Page 1

ECHO Series

Hand-Held Digital Ultrasonic Corrosion/Precision

Thickness Gage and Flaw Detector

n

Simple to Operate

n

Hand Held

n

Field Upgradeable Options

n

IP67 Rated

n

Corrosion, Precision, and

Flaw Detection Modes

n

Live A-scan

n

Made in the USA

Page 2

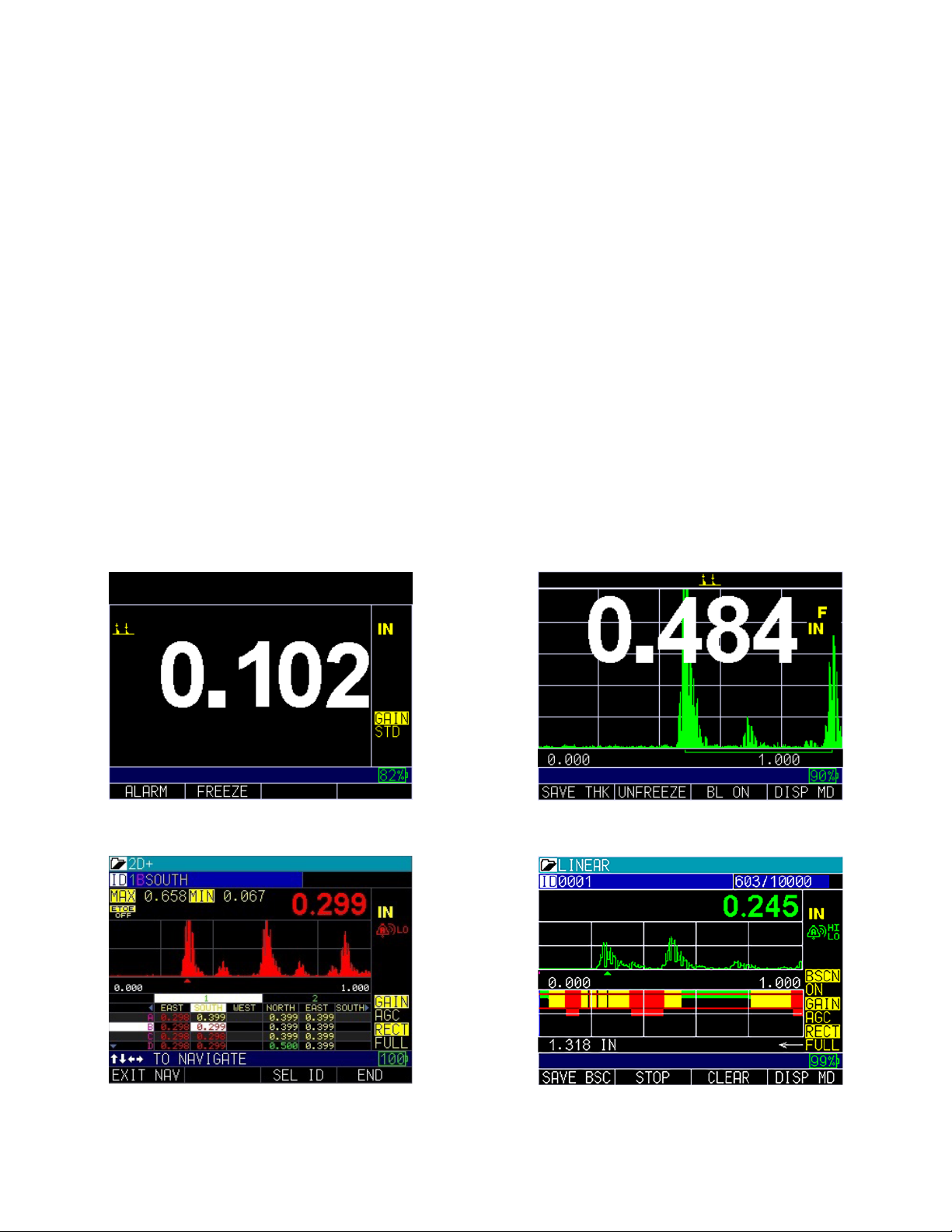

The Ultimate in Portable Ultrasonic Inspection

Our ECHO series represents a breakthrough in portable ultrasonic inspection. The ECHO series can quickly and

easily switch from corrosion or precision thickness gaging, to aw detector all oered in a rugged, custom package.

The perfect size of t and function! Hold the ECHO in your hand and you will agree no detail has been overlooked

and the ergonomics are unmatched by any thickness gage in the industry! The new ECHO series comes in several

congurations. ECHO 9 is our corrosion gage using dual transducers, ECHO 7 is our precision thickness gage with

1 micron resolution using single element transducers and ECHO 8 is the ultimate unit combining corrosion and

precision thickness gage utilizing both dual and single element transducers. ECHO FD is our aw detector.

