Page 1

1.1 Description

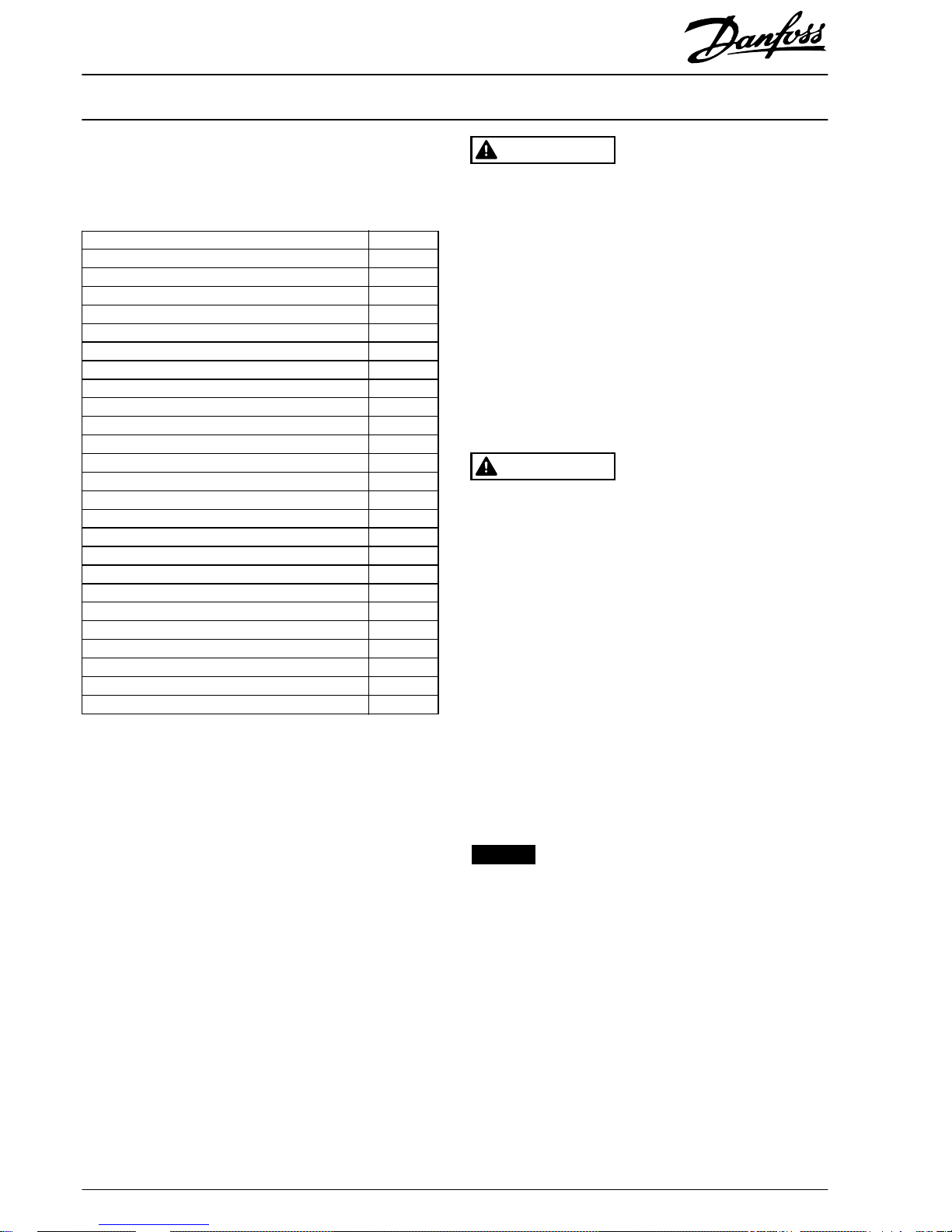

The 300 A current sensor kit contains all components required

to upgrade the current sensor assembly in D1h/D3h/D5h/D6h

drives. The kit is compatible with the power ratings shown in

Tab le 1.1 . To identify the power rating, see

chapter 1.1.1 Identifying the Power Rating.

