and stops safely after

the programmed number of counts.

Increases performance in packaging

applications

Excellent control for shutting down the drive

in low ow situations

Prevents water hammering in pump

applications

No external cooling or oversizing required

Complies with EMC standards incl.

EN55011 1A

Standard feature that increases protection

of electronics against condensation and

hazardous substances in the surroundings

Facts about our products

Page 2

PC software tools

n VLT® Motion Control Tool MCT 10

PC software tool, which is ideal for

commissioning and servicing the

drive

n VLT® Motion Control Tool MCT 31

Harmonic calculation software

RFI lter

The RFI lter ensures that the frequency converter will not disrupt

other electrical components that are

connected to the mains and might

cause operating disruption.

By tting an RFI 1B lter module

between the mains supply and the

VLT® 2800, the solution complies with

the EMC norm EN 55011-1B.

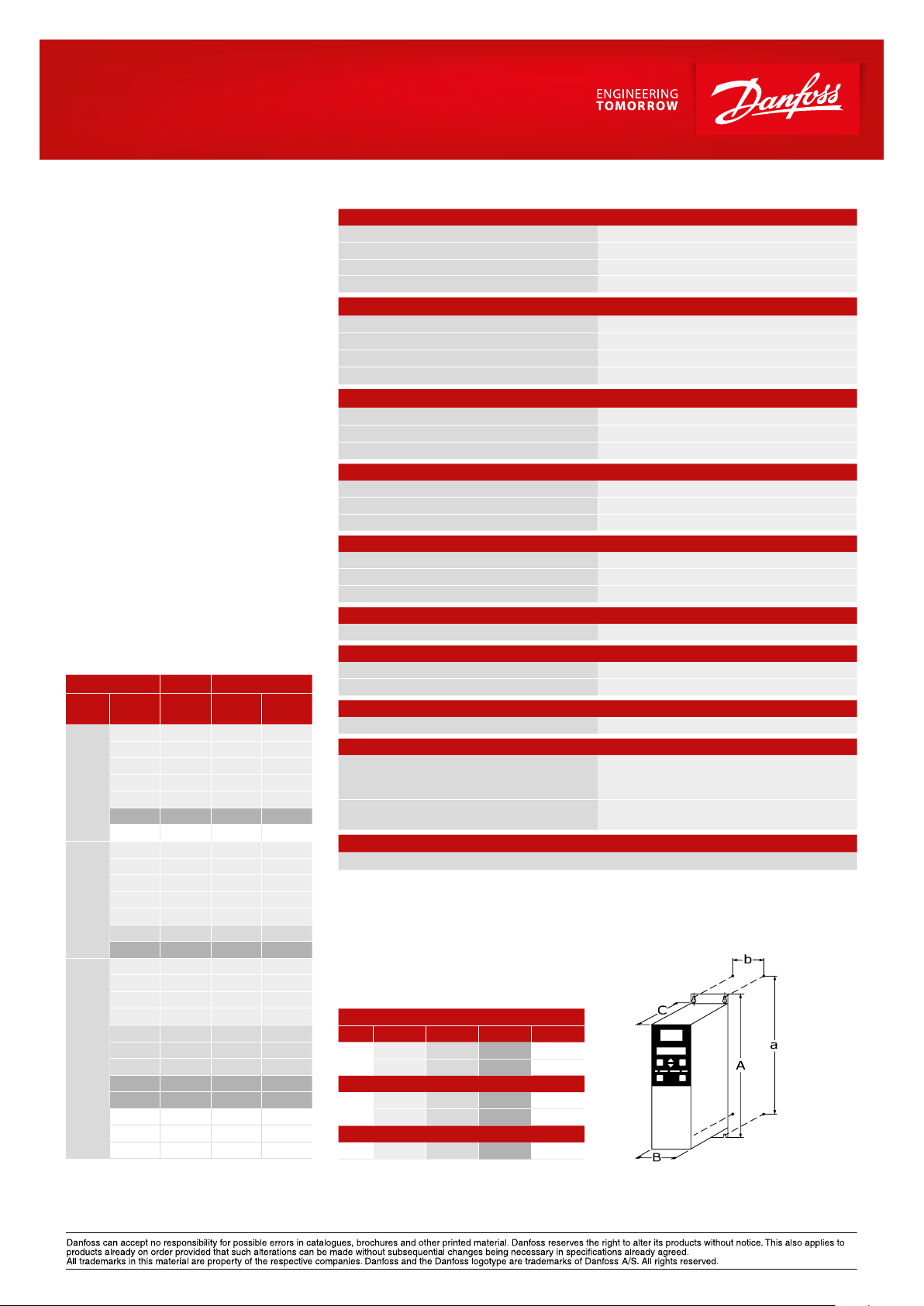

Power Input current

Mains Typ e

2803 0.37 2.2 5.9

2805 0.55 3.2 8.3

2807 0.75 4.2 10.6

2811 1.1 6.0 14.5

2815 1. 5 6.8 15. 2

1 x 220–240 V

2822* 2.2 9.6 22.0

2840* 3.7 16.0 31.0

2803 0.37 2.2 2.9

2805 0.55 3.2 4.0

2807 0.75 4.2 5 .1

2811 1.1 6.0 7. 0

2815 1. 5 6.8 7.6

3 x 200–240 V

2822 2.2 9.6 8.8

2840 3.7 16.0 14.7

2805 0.55 1.7 1.6

2807 0.75 2 .1 1.9

2811 1.1 3.0 2.6

2815 1. 5 3.7 3.2

2822 2.2 5.2 4.7

2830 3.0 7. 0 6.1

2840 4.0 9.1 8 .1

2855 5.5 12 10.6

3 x 380–480 V

2875 7.5 16 14.9

2880 11. 0 24 24.0

2881 15.0 32 32.0

2882 18. 5 37. 5 3 7.5

* Not available with RFI lter

P

[kW]

N,M

I

[A]

INV

I

[A]

L,N

Specications

Mains supply (L1, L2, L3)

Supply voltage 200-240 V ±10%, 380-480 V ±10%

Supply frequency 50/60 Hz

Displacement Power Factor (cos φ) near unity (> 0.98)

Switching on input supply L1, L2, L3 1–2 times/min.

Output data (U, V, W)

Output voltage 0–100% of supply voltage

Switching on output Unlimited

Ramp times 0.02–3600 sec.

Output frequency 0–590 Hz

Digital inputs

For start/stop, reset, thermistor, etc. 5

Logic PNP or NPN

Voltage level 0–24 VDC

Analogue input

No. of analogue inputs 2

Voltage level -10 to +10 V (scaleable)

Current level

Pulse inputs

No. of pulse inputs 2

Voltage level 0 – 24 V DC (PNP positive logic)

Pulse input accuracy (0.1–110 kHz)

Digital output

No. of digital outputs 1

Analogue output

Programmable analogue outputs 1

Current range 0/4–20 mA

Relay outputs

No. of relay outputs 1

Communication

Standard built-in

Fieldbus built-in

Ambient temperature

50˚C

0/4 to 20 mA (scaleable)

RS485

Modbus RTU

Metasys N2 protocols

PROFIBUS DP V1 12 Mbit/s

DeviceNet

Cabinet sizes [mm]

Height

A B C D

A 200 2 67. 5 267. 5 505

a 191 257 257 490

Width

B 75 90 140 200

b 60 70 120 12 0

Depth

C 168 168 168 244

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80

www.danfoss.com/drives • E-mail: info@danfoss.com

DKDD.PFP.403.A3.02 VLT® is a trademark of Danfoss A/S Produced by PE-MMSC 2014.09

Loading...

Loading...