ECHO series was designed specically as a platform to

allow the instrument total exibility. What this means is

you are never stuck with just a basic model, but rath-

er, an instrument that can expand with you as your

business and applications expand. The ECHO series is

available in many congurations as listed in the models

chart. An inspection company may be required to do

every day thickness surveys requiring a live waveform

and datalogger and also need to perform AWS weld

inspection work; the model for you would be the ECHO

9FD allowing you to quickly and easily switch from

corrosion to aw mode in seconds. We also address

a wide variety of features and budgets to meet your

every need. The platform allows for quick updating of

software directly from the keypad so unlocking the unlimited potential of the ECHO platform is simply a few

keystrokes away.

The ECHO series has a remarkable sunlight readable

3.5” color display, up to 32 GB of micro SD memory,

built-in rechargeable high capacity Li Ion battery all

packaged in a custom case designed for IP67 rating.

ECHO Series can measure from 0.020” to 23” in steel in

corrosion mode or as thin as 0.006” in steel when con-

gured as a precision thickness gage.

2

ECHO SERIES

Page 3

ECHO Thickness Gage Series Standard Features

• Compatible with a wide variety of Danatronics and

common competitors dual and single element transducers

• Change color and VIBRATE on alarm (ideal for inspections in loud environments)

• 27 hour battery life with hi-capacity re-chargeable

battery pack via the USB port

• Wide thickness range (0.006” to 23” depending on

gage type, material and transducer)

• Inches, mm or µSec

• Multiple languages

• Velocity mode

• Fast Min/Max mode to display actual thickness and

minimum and maximum at the same time

• Gain, range, rectication, blank adjustments with live

waveform

• Datalogger 2 GB micro SD card standard expandable

to 32 GB

• Datalogger interfaces with Microsoft Excel™

• Designed for IP67

• Simple one hand operation

• Field upgradeable software options

• Made in the USA

ECHO Series Standard Inclusions

Includes transducer (DKS537, dual 5.0 Mhz, 0.375” with

potted 3 foot cable for corrosion gages; for precision

gages, a probe up to 10 Mhz with a lemo to microdot

cable are included), 2 GB micro SD card, Li-ion battery,

battery charger, transport case, manual with data XL,

USB cable, echo-to-echo to ignore coatings. Our most

advanced models include custom rubber boot.

ECHO Series Software Options

Software options are all eld upgradeable with many

advantages:

• Options are activated via the keypad…no need to plug

into a computer

• Only takes less than one minute

• No shipping cost

• No downtime

• Never worry about buying an obsolete unit

• Less initial outlay of capital

Datalogger/B-scan

Internally store millions of thickness readings with ID

location and send readings to Micorsoft Excel via our

Data XL interface program. Interfaces with Ultrapipe.

Oxide Scale

Simultaneously displays the wall thickness of the boiler

tube thickness as well as the internal oxide scale at

their independent velocities. Knowing the thickness of

the boiler tube can greatly improve the eciency and

extended life of the tube.

Live Waveform

Displays the live A-scan for echo verication and real

time control of range, gain, rectication and blanks.

Corrosion Mode

Uses dual transducers to measure remaining wall

thickness on primarily steel structures subject to

corrosion.

Angle Beam Software

Available on ECHO 8 and ECHO 9, displays trig functions of detected echo for angular distance, surface and

depth.

NOTE: When used as a thickness gage it is not meant to be a code

compliant ultrasonic aw detector due to vertical linearity and

display update rate. See ECHO FD for more details.

Precision Mode

Allows for the use of single element transducers along

with up to 2,700 stored application setups with 1

micron resolution (0.0001” or 0.001mm).

Flaw Detection Mode

Code compliant ultrasonic aw detector with fast, 60

Hz. Display update rate, 2 independent gates, AWS and

DAC software standard.

Floating and Tracking gates

For use as a aw detector; this features allows the gate

to oat vertically from -1 to -18 dB for consistent edge

depth thickness readings. Also includes tracking gate to

allow for echo to echo thickness measurements.

Bluetooth

Allows ECHO to export data such as a thickness reading

or le to another device via Bluetooth (Requires exter-

nal software to properly communicate).

www.danatronics.com

3

Page 4

ECHO 9 Corrosion Thickness Gage

Our ECHO 9 is our premier corrosion thickness gage

with a wide thickness range, able to be used with a variety of dual transducers as well as a selection of single

element and angle beam probes. Similar to our preci-

sion thickness gages, ECHO 9 can save and store 2,700

custom setups.

