Page 1

DYNAPAR brand

Encoders & Accessories

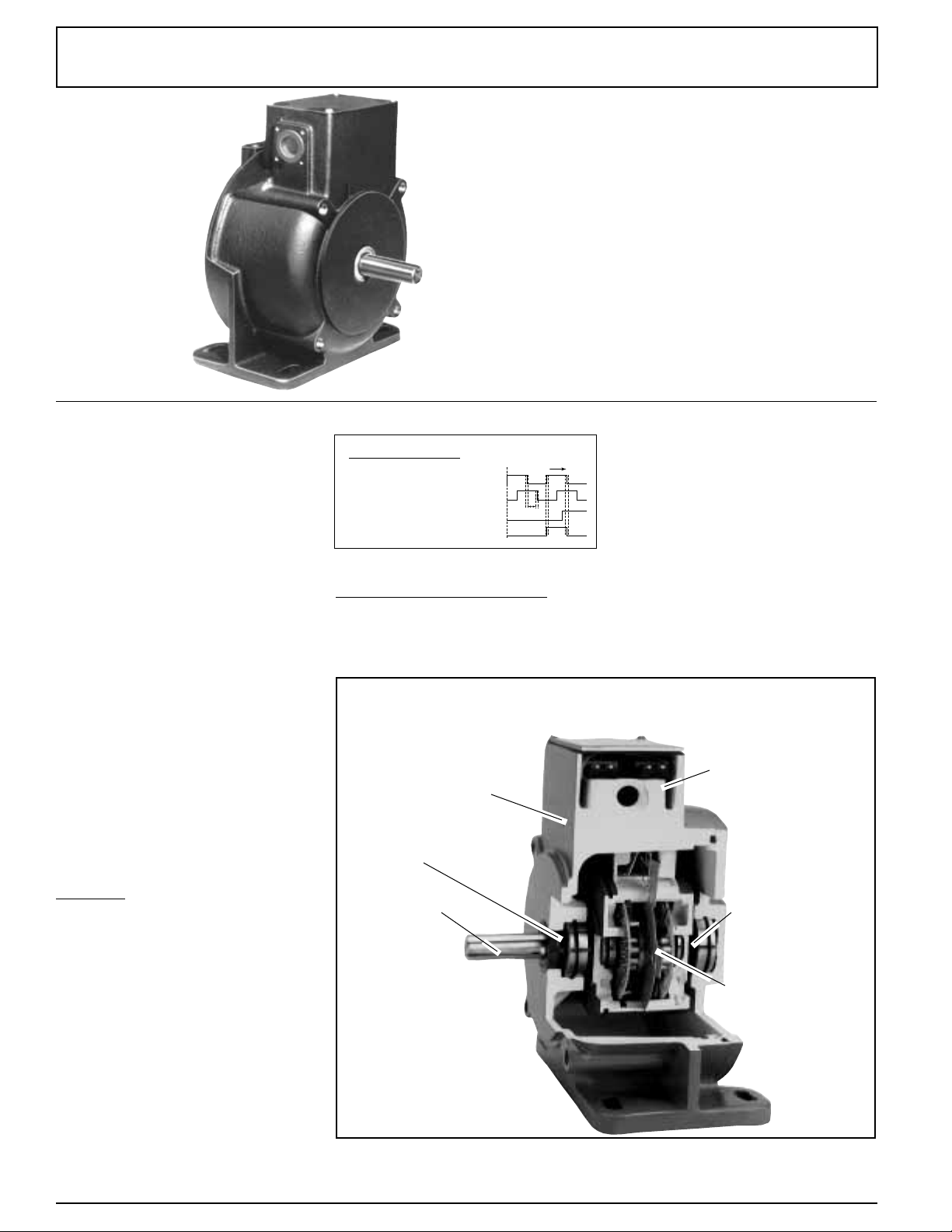

Series 60P Rotopulser

•

Mechanically and

environmentally rugged

•

Unbreakable disk

•

56C face and foot mounting

•

Up to 2500 PPR with optional

marker

•

Interchangeable (bolt-forbolt) with “C” face mount

tachs BC42 & 46

®

The Series 60P Mill-Duty Rotopulser is the

most rugged incremental encoder package

available. It is designed to provide long-term,

precision, digital measurements. The Series

60P is constructed to maintain transducer

alignments and measurements isolated from

external shaft loads.

