DANA Spicer Torque-Hub C017A1 Service Manual

Rev. 6/6/16

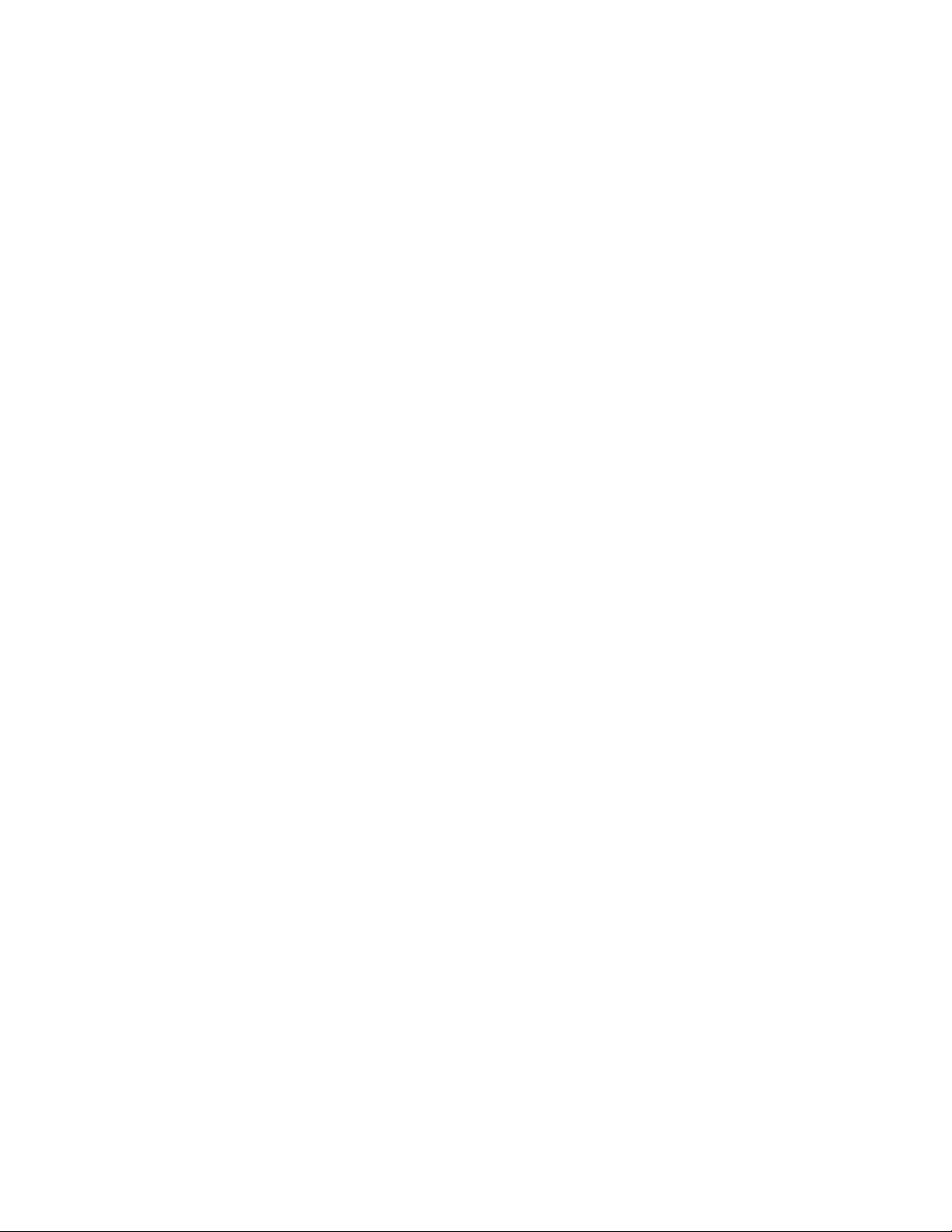

Torque-Hub® Planetary Final Drive

C017A1 Service Manual

2

Fairfield Manufacturing Co. Inc., Lafayette, IN, is now a part of Dana Incorporated

While every precaution has been taken in the preparation of this document, Fairfield Manufacturing Co. Inc.

assumes no liability with respect to the use of the documentation described herein, or for any act or omission

of Fairfield Manufacturing Co. Inc. concerning this documentation. Torque-Hub® is a registered trademark

of Fairfield Manufacturing Co. Inc.

Features and specifications are subject to change without notice.