Typical Applications

• Boiler tubes

• Pressure vessels

• Storage tanks

• Ship hulls

• Pipes

• Steel beams on bridges

Standard Features

• Compatible with a wide variety of Danatronics dual

and single element transducers

• Wide thickness range (.020” to 23” depending on gage

type, material and transducer)

• Coating Thickness and substrate thickness displayed

simultaneously on gage with live waveform using

standard dual transducers

• High temperature probes available up to 950F/509C

(intermittent use)

• Temperature correction

• File compare features shows old readings along with

new readings for datalogger versions (real-time corrosion monitor)

• Available angle beam option

• Gridview

• Password lock

• Supervisor and other locks

• 2,700 stored setups

• Change color and vibrate on alarm

ECHO 9 – Base model includes Echo to Echo

ECHO 9DL – Includes Datalogger, B-scan, Temperature

Correction. Gridview A-scan shown above.

4

ECHO 9W – Includes Waveform, Coating Thickness,

Temperature Correction

ECHO 9DLW – Includes Waveform, Datalogger, B-scan,

Coating Thickness, Temperature Correction, Rubber

Boot

ECHO SERIES

Page 5

ECHO 7 Precision Thickness Gage

ECHO 7 precision hand-held ultrasonic thickness gages

are designed for use with single element contact, delay

line and immersion transducers to provide a wide thickness range and up to 1 micron resolution. ECHO 7 can

save up to 2,700 custom applications setups allowing

the operator to quickly and easily switch transducers

and setups on the y for unique and separate tasks.

Standard Features

• 0.006-23” range in steel

• 1 micron resolution (0.0001” or 0.001 mm)

• Single element, contact, delay line and immersion

transducers (1-30 MHz)

• Store and recall up to 2,700 setups

• Multiple modes for challenging applications

• 30 Mhz bandwidth

• Square wave Pulser

• Zoom Auto Tracking

• Auto Phase Reversal Detection with alarm

• Supervisor and other locks

Typical Applications

• Castings

• Turbine blades and wax molds

• Plastic parts including bottles, pipes,

trays and toys

• Coil steel and automotive body panels

• Fiberglass and gel coatings

• Velocity verication for ductile and

gray iron (Velocimeter)

• Aluminum, glass, ceramics, zinc, and

more

2,700 stored custom application setups.

www.danatronics.com

5

Page 6

ECHO 8 Corrosion and Precision Thickness Gage

ECHO 8 represents our most capable ultrasonic

thickness gage combining both corrosion and precision

thickness into one small instrument. Quickly switch

transducers and “gage type” to essentially nondestructively measure any engineered material. The

ECHO series can keep track of up to 2,700 stored

setups, so switching from materials with dierent

thicknesses and alarm values is simple.

Typical Applications

• Inspection Companies—all-purpose gage for measuring any engineered material thickness

• Airplane Inspection (thin aluminum, plastic

windows, and rubber tires)

• Marine Surveyors (berglass & steel)

Standard Features

• Includes all features from the ECHO 7 and ECHO 9

• Switch from dual to single element transducers

• Switch resolution from .01” to .001” to .0001”

• Store and recall up to 2,700 applications setups

• Rechargeable batteries good for more than 24 hr.

• ECHO 8DLW includes custom rubber boot with stand

ECHO series in split screen A and B-Scan with optional

EZ-Scan 6 magnetic wheel encoder

6

ECHO SERIES

Page 7

ECHO FD Flaw Detector

ECHO FD is the ideal

instrument for portable

applications such as rope

access, storage tanks and

bridges. ECHO FD oers the

most ergonomically balanced unit on the market

today allowing for easy left

or right hand use with just

one thumb to access all

keys. Even operating the

unit in complete darkness

is simple. We are also the

only manufacturer to oer

changing of color while

vibration on alarm for operation in loud environments.

The ECHO, when in aw detection mode, is an everyday

instrument capable of performing a wide varietyof ultrasonic tests. You will be amazed at the many included

standard features such as 2 independent gates, fast-60

Hz. display update rate, DAC, AWS, B-scan, Grid View and

2 GB of micro SD card memory as well as internal memory are all standard. Best of all, ECHO FD is designed and

made in the USA so full factory support is only a call or

click away.

ECHO FD oers a wide variety of unique and easy to

use software features such as Grid View, Peak Pitch

Memory, supervisor lock, oating and tracking gate, leg

indicator, auto 80 FSH, triple DAC, 13 hour battery life,*

AWS software, Reference Gain, echo to echo and Grid

View to view A-scan and grid simultaneously.

