Page 1

Incremental Shaft Encoders

Type RI 76 TD

NUMBER OF PULSES

TECHNICAL DATA

mechanical

Industrial types

■ Through shaft with up to diameter 42 mm

■ Short overall length with an outside diameter of only 76 mm

■ Easy installation by means of clamping ring

■ Operating temperature up to 100 °C

■ Application e.g.:

- motors

- printing machines

- lifts

50 / 100 / 128 / 250 / 256 / 300 / 314 / 360 / 500 / 600 / 720 / 900 / 1000 / 1024 / 1250 / 1500 / 2048 /

2500 / 3072 / 4096 / 5000 / 8192 / 9000 / 10000

Other number of pulses on request

Shaft fixation Clamping ring, front or rear

Coupling stator coupling (hubshaft with tether)

Shaft diameter 15…42 mm (Available: 15, 16, 18, 20, 24, 25, 27,

28, 30, 32, 38, 40, 42 mm as well as 5⁄ 8 “, 15⁄ 8“, 3⁄ 4 “

Mimimum length of mounting shaft

Front clamping ring 32 mm with Ø 15 ... 30, 35 mm with Ø >30 ... 42

Rear clamping ring corresponding to total length of encoder

Max. parallel shaft misalignment

with stator coupling A (flexible) ±2.0 mm axial, ±0.15 mm radial

with 1x stator coupling N (torsionally rigid) ±0.5 mm axial, ±0.3 mm radial

with 2x stator coupling N (torsionally rigid) ±0.3 mm axial, ±0.2 mm radial

Absolute max. speed at 70 °C and IP64: 3 600 min-1für Ø 15 ... 25

at 70 °C and IP64: 1 800 min

at 70 °C and IP40: 6 000 min

at 100 °C always: 1 800 min-1für Ø 15 ... 42

Torque 3…10 Ncm (depending on version )

Moment of inertia 140...420 gcm2(depending on version)

Protection class (EN 60529) Housing IP50, bearings IP40

Option: Housing IP65, bearings IP64

Operating temperature -25 ... +100 °C

Storage temperature -25 ... +100 °C

Vibration resistance (IEC 68-2-6) 10 g = 100 m/s2(10 ... 2000 Hz)

Shock resistance (IEC 68-2-27) 100 g = 1000 m/s2(6 ms)

Connection 1.5 m cablel1radial

Housing Aluminium

Weight 320 - 580 g (depending on version)