Product group and series Voltage rating

(V)

Power rating [kW

(hp)]

VLT

®

HVAC Drive FC 102,

VLT

®

Refrigeration Drive FC 103,

VLT

®

AQUA Drive FC 202

(T4) 380–480 110–200

(150–300)

(T7) 525–690 75–315

(75–350)

VLT

®

AutomationDrive FC 302

(T5) 380–500 90–160

(125–200)

(T7) 525–690 55–250

(75–350)

Table 1.1 Applicable Power Range for 300 A Current Sensor Kit

1.1.1 Identifying the Power Rating

To nd the drive power rating, use the following steps:

1. Obtain the following information from the

nameplate, which is on the drive. Refer to

Illustration 1.1.

•

Product group and drive series

(characters 1–6)

•

Power rating (characters 7–10)

•

Voltage rating (phases and mains)

(characters 11–12)

2. Determine if the power rating is in Ta ble 1.1.

1 Product group and drive series

2Power rating

3 Voltage rating (phases and mains)

Illustration 1.1 Example Nameplate

1.1.2 Kit Ordering Number

Kit number Kit description

176F6516 300 A Current Sensor Conversion Kit for

D1h/D3h/D5h/D6h

Table 1.2 Number for 300 A Current Sensor Kit

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

Danfoss A/S © 07/2018 All rights reserved. MI70Y202

Page 2

1.1.3 Items Supplied

Tabl e 1.3 provides a list of items included in the 300 A current

sensor kit. Refer also to Illustration 1.5.

Description Quantity

R/S/T terminal label 1

M10x30 screw 6

M10 nut 6

Mains input terminal block 1

M5x12 screw 11

EMC shield 1

U/V/W terminal label 1

Motor terminal block 1

Power terminal mounting plate (IP21/IP54) 1

Power terminal mounting plate (IP20/Chassis) 1

M8 nut 3

Mixing fan 1

Mixing fan housing 1

Insulator sleeve 1

Motor busbar (U) 1

Motor busbar (V) 1

Motor busbar (W) 1

M5x16 screw 3

M6x90 screw 3

Cylinder busbar 3

Nomex tubes 3

300 A current sensor 3

M4x10 thread-forming screw 6

Wire harness (current sensor cables) 1

M5x11 thread-forming screw 4

Table 1.3 Items Supplied in 300 A Current Sensor Kit

1.2 Safety Information

Only

qualied,

Danfoss-authorized personnel are allowed to

install the parts described in these installation instructions.

Handling of the drive and its parts must be done in

accordance with the corresponding operating guide.

WARNING

ELECTRICAL SHOCK HAZARD

VLT® FC series drives contain dangerous voltages when

connected to mains voltage. Improper installation, and

installing or servicing with power connected, can cause

death, serious injury, or equipment failure.

To avoid death, serious injury, or equipment failure:

•

Only use

qualied

electricians for the installation.

•

Disconnect the drive from all power sources before

installation or service.

•

Treat the drive as live whenever the mains voltage

is connected.

•

Follow the guidelines in these instructions and local

electrical safety codes.

WARNING

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain

charged even when the drive is not powered. High voltage

can be present even when the warning LED indicator lights

are

o.

Failure to wait the

specied

time after power has

been removed before performing service or repair work can

result in death or serious injury.

•

Stop the motor.

•

Disconnect AC mains and remote DC-link power

supplies, including battery back-ups, UPS, and DClink connections to other drives.

•

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

minimum waiting time is 20 minutes.

•

Before performing any service or repair work, use

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

NOTICE

ELECTROSTATIC DISCHARGE

Follow proper ESD precautions to prevent damage to

sensitive components.

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

2

Danfoss A/S © 07/2018 All rights reserved. MI70Y202

Page 3

1.3 Disassembly Instructions

NOTICE

To make the disassembly/reassembly process easier, use

these general guidelines:

1. Follow the disassembly instructions for each

component.

2. Place the component together with the removed

fasteners.

3. Replace old component with the new component

provided in the kit.

4. If any fasteners are stripped or lost, replace with

similar fastener from the kit.