Standard Features

• Peak Pitch Memory – changes the audible chirp when a

probe’s peak signal is determined

• Supervisor lock – allows the ability to lock parameters

witha password to prevent accidental changes

• Floating and tracking gates – see software options

• Custom color pallet – allows changes to text, grid,

background and more for easy viewing

• Auto 80, automatically places signal within the gate to

80 Full Screen Height (FSH)

• Triple DAC, allow the simple creation and storage of

single, triple and Japanese (JIS) DAC curves

• Continuous 13 hour battery life under factory default

settings

• AWS software, displays the D-rating along with A and C

values in the 3 measurement boxes

• Reference gain…includes dB step to quickly add or

subtract scanning gain such as 2 or 6 dB

• Echo to echo, ideal for measuring painted parts

Additional Options

Floating gate: allows for 60 Hz. update rate while

maintaining consistent thickness readings while oating

the gate. This feature also includes tracking gate for

echo to echo thickness readings as well as V-path

correction for a variety of dual transducers.

Bluetooth: allows Bluetooth interface with Bluetooth

devices set up to interface with ECHO.

Grid view

Leg indicator

www.danatronics.com

ASME DAC-3

AWS D-rating

*Battery life is 13 hours in aw detection mode due to 60 Hz update rate.

7

Page 8

Environmentally Tough, Ergonomically Superior!

Environmentally Tough!

The ECHO series was designed from the ground up. With more than 85 combined years

in designing, manufacturing and using hand held ultrasonic thickness gages, Danatronics

left no detail uncovered. From its new case designed for IP67, to its easy to read sunlight

readable 3.5” color display, you will nd the ECHO series combines practical features with a

simple, clean design built for years of eld service and durability.

Ergonomically Superior!

With its new 3.5” sunlight readable display, The ECHO

series oers many display formats to suit any age opera-

tor and reduce fatigue. So whether you want to view the

largest possible numbers or would prefer more text on

screen, ECHO has you covered.

ECHO is also perfectly balanced and makes holding it in

one hand possible and simple, all keys can be reached

you’re your thumb…no clumsy joy sticks or second

functions needed. There is even a world’s rst vibrate on alarm to inform the operator any

pre-set thickness threshold has been tripped which is great for tired operators and testing

in loud environments.

Hardware Options

• Rubber boot with built-in nger strap and bail (stand)

• Chest harness for rope access

• Magnetic wheel encoder

• Footswitch

• Remote power bank

Chest harness for rope access Magnetic pipe standHeavy duty bail

Data XL and Data XL PRO

At Danatronics we believe managing your saved data

should be simple. As such, we include with every

thickness gage a free interface program we call

Data XL. Data XL saves readings to .csv les that can be

used in any spreadsheet program such as Microsoft

Excel or Google Sheets.

Here are some advantages:

• Write custom batch programs

• Simple double click the le to be transfer and Microsoft

Excel™ with all i.d.’s and readings are displayed

• Magnetic pipe stand

• Heavy duty bail with variable angle adjustment and

anti-slip base

• RS-232

• Bluetooth

• Create le and send them to the ECHO

• Merge les using Data XL

• Saved stored application setups can be sent to the

ECHO or multiple ECHO units to ensure reliability and

repeatability

• Update rmware (latest version of operating software

is available on the support tab of www.danatronics.

com)

• Send Bit Maps (screen shots) to further document your

inspections

Ultrapipe Interface Echo interfaces with Ultrapipe and PSAIM software from Siemens.

8

ECHO SERIES

Page 9

Danatronics Transducers

The ECHO series comes loaded with a default list of

probes to solve a vast variety of applications for any

non-destructive testing wall thickness of most engineering materials.

So, if you are measuring, boiler tubes, pressure vessels,

ship hulls, bridges, coil steel, aluminum, plastic bottles,

toys, trays and anything in between…we have the probe

for you.

Dual Transducers

Standard Dual Transducers

ECHO

Model

8, 9 DK-250 0.100”-20” (2.5mm-508mm) 0.200”-2” (5.08mm-50.8mm) 2.25 MHz 0.500”/12.7mm 32-392F/0-200C Right Angle Potted - Lemo 00

8, 9 DK-525 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.250”/6.35mm 32-392F/0-200C Right Angle Potted - Lemo 00

8, 9 DK-537 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.375”/9.52mm 32-130F/0-54C Right Angle Potted - Lemo 00

8, 9 DKS-537 0.040”-20” (1mm-508mm)

8, 9 DK-550 0.040”-20” (0.76mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.500”/12.7mm 32-392F/0-200C Right Angle Potted - Lemo 00

8, 9 DK-718 0.030”-2” (0.76mm-50.8mm) 0.060”-1” (1.52mm-25.4mm) 7.5 MHz 0.187”/4.75mm 32-130F/0-54C Right Angle Potted - Lemo 00

8, 9 DK-718 LPM* 0.050”-2” (1.25mm-50.8mm) N/A 7.5 MHz 0.187”/4.75mm 32-392F/0-200C Right Angle Potted - Lemo 00

8, 9 DK-1025 0.030”-2” (0.76mm-50.8mm) N/A 10.0 MHz 0.250”/6.35mm 32-392F/0-200C Right Angle Potted - Lemo 00