1

Other cable length on request

Hollow shaft

-1

für Ø >25 ... 42

-1

für Ø 15 ... 42

74 ENCODERS COUNTERS INDICATORS RELAYS PRINTERS CUTTERS

Page 2

Incremental Shaft Encoders

Type RI 76 TD

TECHNICAL DATA

electrical

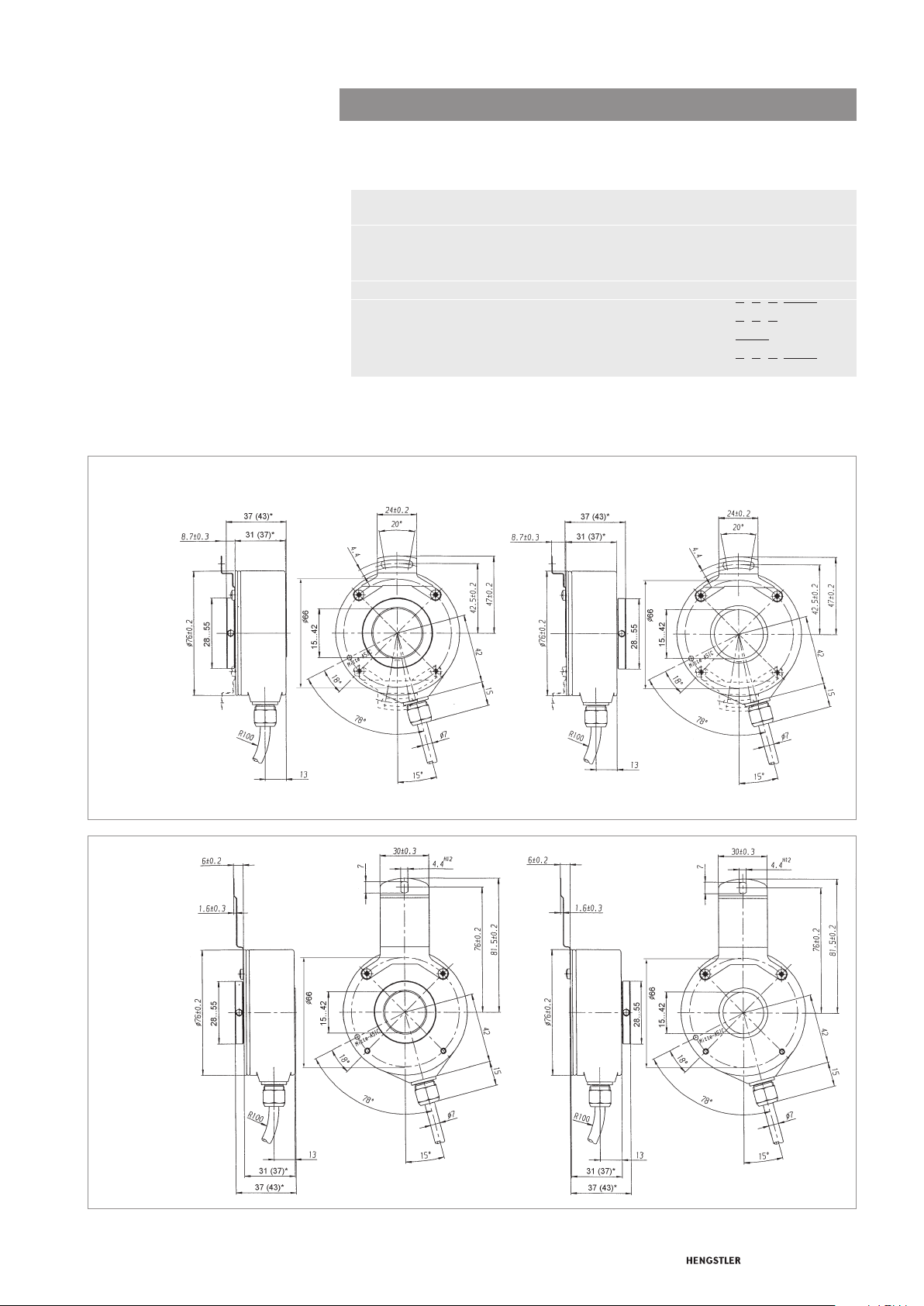

DIMENSIONAL DRAWINGS

WITH HUBSHAFT WITH TETHER

”RIGID”

Industrial types

General design as per DIN EN 61010-Part 1, protection class III,

Contamination level 2, over voltage level II

Supply voltage with RS 422 +Sense (T): DC 5V±10%

(SELV) with RS 422 +Alarm (R): DC 5 V ±10 % oder DC 10 - 30 V

with push-pull (K, I): DC 10 - 30 V

Max. current w/o load max. 60 mA (DC 5 V), 60 mA (DC 10 V), 35 mA (DC 24 V)

Standard RS 422 (R): A, B, N, , , ,

output versions

1

Pole protection with supply voltage DC 10 - 30 V

2

Output description and technical data see chapter “Technical basics”

2

RS 422 (T): A, B, N, , , , Sense

push-pull (K): A, B, N,

push-pull complementary (I): A, B, N, , , ,

Hollow shaft

1

AlarmNBA

NBA

Alarm

AlarmNBA

1

Dimensions in mm

* Values in brackets for shaft diameter >30

Diameter of connection shaft 15g8 … 42g8

WITH HUBSHAFT WITH TETHER

”FLEXIBLE”

