Page 1

DYNAPAR brand

Operator Interface Products

PC15 Panelcoders™

•

Provides digital control inputs

from operator’s panel

•

Bidirectional squarewave

signal outputs

•

Continuous and reversible

rotation

Series PC15 Panelcoders directly convert an

operator's manual rotary inputs into digital

signals. These signals can be used by

microprocessors and electronic counters with

no A/D conversion required. Eliminating A/D

conversion and input de-bounce circuitry

associated with potentiometers and other types

of controls helps reduce memory overhead and

wiring inter-connects. Since Panelcoders are

non-contacting, there are no wipers or contacts

to wear or create electrical noise.

Panelcoders are designed for use as panelmounted operator-interface devices where

extended service, high resolution and precise

linearity are required. They deliver a digital

signal virtually free of distortion, and can be

operated at higher speeds without diminished

output integrity.

Panelcoders give the operator a simple

"analog-feel," while giving designers digital

outputs and greater flexibility.

Panelcoders are designed specifically for

applications where a higher resolution panel

encoder is required (up to 256 PPR). The

standard configuration corresponds to a typical

1.5" panel-mounted potentiometer. Termination

can be made with user's choice of a mating

connector or soldered wires. Panelcoders are

also available with a higher manual starting

torque (drag) option for operator preference or

higher vibration applications.

Typical Applications

• Industrial machine controls

• Electronic test equipment

• Medical electronics

• CAD/CAM/CAE equipment

• Speed controls

• Cursor controls

• Time, temperature, level or frequency

controls

SPECIFICATIONS

Electrical

Code: Incremental; quadrature

PPR: 10, 40, 60, 100, 120, 127, 180, 200,

250, 256 (Other counts available; consult

factory.)

Symmetry: 180° ±36°

Edge Separation: 45° electrical, min.

Phase Sense: Signal A leads Signal B for CW

rotation as viewed from the shaft end of the

Panelcoder

Output Signal: Squarewave, CMOS/TTL

compatible

Logic "1": 3 Volts min. @ 3 mA source

Logic "0": 0.5 Volts max. @ 16 mA sink

Input Power Requirements:

+5 VDC ±5% @ 75 mA max. standard;

+5 VDC ±5% @ 25 mA max. for low current

drain option

Termination: Card edge, contacts on 0.156"

centers

Mating Connector: CINCH 50-6A-20 or

equivalent

Mechanical & Environmental

Weight: 3.0 oz. max.

Shaft Rotation: Continuous and reversible

Shaft: 1/4" dia. w/flat (-0.0003"/-0.0005")

Shaft Speed: 100 RPM max. continuous; 300

RPM @ 10% duty cycle

Shaft Loading: Manually operated, 1 lb. max.

Torque: 2 ±1 oz-in with brake; less than 0.5

oz-in without brake

Disc Material: Etched metal

Housing Material: Polycarbonate

Operating Temperature: 0° to +55°C

Storage Temperature: -40° to +85°C

Mounting: 3/8-32 mounting nut supplied;

Max. torque to mounting nut 300 oz-in

Electrical Connections

Function

Common

No Connection

Signal B

No Connection*

Signal A

5V Power

*Location for mating connector mechanical

keyway.