*LPM = Low Prole Mini; probe height 16mm, top dia. 12mm **In Echo to Echo Mode recommended to use gage with live waveform (A-scan)

Composite Dual Transducers

ECHO

Model

8, 9 DC-110 0.200”-20” (5.08mm-508mm) N/A 1.0 MHz 1”/25.4mm 10-160F/–12-70C Right Angle Potted - Lemo 00

8, 9 DC-175 0.150”-20” (3.81mm-508mm) N/A 1.0 MHz 0.750”/19.05mm 10-160F/–12-70C Right Angle Potted - Lemo 00

8, 9 DC-250 0.100”-20” (2.5mm-508mm) 0.200”-2” (5.08mm-50.8mm) 2.25 MHz 0.500”/12.7mm 10-160F/–12-70C Right Angle Potted - Lemo 00

8, 9 DC-525 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.250”/6.35mm 10-160F/–12-70C Right Angle Potted - Lemo 00

8, 9 DC-537 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.375”/9.52mm 10-160F/–12-70C Right Angle Potted - Lemo 00

8, 9 DC-550 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm 5.0 MHz 0.500”/12.7mm 10-160F/–12-70C Right Angle Potted - Lemo 00

Part

No. Range in Steel

Part

No. Range in Steel

Echo to Echo Range**

in Steel Freq. Diameter

0.100”-0.750”

(2.54mm-19.05mm)

Echo to Echo Range

in Steel Freq. Diameter

5.0 MHz 0.375”/9.52mm 32-130F/0-38C Right Angle Potted - Lemo 00

Temperature

Range Connector Type

Temperature

Range Connector Type

Dual Echo To Echo Transducers

ECHO

Model

8, 9 DK-537EE 0.040”-20” (1mm-508mm) 0.080”-1.5” (2mm-38.1mm) 5.0 MHz 0.375”/9.52mm 32-130F/0-54C Right Angle Potted - Lemo 00

8, 9 DK-718EE 0.030”-1.5” (0.76mm-38.1mm) 0.060”-1.0” (1.5mm-25.4mm) 7.5 MHz 0.187”/4.75mm 32-130F/0-54C Right Angle Potted - Lemo 00

Part

No. Range in Steel

Echo to Echo Range

in Steel Freq. Diameter

Temperature

Range Connector Type

Dual High Temp Transducers

ECHO

Model

8, 9 DHT-537 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.375”/9.52mm

8, 9 DHT-537RM 0.040”-20” (1mm-508mm) 0.080”-2” (2mm-50.8mm) 5.0 MHz 0.375”/9.52mm

Part

No. Range in Steel

Echo to Echo Range

in Steel Freq. Diameter

Temperature

Range Connector Type

–5 to 950F

–20 to 509C

–5 to 950F

–20 to 509C

Straight Microdot

requires detachable cable

Right Angle Microdot

requires detachable cable

Quick Change Composite Element Angle Beam Transducers

Available in: Diameter: 1/4”, 3/8” & 1/2”; Frequencies: 1.0, 2.25, 3.5, 5.0, 7.5 & 10.0 MHz; Standard Wedges: 30°, 45°, 60°, 70°

www.danatronics.com

9

Page 10

Danatronics Transducers

Standard Contact

ECHO

Model

7, 8 DCK-250

7, 8 DCK-525

7, 8 DCK-537

7, 8 DCK-550

7, 8 DCK-718

7, 8 DCK-1025

7, 8

7, 8 DCK-20125

Part

No.

DCK-

1025HR

(2.54mm -508mm)

(0.76mm - 254mm)

(0.76mm - 50.8mm)

(0.76mm - 25.4mm)

Contact Composite

ECHO

Model

7, 8 DCC-110

7, 8 DCC-175

7, 8 DCC-250

7, 8 DCC-537

Part

No.

(7.62mm - 508mm)

(7.62mm - 508mm)

Range in Steel

Class 1

0.100”-20”

0.040”-20”

(1mm-508mm)

0.040”-20”

(1mm-508mm)

0.080”-20”

(2mm - 508mm)

0.030”-10”

0.030”-2”

0.030”-1”

0.025”-0.75”

(0.4mm - 25.4mm)

Range in Steel

Class 1

0.300”-20”

0.300”-20”

0.100”-20”

(2.54 - 508mm)

0.040”-20”

(1mm-508mm)

