Page 1

VLT® MICRO

Danfoss can accept no responsibility for possible errors in catalogs, brochures and other printed material. Danfoss reserves the right

to alter its products without notice. This also applies to products already on order provided that such alterations can be made

without subsequential changes being necessary in specifications already agreed.

Table of Contents

Chapter 1 Introduction

Getting Started .................................................................................1

Receiving, Inspection, and Storage ................................................... 2

Nameplate Information ..................................................................... 2

General Technical Data .....................................................................3

Specifications ................................................................................... 6

External Parts and Labels ................................................................. 7

Chapter 2 Installation and Wiring

Installation Requirements .................................................................. 8

Wiring ...............................................................................................9

Main Circuit Standard Wiring Chart ................................................. 10

Control Terminal Designations (Factory Settings) ............................. 11

Safety Precautions.......................................................................... 12

Chapter 3 Digital Keypad/Display Operation

Digital Keypad/Display Features...................................................... 14

Quick Set-up .................................................................................. 16

Operation ....................................................................................... 18

Chapter 4 Description of Parameters .............................................................. 20

Chapter 5 Summary of Parameters .................................................................62

Chapter 6 Troubleshooting and Fault Information ............................................ 69

Appendix A Dimensions ..................................................................................... 73

Appendix B Accessories .................................................................................... 75

Appendix C CE Labeling ....................................................................................77

Appendix D Serial Communication ..................................................................... 82

Document Version Number 3.10

Software Version 1.06

VLT is a registered Danfoss trade mark

Page 2

VLT® MICRO

Page 3

VLT® MICRO

Chapter 1

Introduction

Congratulations on your purchase of a VLT® Adjustable Frequency Drive. The VLT

®

MICRO is a high-performance / low noise general-purpose drive, manufactured using

the highest quality components and incorporating the latest micro-processor technology

and control algorithms.

The purpose of this chapter is to provide specific yet simple information to unpack,

install, and operate the drive. This chapter contains information on the following:

• Getting Started

• Unpacking, Inspection, and Storage

• Nameplate Information

• Identification of Parts

Getting Started

This manual will help in the installation, parameter setting, troubleshooting, and daily

maintenance of the AC drive. To guarantee safe operation of the equipment, read the

following safety guidelines before connecting the Adjustable Frequency Drive to AC

Power.

The VLT Adjustable Frequency Drive (AFD) contains dangerous voltages

when connected to line voltage. After disconnecting from the line wait at

least one minute before touching any electrical components. Also make

sure that other voltage inputs have been disconnected, such as external 24

VDC, load-sharing (linkage of DC intermediate circuit), as well as the motor

connection for kinetic back-up. Only a competent electrician should carry

out the electrical installation. Improper installation of the motor or the AFD

may cause equipment failure, serious injury or death. Follow this manual,

National Electrical Codes (NEC

®

) and local safety codes.

Electrostatic Precaution; Electrostatic discharge (ESD). Many electronic

components are sensitive to static electricity. Voltages so low that they

cannot be felt, seen or heard, can reduce the life, affect performance, or

completely destroy sensitive electronic components. When performing

service, proper ESD equipment should be used to prevent possible damage

from occurring.

It is the responsibility of the user or the person installing the AFD to provide

proper grounding, as well as motor overload and branch circuit protection

according to the National Electrical Code (NEC

®

) and local codes.

WARNING

WARNING

CAUTION

1

Page 4

VLT® MICRO

Receiving, Transporting, Inspecting, and Storage

This VLT

®

MICRO Adjustable Frequency Drive has gone through rigorous quality control

tests at the factory before shipment. After receiving and before transporting the drive,

check for the following.

Receipt

After receiving the AC drive, inspect the unit to insure it was not damaged during

shipment.

Transportation

Climatic condition : Class 2K3

Inspection

• After unpacking the unit, make sure that the package includes a drive unit and the

Instruction Manual.

• Make sure that the part number indicated on the nameplate and packing carton

corresponds with the part number of your order.

Storage

The AFD should be kept in the shipping carton before installation. In order to retain the

warranty coverage, the drive should be stored properly. Some storage

recommendations are:

• Store in a clean, dry place

• Store within an ambient temperature range of -20°C to +65°C

• If possible, store in an air-conditioned evironment where the relative humidity is less

than 95%, non-condensing.

• Do not store the unit in places where it could be exposed to corrosive gases.

• Do not store the unit on an unstable surface where it could be damaged by falling to

the floor.

Nameplate Information

Example for 1HP 240V AC Adjustable Frequency Drives

Description of Serial Number

1234 01 H 260

Production date:

week, year

Place of production

Series number

Serial number

MODEL : 176F7304 S. N. 123401H260

INPUT : 3PH 200-240V 50/60 Hz 6.3A

OUTPUT : 3PH 0-240V 5.0A 1.9KVA 1HP

Freq. Range: 0.1-400Hz

Model, Serial Number

Input Spec.

Output Spec.

Freq. Range

Tracking number

Part Numbers:

1/2HP 230V single phase 176F7300

1HP 230V single phase 176F7301

2HP 230V single phase 176F7302

1/2HP 230V three phase 176F7303

1HP 230V three phase 176F7304

2HP 230V three phase 176F7305

1/2HP 230V single phase CE 176F7306

1HP 230V single phase CE 176F7307

2HP 230V single phase CE 176F7308

2

Page 5

VLT® MICRO

General Technical Data

AC line supply (L1, L2, L3):

Supply voltage 200-240 V units ............................ 1 x 200/208/220/230/240 V ±10%

Supply voltage 200-240 V units ............................ 3 x 200/208/220/230/240 V ±10%

Supply frequency .......................................................................................... 50/60 Hz

Max. imbalance of supply voltage .................................... ±2% of rated supply voltage

Power factor/cos ϕ ............................................................................0.90/1.0 at rated load

Max short circuit rating ..................................................................................... 5000 A

VLT output data (U, V, W):

Output voltage ..................................................................... 0-100% of supply voltage

Output frequency..................................................................................... 0.1 - 400 Hz

Rated motor voltage, 200-240 V units ................................... 200/208/220/230/240 V

Rated motor frequency ................................................................................. 50/60 Hz

Switching on output...................................................................................... Protected

Ramp times ............................................................................................. 0.1-600 sec.

Torque characteristics:

Starting torque.................................................................................... 150% for 1 min.

Acceleration torque ............................................................................................ 100%

Overload torque, 200-240 V ............................................................... 150% for 1 min.

Control card, digital inputs:

Number of programmable digital inputs ..................................................................... 6

Terminal nos. ....................................................................... M0, M1, M2, M3, M4, M5

3

Page 6

VLT® MICRO

Control card, analog inputs:

No. of programmable analog inputs (selectable voltage or current) ............................ 1

Terminal numbers ................................................................................................. AV 1

Voltage level .............................................................................................. 0 - 10 VDC

Input resistance, R

i

..........................................................................................................................................

approx. 47 kΩ

Current range ................................................................................................ 4-20 mA

Input resistance, R

i

..........................................................................................................................................

approx. 250 Ω

Resolution ................................................................................................ 10 bit + sign

Galvanic isolation: All analog inputs are galvanically isolated from the supply voltage.

Control card, 10 VDC supply:

Terminal numbers ................................................................................................ +10V

Max. load .......................................................................................................... 10 mA

Control card, analog outputs:

Number of programmable analog outputs ................................................................. 1

Terminal numbers ................................................................................................. AFM

Voltage range at analog output .................................................................. 0 - 10 VDC

Galvanic isolation: All analog outputs are galvanically isolated from the supply voltage.