5. Follow the assembly instructions to replace and

secure each component.

1.3.1 General Torque Tightening Values

Use a torque wrench to ensure that correct torque is applied.

Incorrect torque can cause electrical connection problems. For

fastening hardware described in this instruction, use the values

listed in Tab le 1.4 to Tab le 1.6 except where noted in the

procedures.

Shaft

size

Tor x /h ex

drives size

Class A

Nm (in-lb)

Class B

Nm (in-lb)

M4 T20/7 mm 1.2 (10) 0.8 (7)

M5 T25/8 mm 2.3 (20) 1.2 (10)

M6 T30/10 mm 3.9 (35) 2.3 (20)

M8 T40/13 mm 9.6 (85) 3.9 (35)

M10 T50/17 mm 19.1 (169) 9.6 (85)

M12 –/18 mm or

19 mm

37.9 (335) –

Table 1.4 Torque Values Standard Thread

Shaft

size

Tor x d ri ves

size

Class A

Nm (in-lb)

Class B

Nm (in-lb)

M4.8 T25 5.7 (50) 3.1 (27)

M5 T25 1.7 (15) 1.7 (15)

Table 1.5 Torque Values for Thread Cutting into Metal

Shaft

size

Tor x d riv es

size

Class A

Nm (in-lb)

Class B

Nm (in-lb)

M4 T20 2.8 (24) 2.8 (24)

M5 T25 5.1 (45) 4.0 (35)

Table 1.6 Torque Values for Thread Forming into Plastic

Class A: Clamping metal

Class B: Clamping PCA or plastic

1.3.2 Removing AC Input Busbars

1 Nut (10 mm)

2 AC input busbars

3Nuts (13 mm)

Illustration 1.2 AC Input Busbars

To remove the AC input busbars, use the following steps. The

AC input busbars can look

dierent

when the drive includes

extra input options, such as an RFI lter or mains fuses.

Illustration 1.2 shows the AC input busbars with no input

options. Illustration 1.3 shows the AC input busbars with

optional RFI lter and mains fuses.

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

MI70Y202 Danfoss A/S © 07/2018 All rights reserved.

3

Page 4

1. Remove the air bae by removing 4 screws (T25)

and 2 lower screws (T40). If the brake option is

present, there are no lower screws.

2. The next step diers based on the input options

present in the drive. Select the appropriate procedure

for the drive:

•

No options

•

Mains fuses only

•

RFI lter only

•

Mains fuses and RFI lter

1 AC input busbar 6 Power terminal mounting plate

2RFI lter (optional) 7 M8 nut

3 Mains fuse (optional) 8 EMC shield

4 R/S/T terminal label 9 Motor terminal

5 Mains input terminal 10 Mixing fan

Illustration 1.3 AC Input Busbars with RFI Filter and Mains Fuses

1.3.2.1 No Options

1. Remove 3 nuts (13 mm) at the top of the AC input

busbars, 1 per phase.

2. Remove 3 nuts (13 mm) at the bottom of the AC

input busbars, 1 per phase.

3. Remove 1 nut (13 mm) from the center busbar.

4. Remove the busbars from the drive.

1.3.2.2 Mains Fuses Only

1. Remove mains fuses by removing 6 nuts (13 mm), 1

at each end of the 3 fuses.

2. Remove the mains fuses from the drive.

3. Remove 3 nuts (10 mm) at the top of the AC input

busbars, 1 per phase.

4. Remove the AC input busbars.

1.3.2.3 RFI Filter Only

1. Remove 3 nuts (10 mm) at the top of the RFI lter, 1

per phase.

2. Remove 6 nuts (13 mm) at the bottom of the RFI

lter, 2 per phase.

3. Remove 4 mounting screws (T20) connecting the RFI

lter to the side channels of the drive.

4. Remove the RFI lter and unplug the RFI cable from

MK100 on the RFI lter card.

1.3.2.4 Mains Fuses and RFI Filter

1. Remove the mains fuses by removing 6 nuts (13

mm), 1 at each end of the 3 mains fuses.

2. Remove 3 nuts (10 mm) at the top of the RFI lter, 1

per phase.

