Encoders

Series AI25 Profibus Interface

• Up to 14 Bit single-turn resolution

• 4096 revolutions of multi-turn resolution

• Short installation depth

• Safety through self-diagnostics

• Solid shaft and hollow shaft versions

• -40

°

C to +85°C Operating temperature

Dynapar™ brand

APPLICATION/INDUSTRY

The Dynapar brand ACURO Absolute Encoder

offers a modern full-feature design equipped

with Profibus interface.

DESCRIPTION

The

Acuro AI25

encoder is available in a single-turn or multiturn version. The multi-turn design is based on

a reliable high-speed gear with optical scanning

and the latest generation of OptoASIC

technology.

The mechanical concept is based on a double

ball bearing design, which is available as a

solid-shaft or hollow-shaft version in common

shaft diameters.

optical absolute industrial

FEATURES AND BENEFITS

• Compact design to save valuable space

• Low power consumption

• Fast delivery of any model variant

• Additional field-bus and point-to-point

interfaces available

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Single-turn Resolution: 10, 12, 13, 14 Bit

Multi-turn Resolution: 12 bit

Linearity: +/- 1/2 LSB

Absolute Accuracy: ± 0.01° mechanical (36 arc-

sec.)

Repeatability: ± 0.002° mechanical (7.2 arc-

sec.)

Code format: Binary

ELECTRICAL

Connection: Bus Cover with spring terminal

clamps

Supply voltage: 10-30 VDC

Intrinsic current consumption: 200 mA (ST),

220 mA (MT)

Baud Rate: 12 Mbaud

Interface: Profibus-DP, Encoder Profile

Programmable: According to Class 2

Special Functions: Speed, Acceleration

MECHANICAL

Shaft diameter:

Shaft: 6 mm (Servo Mount), 10 mm (Clamping

Mount), 3/8" (Square Flange Mount)

Hubshaft: 10mm, 12 mm, 3/8", 1/2"

Maximum shaft load:

6 mm shaft: 13 lb axial, 24 lb radial

10 mm shaft: 24 lb axial, 35 lb radial

Maximum shaft speed: 10,000 RPM (continuous), 12,000 RPM (peak)

Starting torque: < 1.4 in-oz

Weight (approx.): 350 g ST, 400 g MT

Shaft tolerance (hubshaft only): +/- 1.5 mm

axial, +/- 0.2 mm radial

Flange configurations: Square, Clamp, Servo,

Hubshaft with flexible tether

Bearing life:

10

1 x 10

revolutions at 35% full rated shaft load

9

1 x 10

revolutions at 75% full rated shaft load

8

1 x 10

revolutions at 100% full rated shaft load

ENVIRONMENTAL

Operating Temperature: -40 to 85° C

Storage Temperature: -40 to 100° C

Enclosure Rating: IP64 or IP67

Shock: 1,000 m/s

Vibration: 100 m/s

2

(6 ms)

2

(10 to 2,000 Hz)

Code 1: Model Code 2: Bits Code 3 :Mounting Code 4: Shaft Size Code 5: Protocol Code 6: Electrical Code 7: Connector

AI25

w/o shaft seal (IP64)

0 6 mm

1 3/8"

2 10 mm

3 3/8" Hub Shaft

4 12 mm Hubshaft

5 1/2" Hubshaft

6 10 mm Hub Shaft

w/ shaft seal (IP67)

A 6 mm

B 3/8"

C 10 mm

6 Profibus

2 10-30 VDC

E Bus Cover

G Bus Cover

H Bus Cover Double

A

C

U

R

O

06

4.

A

B

S

O

L

U

T

E

AI25

Size25

Acuro

Absolute

Encoder

Single-Turn

0010 10 Bit

0012 12 Bit

0013 13 Bit

0014 14 Bit

Multi-Turn

1212 12 Bit Multi-

Turn, 12 Bit

Single-Turn

1213 12 Bit Multi-

Turn, 13 Bit

Single-Turn

1214 12 Bit Multi-

Turn, 14 Bit

Single-Turn

Available when

Code 4 is 0 or A

0 Servo*

Available when

Code 4 is 2 or C

1 Clamping*

Available when

Code 4 is 1 or B

2 Square

flange**

Available when

Code 4 is 3, 4,

5 or 6

3 Hubshaft

w/tether†

* 58mm Dia.

** 2.5" Square

† 63mm BC

3 Strain Relief Exits.

Internal T-coupler

included

2 Strain Relief Exits

and 1 M12, 5-Pole

Connector (for Tico

display). Internal

T-coupler included

Conin. Internal

T-coupler included

85.3mm

3.36in

Mounting

Surface

Length (L)