Contact Transducers

Range in Steel

Class 2

n/a n/a n/a 2.25 MHz

n/a n/a n/a 5.0 MHz

n/a n/a n/a 5.0 MHz

n/a n/a n/a 5.0 MHz

n/a n/a n/a 7.5 MHz

n/a n/a n/a 10.0 MHz

n/a n/a n/a 10.0 MHz

n/a n/a n/a 20.0 MHz

Range in Steel

Class 2

n/a n/a n/a 1.0 MHz

n/a n/a n/a 1.0 MHz

n/a n/a n/a 2.25.0 MHz

n/a n/a n/a 5.0 MHz

Range in Steel

Class 3

Range in Steel

Class 3

Range in

Plastic Freq. Diameter

Range in

Plastic Freq. Diameter

0.500”

12.7mm

0.250”

6.35mm

0.375”

9.52mm

0.500”

12.7mm

0.187”

4.75mm

0.25”

6.35mm

0.25”

6.35mm

0.125”

3.175mm

1”

25.4mm

0.750”

19.05mm

0.500”

12.7mm

0.375”

9.52mm

Temperature

Range

32-392F

0-200C

32-392F

0-200C

32-392F

0-200C

32-392F

0-200C

32-392F

0-200C

32-392F

0-200C

32-392F

0-200C

32-392F

0-200C

Temperature

Range

10-160F

–12-70C

10-160F

–12-70C

10-160F

–12-70C

10-160F

–12-70C

Connector

Type*

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Connector

Type*

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Delay Line Standard

ECHO

Model

7, 8, 9

7, 8, 9

7, 8, 9

7, 8, 9

7, 8

7, 8

Part

No.

DLK-525

DLK-1025

DLK-

1525PP-SM

DLK-

1525PP-RM

DLK-2025

DLK-20125

Range in Steel

Corrosion Mode

0.080”-0.750”

(2mm-19mm)

0.080”-0.750”

(2mm-19mm)

0.080”-0.300”

(2mm-7.62mm)

0.080”-0.300”

(2mm-7.62mm)

n/a

n/a

Delay Line Composite

ECHO

Model

7, 8

Part

No.

DLC-525

Range in Steel

Class 1

n/a

Delay Line Transducers

Range in Steel

Class 2

0.025-0.500”

(6.35mm - 12.7mm)

0.020”-0.500”

(0.5mm - 12.7mm)

0.020”-0.200”

(0.5mm - 5.08mm)

0.020”-0.200”

(0.5mm - 5.08mm)

0.015”-0.300”

(3.81mm - 7.62mm)

0.015”-0.200”

(3.81mm - 7.62mm)

Range in Steel

Class 2

0.040”-0.500”

(1mm - 12.7mm)

Range in Steel

Class 3

0.020”-0.375”

(0.5mm - 9.5mm)

0.015”-0.375”

(0.38mm - 9.5mm)

0.015”-0.125”

(0.38mm - 5.08mm)

0.015”-.125”

(0.38mm - 5.08mm)

0.006”-0.200”

(0.152mm- 7.62mm)

0.006”-0.200”

(0.152mm- 7.62mm)

Range in Steel

Class 3

0.030”-0.375”

(0.762mm-9.5mm)

Echo to Echo

Range in Steel

0.025” – 0.400”

(0.635mm-10.16mm)

0.025” – 0.400”

(0.635mm-10.16mm)

0.020” – 0.200”

(0.508mm-5.08mm)

0.020” – 0.200”

(0.508mm-5.08mm)

n/a

n/a

Range in

Plastic Freq. Diameter

0.020”-0.200”

(0.5mm - 5.08mm)

Range in

Plastic Freq. Diameter

0.010”- 0.150”

(0.254mm -3.81mm)

0.010”-0 .150”

(0.254mm -3.81mm)

0.015”-0.060”

(0.15mm - 1.52mm)

0.015”-0.060”

(0.15mm - 1.52mm)

0.003”-0.100”

(0.076mm - 2.54mm)

0.003”-0.100”

(0.076mm - 2.54mm)

5.0 MHz

MHz

10.0

MHz

15.0

MHz

15.0

MHz

20 MHz

20 MHz

0.375”

9.52mm

5.0

0.25”

6.35mm

0.25”

6.35mm

0.080”

2mm (tip dia)

0.080”

2mm (tip dia)

0.25”

6.35mm

0.125”

3.175mm

Temperature

Range

32-122F

0-50C

Temperature

Range

32-122F

0-50C

32-122F

0-50C

32-122F

0-50C

32-122F

0-50C

32-122F

0-50C

32-122F

0-50C

Connector

Right Angle

Microdot

Connector

Type*

Right Angle

Microdot

Right Angle

Microdot

Straight

Microdot

Right Angle

Microdot

Right Angle

Microdot

Right Angle

Microdot

Type*

10

*Right Angle Microdot – requires additional cable

ECHO SERIES

Page 11

Specications

GENERAL

Size: Length 7.25” x Width 4.00” x Height 2.00” (184mm x

101.6mm x 50.8mm)

Weight: 1.15 lbs (.52 kg) with internal Li-Ion battery, 1.0 lb.