PHC output

Number of programmable photocoupler outputs ....................................................... 1

Terminal numbers ...................................................................................... MO1-MCM

Max. output ...................................................................................... -48 VDC, 50 mA

Control card, RS485 serial communication:

Terminal numbers .............................................................................................. RJ-11

4

Page 7

VLT® MICRO

5

Relay outputs:

No. of programmable relay outputs ........................................................................... 1

Terminal numbers .............................................. RA, RC (N.O.) RB, RC (N.C.) (Form C)

Max. terminal load rating ...........................................................120 VAC/28 VDC, 5 A

........................................................................................................... 240 VAC, 2.5 A

Brake resistor terminals:

Terminal numbers ............................................................................................. B1, B2

Cable lengths and cross-sections:

Use 75°C copper wire minimum

Max. motor cable length ...................................................................................... 50 m

Max. cable cross-section for line, motor and brake ......................... 14 AWG (2.0 mm

2

)

Max. cable cross-section for control terminals ................................ 14 AWG (2.0 mm

2

)

Control characteristics:

Frequency range ..................................................................................... 0.1 - 400 Hz

Resolution on output frequency .......................................................................±0.1 Hz

Speed, control range (open loop) ............................................. 1:20 of synchro. speed

Speed, accuracy (open loop) .............................................< 1800 rpm: max. error 2%

......................................................... > 1800 rpm: max. error of 0.5% of actual speed

Environment:

Enclosure .............................................................................. Protected chassis (IP20)

Vibration test ...................................................... 1.0 g less than 20Hz, 0.6 g 20-50Hz

Max. relative humidity ................................................ less than 90% (non-condensing)

Ambient temperature ............................................................................ –10°C - +50°C

Temperature during storage/transport ....................................................... –20 - +60°C

Max. altitude above sea level ............................................................ 3300 ft. (1000 m)

Page 8

VLT® MICRO

6

AC Line 1Ø and 3Ø, 200 - 240 Volt

VLVL

VLVL

VL

T OrT Or

T OrT Or

T Or

der Number 1Øder Number 1Ø

der Number 1Øder Number 1Ø

der Number 1Ø

176F7300176F7300

176F7300176F7300

176F7300

176F7301176F7301

176F7301176F7301

176F7301

176F7302176F7302

176F7302176F7302

176F7302

3Ø3Ø

3Ø3Ø

3Ø

176F7303176F7303

176F7303176F7303

176F7303

176F7304176F7304

176F7304176F7304

176F7304

176F7305176F7305

176F7305176F7305

176F7305

1Ø CE1Ø CE

1Ø CE1Ø CE

1Ø CE

176F7306176F7306

176F7306176F7306

176F7306

176F7307176F7307

176F7307176F7307

176F7307

176F7308176F7308

176F7308176F7308

176F7308

Output current

continuous (200-240) [A] 2.5 5.0 7.0

intermittent (200-240) [A] 3.7 7.5 10.5

Output

continuous (200-240) [KVA] 1.0 1.9 2.7

Typical shaft output [HP] 0.5 1.0 2.0

[kW] 0.4 0.75 1.5

Max. motor cable size [AWG] 14 14 14

[mm

2

]222

Max. input current 1Ø, 200-240 [A] 6.3 11.5 15.7

3Ø, 200-240 [A] 2.9 6.3 8.8

Max. power cable size [AWG] 14 14 14

[mm

2

]222

Max. pre-fuses

1)

1Ø [A] 10 20 25

3Ø [A] 10 20 25

Enclosure Chassis (IP20)

Weight 1Ø [lbs.] 1.75 2.0 2.25

3Ø [lbs.] 1.75 1.75 2.0

1)

200-240 VAC; Bussmann type JJN or exact equivalent

Specifications

Page 9

VLT® MICRO

1: Mounting screw holes

2: Nameplate label

3: Bottom cover

4: Digital keypad

5: Upper cover

6: Ventilation hole

7: Input terminals

8: External input/output

terminals

9: B1, B2 External brake

resistor terminals

10: U, V, W Output terminals

7

7

8

9

10

U V W B1 B2

R S T

5

4

3

6

1

2

Page 10

VLT® MICRO

Air

Flow

5 in.

(120mm)

min.

5 in.

(120mm)

min.

2 in.

(50mm)

min.

2 in.

(50mm)

min.

Chapter 2

Installation and Wiring

Chapter 2 provides the information needed to properly install and wire the AC motor

drive. Make sure that the AC drive is wired according to the instructions contained in

this chapter. The instructions should be read and understood before the actual

installation begins. This chapter contains the following information:

• Installation Requirements

• Wiring

Installation Requirements

Install the drive vertically to provide proper ventilation. Adequate space is required

between the drive and a wall or other equipment. The figure below shows the minimum

space needed.

The AC motor drive should be installed in an environment that is:

• protected from rain or moisture

• protected from direct sunlight

• protected from corrosive gases or liquids

• free from airborne dust or metallic particles

• free from vibration

• free from magnetic noise

• Climate condition : Class 3K3 (temperature between -10°C to 50°C, Operation

above 40°C requires good ventilation to avoid over-heating.)

6 in

(150mm)

min.

6 in

(150mm)

min.

8

Page 11

VLT® MICRO

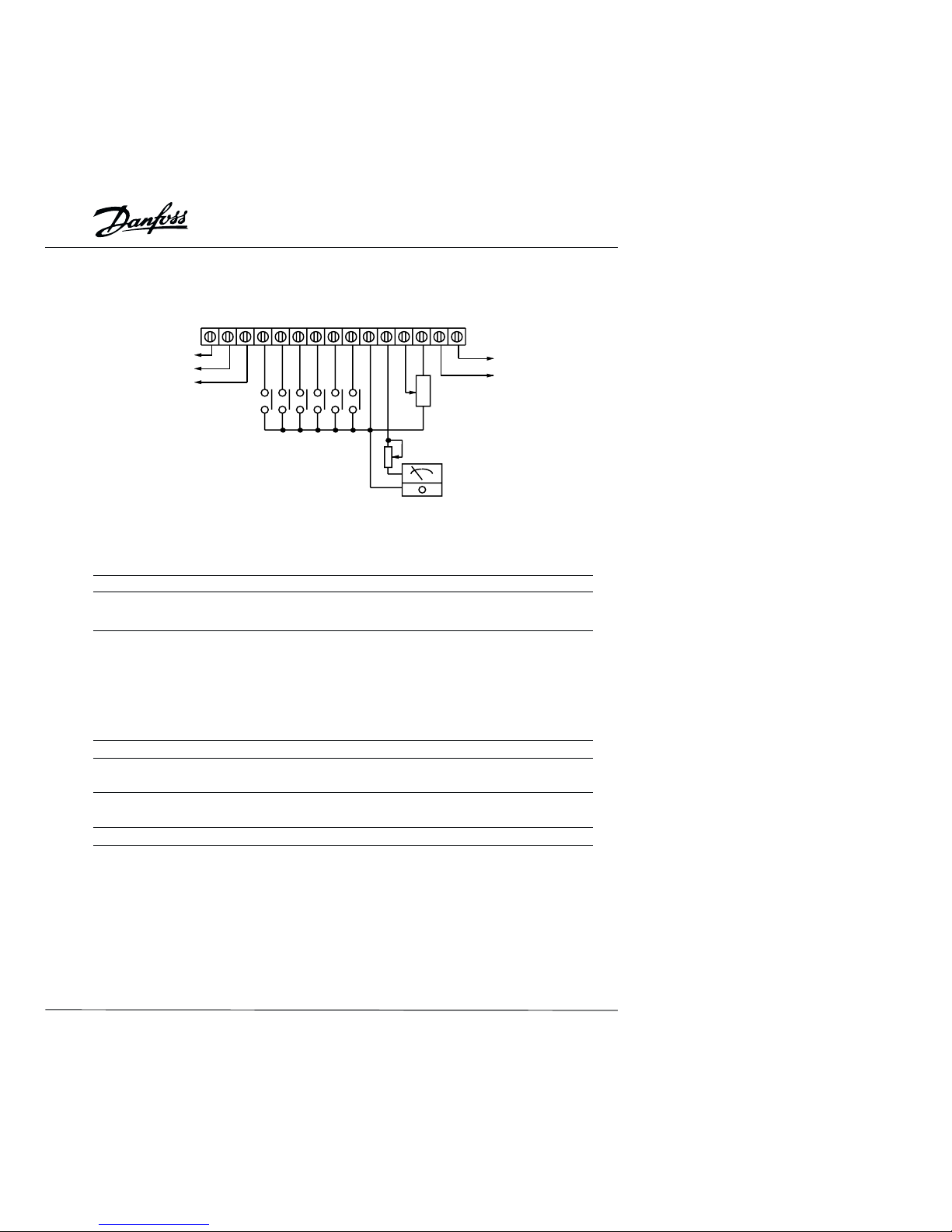

Wiring

There are two wiring systems in an AFD: Main Circuit and Control Circuit. The Main

Circuit terminals are located at the top of the drive. Control Circuit terminals are located

bottom of drive, Both terminal blocks are covered by the plastic housing. Lift the

hinged portion of the housing to gain access to the terminals. Make sure power is

removed before making any connections. Connect wires to the terminals according to

the diagram below. When no connections are made to the control terminals, the drive is

operated by the Digital Keypad/Display.