Easier and more convenient installations are

provided with NEMA 56C face or foot mounting

options. These units are provided with line

driver outputs as a standard feature for longer

cable lengths (hundreds of feet) and/or higher

electrical noise immunity.

Typical Applications

• Motor drive speed feedback

• Back-gage positioning

• PLC and electronic counter inputs

• Speed, draw and length controls

• Winding and roll monitoring

• Finishing equipment, extruders, and test

equipment

• Precision, economical replacement for DC

tach when used with a Dynapar frequencyto-voltage converter

• The drive manufacturer’s standard.

SPECIFICATIONS

Electrical

Power Requirements: 5 to 15 VDC max.

115 mA max. plus load requirements

Output: TC1428 Differential Line Driver,

40 mA Sink/Source

Frequency Response: 50 kHz

Minimum Free Path: Between any A and B

transition (Distance D) will not be less than

12.5% of one full electrical cycle. This

includes effects of jitter, phase and

symmetry shifts.

Mating Connector:

Dynapar Part No. MCN-N6

10-pin: style MS3106A-18-1S,

Electrical Output

Note: Signal C (Marker) is

low for the first 180˚ of

shaft rotation clockwise

(as viewed from shaft

end), and is high for

the next 180˚.

A

B

C

COptional

Clockwise

D

Typical Starting Torque: 15 oz-in

Bearings: Motor Duty Bearings

Weight: 10 lbs.

Shaft Loading: Radial: 45 lbs. overhung;

Axial: 15 lbs.

Operating Temp. Range: 0 to 54°C

Enclosure Rating: NEMA 12 / IP54;

NEMA 4 / IP66 with optional shaft seals

Mechanical & Environmental

Slew Speed: 3600 RPM

Shaft Diameter: 5/8"

Inertia: 285 gm-cm2 max.

Here’s what makes the 60P so rugged

and reliable . . .

Precision die-cast aluminum

housing with external and

internal surfaces plated,

painted and baked for good

corrosion resistance.

Shaft seals

(optional).

Heavy-duty 5/8"

diameter shafts.

The internal transducer housing

and bearings are allowed to

mechanically float on the single

continuous heavy-duty shaft. This

allows the two outer bearings to

become the primary load bearing

elements. The transducer’s

alignments and measurements are

therefore better isolated from the

effects of long-term mechanical

wear and abuse.

Choice of screw terminals with

1/2" NPT conduit entry or quick

connect/disconnect MS pin

connector.

4-bearing construction with

dual housing and extra wide

bearing span.

Solid state LED’s standard.

Rugged mylar or photoplast

disc (no glass disc).