3. Remove 4 screws (T20) connecting the RFI lter to

the side channels of the drive.

4. Remove the RFI

lter

and unplug the RFI cable from

MK100 on the RFI card.

1.3.3 Removing Mains Input Terminal Block

To remove the mains input terminal block, use the following

steps. Refer to Illustration 1.5.

1. Disconnect any customer input power wiring, and

remove the R/S/T terminal label.

2. Remove 2 screws (T25) at the bottom of the terminal

block.

3. Slide the mains input terminal block down to release

it from the 2 metal retaining clips on the mounting

plate. It can be necessary to remove 1 screw (T25)

from the EMC shield when removing the terminal

block.

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

4

Danfoss A/S © 07/2018 All rights reserved. MI70Y202

Page 5

1.3.4 Removing Brake Terminal Block

(optional)

If the drive includes an optional brake, remove the brake

terminal block using the following steps.

1. Disconnect the brake wiring, if any.

2. To detach the R (+) terminal, remove 1 screw ( T25) at

the terminal block, and 1 extra screw (T40).

3. To detach the R (-) terminal, remove 1 screw (T25) at

the terminal block, and 1 extra nut (13 mm).

4. To detach the brake terminal block, remove 2 nuts

(13 mm) and lift the terminal from the drive.

1.3.5 Removing Motor Terminal Block

To remove the motor terminal block, use the following steps.

Refer to Illustration 1.5.

1. Disconnect wiring to the motor, and remove the

U/V/W terminal label.

2. Remove the EMC shield:

2a Remove 2 screws (T25).

2b Release the current sensor wiring from the

cable guides on the EMC shield.

2c Lift the EMC shield from the drive.

3. Remove the U motor busbar:

3a Remove 1 thread-forming screw (T25) from

the middle of the busbar.

3b Unfasten 1 screw (T30) at the current sensor

end of the busbar.

4. Remove the V motor busbar:

4a Remove 1 thread-forming screw (T25) from

the middle of the busbar.

4b Unfasten 1 screw (T30) at the current sensor

end of the busbar. Note that the V screw is

shorter than the U and W screws.

5. Remove the W motor busbar:

5a Remove 1 thread-forming screw (T25) from

the middle of the busbar.

5b Unfasten 1 screw (T30) at the current sensor

end of the busbar.

6. Remove 2 screws (T25) at the bottom of the motor

terminal block.

7. Remove the motor terminal block by sliding it down

to release it from the 2 metal retaining clips.

8. Remove the 3 cylinder busbars, 1 from the center of

each current sensor and discard the busbars.

1.3.6 Removing Power Terminal Mounting

Plate

To remove the power terminal mounting plate, use the

following steps. Refer to Illustration 1.4.

1. Remove the mixing fan from the slot in the power

terminal mounting plate:

1a Place the end of a screwdriver under each

of the mixing fan release tabs.

1b Lift to free the fan and housing from the

power terminal mounting plate.

1c Unplug the mixing fan in-line cable

connector.

2. Remove 4 thread-cutting screws ( T20), 2 from each

side of the power terminal mounting plate.

3. For IP21/Type 1 and IP54/Type 12 enclosures only,

loosen 3 screws ( T25) at the bottom of the drive.

4. For IP20/Chassis enclosures only, remove 3 nuts

(10 mm) from the bottom edge of the plate.

5. Unplug 3 current sensor cables, 1 from the back of

each current sensor. Unplug the 16-pin connector

from MK101 on the power card. Discard the current

sensor wire harness.

6. Remove the power terminal mounting plate with the

old current sensors attached, and discard it.

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

MI70Y202 Danfoss A/S © 07/2018 All rights reserved.

