Page 1

Series

pe15

Disc"

Pane/coders

..

• Provides digital control inputs

from

• Bld"scUonalsquarewave

signal outputs

operator.'s panel

Series

pe15

Panelcoders directly convert an

operator's

signals.

microprocessors and

no AID conversion required.

conversion and input de-bounce circuitry

associated with potentiometers and other types

of

wiring inter-connects.

non-contacting, there are no wipers or contacts

to wear

Paneleaders are designed for use as panelmounted operator-interface devices where

extended service. high

linearity are required. They deliver a digilgj

signal

operated at higher speeds without

output integrity.

Panelcoders give the operator a simple

·'analog-feel." while

outputs and greater flexibility.

Panelcoders are designed specifically for

applications where a higher

encoder is required (up

standard configuration corresponds to a typical

1.5'

can be made with

connector or

also available

torque (drag) option for operator

higher vibration applications.

manual rotary inputs into digital

These signals can be used by

controls helps reduce memory overhead and

or

create electrical noise.

virtually free of distortion. and

panel-mounted potentiometer. Termination

electronic counters with

Eliminating AID

Since Panelcoders are

resolution and precise

can

~

dimini~l100

giving designers digital

resolution panel

to

256 PPR). The

user's choice of a mating

soldered wires. Paneleoders are

With

a higher manual starting

preference

or

Typical Applications

• Industrial machine controls

• Electronic

• Medical electroniCS

•

CAD/CAM/CAE equipment

• Speed controls

•

Cursor controls

•

Time. temperature. level or frequency

controls

test equiplT'i<nt

• Continuous

and

reversible

rotation

SPECIFICATIONS Electrical Connections

Electrical

Code:

Incremental; quadrature

10.40.60.100.120.

PPR:

250.256

factory.)

Symmetry:

Edge

Pha

..

rotation

Paneicoder

Output

compatible

i..ogic'1":

LogiC

I~l"&j~

.;.5

+5

Termination:

centers

Mating

equivalent

Mtchlnlcal

Weight:

Shaft

Shaft:

Shaft

RPM 0 10% duty cycle

Shaft

Torque: 2 ±1

oz-in without brake

Ofac Mat

Housing

Operating

Storage

Mounting:

Max. torque to .mounting nut 300 oz-in

(Other counts available; consult

180° ±36°

SeptlmJon: 45° electrical. min.

Sen

..

: Signal A leads Signal B for

as

viewed from the shaft end of the

Signal:

Squarewave. CMOSITTL

:3

VoltA

'0": 0.5 Volts max

PO\W'.V

Aequfrcmontll:

VCC

i:5% &

VDe

drain option

Connector:

75

±5% II 25

Card edge, contacts on 0.156"

• Enylronmental

3.0 oz. max.

Rotation:

1/4" dia. (flat standard)

Speed: 100 RPM max. continuous: 300

Loading:

Continuous and reversible

Manually operated, 1 lb. max.

oz-in with brake; less than 0.5

.....

I:

Etched metal

MaterI.I: Polycarbonate

Temperature:

Temperature:

318-32

127. 180.200.

miN

.•

3

rnA

.•

16 mA sink

rnA

max. standard:

rnA

max. for low current

CINCH 5O-6A-20

00

to +55°C

-400

to +65°C

mounting nut supplied:

source

or

CW

Function

Common 1

No

Connection

Sianal B 3

No Connection' 4

Signal A

5V Power

'LocatlOn

lor mating

~.

~

Terminal

2

5

6

mecn.noc:af

701733,

Rev. A

11/20/90

DANAHII

CON11lOI.I

• Gurnee.