9

Braking Resistor (Option)

Select 80 ohm 120V

/200 ohm 120V

R

S

T

VAC Input

(Select two

terminals as

input for 230V

single phase

models)

Factory set as

multi-function input terminals

Forward/Stop

Reverse/Stop

Reset

Multi-Step 1

Multi-Step 2

Multi-Step 3

Signal Common

M0

M1

M2

M3

M4

M5

GND

M

Grounding

Trim (1K ohm)

Analog +

output

DC 0-10V –

Factory set as,

Indication of output frequency

Multi-function indication output

contacts 120VAC/28VDC 5A

240VAC 2.5A

Factory set as,

Indication of fault

RA

RB

RC

Multi-function PHC output

48V 50mA below

Factory set as,

Indication of "At work"

MO1

MCM

Power for

speed setting

+10V 10mA (max)

AV1

GND

Output Freq. determined

Analog voltage

0-10VDC

VR: 3K-5K ohm

Analog current

4-20mA

Factory set as, output frequency

determined by the potentiometer on

the control panel

R

S

T

E

U

V

W

F

AFm

GND

Ground

Control Circuit Terminals

Main Circuit (power) Terminals

RJ-11 communication port with

RS-485 serial interface

2: GND

3: SG–

4: SG+

5: +5V

6

* NOTE: Do not plug a modem or telephone in to the RS485 port. Do not use terminals

2 or 5 when using the port.

Page 12

VLT® MICRO

Recommended Input Fuses

BUSSMAN Type JJN

Fuse

VLT MICRO model176F7300 JJN-10

VLT MICRO model176F7301 JJN-20

VLT MICRO model176F7302 JJN-25

VLT MICRO model176F7303 JJN-10

VLT MICRO model176F7304 JJN-20

VLT MICRO model176F7305 JJN-25

VLT MICRO model176F7306 JJN-10

VLT MICRO model176F7307 JJN-20

VLT MICRO model176F7308 JJN-25

10

NOTE:

1. Main-circuit terminals spec. is M3.

2. Main-circuit wiring is 600V 14AWG max.

3. Wiring between drive and motor should

not exceed 330 ft. (100m)

(1) 100 ft. (30m) below, the PWM carrier

frequency should be 15kHz below.

(2) 165 ft. (50m) below, the PWM carrier

frequency should be 10kHz below.

(3) 300 ft. (100m) below, the PWM carrier

frequency should be 5kHz below.

4. Voltage drop (V) = √3 • line resistance

(Ω.Km) • line lengfh (m) • Current (A) • 10

-3

Connection for optional brake resistor.

Refer to Appendix for model numbers.

R S T

U

V

W

B1 B2

200-240 V200-240 V

200-240 V200-240 V

200-240 V

AC unitsAC units

AC unitsAC units

AC units

Page 13

VLT® MICRO

RA

M01MCM+10VAVIAFMGND

M5M4M3M2M1M0RCRB

Relay contactor output

Factory setting:

Forward / Stop

Reverse / Stop

Reset

Multi-step speed 1

Multi-step speed 2

Multi-step speed 3

Photo coupler output

Factory set: Operation

Speed: 3K-5K

Trim potentiometer

VR:1K-5K

Freq. meter

0-10VDC

Full scale voltmeter

Control Terminal Designations

AWG 12-14

Torque 4 kg-cm

Terminal symbol Terminal name Remarks

RA - RC Multi-function output contact Refer to P46,

RB - RC Multi-function output contact Relay Output Contact

M0 - GND Multi-function input 1 Refer to P38, 39, 40, 41, 42

M1 - GND Multi-function input 2

M2 - GND Multi-function input 3

M3 - GND Multi-function input 4

M4 - GND Multi-function input 5

M5 - GND Multi-function input 6

MO1 - MCM Multi-function PHC output 1 Refer to P45

+10V - GND Power supply for speed control Command for power supply

(+10 V)

AVI - GND Analog voltage freq. command 0 - 10V or 4 - 20mA

inputs (10V and 20mA = max. freq.)

AFM - GND Analog frequency/current meter 0 - 10 V output ( 10 V = max. freq.)

Note : Use twisted-shielded or twisted-pair shielded wires for the control signals. It is

recommended to run all signal wiring in a separate steel conduit. The shield wire should

only be connected to ground at the drive end of the cable.

11

Page 14

VLT® MICRO

Installation Notes:

• Make sure that the appropriate input fusing with specified current ratings are

connected between the AC Power Line and the AC drive. A MCC (contactor with

magnetic trip) is recommended between the drive and circuit breaker to provide a

means to disconnect the drive from the power line in the event of a fault.

• Make sure that the leads are connected correctly and the drive is properly grounded.

(Ground leads should be at least as the same size as input terminals R, S and T.)

• Use ground leads that comply with AWG standards. Make the length of these ground

leads as short as possible.

• Should several units be installed side by side, all the units should be grounded directly

to the ground terminal. Do not form a loop with the ground leads.

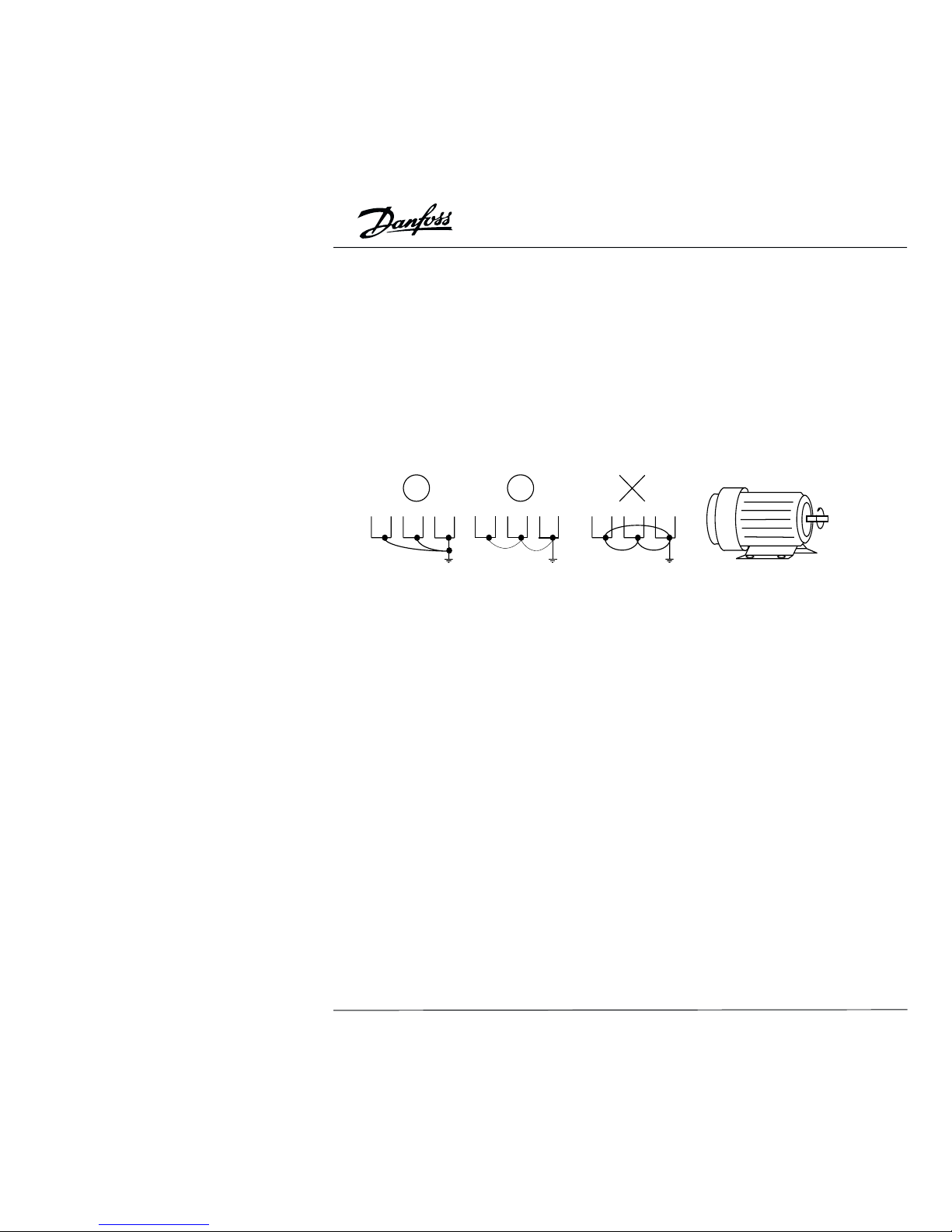

Forward

running

• When the drive output terminals U, V, and W are connected to the motor terminals U,

V, and W, respectively, the motor will rotate counter-clockwise (viewed from the shaft

of the motor as shown above) when a forward operation command is received ( FWD

lamp is ON).

• Make sure that the power source supplies the correct voltage and is capable of

supplying the required current to the drive.

• When power is applied to the drive, the internal DC bus charge indicator LED will be

on.

• Do not attach or remove wiring or connectors when power is applied to the drive. Do

not attempt to probe signals on the circuit board while the drive is operating.

• For single phase applications, the AC input line can be connected to any two of the

three input terminals R, S, T. Note: The drive is not intended for use with single-phase

motors.

• To reverse the direction of rotation, interchange the connection of any of the two

motor leads.