5

Page 6

1 Current sensor 4 Mixing fan cable

2 Thread-cutting screw (T20) 5 Mixing fan

3 Power terminal mounting plate 6 Mixing fan slot

Illustration 1.4 Power Terminal Mounting Plate

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

6

Danfoss A/S © 07/2018 All rights reserved. MI70Y202

Page 7

1.4 Assembly Guidelines

1 R/S/T terminal label 13 Insulator sleeve

2 M10x30 screw 14 U busbar

3M10 nut 15V busbar

4 Mains input terminal block 16 W busbar

5 M5x12 screw 17 M5x16 screw

6 EMC shield 18 M6x90 screw

7 U/V/W terminal label 19 Cylinder busbar

8 Motor terminal block 20 Nomex tube

9 Power terminal mounting plate (IP21/IP54) 21 Current sensor

10 M8 nut 22 M4x10 thread-forming screw

11 Mixing fan 23 Wire harness (current sensor cables)

12 Mixing fan housing – Power terminal mounting plate, not shown (IP20/Chassis)

Illustration 1.5 Exploded View of 300 A Current Sensor Kit

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

MI70Y202 Danfoss A/S © 07/2018 All rights reserved.

7

Page 8

1.4.1 Installing Current Sensors

NOTICE

MOUNTING PLATE SELECTION

The 300 A current sensor kit includes 2 power terminal

mounting plates, select the correct plate for the enclosure.

Illustration 1.5 shows the plate for IP21/Type 1 and IP54/

Type 12 enclosures. Illustration 1.6 shows the plate for IP20/

Chassis enclosures.

To install the new current sensors on the power terminal

mounting plate, use the following steps. Refer to

Illustration 1.6.

1. Position the outer 2 current sensors at the top of the

power terminal mounting plate with the base against

the plate.

2. Invert the middle current sensor so that the base is

at the top.

3. Align the current sensors so that the cable

connectors face the back of the unit, and the arrows

on the sensors point outward.

4. Attach the 3 current sensors to the power terminal

mounting plate by fastening 6 thread-forming screws

(T20), 2 per sensor. Torque screws to 2.0 Nm

(17.7 in-lb).

5. Connect the wire harness by attaching 3 current

sensor cable connectors to the back of the current

sensors, 1 per current sensor.

6. Attach the 16-pin connector to MK101 on the power

card.

7. Route the current sensor cables through the cable

guides on the power terminal mounting plate.

1 Middle current sensor (inverted position)

2 Outer current sensor (upright position)

3Thread-forming screw (T20)

4 Power terminal mounting plate (IP20/Chassis)

Illustration 1.6 Current Sensor Mounting Position

1.4.2 Installing Power Terminal Mounting

Plate

To install the power terminal mounting plate, use the

following steps. Refer to Illustration 1.5.

1. Position the power terminal mounting plate in the

drive.

2. Fasten 4 thread-cutting screws (T20), 2 screws in

each side of the plate.

3. Attach the mixing fan cable in-line connector.

4. Insert the mixing fan into the fan housing with the

label facing the open side of the housing.

5. With the mixing fan label facing up, snap the mixing

fan assembly into the slot in the power terminal

mounting plate.

6. For IP21/Type 1 and IP54/Type 12 enclosures only,

fasten 3 screws (T25) at the bottom of the drive.

7. For IP20/Chassis enclosures only, fasten 3 M8 nuts.

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

8

Danfoss A/S © 07/2018 All rights reserved. MI70Y202

Page 9

1.4.3 Installing Motor Terminal Block

To install the motor terminal block, use the following steps.

Refer to Illustration 1.5.

1. Position the motor terminal block by sliding it

upward under the 2 metal retaining clips.

2. Fasten 2 screws (T25) at the lower end of the motor

terminal block.

3. Place 3 Nomex tubes in the drive, 1 in the center of

each current sensor. Place the shorter tube (marked

with a red line) through the middle current sensor.

4. Place 3 cylinder busbars in the drive, 1 inside each

Nomex tube. Place the shorter busbar through the

middle Nomex tube.

5. Replace the U motor busbar:

5a Slide the insulator sleeve over the U busbar.

5b Fasten 1 screw (T30) in the current sensor

end of the busbar.

5c Fasten 1 thread-forming screw (T25) in the

middle of the busbar.

6. Replace the V motor busbar:

6a Fasten 1 screw (T30) in the current sensor

end of the busbar. Note that the V bolt is

shorter than the U/W bolts.

