VEEDER-ROOT brand

DYNAPAR brand

VEEDER-ROOT brand

Electronic Predetermining Counters

Predetermining Counters

Electronic Predetermining Counters

R

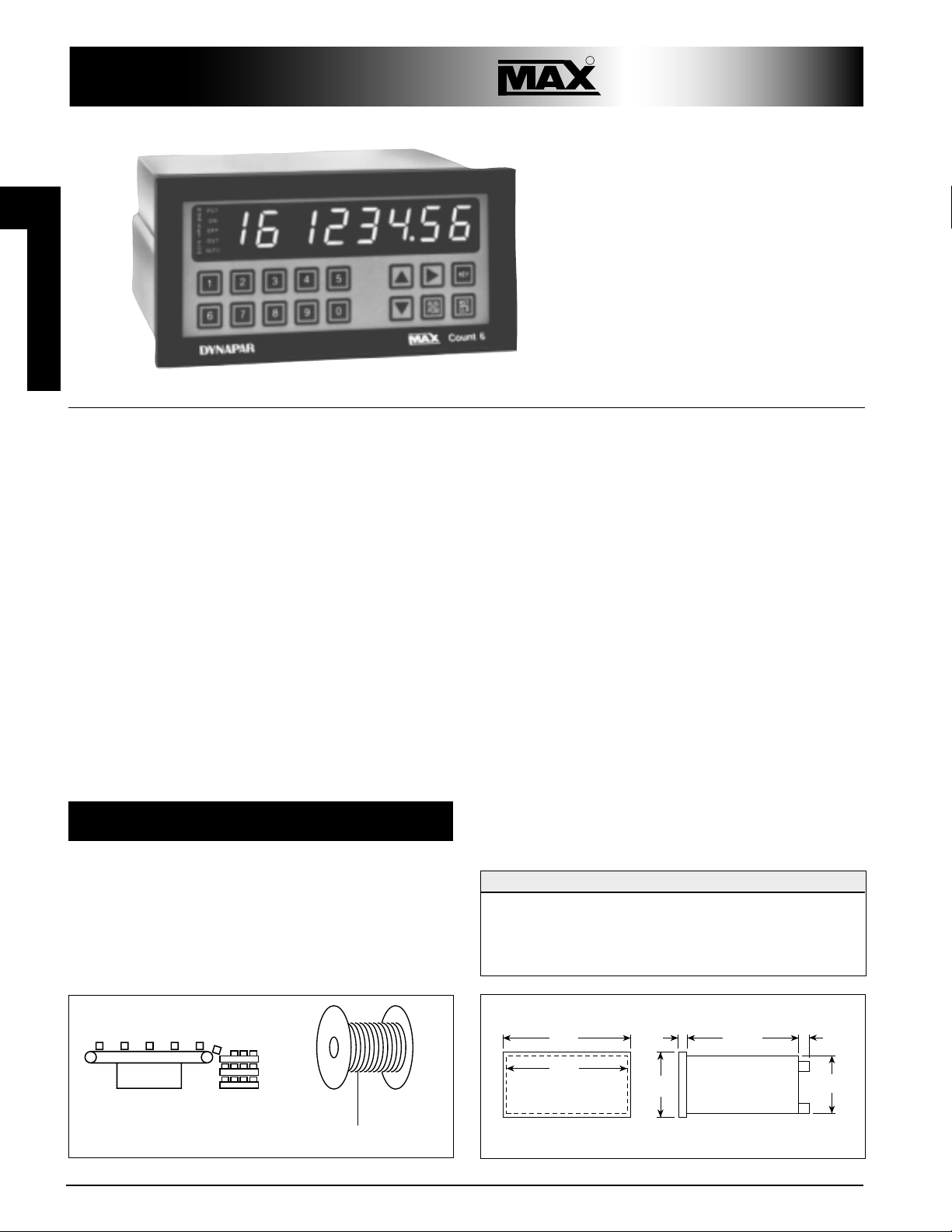

Count 6

2

P

R

E

E

L

D

E

E

C

T

T

E

R

R

O

M

N

I

I

N

C

I

N

G

The simple solution

to complex multi-step

control problems

. . .16 presets, plus

separate batch control

and totalizing counters

Applications needing several uniquely spaced punching, drilling,

welding, printing, or other operations, are no problem for MAX Count 6.