• Do not connect the AC input to any of the U, V, W terminals, as this will damage the

drive.

12

Page 15

VLT® MICRO

• Avoid loose wiring and possible shorts. Tighten all screws on AC circuit terminals

securely.

• It is a good practice to maintain a 90° angle between wires connected to the AC

circuit terminals and wires connected to the control terminals.

• Use shielded cables for Control Circuit wiring,

• Use conduit for the AC power line. The conduit on both the input and output of the

power line should be grounded.

• If an EMI filter is required, it should be located close to the drive. Reducing carrier

frequency can also be a way to reduce EMI noise, however audible noise from the

motor will increase.

• An L-Filter can be added to the U.V.W. side of AC Motor Drives if needed. Do not use

a Capacitor, or L-C Filter (Inductance-Capacitance), or R-C Filter (ResistanceCapacitance).

• A “Ground Fault Interrupt Circuit” can be used. To avoid malfunctioning of the motor

and drive, sensitivity of the current sensor should not be less than 200 mA with a

response time not less than 0.1 second.

13

Page 16

VLT® MICRO

Chapter 3

Digital Keypad/Display Operation

Chapter 3 describes the various controls and indicators found on the Digital Keypad/

Display. The information in this chapter should be read and understood before

performing the start-up procedures described in Chapter 4.

• Description of the Digital Keypad/Display

• Description of Display

• Digital Keypad Operating Modes & Programming Steps

Description of the Digital Keypad/Display

Operating Modes and Functions

When delivered from the factory, the Digital Keypad/Display module is mounted on the

front panel of the AC drive. This module has two functions: display and control. The

Display shows the current status of the drive. The control function provides the

programming interface.

RUN

STOP

FWD

REV

MODE

RUN

ENTER

STOP

RESET

FREQ SET

50

100

0

LED Display

Indicates frequency, motor

parameter setting value and

alarm contents.

Program / Function Data Key

Selects normal mode / program mode.

Displays the motor drive status, such

as output freq., selects the parameters,

FWD/REV or output current, etc.

ENTER Key

Sets the different parameters

LED Indication

Lamp lights during RUN,

STOP, FWD & REV operation.

RUN Key

Starts inverter drive operation.

STOP/RESET Key

Stops and resets the parameter

after faults occur.

UP and DOWN Key

Sets the parameter number or

changes the numerical data

such as the freq. reference.

VR for Setting Freq.

Could be the main-freq. input by

setting parameter Pr.00.

14

Page 17

VLT® MICRO

Function / Program

Pressing the “mode” key repetitively displays the AFD status such as the

reference frequency, output frequency, direction or output current and

selects the parameter setting mode.

Enter

Pressing the “ENTER” key to enter the data change mode and again to

store the value in memory.

Run

Used to start the AC drive operation. This key has no effect when the

drive is controlled by the External Control Terminals.

Stop / Reset

Used to stop AC drive operation. If the drive has stopped due to a fault,

clear the fault first, then press this key to reset the drive. This key has no

effect when the drive is controlled exclusively by the External Control

Terminals.

Up / Down

Press the “Up” or “Down” keys momentarily to change parameter

settings. These keys may also be used to scroll through different operating

values or parameters. Pressing the “Up” or “Down” key momentarily, will

changes the parameter settings in single-unit increments. To quickly run

through the range of settings, press down

and hold the key.

Press the "Up" or "Down" key momentarily to select Forward or Reverse

directions when in Direction Mode and the drive is controlled by the digital

control panel.

MODE

ENTER

RUN

STOP

RESET

RUN

STOP

FWD

REV

Green lamp lights during REV operation.

Green lamp lights during FWD operation.

Red lamp lights by pressing STOP.

Green lamp light by pressing RUN.

Explanation of the LED Indicators

15

Page 18

VLT® MICRO

Quick Set-up

Refer to the relevant chapters of this manual for detailed instructions to configure the

VLT MICRO for your specific requirements.

Before you start, please read the safety instructions in Chapter 1 of this

manual. The adjustable frequency drive contains dangerous voltages when

connected to the AC line. Improper connection of the motor or the VLT

MICRO may cause equipment failure, serious injury or death.

Follow the directions in this Quick Set-up, as well as all local and national safety codes.

Electrical Installation, Power

Connect the AC line and motor cables as shown in Chapter 2 of this manual.

Programming

The VLT adjustable frequency drive is programmed by

means of the Digital Keypad. Refer to Chapter 3 for the

keypad functions.

In order to operate in Quick set-up the Pin Header/Jumpers

(located next to the input terminals) should be as shown.

NOTE:

Speed reference is controlled by the "Arrow" keys. If the

potentiometer is to be used as the speed reference

parameter Pr.00 will need to be programmed to d01.

Set the following parameters according to the motor

nameplate:

Max motor frequency Parameter Pr.04

Max motor voltage Parameter Pr.05

Motor rated current Parameter Pr.52

Motor Full Load Amps

Drive's Max. Cont. Amps

Set the ramp times:

Accel time Parameter Pr.10

Decel time Parameter Pr.11

Motor Start

Press the "RUN" key to start the motor. Adjust desired speed using the "Arrow" keys.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

Pr.52 = x 100

Drive's Max Continuous Amps

Model Amps

176F7300 & 176F7303 2.5

176F7301 & 176F7304 5.0

176F7302 & 176F7305 7.0

J5

J6

J7

16

Page 19

VLT® MICRO

Explanation of Displayed Messages

Displays the AC drives output frequency. The frequency may be

determined by any one of the frequency sources that is selected by

the [Master frequency setting] or [Jog Frequency] command. It may

also be set using the [Multi-step speed setting 1 - 7] as determined by

the inputs to Multi-function Input terminals 1, 2 and 3.

If the frequency source originates from the control panel, the user

can use either the "up" or "down" key to select the frequency.

Displays the output frequency present at terminals U, V, and W.

Displays the custom unit (v), where v = H x Pr.-65.

Displays the internal counter value (C).

Note : Refer to Chapter 5, Pr.-45, 46, 64 - 66 for detailed description.

Displays the custom unit (v), where v = H x Pr.-65.

Displays the custom unit (r), where r = H x Pr.-65.

Displays the custom unit (L), where L = H x Pr.-65.

Displays the custom unit (%), where % = H x Pr.-65.

Displays the counter value (c).

Displays the output current present at terminals U, V, and W

Displays the internal PLC process step currently being performed.

Displays the specified parameter.

Displays the actual value stored within the specified parameter.

AC drive forward run status.

AC drive reverse run status.

The display will read “end” (as shown in the display to the left) for

approximately 1 second if an input has been accepted. After a

parameter value has been set, the new value is automatically stored in

memory. To modify an entry, use the "up" and "down" keys.

The display will read “Err”, if as input is not accepted, or a parameter

value is selected outside the limit of the parameter.

17

Page 20

VLT® MICRO

Press keys

to select the

parameter value.

Press keys

to select the

parameter number.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

• Operating The Digital Control Panel

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

Press to set

the motor running

frequency

Note: Set parameter Pr.00 to d00 to enable setting the frequency by the keypad.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

Press the freq.

will decrease

3.5Hz/sec.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

Press the freq.

will increase 3.5Hz/

sec.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

• Operate the parameter value setting.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

Displays the

parameter

number

automatically.

Press

Key

MODE

MODE

Press

Key

MODE

Press

Key

MODE

Press

Key

MODE

Press

Key

ENTER

Press

Key

Press

Key

ENTER

Press

Key

Press

Key

Press

Key

and

hold

Press

Key

and

hold

Release

Key

• Indicate the operation mode.

Indication after

power on.

Parameter value

setting motor.

Output frequency

monitor.

Output current

monitor.

Fwd./Rev.

monitor.

Displays the frequency

setting monitor.

Parameter value

setting motor.

The setting

value monitor

Modified the Pr.

value to d01.

The setting

value is right.

Parameter

setting monitor.

"End" The new value has

been automatically

stored in the

internal

memory.

"Err" The value entered

is not correct.

Frequency value

setting monitor.

Setting the freq.

to 59.9Hz.

Decrease the freq.

to 0Hz approx 17

sec. later.

Increase the freq.

to 60Hz approx

17 sec. later.

The freq. value can

be entered in stop

or operating mode.

18

Page 21

VLT® MICRO

• Change the different indication mode as follows:

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

• Reset the fault messages.

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

RUN

STOP

FWD

REV

MODE

ENTER

RUN

STOP

RESET

FREQ SET

50

100

0

Press

Key

or

MODE

Press

Key

STOP

RESET

Press

Key

Press

Key

RUN

MODE

Press

Key

MODE

Press

Key

MODE

Press

Key

After

10 sec.

twice

After

10 sec.

STOP

RESET

Press

Key

Fault message

O.H. is displayed.