58.5mm

2.3in

Ø42 ±0.1mm

1.65±0.004in

Encoders

Series AI25 Profibus Interface

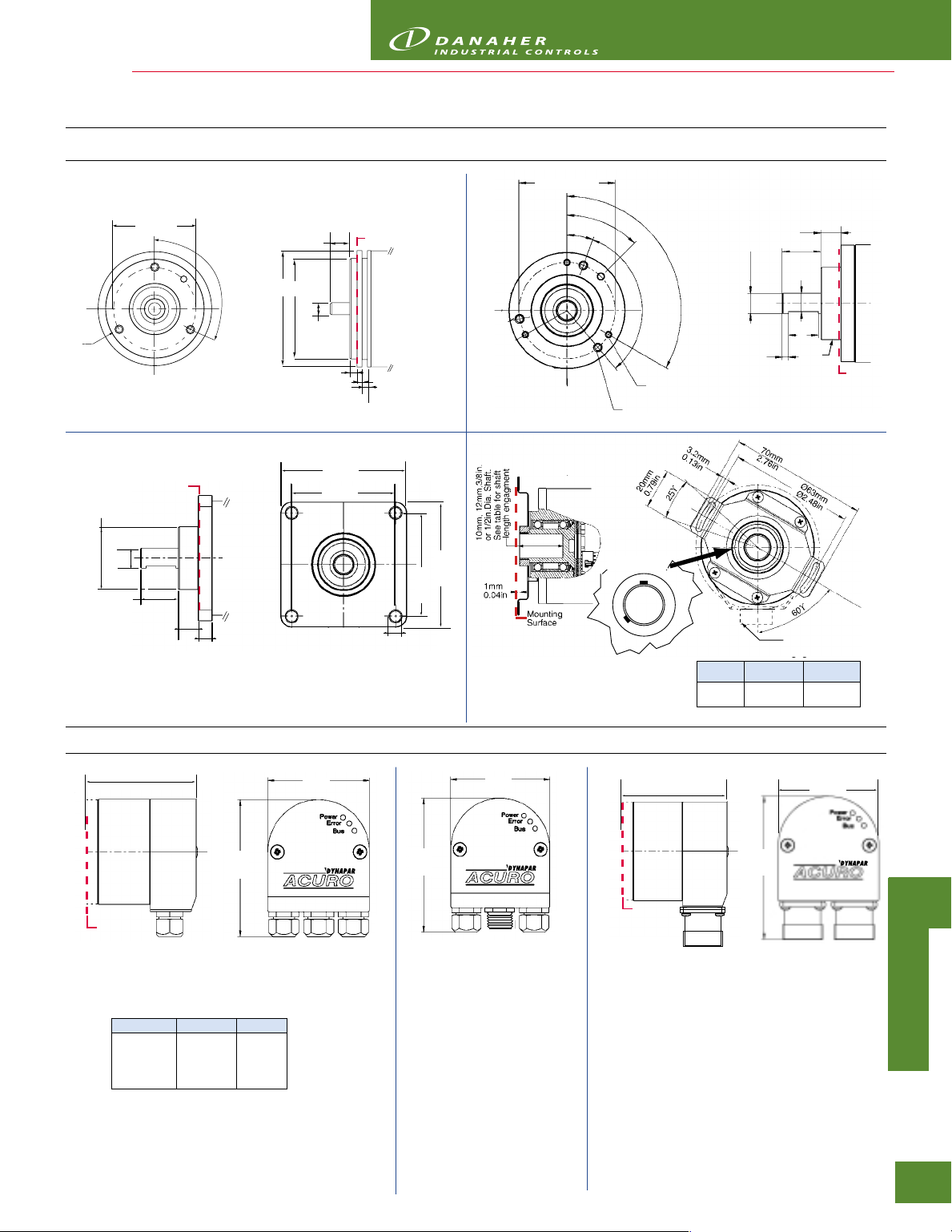

Code 3: Mounting

Ø48 ±0.1mm

Ø1.89 ±0.004in

45

°

20

10mm

58mm

2.28in

50mm

1.97in

0.39in

120°

Mounting

Surface

°

120°

12

0°

10mm

Diameter

10mm

0.39in

19.27mm

0.76in

9mm

0.35in

M4x5

0

Servo

Ø31.75mm

1.25in

3/8in Dia. Shaft

19.5mm ±0.3

0.77in ±0.01

2

Square Flange

Length (L)

Mounting

Surface

10mm

0.39in

7mm

0.28in

6mm

58.5mm

2.3in

4mm

0.16in

3mm

0.12in

63.5mm

2.5in

52.4mm

2.06in

3mm

0.12in

63.5mm

2.5in

52.4mm

2.06in

Ø5.6mm

0.22in

Code 7: Connector

1

Clamping

3

Hubshaft w/Tether

58.5mm

2.3in

M3x5

M4x5

Note: two M3 set screws in

colar around hub shaft

(will not mar shaft)

15mm

0.59in

3mm

0.12in

Ø36mm

Ø1.42in

Radial Connector

Area (if used). See

Connection Diag.

Hubshaft Shaft Engagement

HubShaft Min. Shaft Max. Shaft

Diameter Length Length

10mm, 3/8" 15mm (0.59") 20mm (0.79")

12mm, 1/2" 18mm (0.71") 20mm (0.79")

Mounting

Surface

Mounting

Surface

3 Strain Relief Exits

Length (L) Mounting Surface to Rear

For connector types E, G, H & L

76.5mm

3.01in

E

Mount (Code 3) Single-Turn Multi-Turn

(0) Servo 63.3/2.49 72.3/2.85

(1) Clamping 62.3/2.45 71.3/2.81

(2) Square Flng 64.8/2.55 73.8/2.91

(3) Hubshaft 72.2/2.84 81.2/3.2

76.5mm

3.01in

G

2 Strain Relief Exits

1 M12, 5-pole Connector*

*M12, 5-pole Connector used

to interface Hengstler Tico 731

LCD display

H

Double Conin

A

A

C

B

U

S

R

O

O

L

U

T

E

4.

07

Loading...

Loading...