Page 1

EncodersEncoders

Series M21 Modular

• Modular, Incremental Encoder for Stepper and Small Servo Motor Feedback

• Phased Array Sensor Technology Provides High Temperature and Operating

Frequency and Allows 0.020" (0.5 mm) of Axial Play

• Resolutions to 2048 PPR with Index Standard; Optional 4, 6, 8 or 12 Pole

Commutation Tracks for Brushless Servo Motors

• Easy Installation and Removal without Special Tools or Parts

Dynapar™ brand

APPLICATION/INDUSTRY

The Dynapar brand M21 modular encoder

M

provides high-performance, cost effective

O

feedback for stepper and servo motor controls.

T

O

DESCRIPTION

R

Using industry standard package

dimensions, the M21 is easily installed

M

onto the motor without time-consuming

O

adjustments or special tools. Its unique

U

mechanical design automatically centers

N

and gaps the disc during installation.

T

For Brushless DC (BLDC) servo control,

optional 3 phase commutation tracks

replace the traditional Hall Effect sensors.

These optically-generated signals provide

higher accuracy and reliability, improving

the performance and reliability of the

servo system.

FEATURES AND BENEFITS

• The M21 design operates up to 120°C.

The high temperature plastics, phased

array sensor, and low current requirements stabilize the output signals over a

wide range of input voltage, ambient

temperature, or output frequencies.

• The M21 provides 30 degrees of

adjustment to align the signal outputs to

the shaft position. Using an industry

standard Size 21 modular mounting

pattern, the index mark on the disc hub

can be coarse aligned to the index

sensor position on the housing. The

housing rotates to allow further

adjustment of the index or fine alignment

of the commutation channels to the

BLDC motor windings.

• The M21 enclosure is dirt-tight, rated

NEMA 1 / IP50. The cover is gasketed to

seal the disc and optics from contamination. Additionally, the base can be

sealed to the motor for further

environmental protection.

• The M21 outputs are protected from

short circuits, and operate on 5 or 12

VDC power.

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Code: Incremental

Resolution: (pulses/revolution)

Incremental: 500 to 2048 PPR

Commutation: 4, 6, 8 or 12 pole

Accuracy:

Incremental: ±5 arc-mins. max. edge to edge;

Commutation: ±6 arc-mins. max.

Sense: (viewing encoder mounting surface)

Incremental: A leads B by 90° for CCW rotation

of motor shaft;

Commutation: U leads V, V leads W by 120° for

CW rotation of motor shaft

Phasing:

Incremental: 90° ±18°

Commutation: 8 Pole: 30°; 6 Pole: 40°;

60° mechanical

Index to U Channel: ±1°

center to U channel edge

Symmetry:

Incremental: 180° ±18°

Commutation: 8 Pole: 45°;

6 Pole: 60°; 4 Pole: 90°

Index Pulse Width: 180° ±36°

with B low) standard

ELECTRICAL

Input Power Requirements:

Incremental: 5 or 12 VDC ±10% at 100 mA max.

(excluding output load);

Commutation: 5 or 12 VDC ±10% at 75 mA max.

(excluding output load)

Output Signals:

7272 Line Driver: 40 mA sink/source max.;

Open Collector w/2.0 kΩ pull-ups: 16 mA sink

max.

Frequency Response: 200 kHz min.

Termination:

Connector: PCB mounted dual row head with

0.1" x 0.1" pin spacing, 10 pins (incremental

only), 16 pins (w/commutation); Cable:

conductors - 28 AWG, stranded (7/36),

insulation - black, PVC; Shield: aluminum/

polyester foil plus tinned, copper drain wire (28

AWG, 7/36)

Noise Immunity: Conforms to EN50082-1 Light

Industrial for Electro-Static Discharge, Radio

Frequency Interference, Electrical Fast

Transients, Conducted Interference, and

Magnetic Fields (for models or applications with

shielded cable)

electrical

mechanical - Index

electrical

mechanical

electrical (Gated

4 Pole:

MECHANICAL

Weight:

Connector: 1 oz. (28 gm) typ.