DANAHER CONTROLS

1/23/96

Page 2

DYNAPAR brand

Encoders & Accessories

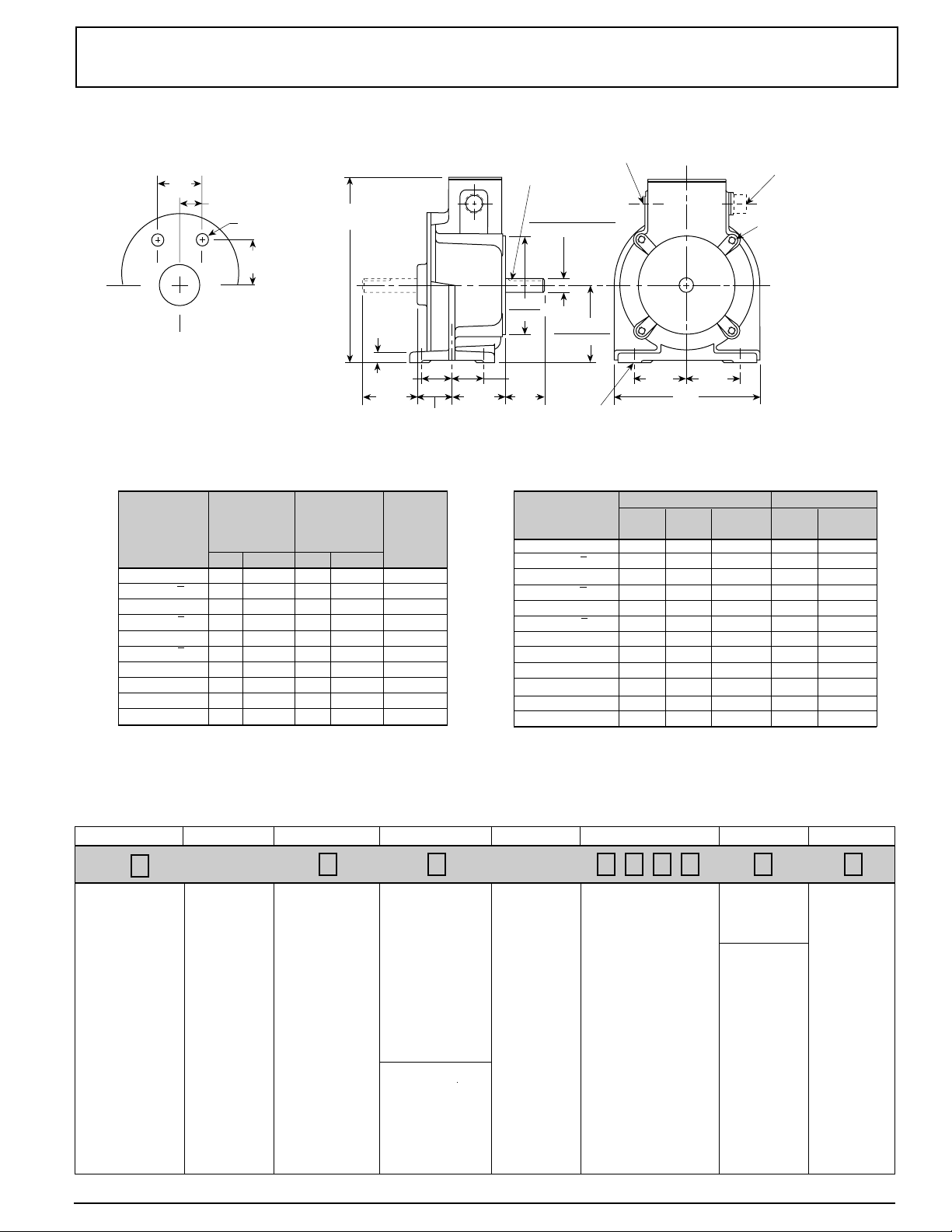

Purge Plug Location

1.5"

38.1 mm

Function

(If Used)

Signal A

Signal A

Signal B

Signal B

Signal C (Marker)

Signal C

+V

Common

Shield

Not Used

*This is a mating connector/cable assembly described in the

Encoder Accessories section of this catalog. Color-coding

information is provided here for reference.

.75"

19.05 mm

PURGE PLUGS

2 HOLES, 1/4 - 18 NPT

2.12"

53.85 mm

Single-Ended Output Dual Isolated Output

Cable

#14002090010*

6 PIN

Single-Ended

Pin

Color

B

RED

-

-

D

BLU

-

-

A

GRN

-

-

E

WHT

C

BLK

F

SHIELD

-

—

8.43"

214.1 mm

Twisted Pairs

Cable

#14004190010*

10 PIN

Differential

Pin

Color

B

RED

G

BLK

D

BLU

H

BLK

A

GRN

I

BLK

E

WHT

C

BLK

F

SHIELD

J

—

.44"

11.2 mm

38.1 mm

2.66"

67.5 mm

Connector

1.50"

Terminal

Approximate Dimensions

.188" x .094"/4.8 x 2.4 mm

KEYWAY

.6246" +.0000 -.0004

15.9 mm +.0000 -.0102

4.50"

DIA.