Frequency setting

will be displayed

after the fault is

removed.

Change to Reverse

oprtation.

Change the Fwd.

or Rev. operation.

Setting the

frequency.

Decrease motor

speed to stop. Stop mode.

"STOP" "REV"

will light up.

"STOP" "REV" will

light "RUN" will

flash.

"STOP" "FWD"

will light up.

"RUN" "FWD"

will light up.

Indication after

power on.

Operate at

60.0Hz.

Output frequency

monitor.

Output current

monitor.

Forward

operation

monitor.

"RUN" "REV" will light

"FWD" will flash.

19

Page 22

VLT® MICRO

Chapter 4

Description of Parameters

Pr.00 Master Frequency Source Select

Factory Setting d00

Units None

Settings d00 Master frequency determined by keypad digital control.

d01 Master frequency determined by analog signal of DC 0V - +10V,

a. Performed by keypad potentiometer. The pin header and jumper

combined as 1 and 3 in the diagram below.

b. Performed by external terminal AVI. The pin header and jumper

combined as 2 and 3 in the diagram below.

d02 Master frequency determined by analog signal of DC 4mA - 20mA.

Performed by external terminal AVI. The pin header and jumper

combined as 2 and 4 in the diagram below.

Pin Header/Jumper Diagrams:

The pin headers and jumpers are located on the upper right corner of the control board

and can be accessed by opening the input terminal cover.

J5: Selects the source of the potentiometer input from

the External Control Terminal (AVI) or from the

Digital Keypad/Display (LC-03P) potentiometer.

J6, J7: This jumper is used to select the DC voltage signal

or DC current signal for master frequency control.

J5 J6 J7

1

2

3

12

34

J5

J5

J6 J7

J6 J7

1

2

3

1

2

3

1

2

3

1

2

3

External terminal

AV1 effective

Analog current

signal selection

Keypad

VR effective

Analog voltage

signal selection

20

Page 23

VLT® MICRO

Pr.01 Operation Command Source Select

Factory Setting d00

Units None

Settings d00 Operating instructions determined by the Digital Keypad/Display.

d01 Operating instructions determined by the External Control Terminals.

Keypad STOP key is effective.

d02 Operating instructions determined by the External Control Terminals.

Keypad STOP key is not effective.

(Refer to parameters 38, 39, 40, 41 and 42 for more details.)

Pr.02 Motor Stop Method Select

Factory Setting d00

Units None

Settings d00 Ramp stop

d01 Coast to stop

This parameter determines how the motor is stopped when the AC drive receives a valid

stop command.

Ramp: The AC drive output frequency decelerates down to the minimum output

frequency (Pr.08) in the time specified by Pr.11 or Pr.13, then the output is turned off.

Coast: The AC drive output is turned off immediately and the motor free runs until it

comes to a stop.

Ramp Coast

To determine the best method to stop the motor, the type of load needs to be

considered.

1. In many applications operator safety and material processing can be improved when

"Ramp Stop" is selected. The accel./decel. time required will depend on the specific

parameters of your application.

2. The advantage of using "Coast-to-stop" is the motor will heat less during

frequent starting and stopping. Applications where "Coast-to-stop" is commonly

used are fans, pumps, blowers, mixing and agitating.

Frequency command

sec. sec.

Speed

Stop command Setting value Stop command ?

Speed (Free running to stop)

Frequency command

Hz

Hz

21

Page 24

VLT® MICRO

Pr.03, Pr.04, Pr.05, Pr.06, Pr.07, Pr.08, Pr.09 – V / F Curve

Pr.03 Maximum Output Frequency

Factory Setting d60.0 Hz

Units 0.1 Hz

Parameter value d50.0 - d400.0 Hz

This parameter determines the maximum AC drive output frequency. Analog inputs (0 10 V, 4 - 20 mA) are scaled to correspond to the output frequency range.

Pr.04 Motor Frequency

Factory Setting d60.0 Hz

Units 0.1 Hz

Parameter value d10.0 - d400.0 Hz

This value should be set according to rated frequency of the motor as indicated on the

motor nameplate.

Pr.05 Motor Voltage

Factory Setting d220.0

Units 0.1 V

Parameter value d2.0 - d255.0

This parameter determines the Maximum Output Voltage of the AC drive. The maximum

output voltage setting must be smaller than or equal to the rated voltage of the motor as

indicated on the motor nameplate.

Pr.06 Mid-point Frequency

Factory Setting d1.50 Hz

Units 0.1 Hz

Parameter value d0.1 - d400.0 Hz

This parameter sets the Midpoint Frequency of the V/F curve. It may be used to

determine the V/F ratio between the Minimum Frequency and the Mid-point Frequency.

Pr.07 Mid-point Voltage

Factory Setting d12.0 V

Units 0.1 V

Parameter value d2.0 - d255.0

This parameter sets the Midpoint Voltage of the V/F curve. It may be used to determine

the V/F ratio between the Minimum Voltage and the Mid-point Voltage.

22

Page 25

VLT® MICRO

Pr.08 Minimum Output Frequency

Factory Setting d1.50 Hz

Units 0.1 Hz

Parameter value d0.1 - d20.0 Hz

This parameter programs the Minimum Output Frequency of the AC drive.

Pr.09 Minimum Output Voltage

Factory Setting d12.0 V

Units 0.1 V

Parameter value d2.0 - d50.0 V

This parameter programs the Minimum Output Voltage of the AC drive.

Voltage

Pr.05

Pr.07

Pr.09

Pr.08 Pr.06

Pr.04

Pr.03

Frequency

Fan/Pump V/F Curve

Custom V/F Curve

Frequency

Pr.03Pr.04

Pr.06

Pr.08

Pr.05

Pr.07

Pr.09

Voltage

Voltage

Pr.05

Pr.07

Pr.09

Pr.06

Pr.08

Pr.03

Pr.04

Frequency

Standard V/F Curve

0

23

Page 26

VLT® MICRO

Pr.10, Pr.11, Pr.12, Pr.13 Acceleration / Deceleration Time

Pr.10 Acceleration Time 1 (Can be programmed while the drive is running.)

Factory Setting d10.0 Sec

Units 0.1 Sec

Parameter value d0.1 - d600.0 Sec

Commonly Used V/F Pattern Settings

(1) General Purpose

(2) Fans and Pumps

(3) High Starting Torque

Motor Spec 50Hz

Motor Spec 50Hz

Motor Spec 50Hz

Motor Spec 60Hz

Motor Spec 60Hz

Motor Spec 60Hz

No. Set value

Pr.03 50.0

Pr.04 50.0

Pr.05 220.0

Pr.06 1.3

Pr.07 12.0

Pr.08 1.3

Pr.09 12.0

No. Set value

Pr.03 60.0

Pr.04 60.0

Pr.05 220.0

Pr.06 3.0

Pr.07 23

Pr.08 1.5

Pr.09 18.0

No. Set value

Pr.03 50.0

Pr.04 50.0

Pr.05 220.0

Pr.06 25

Pr.07 50.0

Pr.08 1.3

Pr.09 10.0

No. Set value

Pr.03 50.0

Pr.04 50.0

Pr.05 220.0

Pr.06 2.2

Pr.07 23.0

Pr.08 1.3

Pr.09 14

Factory Settings

No. Set value

Pr.03 60.0

Pr.04 60.0

Pr.05 220.0

Pr.06 1.5

Pr.07 10.0

Pr.08 1.5

Pr.09 10.0

No. Set value

Pr.03 60.0

Pr.04 60.0

Pr.05 220.0

Pr.06 30

Pr.07 50.0

Pr.08 1.5

Pr.09 10.0

V

220

23

14

1.3 2.2 60.0

f

1.3 25 50.0

f

1.5 30 60.0

f

1.5 50.0

f

1.5 60.0

f

1.5 3 60.0

f

V

220

50

10

V

220

10

V

220

10

V

220

23

10

V

220

50

10

24

Page 27

VLT® MICRO

This parameter is used to determine the time required for the AC drive to ramp from 0

Hz to its Maximum Output Frequency (Pr.03). The rate is linear unless S Curve is

"enabled". This rate of acceleration applies to any incremental increase in command

frequency unless selected using the Multi-Function Inputs, MI1 - 3. See Parameters 39,

40 and 41. Acceleration time 1 is the default when a Multi-Function Input Terminal has

not been programmed to select between Acceleration time 1 and Acceleration time 2.

Pr.11 Deceleration Time 1 (Can be programmed while the drive is running.)

Factory Setting d10.0 Sec

Units 0.1 Sec

Parameter value d0.1 - d600.0 Sec

This parameter is used to determine the time required for the AC drive to decelerate

from the Maximum Output Frequency (Pr.03) down to 0 Hz. The rate is linear unless S

Curve is "enabled". Deceleration time 1 is the default when a Multi-Function Input

Terminal has not been programmed to select between Deceleration time 1 and

Deceleration time 2.

