DANA Spicer Torque-Hub W3B Series, Spicer Torque-Hub W3C Series Service Manual

1

Torque-Hub® Planetary Final Drive

W3B/W3C Series Service Manual

Rev 03/07/13

2

Fairfield Manufacturing Co. Inc., Lafayette, IN, is now a part of Dana Incorporated

While every precaution has been taken in the preparation of this document, Fairfield Manufacturing Co. Inc. assumes no

liability with respect to the use of the documentation described herein, or for any act or omission of Fairfield Manufacturing

Co. Inc. concerning this documentation. Torque-Hub® is a registered trademark of Fairfield Manufacturing Co. Inc.

Features and specifications are subject to change without notice.

3

Planetary Final Drive Service Manual

Content

Introduction

04

Roll and Leak Test

05

Tightening and Torquing Bolts

07

Lubrication Information

08

Disassembly Instructions

Main Disassembly

12

Carrier Disassembly

15

Coupling Disassembly

16

Input Shaft Disassembly

17

Cover Disassembly

18

Housing-Spindle Disassembly

19

Assembly Instructions

Cover Subassembly

24

Carrier Subassembly

26

Housing Spindle Subassembly

28

Coupling Subassembly

30

Input Shaft Subassembly

31

Main Assembly

32

Assembly Drawing

36

Parts List 37

Assembly Tools

40

General Information

Contact Information

52

4

Planetary Final Drive Service Manual

Introduction

This manual is a step-by-step guide to the disassembly and

assembly of the W3C/W3B Series Torque-Hub® units. It is designed

for the customer or mechanic who is repairing this particular

Torque-Hub® model.

Users of this manual should note that each part mentioned is

followed by an identification number enclosed in parentheses.

These part numbers may be referred to in the Parts List and

Assembly Drawing sections of this manual.

Specialized tools used to assemble this unit are noted in the

assembly procedures and diagrammed in the Assembly Tools

section.

Users should familiarize themselves with the procedures for roll and

leak testing, as well as bolt tightening and torquing found on the

following three pages before starting any repairs.

Standard safety practices should be followed during the

disassembly and assembly procedures described. Safety glasses

and safety shoes should be worn, and heavy, heat resistant gloves

should be used when handling heated components. Be especially

alert when you see the word CAUTION. This indicates that a

particular operation could cause personal injury if not performed

properly or if certain safety procedures are not followed. The word

NOTE is used to bring attention to certain procedures or helpful

hints that will aid in the disassembly and assembly process.

5

Planetary Final Drive Service Manual

Roll and Leak Test

Torque-Hub® units should always be roll and leak tested before

disassembly (if possible) and after assembly to make sure the unit’s

gears, bearings, and seals are working properly. The following

information briefly outlines what to look for when performing these

tests.