Its complement of 16 preset limits can operate several machine control

functions by timed actuation, or by turning them on or off at specific

count values. A large LED display panel keeps the equipment operator

informed, while an RS-485/422 communications port can support twoway data transfer with a computer, or other remote system.

■ Bidirectional counting in quadrature, add/subtract, or add/add modes

■ Programmable features include calibration factor, and decimal point

■ Multi-step 16 preset/6 decade control counter

■ Big red LED display – plus illuminated annunciators

■ Non-volatile memory of program and preset values

■ Selectable count memory – reset or retained after power interruption

■ RS-422/485 data allows local printer or remote system interface

■ NEMA-4 rated, sealed front panel – tactile response keyboard

■ Self diagnostics for inputs, outputs, keyboard, display, and memory

Two versions are available: MAX Count 6, for applications requiring up

to 16 preset limits to be processed in the order of their absolute value

as compared to the counted value, therefore preset limits may be

processed out of sequence. MAX Count 6S is for applications requiring

preset limits to be processed in ascending sequential order, with preset

limit 1 controlling the process until the counted value equals its value,

then preset limit 2 controls the process, and so on.

For more presets, see Series 7920, Series 79201

For specialized web control, see MAX S.L.R.C.

SPECIFICATIONS

Input Power: Selectable, 100 to 130 VAC or 200 to 260 VAC, 50/60 Hz, 20 VA

(12 VDC @ 0.3 A optional).

Accessory Power: DC output provided for transducer, 12 VDC ±5%, 175 mA

maximum

Display: 0.6" (15.2 mm) red LED, 8 annunciators

Decimal Point: Selectable decimal point (XX.X.X.X.X.)

Keyboard: Sealed, 16 tactile response keys

Input Modes: Add/subtract, add/add, quadrature

Input Logic: X1, X2, X4 (X4, quadrature only)

Count Rate: X1 Logic = 20 kHz; X2 Logic = 10 kHz; X4 Logic = 5 kHz

Input A & B Signal: Contact Closure (25 Hz, maximum) or sourcing 3.5 to 15 VDC

Calibration: Scaling common to inputs A and B; Range: 0.0001 to 9.9999

Preset Limits: 16 individual; each allows preset to any 6 digit value

Main Counter Capacity: 6 decades

Main Counter Modes: Up Mode: Resets to zero; Down Mode: Resets to

start count preset value

Secondary Counters: 6 decade single preset batch counter, 6 decade

background totalizer

Control Inputs: Reset and stop count/hold (commands initiated when

switched to common)

Control Outputs: 8 open collector NPN, 28 VDC/100 ma

Reset: Front panel pushbutton, remote, automatic

Security: Selectable locks for reset, preset, and program mode

Diagnostics: Tests signal and control inputs, outputs, keyboard, display

Communications: RS-422/485; ASCII; 300, 600, 1200, 2400 baud

Operating Temperature: +32° to +122°F (0 to +50°C)

Weight: 2.2 lbs. (997.9 g)

Model No. Description

MC600S00 MAX Count 6, Standard Model, AC Powered

MC600D00 MAX Count 6, Standard Model, DC Powered

MC60SS00 MAX Count 6, Sequential Model, AC Powered

MC60SD00 MAX Count 6, Sequential Model, DC Powered

Typical Applications:

Packaging Line

Ideal for coil winding, heat treating, packaging machinery,

position controls.

2.12

DANAHER INDUSTRIAL CONTROLS

Coil Winding

Dimensions:

5.67"

144 mm

5.35"

136 mm

FRONT SIDE

Panel Dims: Cutout: 2.68" x 5.43". Thickness: 1/16" to 1/4". Depth: 5.68" min.

.39"

10 mm

74 mm

2.91"

5.20"

132 mm

.50"

13 mm

2.60"

66 mm

Loading...

Loading...