Connector w/cover: 1.5 oz. (43 gm) typ.

Cable: 2.5 oz (71 gm) typ.

Cable w/cover: 3 oz. (85 gm) typ.

Dimensions:

Outside Diameter: 2.1" (53 mm) max. w/cover,

2.0" (51 mm) max. without cover; Height: 0.8"

(20.3 mm) max. (w/cover, excluding connector);

Emitter to Detector Gap: 0.070" (1.8 mm) min.

Material:

Base, Housing, & Cover: high temperature, glass

filled polymer;

Hub: Aluminum; Disk: 0.030" thick glass

Finish:

Base & Housing: black;

Cover: RAL 7010 (dark grey)

Moment of Inertia: 6.64 x 10

2

gm-cm

)

Hub Diameters: 1/4", 3/8", 7/16", 1/2", 6 mm, 8

mm, 10 mm, 12 mm nominal

Hub Dia. Tolerance: +0.001"/-0.000" (+0.026

mm/-0.000 mm)

Mating Shaft Length: 0.45" (12 mm) min. blind

hub clamp screw, 0.65" (16.5 mm) exposed hub

clamp screw; 0.75" (19 mm) max. inside cover

Mating Shaft Runout: 0.002" (0.05 mm) max.

(Includes shaft perpendicularity to mounting

surface)

Mating Shaft Endplay: +0.005"/-0.015" (+0.13

mm/-0.38 mm) nominal ("+" indicates away from

mounting face)

Mounting:

Base: (2) #4-40 (M2.5) #1 Phillips fillister head

cap screw on 1.812" (46 mm) B.C., 0.01" (0.254

mm) true position to shaft; Shaft: split hub w/

collar clamp, #2-56 hex socket cap screw (5/64"

hex wrench included)

Electrical/Mechanical Alignment Range: ±15°

mechanical

Acceleration: 100,000 rad/sec.

Velocity: 12,000 RPM max.

-5

in-oz sec.2 (4.7

2

max.

ENVIRONMENTAL

Operating Temperature: -40° to 120°C

Storage Temperature: -40° to 85°C

Shock: 50 G’s for 11 msec duration

Vibration: 2.5 G's at 5 to 2000 Hz

Relative Humidity: 90% non-condensing

Enclosure Rating: NEMA 1 / IP50 dirt-tight (for

models with cover)

2.