114.3 mm

1.50"

38.1 mm

2.50"

1.84"

46.7 mm

.34"/8.6 mm WIDE x .90"/22.9 mm LONG

1.69"

42.9 mm

63.5 mm

Electrical Connections

Strip

No.

1

12

3

11

4

10

5

2

6

7, 8, 9

Primary Power

Primary Common

Secondary Power

Secondary Common

*To provide quick backup, jumper cable assembly pins E & J and C & I;

then, if the primary output fails, move the connection from the primary to

secondary connector.

1/2" PIPE TAP FOR LEAD OUTLET –

STANDARD ON ALL UNITS

SECONDARY

OUTPUT

DIA.

3.50" +.003

88.9 mm +.076

4 SLOTS

Function

(If Used)

Signal A

Signal A

Signal B

Signal B

Signal C

Signal C

Shield

Not Used

2.50"

63.5 mm

Code 4 is K or L

6 PIN

Primary

B

-

D

-

A

E

C

-

F

-

MS3102A-18-1P CONNECTOR

(Mates with MS3106-18-1S)

2.50"

63.5 mm

6.66"

169.2 mm

10 PIN

Primary

B

G

D

H

A

I

E

C

-

F

J

7 PIN

Secondary

(No Marker)

(No Marker)

PRIMARY

OUTPUT

3/8-16 x .62"/15.7 mm

DEEP 4 MTG. HOLES ON

5-7/8"/149.2 mm DIA.

CENTER

Compatible with

NEMA 56 and 56C

hardware

Code 4 is M*

10 PIN

Primary

A

C

B

E

D

F

-

-

G

-

B

G

D

H

-

E

C

-

F

A,I,J

10 PIN

Secondary

B

G

D

H

(No Marker)

(No Marker)

E

C

J

I

F

A

1/23/96

Code 1: Model

6

2 Bidirectional,

Heavy Duty

3 Bidirectional

with Marker,

Heavy Duty

Code 2: Housing

P

P Mill Duty

Ordering Information

To order, complete the model number with code numbers from the table below:

Code 3: Shaft

Code 4: Output

Code 5: Voltage

Code 6: Pulses/Rev Code 8: Misc

F

M 5/8" Dia,

Single Shaft

with Keyway

N 5/8" Dia,

Double Shaft

with Keyway

D Differential

E Single Ended

K Single Ended,

Dual Isolated,

6 and 7 pin

connectors

L Differential,

Dual Isolated,

10 and 7 Pin

Connectors

Available when

Code 1 is 62:

M Differential,

Dual Isolated,

10 and 10 Pin

Connectors

F 5 to 15

VDC

0001

0002

0004

0005

0006

0010

0012

0015

0018

0020

0025

0040

0045

0050

0060

0064

0090

0096

0100

0120

0125

0127

0128

0150

0180

0192

0200

0203

0240

0250

0256

0300

0306

0315

0750

0360

0800

0375

0805

0382

0833

0384

0900

0390

1000

0400

1024

0402

1200

0430

1250

0450

1270

0500

1500

0508

1800

0512

2000

0530

2160

0550

2250

0600

2400

0625

2500

0720

DANAHER CONTROLS

Code 7: Wiring

A MS

Connector

Available when

Code 4 is D or

E:

T Terminal

Strip

0 No Purge

Plugs, No

Shaft Seals

A Purge

Plugs, No

Shaft Seals

B No Purge

Plugs,

Shaft Seals

C Purge

Plugs and

Shaft Seals

Loading...

Loading...