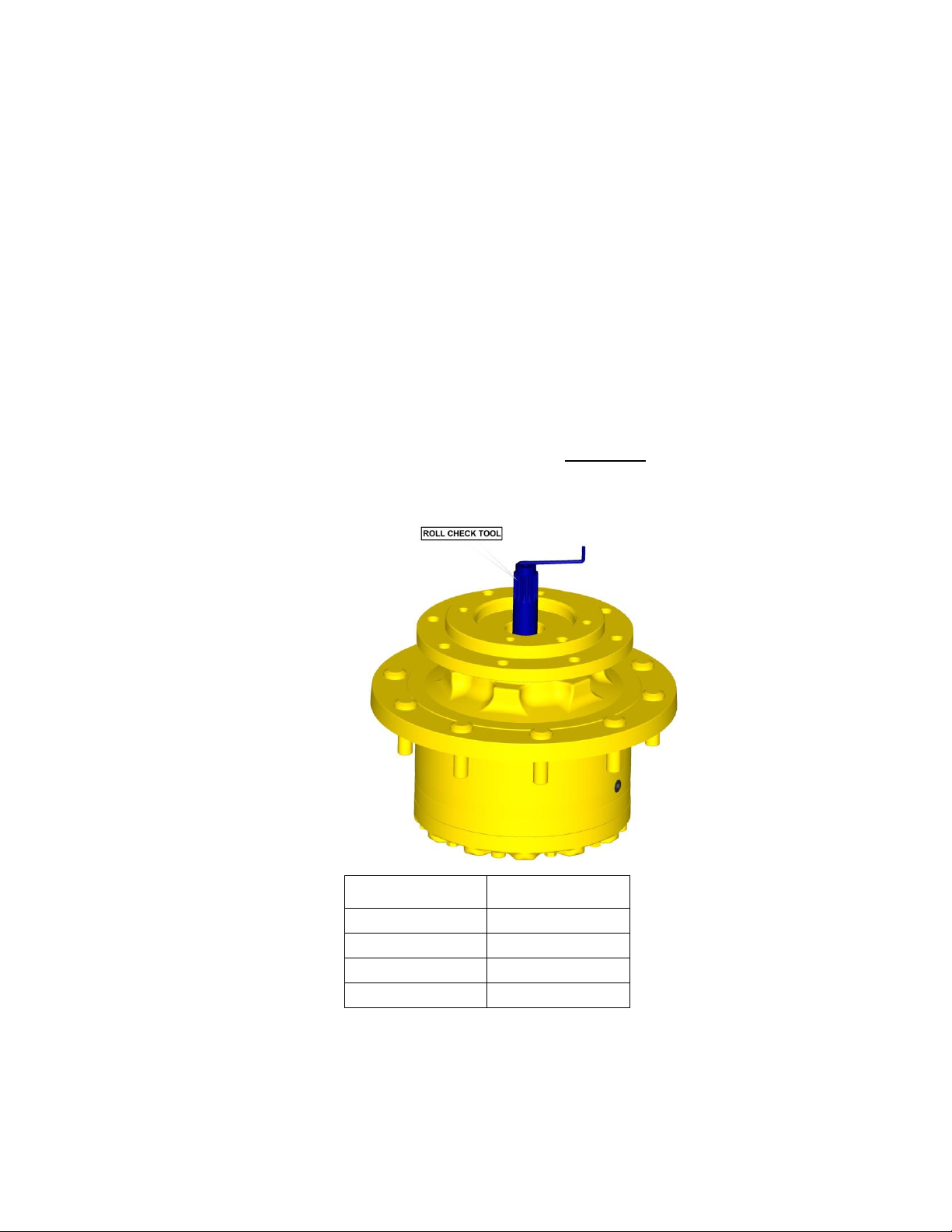

The Roll Test The purpose of the roll test is to determine if the unit’s gears are

rotating consistently, easily and properly. Release the brake by

applying 400 Psi to the brake port. To perform a roll test, use the

recommended tool from table below (or something equivalent) to

apply constant rotational force to the input of the gearbox. If more

drag is felt in the gears only at certain points, then the gears are not

rolling consistently and easily and should be examined for improper

installation or defects. Some gear packages roll with more difficulty

than others. Do not be concerned if the gears in the unit seem to roll

hard as long as they roll with consistency. Rotate the gearbox both

clockwise and counterclockwise the same number of turns as the

ratio of the unit. The gearbox ratio is the same number as the last

three numbers on the ID tag.

