Page 1

HEAVY DUTY

SERIES HS85

Hollow Shaft Encoder

Key Features

• Hollowshaft Design Mounts Easily to Large

Motor Shafts, up to 4.5” in Diameter

• Magneto-Resistive T echnology with

Removable On-The-Fly Sensor Modules

• Multiple Bore Sizes Available, Including

T apered Shafts

• Stainless Steel and Ductile Cast Iron

Construction

NorthStar

™

brand

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Code: Incremental

Pulses per Revolution: 60-2048

Phasing Sense: A leads B for Counter-Clockwise

rotation (CCW) viewing encoder-mounted end

Quadrature Phasing: 90° ± 22°

Symmetry: 180° ± 54°

Index:

270°, ungated (optional gated to falling B edge)

ELECTRICAL

Input Voltage Requirement: 5-15 or 15-26 Volts

DC

Current Requirement:

With Electrical Option L: 45mA typical per sensor

module plus line driver load

With Electrical Option R: 65mA typical per sensor

module plus line driver load

With Electrical Option 5: 65mA typical per sensor

module plus line driver load

Output Signals:

With Elec Option L: 5-15 V Line Driver, 150mA

With Elec Option R: 15 V Line Driver, 150mA

With Elec Option 5: 5V Line Driver, 150mA

Electrical Immunity: 2kV ESD, Reverse Polarity,

Short Circuit

Connector: 10 pin industrial duty latching, sealed

NEMA 4 &12, IP65; MS connector or pig-tail

EN 61326

MECHANICAL

Mating shaft sizes: 1-1/8" to 4-1/2", straight or

tapered bore

Shaft Speed: 3,600 RPM

Mounting Configuration: Hollow Shaft mount

with Anti-Rotation Tether

Housing Material: Cast Iron/Stainless Steel

Acceleration Rate: 3,600 rpm/sec max

Allowable Shaft End-Play: 0.25” (Subject to

RPM Limitation)

Allowable Shaft Runout: 0.010” TIR (Subject to

RPM Limitation)

ELECTRICAL CONNECTIONS

Signal Connector Pin Pigtail Cable MS 3102E18-IT#

Common

B

A

Z *

No Connection

Vcc

—

B

—

A

—

Z *

Shield

* Index (Z) optional. See Ordering Information

1

2

3

4

5

6

7

8

9

10

ENVIRONMENTAL

Operating Temperature Range: -20°C to +70°C

Storage Temperature Range: -40°C to +120°C

Humidity: to 98% RH (non-condensing)