64

Page 2

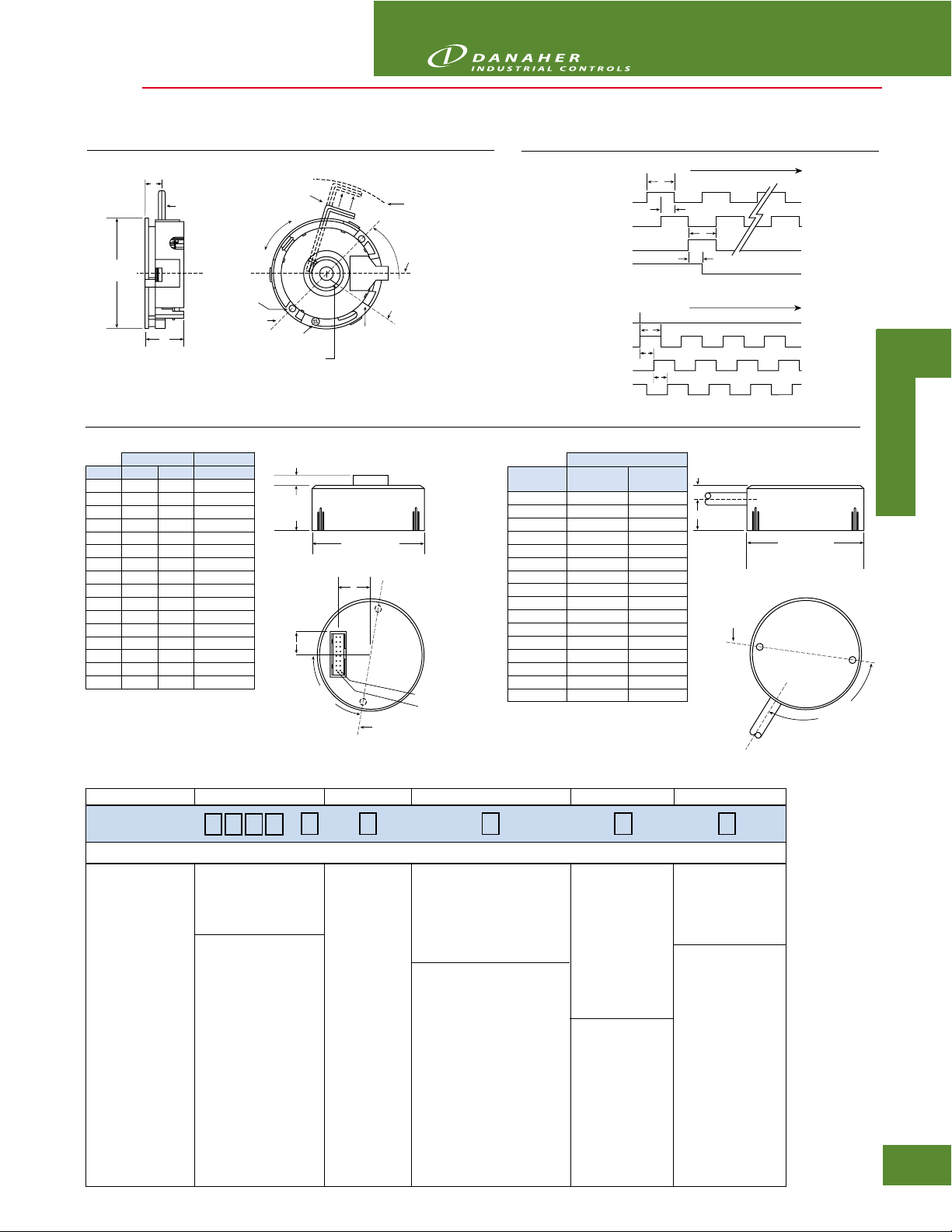

Dimensions/Installation

0.24" TYP.

(6.1 mm)

2.10" DIA.

53 mm

0.56" TYP.

(14.2 mm)

(MOUNTING

HOLE AXIS)

115° NOM.

(±15° ADJ.)

FOR BLIND HUB

CLAMP SCREW:

0.30"

(7.65 mm)

2.0" DIA.

(51 mm)

0.70" TYP.

(17.85 mm)

5/64"

HEX KEY

CCW SHAFT

ROTATION

2 x 0.125" DIA.

(3.2 mm) on

1.812" DIA. B.C.

(46 mm)

(MOUNTING

HOLE AXIS)

5/64"

HEX KEY

CW SHAFT

ROTATION

#1 PHILLIPS

ALIGNMENT SCREW

INDEX MARK ON HUB

Installation Instructions: Drawing #200567-0001

Alignment Instructions: Drawing #200567-0002

10 Pin

A

Vcc

GND

—

—

—

—

B

—

Z

—

—

—

—

—

—

L.D.

—

Vcc

GND

—

A'

A

B'

B

Z'

Z

—

—

—

—

—

—

Vcc com

Vcc Inc

GND Inc

GND com

Pin O.C.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

————

Mating Cable Assembly:

16 Pin

A'

A

B'

B

Z'

Z

U'

U

V'

V

W'

W

0.18" TYP.

(4.6 mm)

0.80" TYP.