Model code

Roll Test Tool

W3xxxx3xxxx

T223988

W3xxxx4xxxx

T223989

W3xxxx7xxxx

T223990

W3Bxxx8xxxx

T223997

Continued on Next Page

6

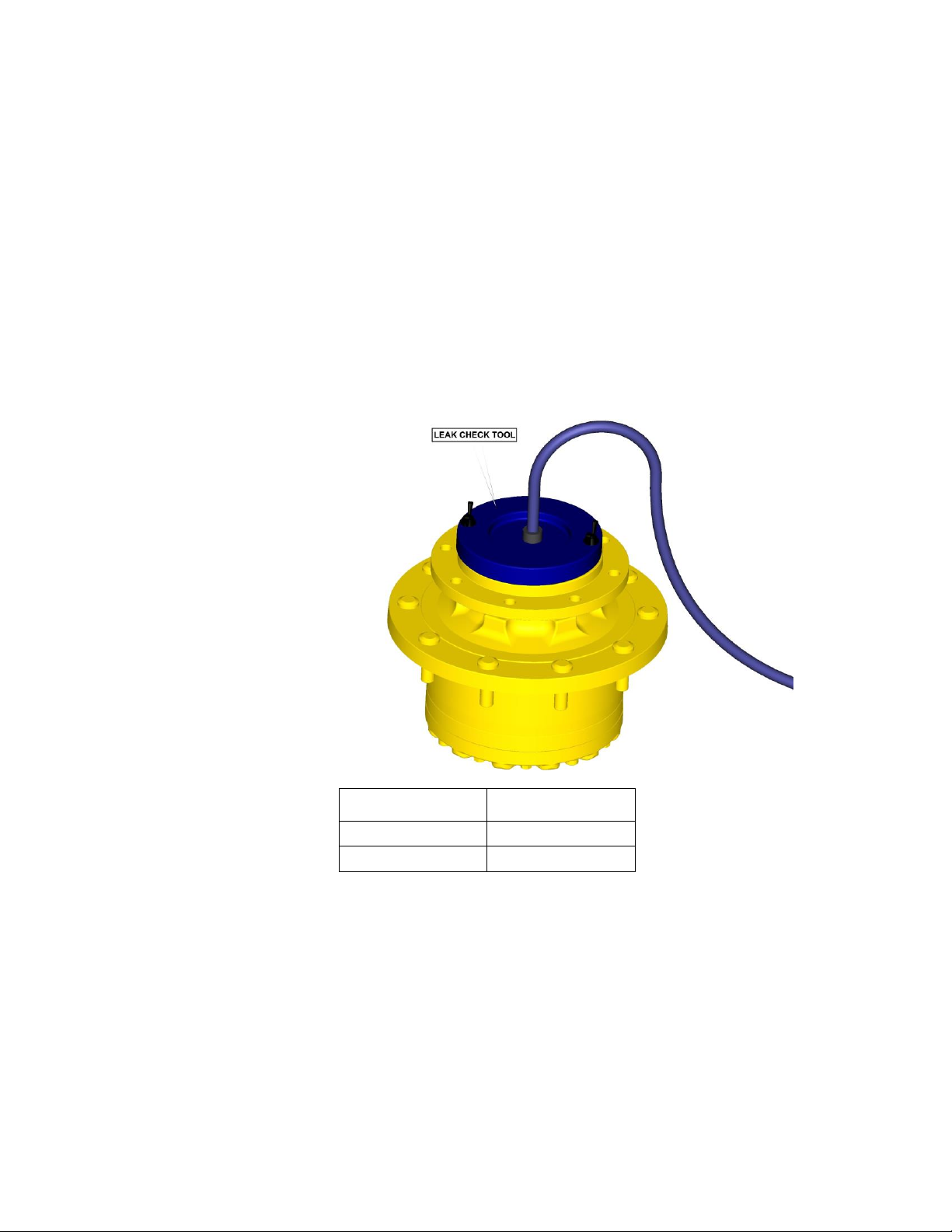

The Leak Test The purpose of a leak test is to make sure the unit is airtight. To

perform a leak test use the leak test fixture from the table below. If

the tool is not available, the gearbox must be sealed to perform the

test. This can be accomplished by assembling the sealed input

device onto the gearbox at the input end and replace one of the oil

plugs with an air chuck. DO NOT EXCEED 10 PSI PRESSURE

DURING THE LEAK TEST. Higher pressure will create a false

sealing effect in assemblies with lip-seals. The unit has a leak if the

pressure gauge reading on your leak check fitting starts to fall after

the gearbox has been pressurized and allowed to equalize. Leaks

will most likely occur at the pipe plugs, the main seal or wherever

o-rings or gaskets are located. The exact location of a leak can

usually be detected by brushing a soap and water solution around

the main seal and where the o-rings or gaskets meet on the exterior

of the unit and then checking for air bubbles. If a leak is detected in

a seal, o-ring, or gasket, the part must be replaced and the unit

rechecked. Leak test at 10 psi for 20 minutes.