Note: See Pr.101; Automatic Accel and Decel times are default. Change to "Linear

Acceleration/Deceleration" to enable manual adjustment.

Pr.12 Acceleration Time 2 (Can be programmed while the drive is running.)

Factory Setting d10.0 Sec

Units 0.1 Sec

Parameter value d0.1 - d600.0 Sec

This parameter determines the time required for the AC drive to ramp from 0 Hz to the

Maximum Operating Frequency (Pr.03). The rate is linear unless S Curve is "enabled".

The rate of acceleration applies to any incremental increase in command frequency

unless Acceleration Time 1 (Pr.10) is selected. Acceleration Time 1 and 2 may be

selected using the Multi-Function Inputs M1 - 3. (See Parameters 39, 40 and 41.)

Speed

Time

Decel

Time

Accel

Time

Frequency command

Pr.10 or Pr.12

Pr.11 or Pr.13

25

Page 28

VLT® MICRO

Frequency

S-curve characteristics Time

Time

Time

Pr.14 > d01

"S curve Enabled"

Pr.14 = d00

"S curve Disabled"

Accel time

1 or 2

Decel time

1 or 2

Note: See Pr.101; Automatic Accel and Decel times are default. Change to "Linear

Acceleration/Deceleration" to enable manual adjustment.

Pr.13 Deceleration Time 2 (Can be programmed while the drive is running.)

Factory Setting d10.0 Sec

Units 0.1 Sec

Parameter value d0.1 - d600.0 Sec

This parameter determines the time for the AC drive to decelerate from the Maximum

Output Frequency (Pr.03) down to 0 Hz. The rate is linear unless S Curve is "enabled".

The rate of deceleration applies to any decrease in command frequency unless

Deceleration Time 1 is selected. Deceleration Time 1 and 2 may be selected using the

Multi-Function Inputs M1 - 3. (See Parameters 39, 40 and 41.)

Application Notes:

1. The Accel./Decel. Time is defined as the time required to change the output

frequency from the value of Pr.03 to the value of Pr.08 (Maximum and Minimum

Output Frequencies).

2. The Accel./Decel. time can be calculated by using the parameter values of the

following formula: a = [(Pr.10, 11, 12, 13)(Pr.03 Pr.08)](Pr.03 0 Hz).

3. The actual Accel./Decel. time should be measured to insure it meets the system

requirements.

Pr.14 S-curve

Factory Setting d00 Sec

Units None

Parameter value d00 - d07

This parameter should be programmed during start-up. It is used to provide smooth

acceleration and deceleration. S-curves can be selected from 1 to 7. Settings 1 to 7 are

added to the active accel./decel. times to form an adjustable S-curve.

26

Page 29

VLT® MICRO

Pr.15 Jog Accel. / Decel. Time

(Can be programmed while the drive is running.)

Factory Setting d1.0 Sec

Units 0.1 Sec

Parameter value d0.1 - d600.0 Sec

This parameter, together with the Jog Frequency (Pr.16), determines the time required

for the AC drive to ramp from 0 Hz to the Jog Frequency, or the time required to ramp

from the Jog Frequency to 0 Hz.

Pr.16 Jog Frequency

(Can be programmed while the drive is running.)

Factory Setting d6.00 Hz

Units 0.1 Hz

Parameter value d0.1 - d400.0 Hz

Jog Frequency can be controlled through a Multi-Function Input Terminal: M1 to M5

(See Pr.38 - pr.42). Jog starts from the Minimum Output Frequency (Pr.08) accelerating

to the Jog Frequency (Pr.16) in the time interval set by the Accel./Decel. Time (Pr.15).

Pr.17, Pr.18, Pr.19, Pr.20, Pr.21, Pr.22, Pr.23 – Multi-speed Operation

Multi-Step Speeds 1, 2, 3, 4, 5, 6, 7

(Can be programmed while the drive is running.)

Factory Setting d0.00 Hz

Units 0.1 Hz

Parameter value d0.1 - d400.0 Hz

Multi-step speed Parameters 17 - 23 in conjunction with Parameters 78, 79, 81 - 87

provide multi-step motion control.

Speed

JOG frequency P16

JOG command

ON

OFF

Decel

Time

Pr.15

Accel

Time

Pr.15

Time

27

Page 30

VLT® MICRO

Pr.24 Reverse Run Inhibit

Factory Setting d00

Units None

Settings d00 REV run enabled

d01 REV run disabled

This parameter inhibits AC drive operation in the reverse direction.

Pr.25 Over-voltage Stall Prevention

Factory Setting d01

Units None

Settings d00 Disable over-voltage stall prevention

d01 Enbable over-voltage stall prevention

During deceleration, the DC bus voltage may exceed the maximum amount allowable

due to motor regeneration. When this function is enabled, the AC drive will cease to

decelerate and then maintain a constant output frequency. The drive will only resume

deceleration when the voltage drops below the preset value.

Pr.26, Pr.27 Over-Current Stall Prevention

Pr.26 Over-Current Stall Prevention During Acceleration

Factory Setting d170%

Units 1%

Parameter value d50 - d200%

Over voltage stall prevention

Time

Time

Output

frequency

DC bus

voltage

Over voltage

detection

level

28

Page 31

VLT® MICRO

During periods of rapid acceleration or excessive load, the AC drive output current may

increase abruptly and exceed the value specified by Pr.26. When this function is

enabled, the AC drive will cease to accelerate, then maintain a constant output

frequency. The drive will only resume acceleration when the current drops below the

preset value.

Pr.27 Over-Current Stall Prevention During Operation

Factory Setting d170%

Units 1%

Parameter value d50 - d200%

During steady-state operation with the motor load rapidly increasing, the AC drive output

current may exceed the limit specified in Pr.27. When this occurs, the output frequency

will decrease to maintain a constant motor speed. The drive will accelerate to the

steady-state operating frequency only when the output current drops below the level

specified by Pr.27. A setting of 100% is equal to the rated current of the drive.

Pr.28, Pr.29, Pr.30, Pr.31 – DC Braking Current

Pr.28 DC Braking Current

Factory Setting d00%

Units 1%

Parameter value d00 - d100%

This parameter determines the DC current that will be applied to the motor during

braking when the Motor Stop Method (Pr.02) is programmed to "Ramp Stop". The DC

braking current is set at increments of 1%. A setting of 100% is equal to the rated

current of the drive.

NOTE: When setting this parameter, begin at a lower current level, then increase the

value until sufficient holding torque is achieved. The rated motor current should not be

exceeded.

Output

current

Output

current %

Pr.26

Overcurrent

detection

level

Output

frequency

Time

Time

Stall prevention during acceleration Over-current stall prevention during operation

Time

Time

Output

frequency

Overcurrent

detection

level

Pr.27

29

Page 32

VLT® MICRO

Pr.29 DC Braking Time During Start-up

Factory Setting d0.0 Sec

Units 0.1 Sec

Parameter value d0.0 - d5.0 Sec

This parameter determines the time duration that DC braking current will be applied to

the motor during the AC drive start-up.

Pr.30 DC Braking Time During Stopping

Factory Setting d0.0 Sec

Units 0.1 Sec

Parameter value d0.0 - d25.0 Sec

This parameter determines the time duration that DC braking current will be applied to

the motor when the Motor Stop Method (Pr.02) is set to "Ramp Stop".

Pr.31 DC Braking Start-up Frequency

Factory Setting d0.00 Hz

Units 0.1 Hz

Parameter value d0.0 - d60.0 Hz

This parameter determines the Start-up Frequency for DC braking when the AC drive

starts to decelerate. The frequency may be set in 0.1 Hz increments. When the value is

less than that specified by Pr.08, Minimum Output Frequency, the start-up frequency for

DC braking will be the value specified by this parameter.

Pr.32, Pr.33, Pr.34, Pr.35 – Momentary Power Loss Protection

Pr.32 Momentary Power Loss Operation Mode Selection

Factory Setting d00

Units None

Settings d00 Operation stops after momentary power loss.

d01 Operation continues after momentary power loss. Speed search

starts with the Frequency Reference Value.

Minimum output

frequency

DC brake starting frequency

DC braking current %

Pr.08

Pr.29

Pr.28

Pr.31

Pr.30

30

Page 33

VLT® MICRO

d02 Operation continues after momentary power loss. Speed search

starts with the Minimum Frequency.

NOTE: Fault contact is not energized during restart after a momentary power loss. This

parameter determines the AC drive mode of operation after recovery from a momentary

power loss.

Pr.33 Maximum Allowable Power Loss Time

Factory Setting d2.0 Sec

Units 0.1 Sec

Parameter value d0.3 - d5.0 Sec

During a power failure, if the power loss time is less than the time defined by this

parameter, the AC drive will resume operation. If the Maximum Allowable Power Loss

Time is exceeded, the AC drive output power will be turned off.