(20.3 mm)

0.60"

(15.24 mm)

(10 & 16 PIN)

16 PIN: 0.55"

(13.97 mm)

10 PIN: 0.40"

(10.16 mm)

80° NOM.

(±15° ADJ.)

10 pin, 109524-000x

16 pin, 109523-000x

x= length in feet

To order, complete the model number with code numbers from the table below:

Code 1: Model

Code 2: PPR, Poles

Series M21 Modular

Output Waveforms (For clarity, compliments are not shown.)

4.3"

(120 mm)

RADIUS

INDEX

SENSOR

POSITION

80° OFFSET BETWEEN

MOUNTING HOLE AXIS AND

ACTIVE INDEX OUTPUT

(CENTERED IN ADJUSTMENT

RANGE)

(FOR BLIND HUB CLAMP SCREW:

ALIGN INDEX MARK ON

HUB WITH VERTICAL EDGE ON

HOUSING TO PROPERLY

ORIENT HUB CLAMP SCREW

TO HEX KEY ACCESS HOLE

THRU SIDE OF HOUSING)

Code 6: Terminations (Not all signals present on all models)

Function Incr. Only

Vcc com

Vcc Inc

GND Inc

2.10" DIA.

(53 mm)

GND com

A'

A

B'

B

Z'

Z

U'

U

V'

V

W'

W

(MOUNTING

HOLE AXIS)

PIN #1

PIN #2

Ordering Information

Code 3: Cover

Code 4: Electrical

CH. A

CH. B

CH. Z

CH. U

CH. Z

CH. U

CH. V

CH. W

Wire Color

—

RED

BLK

—

RED/BLK

GRN

WHT/BLK

ORN

BLU

WHT

—

—

—

—

—

—

Code 5: Hub

180°

±1°

m

180°

120°

120°

A-H: Shielded Cable0: Pin Header 1-8: Ribbon Cable

Incr. &

Comm.

RED/WHT

RED

BLK

BLK/WHT

BLU/BLK

BLU

GRN/BLK

GRN

VIO/BLK

VIO

BRN/BLK

BRN

GRY/BLK

GRY

WHT/BLK

WHT

CCW SHAFT ROTATION

e

180°

90°

e

e

CW SHAFT ROTATION

e

e

e

Code 6: Termination

EncodersEncoders

M

O

T

O

R

M

O

U

N

T

M21

M21 Size 20

Commutating

Modular

/

Incremental channels only

0500/0

0512/0

1000/0

Incremental plus

Commutation channels

0500/†

1000/†

1024/†

† Available with 4, 6, 8

or 12* pole

designated by character "C")

Examples: 1024/8 is

1024PPR, 8 pole;

2000/C is 2000PPR,

12 pole

1024/0

2000/0

2048/0

2000/†

2048/†

(12 pole is

0 No cover

1 Enclosed,

end-of-shaft

mount

2 Through

shaft

Ordering Information

0 5V in, open collector out

incremental only

1 12V in, open collector out

incremental only

3 5V in, line driver out

incremental only

Available when Code 2 is XXXX/4,

XXXX/6, XXXX/8, XXXX/C

6 5V in, line driver out incr.; 5V

in, open collector out comm.

7 5V in, line driver out incr.; 12V

in, open collector out comm.

9 5V in, line driver out incr.; 5V

in, line driver out comm.

Blind hub clamp screw:

0 1/4 in.

1 3/8 in.

2 7/16 in.

3 1/2 in.

4 6 mm

5 8 mm

6 10 mm

7 12 mm

Exposed hub clamp

screw:

A 1/4 in.

B 3/8 in.

C 7/16 in.

D 1/2 in.

E 6 mm

F 8 mm

G 10 mm

H 12 mm

0 Pin Header

1-8 Mating ribbon

cable included;

1=1 ft., 2=2 ft.,

etc.

Available when Code 4 is

3 or higher:

A-H Shielded cable;

A=1 ft., B=2 ft.,

etc.

2.

65

Loading...

Loading...