(.45 kg) with optional Alkaline tray including 3 AA batteries

Temperature (Gage Operating): -4 to 122F (-20 to 50C)

Package: Designed for IP67 rating, custom, splash-proof, high

impact plastic with illuminating rubber keypad for go/no-go

testing

Transducer Connector Type: Lemo 00 (2 qty)

Bandwidth: 0.5-30 Mhz (-3dB) Measurement Rate: 4 Hz or

25 Hz. Pulser: 150V, Square Wave

Range: Thickness range depends on gage type, probe selec-

tion and material conditions. Typical range in corrosion mode,

0.020-23” (0.076 - 584 mm). Typical range in precision mode,

0.006-23” (0.152 -584 mm) in steel, as low as 0.003” (0.076 mm)

in plastic

Calibration: Cal zero, Cal velocity, Two-point calibration or

Auto Calibration performs a two-point calibration using a

5-step test block

Material Velocity Range: 0.0200 in/usec-0.7362 in/ µS (0.508-

18.699 mm/ µS)

Languages: English, French, German, Spanish, Italian, Russian,

Czech, Finnish, Chinese, Japanese, Hungarian

Batteries: Standard 3.7 V Li Ion internally rechargeable

battery (11-27 hours; Standard mode of 4Hz and 74%

brightness: 27 hour continuous operation, Fast mode at 25Hz,

continuous measurements in echo to echo mode: 11 hours;

aw detection mode: 13 hours) or optional alkaline tray for

3 AA batteries (3 hours)

Shut O: selectable auto shut o 1-31 min. or never shut o

Transport case: Hard Plastic with high density molded foam

cut out for gage and most accessories

Certications: CE certied, RHOS compliant, designed for

IP67, NIST traceable calibration certicate included with gage

Standard Inclusions: ECHO series ultrasonic thickness gage,

a transducer (ECHO 9 – DKS-537, ECHO 7,8 – choice of trans-

transducer up to 10mhz), transducer cable, 2oz bottle of

couplant, operation manual, Data XL interface program, USB

cable, Charger Adapter, Transport Case. A transducer is included with each model. Contact Danatronics for details based on

exact inclusion per model.

Warranty: Limited 2 year warranty under normal use on parts

and labor for gage. Optional Dan-A-Care to add up to 3 more

years

DISPLAY

Display: 3.5” high resolution color TFT display, 320 x 240 pixels

(1/4 VGA), sunlight readable, including multiple color pallets

Backlight: Light Emitting Diode (LED) backlight. Includes vari-

able light intensity.

DATALOGGER

Memory: Internal memory for stored setups standard on all

models. For Datalogger models 2 GB micro SD card standard

and expandable up to 32 GB

Stored Application Setups: Storage and recall of 2,700 cali-

bration and set up les

Data XL: Interface program to send and receive stored read-

ings, latest rmware and application set up les as two way

communication from ECHO to computer (Excel). Saved readings are .csv les and directly interfaces with Microsoft Excel.™

USB: USB 2.0

www.danatronics.com

MEASUREMENTS

Gain: Low, Standard, High, and Automatic Gain Control (AGC).

20-94 dB in 1 dB increments for gages with waveform.

Zoom: Automatically centers echos in the center of the display

independent of material thickness

Units: English, Metric, Microseconds

Fast Min/Max: Displays minimum and maximum simultane-

ously with actual thickness at 25 Hz.

Alarms: Gage beeps and display changes color based on

alarm condition

Vibrate: Gage can be set to vibrate on alarm (ideal for loud

environments)

Transducers: Single, dual, delay lines, immersion, contact,

angle beam (depends on gage type)

ECHO 9 Measurement Types: ECHO 9 corrosion gage: Main

bang to rst backwall echo, echo to echo and velocity mode

(displays acoustic sound speed based on entered thickness)

ECHO 7 & 8 Measurement Types: A precision gage: Class 1,

Main bang to rst back wall echo, Class 2, Interface echo to

rst backwall and Class 3, echo to echo after interface echo…

Class 2 and 3 use high frequency single element delay lines

or immersion probes, velocity mode (displays acoustic sound

speed based on entered thickness)

Freeze Mode: Direct access to freeze display (ideal for high

temperature applications)

Hold Mode: Holds display to retain last thickness reading

Dierential Mode: Displays the dierence from actual

thickness measurement in absolute or percentage of a user

entered reference value

Resolution: 0.001” or 0.010” (0.01mm or 0.1mm) as corrosion

gage and 0.0001” or 0.001” (0.001mm or .01mm) as a precision

gage

Flaw Detector Specications

60 Hz. Update rate, 2 independent gates, A and B-scan, data-

logger with 2 GB micro SD card, interface to Excel via Data XL,

13 Hour battery life, AWS and DAC software included along

with rubber boot with stand.