Terminal

1

2

3

4

5

6

DANAHER CONTROLS

Page 2

DYNAPAR brand

Operator Interface Products

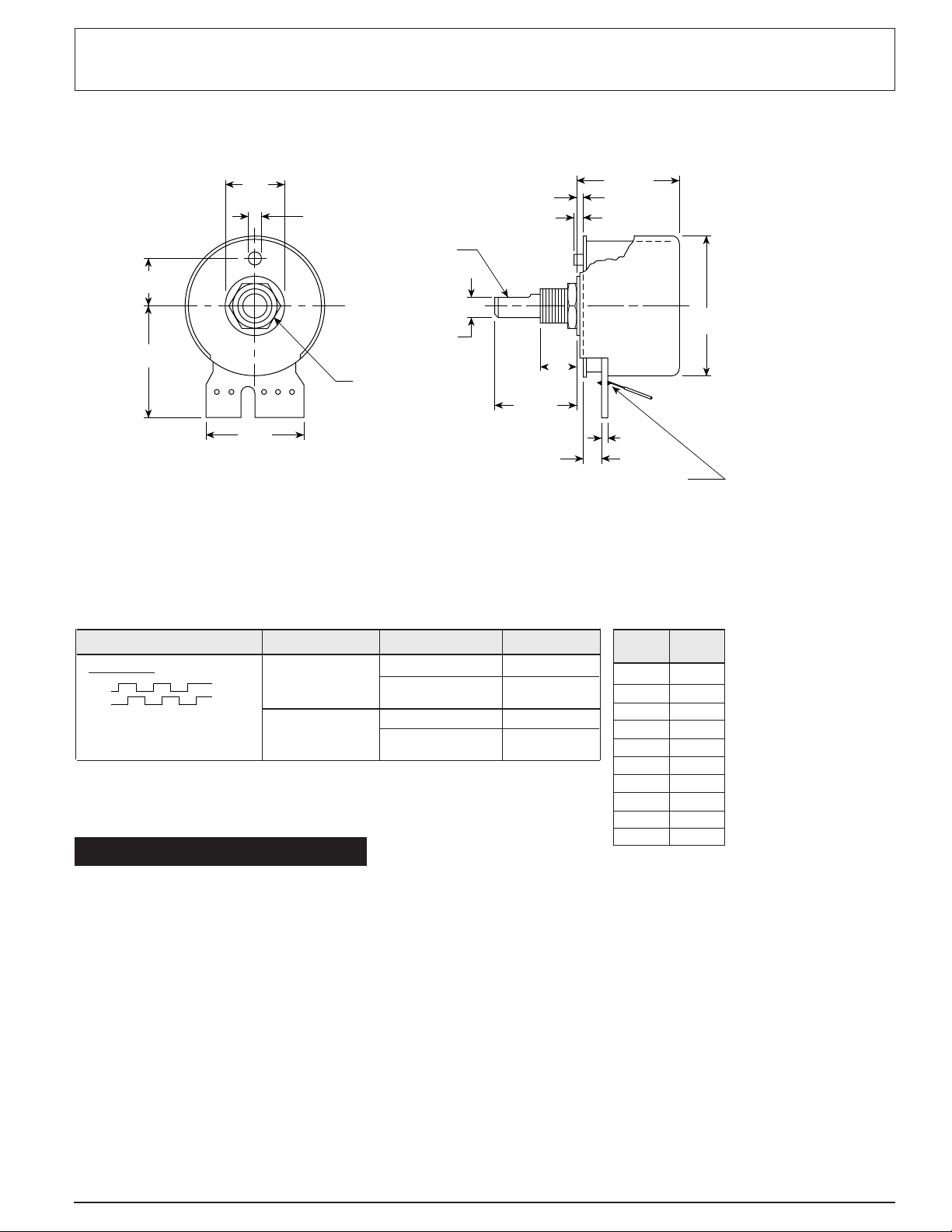

Approximate Dimensions (inches/mm)

.625

15.88 mm

.50

12.7 mm

1.18

30.0 mm

1.07

27.2 mm

.12 MAX

3.0 mm

FLAT .37 LG. NOM.

X .03 DP. NOM.

9.4 mm LG. X

.77 mm DP.

.2497 MAX

6.342 mm

3/8-32 UNEF

MOUNTING NUT

SUPPLIED

1.08 MAX

.06/1.5 mm

.1/2.5 mm

.38

9.6 mm

.86

21.8 mm

.228/5.79 mm

IF CONNECTOR IS NOT USED, SOLDER

BOTH SIDES OF WIRE FOR CONTINUITY

27.4 mm

.062 REF.

1.57 mm

1.50

38.1 mm

Ordering Information

To choose a model number, follow the table from left to right. Complete the model number with

a 3-digit code for choice of pulses per revolution (PPR).

MechanicalOutput Waveform

Bidirectional (CW)

A

B

1.5" Diameter Pkg.

1/4" Diameter Shaft

1.5" Diameter Pkg.

1/4" Diameter Shaft

w/ Manual Drag Option

For MAXjr Speed 3, use PC15- 100-E01

Electrical Power

Standard

Optional

Low Current Input

Standard

Optional

Low Current Power

Model No.

PC15-_ _ _-C

PC15-_ _ _-L

PC15-_ _ _-D

PC15-_ _ _-E

PPR

10 010

40 040

60 060

100 100

120 120

127 127

180 180

200 200

250 250

256 256

Other counts available;

consult factory.

Code

Option

DANAHER CONTROLS

Loading...

Loading...