Model code

Leak Test Tool

W3Cxxxxxxxx

T220225

W3Bxxxxxxxx

T201476

7

Planetary Final Drive Service Manual

Tightening and Torquing Bolts

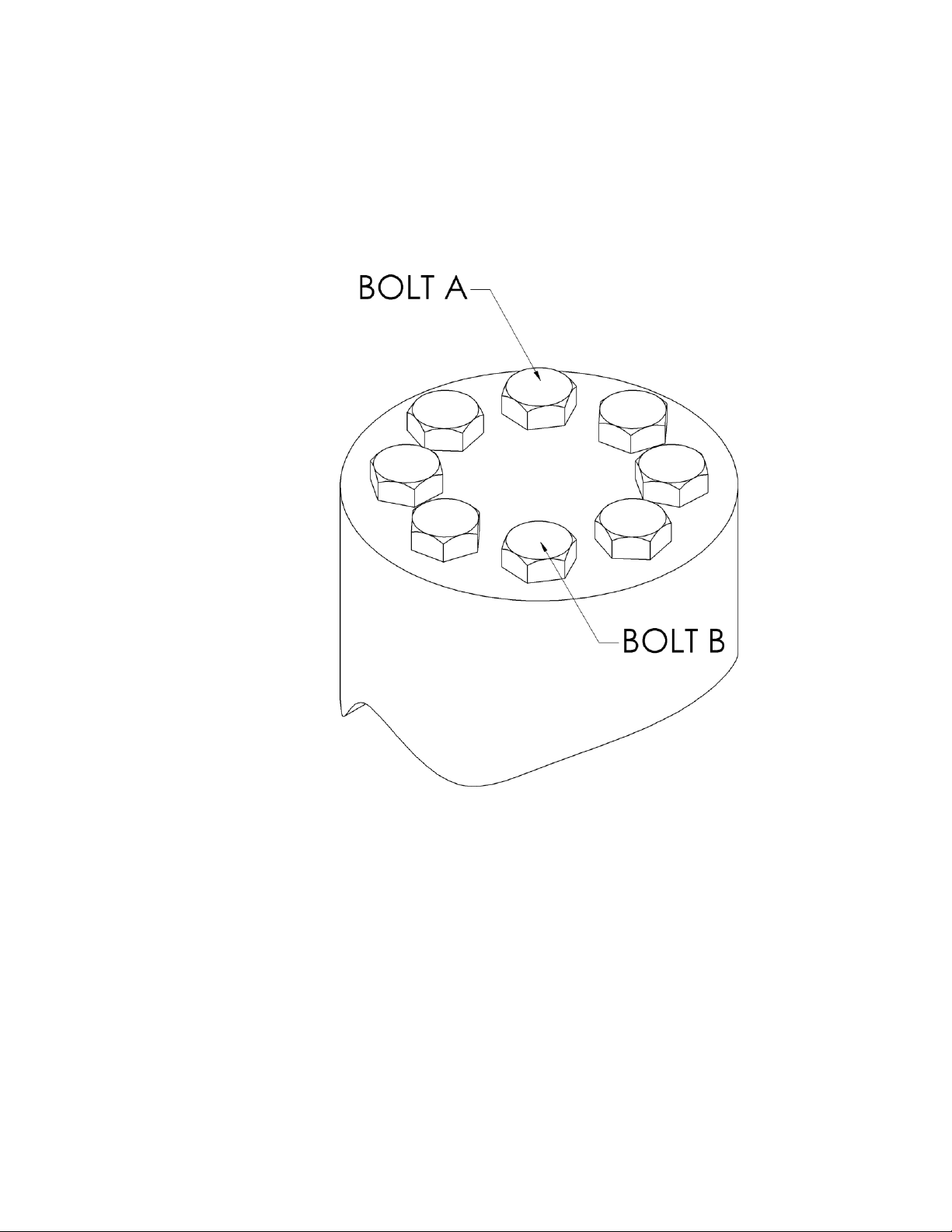

If an air impact wrench is used to tighten bolts, extreme care should

be taken to ensure the bolts are not tightened beyond their specified

torque. The following steps describe how to tighten and torque bolts

or socket head cap screws in a bolt circle.

1.

Tighten (but do not torque) bolt “A” until snug.

2.

Go to the opposite side of the bolt circle and tighten bolt “B” until

equally snug.

3.