6b Fasten 1 thread-forming screw (T25) in the

middle of the busbar.

7. Replace the W motor busbar:

7a Fasten 1 screw (T30) in the current sensor

end of the busbar.

7b Fasten 1 thread-forming screw (T25) in the

middle of the busbar.

8. Position the EMC shield between the mains input

terminal block and motor terminal block and secure

with 2 screws (T25).

9. Reconnect wiring to motor terminals, and replace the

U/V/W terminal label.

1.4.4 Installing Brake Terminal Block (optional)

If the optional brake is present, reinstall the brake terminal

block using the following steps.

1. Position the optional brake terminal block in the

drive.

2. Secure 2 M8 nuts (T40) in the terminal block.

3. Fasten the R (-) terminal using 1 M4x8 thread-forming

screw (T20) at the terminal block, and 1 M8 nut

(T40).

4. Fasten the R (+) terminal using 1 M4x8 threadforming screw (T20) at the terminal block, and 1

screw (T40).

5. Reconnect the brake wiring.

1.4.5 Installing Mains Input Terminal Block

To install the mains input terminal block, use the following

steps. Refer to Illustration 1.5.

1. Place the mains input terminal block in position by

sliding it under the 2 metal retaining clips.

2. Secure 2 screws (T25) at the bottom of the mains

input terminal block.

3. Reconnect any customer input wiring, and replace

the R/S/T terminal label.

1.4.6 Installing AC Input Busbars

To install the AC input busbars, use the following steps. The

AC input busbars can look dierent when the drive includes

extra input options, such as an RFI

lter

or mains fuses.

Illustration 1.2 shows the drive with no input options.

Illustration 1.3

The next procedure diers based on options present in the

drive. Select the appropriate procedure for the drive:

•

No options

•

Mains fuses only

•

RFI lter only

•

Mains fuses and RFI lter

Installation Instructions

300 A Current Sensor Kit for

D1h/D3h/D5h/D6h Drives

VLT

®

FC Series FC 102, FC 103, FC 202, FC 302

MI70Y202 Danfoss A/S © 07/2018 All rights reserved.

9

Page 10

1.4.6.1 No Options

1. Position the 3 AC input busbars in the drive.

2. Fasten 1 nut (13 mm) in the center of the middle

busbar.

3. Secure 6 nuts (13 mm) at the bottom of the AC input

busbars, 1 per phase.

4. Fasten 3 nuts (13 mm) at the top of the AC input

busbars, 1 per phase.

5. Position the air

bae

in the drive, and fasten with 4

screws (T25).

1.4.6.2 Mains Fuses Only

1. Position the AC input busbars in the drive.

2. Fasten 3 nuts (13 mm) at the top of the AC input

busbars, 1 per phase.

3. Position the 3 mains fuses in the drive.

4. Fasten 6 nuts (13 mm), 1 at each end of the 3 fuses.

5. Position the air bae in the drive, and fasten with 4

screws (T25).

1.4.6.3 RFI Filter Only

1. Connect the RFI cable to MK100 on the RFI lter card.

2. Position the RFI lter in the drive.

3. Fasten 4 thread-cutting screws (T20), connecting the

RFI lter to the side channels of the drive.

4. Secure 6 nuts (13 mm) at the bottom of the RFI lter,

2 per phase.

5. Secure 3 nuts (13 mm) at the top of the RFI lter, 1

per phase.

6. Position the air

bae

in the drive, and fasten with 4

screws (T25).

1.4.6.4 Mains Fuses and RFI Filter

1. Connect the RFI cable to MK100 on the RFI card.

2. Position the RFI lter in the drive.

3. Fasten 4 thread-cutting screws ( T20), connecting the

RFI

lter

to the side channels of the drive.

4. Secure 3 nuts (13 mm) at the top of the RFI

lter,

1

per phase.

5. Secure the 3 mains fuses by fastening 6 nuts (13

mm), 1 at each end of the fuses.

6. Position the air

bae

in the drive, and fasten with 4

screws (T25).

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this materi al are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

*MI70Y202*

MI70Y202130R0721 07/2018

Loading...

Loading...