Pr.34 Minimum Base Block Time

Factory Setting d0.5 Sec

Units 0.1 Sec

Parameter value d0.3 - d5.0 Sec

When a momentary power loss is detected, the AC drive output turns off for a specified

time interval determined by Pr.34 before resuming operation. This time interval is called

the "Base Block Time". This parameter should be set to a value where the residual

output voltage is nearly zero.

Pr.35 Speed Search Deactivation Current Level

Factory Setting d100%

Units 1%

Parameter value d30 - d200%

Following a power failure, the AC drive will start its speed search operation only if the

output current is greater than the value determined by Pr.35. When the output current is

less than that of Pr.35, the AC drive output frequency is determined to be at a "speed

synchronization" point. The drive will start to accelerate or decelerate back to the

operating frequency at which it was programmed to operate.

INPUT

POWER

OUTPUT

FREQUENCY

OUTPUT

VOLTAGE

Allowable maximum

power loss time

Speed synchronization

detection

OUTPUT

VOLTAGE

OUTPUT

FREQUENCY

INPUT

POWER

Pr.33

Pr.32 = d01

Speed search starts with

the frequency reference value

Pr.34

Min. baseblock

time

Speed

search

operation

Allowable maximum

power loss time

Pr.33

Pr.32 = d0002

Speed search starts with

minimum starting frequency

Pr.34

Min. baseblock

time

31

Page 34

VLT® MICRO

Pr.36, Pr.37 – Reference Frequency: Upper / Lower limit

Pr.36 Reference Frequency Upper Limit

Factory Setting d400.0 Hz

Units 0.1 Hz

Parameter Value d0.1 - d400.0 Hz

This parameter programs the upper limit of the reference frequency in 0.1 Hz

increments.

Pr.37 Reference Frequency Lower Limit

Factory Setting d0.0 Hz

Units 0.1 Hz

Parameter Value d0.1 - d400.0 Hz

Determines the lower limit of the reference frequency in 0.1 Hz increments.

Application Notes:

1. Parameters 36, 37 are provided to prevent damage to the AC motor and applicable

machinery. Under certain conditions a motor can overheat and/or machinery can be

damaged at excessively high speeds.

2. The lower limit for AC drive operation is determined by the greater value of Pr.08

(Minimum Output Frequency) and Pr.37 (Reference Frequency Lower Limit). The

upper limit for AC drive operation is determined by the lesser value of Pr.03

(Maximum Output Frequency and Pr.36 Reference Frequency Upper Limit).

Pr.38 Multi-Function Input Terminals (M0, M1)

Factory Setting d00

Units None

Settings d00 - d02

Pr.39 Multi-Function Input Terminals (M2)

Factory Setting d05

Units None

Settings d03 - d20

Output frequency

Pr.36

Pr.37

Input frequency

32

Page 35

VLT® MICRO

Pr.40 Multi-Function Input Terminals (M3)

Factory Setting d06

Units None

Settings d03 - d20

Pr.41 Multi-Function Input Terminals (M4)

Factory Setting d07

Units None

Settings d03 - d20

Pr.42 Multi-Function Input Terminals (M5)

Factory Setting d08

Units None

Settings d03 - d20

Parameter - Function List:

Value Function Value Function

d00 M0: Fwd./Stop, M1: Rev./Stop d11 1st-2nd Accel./Decel. Time Select

d01 M0: Run/Stop, M1: Fwd./Rev. d12 External Base Block

(Normally Closed)

d02 3-Wire Operation Control Mode d13 External Base Block (Normally Open)

d03 External Fault (Normally Open) d14 Increase Output Frequency Control

d04 External Fault (Normally Closed) d15 Decrease Output Frequency Control

d05 External Reset d16 Run PLC Program

d06 Multi-Step Speed Control 1 d17 Pause PLC Program

d07 Multi-Step Speed Control 2 d18 Counter Trigger

d08 Multi-Step Speed Control 3 d19 Counter Reset

d09 Jog Frequency d20 No Operation

d10 Accel./Decel. Speed Inhibit Control

33

Page 36

VLT® MICRO

Explanation:

1.

d00, d01: Start/Stop/Directional Control – Mode 1 - Two wire control: Parameter value

set to d00 (Pr.38 only).

Mode 2 - Two wire control: Parameter value set to d01 (Pr.38 only).

Mode 3 - Three wire control: Parameter value set to d02 (Pr.38 only).

When value d02 is selected for Pr.38, the program value for Pr.39 will be ignored.

Three Wire Control remains in effect.

2. d03, d04: External Fault – Parameter values d03, d04 programs Multi-Function Input

Terminals: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or (Pr.42) to be External Fault

(E.F.) inputs.

The External Fault input signal has fast priority for display of "E.F." by the Digital

Keypad/Display. All AC drive functions will be stopped and the motor will free-run.

Normal operation can resume after the external fault is cleared and the AC drive is reset.

FWD/STOP

REV/STOP

M0 "Open': Stop; "Close": FWD Run

M1 "Open": Stop; "Close": REV Run

GND

VLT MICRO

M0 "Open': Run; "Close": Stop

M1 "Open": FWD; "Close": REV

GND

VLT MICRO

RUN/STOP

REV/FWD

M0

(Run command, Runs when "Closed")

M2

(Stop command, stops when "Open")

M1

(REV/FWD Run select

VLT MICRO

STOP

RUN

REV/FWD

"Open": FWD Run

"Closed": REV Run)

GND

Mx "Close": Operation available.

Mx "Open": Operation available.

GND

VLT MICRO

Setting by d04

E.F.(N.O)

Setting by d03

E.F (N.C)

34

Page 37

VLT® MICRO

3. d05: External Reset – Parameter value d05 programs a Multi-Function Input

Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) to be External

Reset.

External Reset has the same function as the Reset key on the Digital keypad. External

faults O.H., O.C. and O.V. are cleared when this input is used to reset the drive.

4.

d06, 07, 08: Multi-Step Speed Command – Parameter values d06, d07, d08

programs any three of the following Multi-Function Input Terminals: M1 (Pr.38), M2

(Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) for multi-step speed command function.

These three inputs select the multi-step speeds defined by Parameters 17 - 23 as

shown in the following diagram. Parameters 78 - 87 can also control output speed by

programming the AC drive's internal PLC function.

Mx "Close": Operation available.

GND

VLT MICRO

RESET

Setting by d05

Mx "Closed": Operation available.

Mx "Closed": Operation available.

Mx "Closed": Operation available.

GND

d06 Multi-step 1

d07 Multi-step 2

d08 Multi-step 3

VLT MICRO

P17 STEP 1

P18 STEP 2

P19 STEP 3

P20 STEP 4

P21 STEP 5

P22 STEP 6

P23 STEP 7

Master Freq.

Freq.

Mx 1-GND

Mx 2-GND

Mx 3-GND

Operation Command

ON

ON

ON ON ON

ON ON ON ON

ON ON ON ON

OFF

step 2

step 3

step 4

step 5

step 6

step 7

step 1

Time

35

Page 38

VLT® MICRO

5. d09: Jog Frequency Control – Parameter value d09 programs a Multi-function Input

Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) for Jog control.

Jog operation programmed by d09 can only be initiated with the motor stopped (refer

to Pr.15, Pr.16).

6.

d10: Accel./Decel. Speed Inhibit – Parameter d10 programs a Multi-functional Input

Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41), M5 (Pr.42) for "hold speed"

control. When the command is accepted, acceleration and deceleration is stopped

and the AC drive maintains the motor at a constant speed.

7.

d11: First or Second Accel./Decel. Time Select – Parameter value d11 programs a

Multi-function Input Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5

(Pr.42) to control selection of first or second Accel./Decel. times (refer to Pr.10, Pr.11,

Pr.12, Pr.13).

NOTE: This function is disabled when the drive is performing other functions.

d09 jog operation

Command

Mx "Closed": Operation available.

GND

VLT MICRO

d11 Switch for 1st / 2nd

Accel./Decel.

Mx "Closed": Operation available.

Running with 2nd Accel./Decel.

GND

VLT MICRO

Freq.

Setting Freq,

Mx-GND

Operation

Command

Timing

ON

ON

ON

ON

ON

OFF

Actual operation Freq.

Actual operation Freq.

Setting Freq.

Accel. inhibit

Accel. inhibit

Decel. inhibit

Decel. inhibit

36

Page 39

VLT® MICRO

8. d12, d13: External Base Block – Parameter values d12, d13 program Multi-functional

Input Terminals: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) for

external Base Block control. Value d12 is for normally open (N.O.) input, and value

d13 is for a normally closed input (N.C.).