Crisscross around the bolt circle and tighten the remaining bolts.

4.

Use a torque wrench to apply the specified torque to bolt “A”.

5.

Using the same sequence, crisscross around the bolt circle and

apply an equal torque to the remaining bolts.

8

Planetary Final Drive Service Manual

Lubrication Information

General Properties: The lubricant used in most Torque-Hub® drives should be petroleum

based gear fluid containing anti-oxidation, anti-foaming and extreme

pressure additives. The lubricant should have a minimum viscosity

index of 95 cst and maintain a minimum viscosity of 40 cst under

normal operating conditions. Some applications require special

considerations; consult the machine manufacturer and Fairfield for

more additional information.

The table below lists the recommended viscosities for various

ambient operating temperatures. These recommendations are

based on temperature rise of 50°to 100°F at normal operating

conditions.

Differential Planetary Simple Planetary

Ambient

Temperature

ISO Index

AGMA

Lubricate

Number

ISO Index

AGMA

Lubricate

Number

-40°to -5°F

(1)

VG100

3EP

VG100

3EP

-5°to 40°F

VG150

4EP

VG100

3EP

40°to105°F

VG220/VG320

5EP/6EP

VG150/VG220

4EP/5EP

105°to 150°F

(2)

VG460

7EP

VG320

6EP

Footnotes

1. For operation in this ambient temperature range, synthetic oil is recommended with a pour point of

10°F lower than the minimum ambient temperature.

2. For operation in this ambient temperature range, synthetic oil is recommended for proper lubricant

life at elevated temperatures.

Continued on Next Page

9

Maintenance Oil amounts for each series of Torque-Hub® drives are indicated in

the appropriate series literature. An initial oil change should be

made after the first 50 hours of operation. Subsequent oil changes

should be made at 1,000 hour intervals or annually, whichever

comes first.

Oil temperatures should be not higher than 160°to 180°F for

continuous operation, and no higher than 200°F for intermittent

operation. For special applications, high horsepower, high speeds

or wide temperature changes, please consult Fairfield.

Oil Fill Level When the Torque-Hub® unit is mounted horizontally, unless

otherwise specified, the gearbox should be filled half-full of oil.

Consult the appropriate series literature for approximate fill

volumes. Vertically mounted Torque-Hub® units may require special

lubrication procedures. Please contact Fairfield for vertically

mounted applications.