ECHO-MBH: Magnetic ball head/pipe stand for ECHO series

(attaches to 1/4x20 standard connection point on the back of

the unit)

ECHO RB: Rubber boot available with padded wrist strap, 4

point chest harness, chest harness, built in bail (stand) with

locking position and nger strap for easy one hand operation.

ECHO RB is included with ECHO 7,8 or 9 as DLW models

ECHO-ABP: Alkaline Battery Pack (3- AA) for ECHO series.

Battery life 3 hours

ECHO-RPP: Remote Power Pack plugs into USB port to pro-

vide power/recharge to ECHO series

ECHO-HDB: Heavy Duty bail with variable angle adjustment

and anti-slip base

HARDWARE/SOFTWARE

Hardware Options: EZ Scan B-Scan encoder, Bluetooth, foot

switch, RS232

Field Upgradeable Software Options: Datalogger with

B-scan, Live waveform, Precision mode, Corrosion mode, Oxide scale, Angle Beam

Data XL Pro Software: allows sending of A and B-scan images

to computer for advanced reporting

11

Page 12

ECHO 9

Corrosion Gage

Item

Scan Mode

Datalogger

Memory

Flaw Detector

Corrosion

Thickness

Gage

Precision

Thickness

Gage

Disply Update

DAC

AWS

Floating and

Tracking

Gates

Auto 80

Peak Pitch

Memory

Echo to Echo

Range

Recitication

Live

Waveform

(A-scan)

B-scan

(Non-encoded)

B-scan

(Encoded)

Temperature

Correction

Coating

Thickness

Oxide Scale

Auto Phase

Reversal with

Alarm

O = Software Options that are eld upgradeable. Encoded B-scan requires additional hardware modications.

Specication

4 or 25 Hz. displays actual and min or max

at same time

Internal and micro sd card based

datalogger with linear, 2D, 3D boiler and

some with custom points (interfaces with

Excel)

Internanal memory, 2 GB standard,

expandable to 32 GB micro sd card

Ultrasonic aw detector: 60 Hz, update

rate, 2 gates, aws code, dac, datalogger,

manual B-scan

Ultrasonic corrosion gage using primarily

dual probes, A and B-scan, echo to echo,

datalogger

Ultrasonic precision gage (1 micron

resolution) using single element probes, A

and B-scan, echo to echo, datalogger

Fast 60 Hz update rate

Distance Amplitude Correction (DAC),

ASME, ASME 3, JIS and Custom

Ameican Welding Socity (AWS) code for D

rating

Floats gate at -1 to -18dB for cosistent,

60 Hz update rate edge depth thickness

readings, includes tracking gate for echo

to echo readings

Automatically adjusts echo to 80 Full

Screen Height (FSH) for gate 1

Variable Chirp of gate 1 signal in peak hold

for peaking signlas as an audible indicator

Measures the metal thickness only

(ignores paint and coatings)

Adjustment of manual range control

or auto zoom tracking to center echos

independent of selected range

RF, Half Wave Positive, Half Wave Negative

and Full Wave Rectication

Full Adjustments, for gain in 1dB step or

AGC, main bang blank, blank after rst

received echo, range including zoom auto

tracking to center echos independent of

material rectication

Displays a cross section of the test piece

Displays a cross section of the test piece

using the EZ Scan magnetic wheel linear

access encoder

Corrects thickness value for sound speed

dierence at elevated temperatures

Displays coating and substrate thicknesses

simultaneously

Simultaneously displays the thickness of

the oxide layer and boiler tube thickness

Automatically can alarm on a phase

change in RF mode

9 9W 9 DL 9 DLW 7 7W 7 DL 7 DLW 8 8W 8 DL 8 DLW FD 9FD 7FD 8FD

O O

O O O O O O O O O O O O

O O O O

O O O O O O O O O O O O

O O O O O O O O O O O O

O O O O O O O O O O O O

O O O O O O O O O O O O O O O O

O O O O O O O O O O O O

O O O O O O O O O O O O

O

O

O O

O O O O O O O O O O O O O O O O

O

O

O O O O O O O O O O O O O O O O

O O O O O

O

O

ECHO 7

Precision Gage

O O

O O O O

O

O

O O

O

O

O

O

O

ECHO 8

Corrosion & Precision Gage

O O

O

O

O O

O

O

O

ECHO FD

Flaw Detector

/ / / /

O

O O

N/A N/A N/A N/A

O

O

O O O O

O O O O

O

O O

O O

O

Danatronics Corporation, 150A Andover St., Suite 8C, Danvers, MA 01923

Tel: 978-777-0081 • Fax: 978-777-3798 • www.danatronics.com

Copyright 2018 by Danatronics • Specications subject to change without notice.

Loading...

Loading...