Dimensions in mm

* Values in brackets for shaft diameter >30

Diameter of connection shaft 15g8 … 42g8

R for alternating bending > 100 mm

R for permanent bending > 40 mm

R for alternating bending > 100 mm

R for permanent bending > 40 mm

75ENCODERS COUNTERS INDICATORS RELAYS PRINTERS CUTTERS

Page 3

Incremental Shaft Encoders

Type RI 76 TD

SHAFT CONNECTION

MOUNTING NECESSITIES

PIN ASSIGNMENT

Cable TPE

Industrial types

Shaft fixing is done through a clamping ring either on the flange or cap side. As a rule,

flange side clamping is better for smaller motors as the available shaft stub is correspondingly shorter.

On the other hand, cap side clamping is easier when there is sufficient shaft length

available.

In order to compensate for axial and radial shaft eccentricity as well as any angle offset, the

encoder flange must not be rigidly mounted. Please mount the flange with a flexible stator

coupling (e.g. hubshaft with tether) as torque support.

There are two flexible mounting plates:

• A flexible hubshaft with tether (A) for higher levels of play and lower requirements

for accuracy.

• A rigid hubshaft with tether (N) for reduced play and rigid connection with reduced

swing angle. This is suitable in the case of higher accuracy and dynamics requirements.

Output circuit

Colour (TPE) RS 422 RS 422 push-pull (K) push-pull

+ Sense (T) + Alarm (R) complementary (I)

brown Channel A Channel A Channel A Channel A

green Channel Channel Channel

grey Channel B Channel B Channel B Channel B

pink Channel Channel Channel

red Channel N Channel N Channel N Channel N

black Channel Channel Channel

violet (white)2 Sense GND

blue Sense V

brown/green DC 5 V DC 5/10.- 30 V DC 10 - 30 V DC 10 - 30 V

white/green GND GND GND GND

Cable screen

1

connected with encoder housing

2

white for version Sense (T)

1

CC

Cable screen1Cable screen1Cable screen1 Cable screen

Sense V

CC

Hollow shaft

AAA

BBB

NNN

AlarmAlarmAlarm

Sense V

CC

1

ACCESSORIES

76 ENCODERS COUNTERS INDICATORS RELAYS PRINTERS CUTTERS

Hubshaft with tether flexible ordering code 1 533 079

Hubshaft with tether rigid ordering code 1 533 078

Page 4

Incremental Shaft Encoders

Type RI 76 TD

Industrial types

ORDERING INFORMATION

Stator

coupling

Shaft

Type Model

Number

of pulses

Supply

voltage

Flange Protection

.

1

RI76 TD High

1

only with output R, T,

2

only with output R, K, I

3

Available with front clamping ring and IP40: 15, 20, 24, 25, 27, 28, 30, 38, 40, 42, 50 (5⁄ 8

Available with front clamping ring and IP64: 15, 16, 18, 20, 24, 25, 27, 28, 30, 32, 38, 40, 42, 50 (

Available with rear clamping ring and IP40: 25, 28, 30, 32, 38, 40, 42

Available with rear clamping ring and IP64: 20, 25, 30, 32, 38, 40, 42

Preferably available versions are printed in bold type.

Others: please request delivery time

temperature,

direct

hollow shaft

1…10 000

A DC 5 V

E DC

10-30 V

Clamping

shaft with

2

D Front

clamping

ring

H Rear

clamping

ring

1 IP40

4 IP64

O without

A flexible

N rigid

15…42 metric

50…99

coded by inches

50 =

51 = 15⁄ 8 “

52 =

“), 51 (1

Hollow shaft

Output Connection

in mm

5

⁄ 8

“

3

⁄ 4“

5

⁄ 8

“)

5

⁄ 8 “), 51 (15⁄ 8 “), 52 (3⁄ 4 “)

R RS 422 +

Alarm

T RS 422

+ Sense

K push-pull

I push-pull

complementary

F TPE cable

radial

77ENCODERS COUNTERS INDICATORS RELAYS PRINTERS CUTTERS

Loading...

Loading...