10

THIS PAGE

INTENTIONALLY

LEFT BLANK

11

DISASSEMBLY

12

Planetary Final Drive Service Manual

Main Disassembly

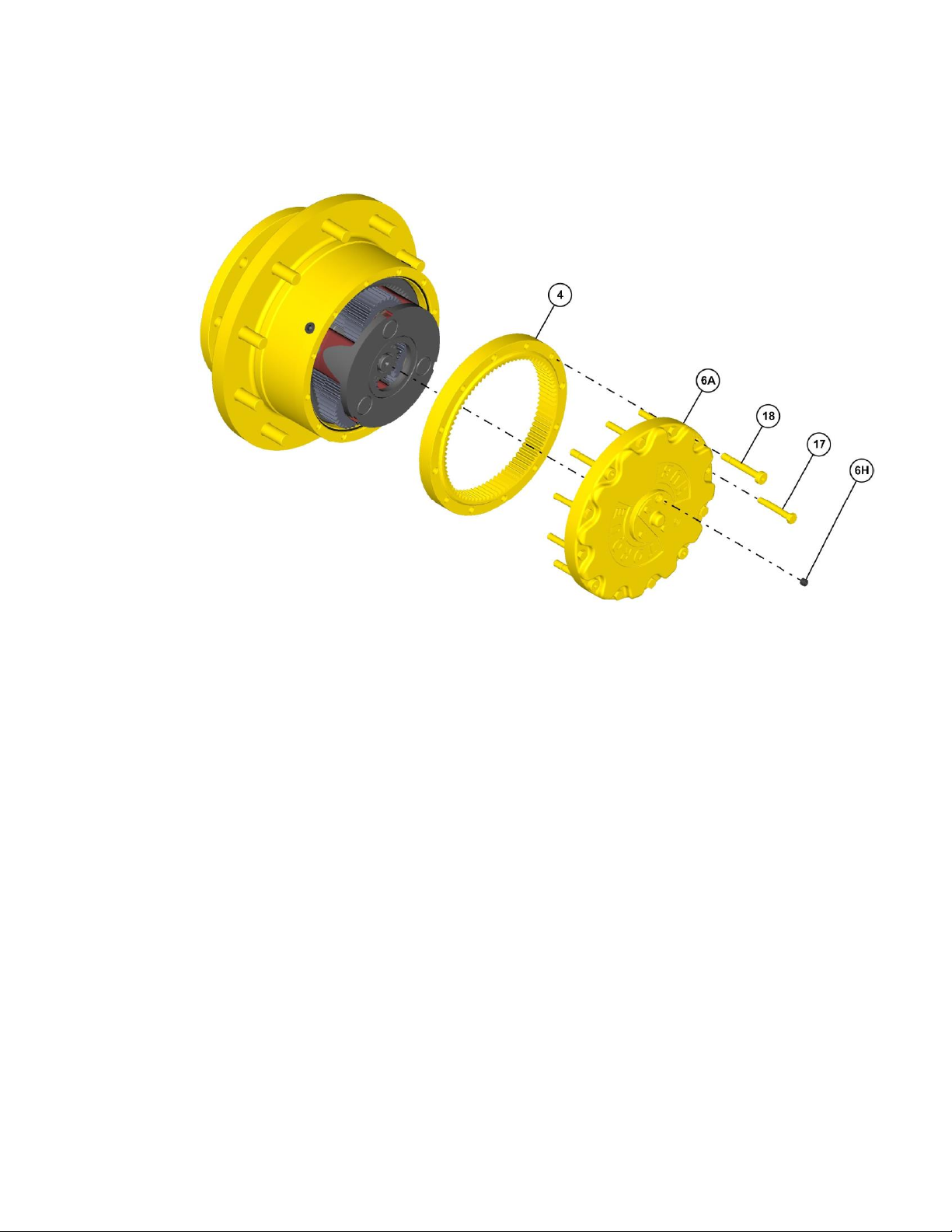

1.

Perform roll check and leak check prior to disassembling the unit.

2.

Remove the magnetic Pipe Plug (6H) from Cover Plate (6A) and drain the oil out of the

gearbox.

NOTE: Record the condition and volume of the oil.

3.

Remove eight of Bolts (17) followed by four of Bolts (18) from Cover Subassembly.

4.

Lift the Cover Subassembly off of the unit.

5.

Lift Ring Gear (4) off the unit.