Shock (Sensor Module): 1 meter drop test,

30 G’s Min

Vibration: 18 G’s @ 5-2000 Hz spectrum

Black

Green

Blue

Violet

—

Red

Yellow

Gray

Orange

Braid

A

E

D

C

—

B

H

G

I

J

1.62

Page 2

by

Code 1: Model

H8

H8 Hollow

Shaft

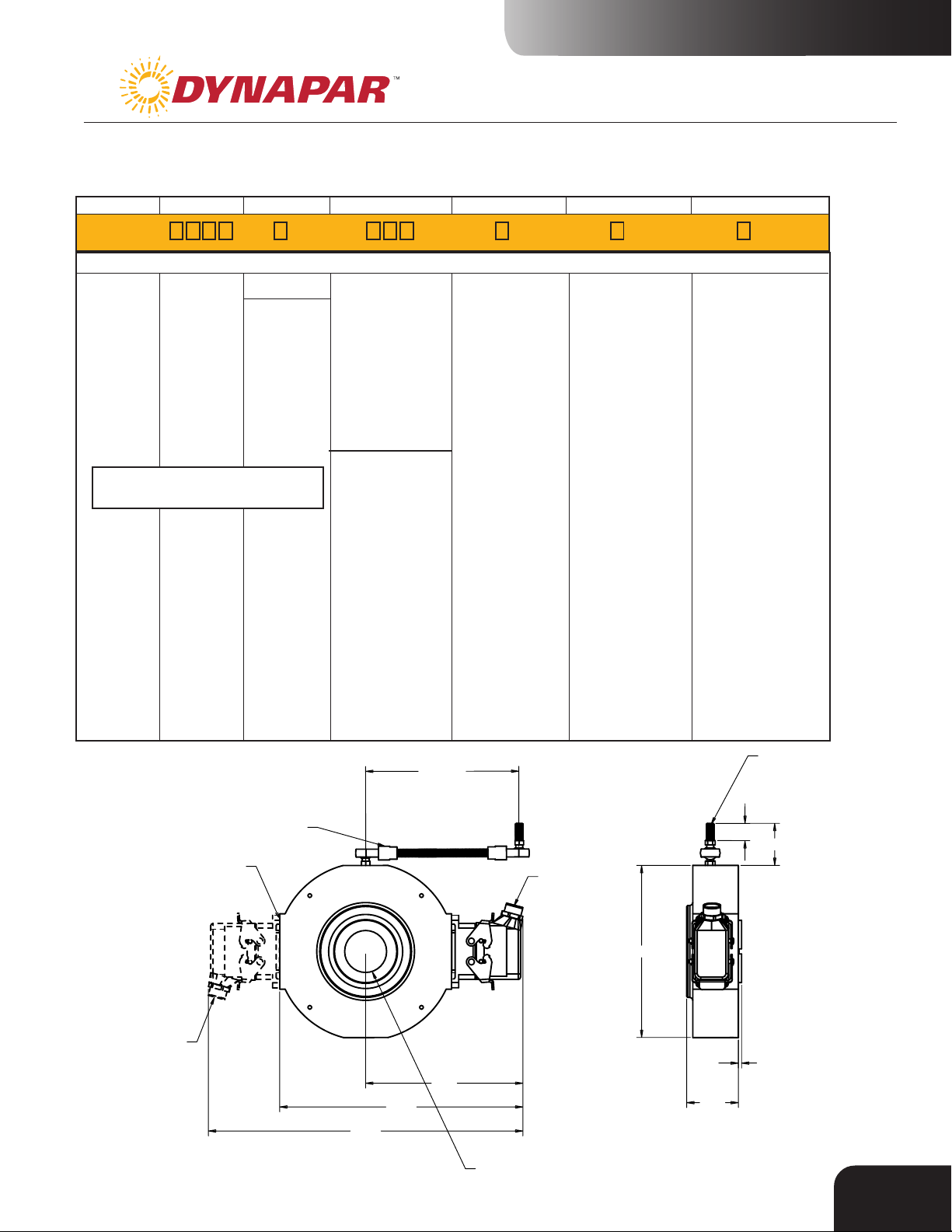

Ordering Information

To order, complete the model number with code numbers from the table below:

Code 2: PPR

0300

0060

0480

0064

0512

0075

0600

0120

0960

0128

1024

0150

1200

0240

2048

0256

Code 3: Index

L No Index

Available when

Code 2 is 0480,

0512, 0600,

0960, 1024,

1200 or 2048

G Gated

Index (Z,

Z Differential

Index (Z,

Code 4: Wheel Bore

Thru-bores

T01 1-1/8" bore

T02 1-3/8" bore

T03 1-5/8" bore

T04 1-7/8" bore

T05 2.00" bore

T06 2-1/8" bore

T07 2-1/4" bore

—

Z)

T08 2-3/8" bore

T09 2-1/2" bore

—

T10 2-7/8" bore

Z)

Ordering Information

Code 5: Output

1 Single

2 Dual (Isolated)

Differential,

bidirectional

signals

—

(A,

A, B, —B)

HEAVY DUTY

SERIES HS85

Code 6: Electrical

L 5-15V in, 5-15V

Line Driver (4428) out

R 15-26V in, 15V

Line Driver (4428) out

5 5-15V in, 5V

Line Driver (4428) out

Code 7: Termination

C Latching Industrial

Connector with 1/2" NPT

M 10 pin MS Connector

P 18" Pigtail

Note: See ACCESSORIES Section For

Connectors, Spare Parts and Pulse Wheels

inch

DIMENSIONS

8X M4-0.7X20 SOCKET HEAD SCREW

TIGHTEN TO 15IN-LBF (REF)

[mm]

ANTI-ROTATIONAL ARM

Bores with 1.25" per

foot taper

P01 1-1/8" bore

P02 1-3/8" bore

P03 1-5/8" bore

P04 1-7/8" bore

P05 2.00" bore

P06 2-1/8" bore

P07 2-1/4" bore

P08 2-3/8" bore

P09 2-1/2" bore

P10 2-7/8" bore

Additional Shaft Sizes

Up to 4.50" Maximum

Available (thru and

taper shaft)

Call factory for details

7.75±.25

[196.85

±

6.35]

1/2" NPT

CONDUIT CONNECTION

.375X24 UNF

TIGHTEN TO 20FT-LBS (REF)

0.87 [22.1]

2.13 [54.1]

SECOND OUTPUT

(OPTIONAL)

15.92

[404.37]

12.31

[312.67]

7.96

[202.18]

REFER TO ORDERING INFORMATION

FOR AVAILABLE BORE SIZES.

8.71 [221.23]

2.62

[66.55]

0.16

[4.06]

1.63

Loading...

Loading...