IL

• 708-662-2688

Page 2

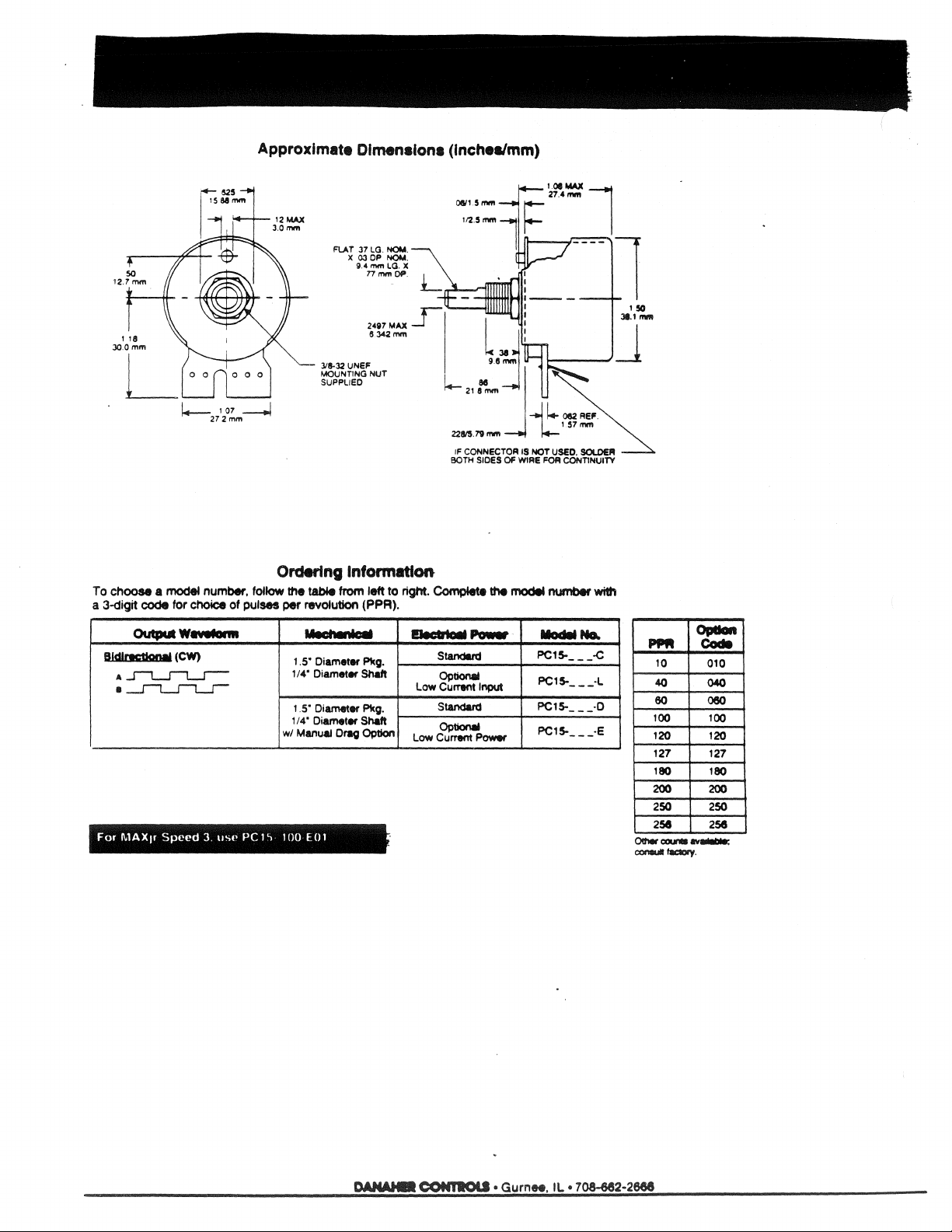

Approxlmat. Dlmenalona (Inch.almm)

F\.A T 31

LG.

NOM.

X

030P

NOM.

9.4mmLG.

nmmOP.

318-32

UNEF

MOUNnNGNUT

SUPPLIED

!.--

107

-..I

272mm

Ordering Information

To

choose.

a 3-digit code for choice of pulses per revolution (PPR).

Bldlrw:tIonII

A~

.~

For

Output

MAX"

model

nUmber.

W...,...,.

(ew)

Speed

3

follow the table from left to right. Complete the model

uSP

PC1',

11.'

11.'

wI

l()O

........

1

.5'

1

.5'

Man,*

Diam.,er

Diameter

Diameter

Diameter

EOI

111

..

Plcg.

Shaft

Plcg.

Shaft

Drag OptIon

X

IIectrIoII

SI8r1dItd

0ptI0n8I

l.ow Current

Standard

0ptI0n8I

Low

Current

,.,....

,~

Power

nurnCer

IIodII No.

PC15-

___

PCI5-

___

PCI5-

___

PCI5-

___

with

.c

·l.

·D

·E

31.1

150

.....

....

0pII0ft

10

.a

eo

100

120

127

180

200

250

251

eo.

010

040

oeo

100

120

127

180

200

250

251

DANAI.

CONnlOI.I. Gurn

...

IL.

708-682-2_

Loading...

Loading...