Continued on Next Page

13

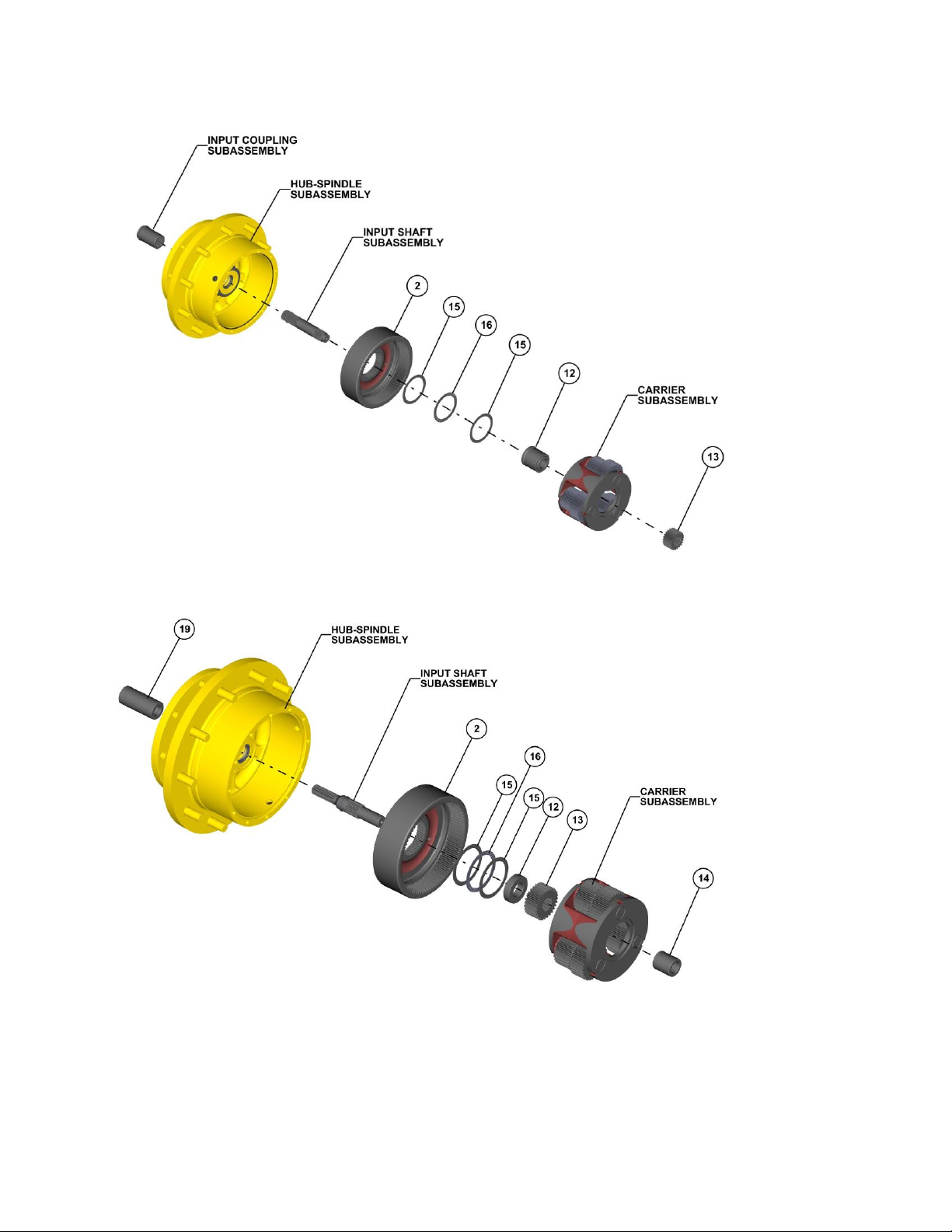

NOTE: Figure 1 refers to 30, 35, 50, 64 & 73 : 1 Ratios

NOTE: Figure 2 refers to 18, 24, 31 & 43 : 1 Ratios

Continued on Next Page

14

6.

If applicable remove Spacer (14) from the Input Shaft (11)

7.

Remove the Sun Gear (13).

8.

Lift out the Carrier Subassembly from the unit.

9.

Remove the Input Spacer (12) from the unit.

10.

Remove two Thrust Spacers (15) and Thrust Bearing (16) from the Internal Gear (2).

11.

Remove Internal Gear (2).from the unit.

12.

Remove Input Shaft Subassembly from the Hub Spindle Subassembly.

13.

Take out Input Coupling Subassembly of the Hub Spindle Subassembly.

This concludes the Main Disassembly.