Application Note:

When the programmed inputs for d12 or d13 are used to activate base block control,

the motor will free run. When base block control is deactivated, the AC drive will start its

speed search function and synchronize with the motor speed then accelerated to

programmed frequency.

INPUT

POWER

OUTPUT

FREQUENCY

OUTPUT

VOLTAGE

Allowable maximum

power loss time

Pr.33

Pr.32 = d0001

Speed search starts with

the frequency reference value

Min. baseblock

time

Speed search

operation

Speed synchronization

detection

Pr.34

B.B. (N.O.)

Setting by d12

B.B. (N.C.)

Setting by d13

Mx "Closed': Operation available.

Mx "Open": Operation available.

GND

VLT MICRO

Operation

Command

Mx-GND

ON

ON

ON

ON

ON

OFF

Setting Value

Freq.

P10 P11 P12 P13 P10 P13

Time

37

Page 40

VLT® MICRO

9. d14, d15: Increase/Decrease Output Frequency Control – Parameter value d14

programs a Multi-function Input Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4

(Pr.41) or M5 (Pr.42) to incrementally increase the AC drive output frequency by one

unit each time the corresponding input is activated. Parameter value d15 programs an

input to decrease the output frequency.

Application Note:

If the Multi-function Input Terminals programmed for Increase/Decrease Output

Frequency Control (d14, d15) are asserted continuously, the output frequency will

increase or decrease unit by unit continuously. If the input is pulsed, the output

frequency will change one unit. This control function is enabled when the drive is

running. The modified frequency is stored in non-volitile memory.

10.

d16, d17: PLC Function Control – Parameter value d16 programs a Multi-function

Input Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr. 41), M5 (Pr.42) to enable the

AC drive internal PLC function. Parameter value d17 programs and input terminal to

pause the PLC program.

Application Note:

Parameter value d16 programs a Multi-function Input Terminal: M1 - M5 to start the

internal PLC program control of the AC drive. Parameters 17 - 23, 78, 79 and 81 to 87

define the PLC program. Parameter value d17 programs an input to pause the PLC

program when the input is shorted to ground. When the input terminal is not closed, the

PLC program runs continuously.

UP (N.O.)

Setting by d14

DOWN (N.C.)

Setting by d15

Mx "Closed": Operation available

Freq. will increase one unit.

GND

Mx "Closed": Operation available

Freq. will increase one unit.

VLT MICRO

Mx "Closed": Operation available.

Auto-Running is available.

Mx "Closed": Operation available.

Auto-Running is available.

GND

AUTO-RUN (N.O.)

Setting by d16

Setting by d17

VLT MICRO

38

Page 41

VLT® MICRO

12.d18: Counter Trigger – Parameter value d18 programs a Multi-function Input

Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) to increment the

AC drive's internal counter. When the input transitions from low to high the counter is

incremented by 1.

Application Note:

The Counter Trigger input can be connected to an external sensor to count a process

step or unit of material used in a process. Refer to the diagram below.

13.

d19: Counter Reset – Parameter value d19 programs a Multi-function Input

Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) to reset the

counter.

Application Note:

The input terminal resets the counter to "00" which can be displayed on the Digital

Keypad/Display.

GND

Mx Counter value add. one unit by

signal "On" to "Off".

Trigger

d18 Counter trigger

signal input.

VLT MICRO

Mx "Closed": Operation available.

Indicated by c00 on display.

GND

Reset Counter

d19 Reset the counter

value.

VLT MICRO

Counter trigger signal

Indication Value

(P64)

Multi-function input terminal

Signal output with (P96 = d05)

Pr.-96 counter (P45/P46)

value is attained.

Signal output with (P97 = d03)

Pr.-97 counter (P45/P46)

value is attained.

2mS

2mS

The trigger timing can not be

less than 2mSec. (<250Hz)

c 02

c 03

c 02

c 01

c 00

c 01c 05c 04

39

Page 42

VLT® MICRO

13.d20: (not used) – Parameter value d20 programs a Multi-function Input

Terminal: M1 (Pr.38), M2 (Pr.39), M3 (Pr.40), M4 (Pr.41) or M5 (Pr.42) to provide no

function.

Application Note:

The purpose of this function is to provide isolation for unused Multi-function Input

Terminals. Any unused terminals should be programmed to d20 to insure they have no

effect on drive operation.

Pr.43 Analog Output to Drive External Meter

Factory Setting d00

Units None

Settings d00 Analog frequency meter (0 to Maximum Frequency, Pr.03)

d01 Analog current meter (0 to 250% of the rated drive output current)

This parameter selects the AC drive output frequency or output current that will be

proportional to the analog meter output signal voltage (DC: 0v - 10v).

Pr.44 Analog Output Gain

(can be programmed while the drive is running)

Factory Setting d100%

Units 1%

Parameter value d01 - d200%

This function regulates voltage level of the AC motor drives analog signal output (either

frequency or current output) at the AFM output terminal, which is then fed to a frequency

or current indication meter.

The analog voltage output is proportional to the AC

drive output frequency. The AC drive's Maximum

Output Frequency (Pr.03) is equivalent to 10 v DC. If

required, adjust the output level using Pr.44, Analog

Output Gain.

The analog voltage output is proportional to the AC

drive output current. 10 v DC of analog is equivalent to

2.5 times the AC drive's Rated Output Current. If

required, adjust the output level using Pr.44, Analog

Output Gain.

GND

Mx Both "Open" or "Closed" without

any operation.

NO FUNCTION

d18 No function

VLT MICRO

AFM

ACM

Analog frequency meter

+

–

Analog current meter

AFM

ACM

+ –

40

Page 43

VLT® MICRO

Pr.45 Multi-function PHC Output Terminal (MO1)

Factory Setting d00

Units None

Settings d00 - d14

Pr.46 Multi-function Output Relay Contact RA-RC (NO), RB-RC (NC)

Factory Setting d07

Units None

Settings d00 - d14

Multi-function Output Program Values

Value Function Value Function

d00 AC drive operational d08 Desired Frequency Attained

d01 Pre-set frequency attained d09 PLC Program Running

d02 Non-zero speed d10 PLC Program Step Completed

d03 Over-torque detection d11 PLC Program Execution Completed

d04 Base Block (B.B.) indicator d12 PLC Program Execution Paused

d05 Low-voltage Detect Indicator d13 Terminal Count Value Reached

d06 AC Drive Control Mode d14 Preliminary Counter Value Reached

d07 Fault Indicator

Explanation:

1.

d00: AC Drive Operational – The Multi-function Output Terminal contacts will be

"closed" when the AC drive is running or the FWD or REV command is executed.

2.

d01: Pre-set Frequency Attained – The Multi-function Output Terminal contacts will

be "closed" when the AC drive reaches the specified operating frequency defined by

Pr.04.

3.

d02: Zero-speed Indicator – The Multi-function Output Terminal contacts will be

"closed" when the AC drive output frequency is less than the minimum output

frequency.

4.

d03: Over-torque Detection Indicator – The Multi-function Output Terminal contacts

will remain "closed" as long as over-torque is detected. Parameter Pr.61 programs

the Over-torque Detection Level. Pr.62 sets for the time limitation for over-torque

before the AC drive output is turned off.

5.

d04: Base Block Indicator – The Multi-function Output Terminal contacts will always

be "closed" as long as the AC drive output is turned off.

6. d05: Low-voltage Detect Indicator – The Multi-function Output Terminal contacts will

be "closed" when the AC drive detects a low-voltage state.

41

Page 44

VLT® MICRO

7. d06: AC Drive Control Mode – The Multi-function Output Terminal contacts will be

"closed" when the AC drive operation is controlled by the external terminals.

8. d07: Fault Indicator – The Multi-function Output Terminal contacts will be

"closed" when a fault is detected.

9.

d08: AC Drive Control Mode – The Multi-function Output Terminal contacts will be

"closed" when the output frequency equals the Desired Frequency attained (Pr.47).

10.

d09: PLC Program Running – The Multi-function Output Terminal contacts will be

"closed" the PLC program is executing.

11.

d10: PLC Program Step Completed – The Multi-function Output Terminal contacts

will be "closed" within 5 seconds when each multi-step speed is attained.

12. d11: PLC Program Completed Execution – The Multi-function Output Terminal

contacts will be "closed" within 5 secs. after the PLC program completes execution.

13.

d12: PLC Program Execution Paused – The Multi-function Output Terminal contacts

will be "closed" when the PLC program execution is paused by a multi-function input

terminal that has been programmed to pause the drive operation.

14.

d13: Terminal Count Reached – The Multi-function Output Terminal contacts will be

"closed" when the counter value is equeal to the value programmed by Pr.96.

15. d14: Preliminary Counter Value Reached – The Multi-function Output Terminal

contacts will be "closed" when the counter value equeals the value of Pr.97.