15

Planetary Final Drive Service Manual

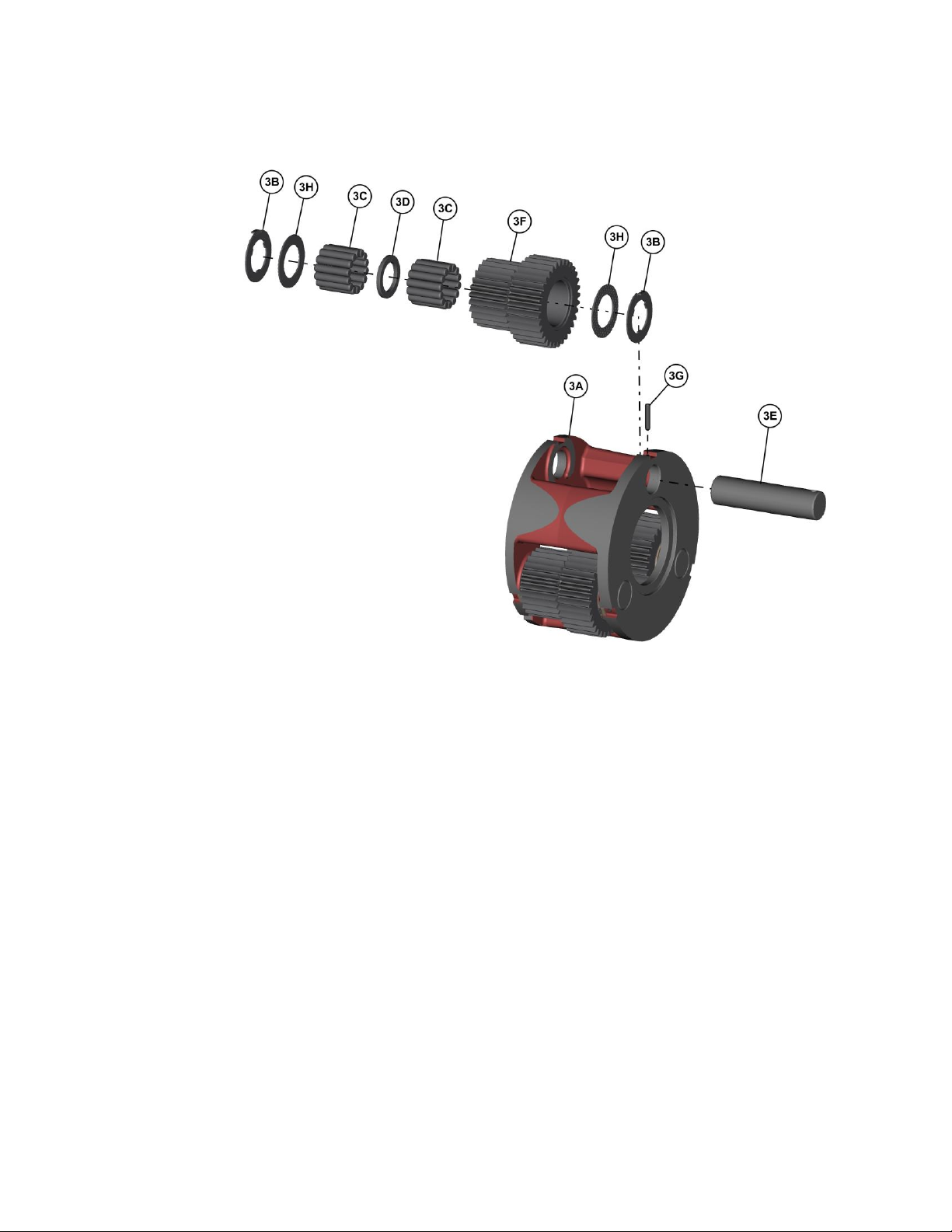

Carrier Disassembly

1.

Drive Planet Shaft (3E) out of the carrier pin holes; forcing the Roll Pin (3G) to sheer off.

2.

Hold on to the Planet Gear (3F) and push the Planet Shaft (3E) out of the Carrier (3A). The

Thrust Washers (3B and 3H) will slide off the shaft as it is removed.

3.

Using a hammer and punch, drive the Roll Pin (3G) out of the Planet Shaft (3E) and Carrier

(3A).

4.

Remove first set of Needle Bearings (3C) from the inside of the Planet Gear (3F).

5.

Remove Thrust Washer (3D) from Planet Gear (3F).

6.

Remove second set of Needle Bearings (3C) from the inside of the Planet Gear (3F).

7.

Repeat steps 1-6 for the remaining two Planet Gears (3F).

This concludes the Carrier Disassembly.

16

Planetary Final Drive Service Manual

Coupling Disassembly

CAUTION: Safety glasses must be worn during this next steps.

1.

If necessary, remove Internal Retaining Ring (20).from the groove of Coupling (19).

2.

If necessary, remove External Retaining Ring (21) from the groove of Coupling (19).

This concludes the Coupling Disassembly.

17

Planetary Final Drive Service Manual

Input Shaft Disassembly

CAUTION: Safety glasses must be worn during this next steps.

1. If necessary, remove External Retaining Ring (10) from the groove of the Input Shaft (11).

This concludes the Input Shaft Disassembly.

Loading...

Loading...