3

Planetary Final Drive Service Manual

Table of Contents

Introduction.................................................................................................................................................... 4

Park Brake Test ............................................................................................................................................ 5

Service Brake Test ........................................................................................................................................ 6

Roll and Leak Test ........................................................................................................................................ 7

Tightening and Torquing Bolts ...................................................................................................................... 9

Lubrication Information ................................................................................................................................ 10

Park Brake Disassembly ............................................................................................................................. 12

Main Disassembly ....................................................................................................................................... 13

Service Brake Disassembly ........................................................................................................................ 16

Cover Disassembly ..................................................................................................................................... 18

Input Carrier Disassembly ........................................................................................................................... 19

Input Carrier Subassembly.......................................................................................................................... 22

Cover Subassembly .................................................................................................................................... 23

Main Assembly ............................................................................................................................................ 24

Service Brake Subassembly ....................................................................................................................... 25

Park Brake Subassembly ............................................................................................................................ 31

Assembly Drawing....................................................................................................................................... 32

Parts List ..................................................................................................................................................... 33

Service Kits ................................................................................................................................................. 34

Assembly Tools ........................................................................................................................................... 35

Contact Information ..................................................................................................................................... 43

4

Introduction

This manual is a step-by-step guide to the disassembly and assembly

of the specific Torque-Hub® family of units shown on the cover. It is

designed for the customer or mechanic who is repairing this particular

Torque-Hub® model.

Users of this manual should note that each part mentioned is followed

by an identification number enclosed in parentheses. These part

numbers may be referred to in the Parts List and Assembly Drawing

sections of this manual.

Specialized tools used to assemble this unit are noted in the assembly

procedures and diagrammed in the Assembly Tools section.

Users should familiarize themselves with the procedures for brake

test, roll and leak test, as well as bolt tightening and torquing found on

the following pages before starting any repairs.

Standard safety practices should be followed during the disassembly

and assembly procedures described. Safety glasses and safety shoes

should be worn, and heavy, heat resistant gloves should be used

when handling heated components. Be especially alert when you see

the word CAUTION. This indicates that a particular operation could

cause personal injury if not performed properly or if certain safety

procedures are not followed. The word NOTE is used to bring attention

to certain procedures or helpful hints that will aid in the disassembly

and assembly process.

5

Park Brake Test

The Park Brake Test 1) Install Roll and Leak Test fixture into coupling and onto

spindle. Install an SAE J1926-1 #6 (9/16-18) O-ring fitting into

the “Park” port on the spindle.

2) Apply 25 in-lbs. torque to the input while slowly increasing the

pressure to the “Park” port on the spindle, until the brake slips.

Record the pressure. The “just release pressure” should be

between 150-181 psi. Increase the pressure to 198 psi. The

gearbox should roll freely. Increase the pressure in this port to

1500psi and hold for one minute. If the brake does not leak or

lose pressure, the unit passed the test. If the brake loses

pressure, the brake must be repaired. See procedures in this

manual for dis-assembly and assembly procedures.

Service Brake Test

The Service Brake Test 1) Install Roll and Leak Test fixture into coupling and onto spindle.

Install an SAE J1926-1 #6 (9/16-18) O-ring fitting into the “Park”

and “Service” ports on the spindle. Release the Park brake by

applying 1500 psi to this port.

2) Apply 25 in-lbs. torque to the input while slowly increasing the

pressure to the “Service” port on the spindle, until the brake stops

the hub. Increase the pressure in this port to 2,100 psi and hold

for one minute. If the brake does not leak or lose pressure, the unit

passed the test. If the brake loses pressure, the brake must be

repaired. See procedures in this manual for dis-assembly and

assembly procedures.

NOTE: FAILURE TO PERFORM THIS TEST MAY RESULT IN

DAMAGED OR INEFFECTIVE BRAKE PARTS.

6

7

Roll and Leak Test

Torque-Hub® units should always be roll and leak tested before

disassembly (if possible) and after assembly to make sure the unit’s

gears, bearings, and seals are working properly. The following

information briefly outlines what to look for when performing these

tests.

The Roll Test The purpose of the roll test is to determine if the unit’s gears are

rotating consistently, easily and properly. Install Roll and Leak Test

fixture into coupling and onto spindle. Install an SAE J1926-1 #6 (9/16-

18) O-ring fitting into the “Park” port on the spindle. Release the Park

brake by applying 1500 psi to this port. Apply constant rotational force

to the input of the gearbox. If more drag is felt in the gears only at

certain points, then the gears are not rolling consistently and easily

and should be examined for improper installation or defects. Some

gear packages roll with more difficulty than others. Do not be

concerned if the gears in the unit seem to roll hard as long as they roll

with consistency. Rotate the gearbox both clockwise and

counterclockwise six revolutions.

Model Code

Roll Test Tool

C017A1

T-226231

8

The Leak Test The purpose of a leak test is to make sure the unit is airtight. To

perform a leak test use the leak test fixture from the table below. If the

tool is not available, the gearbox must be sealed to perform the test.

This can be accomplished by replacing one of the oil plugs in the cover

with an air chuck. DO NOT EXCEED 10 PSI PRESSURE DURING

THE LEAK TEST. Higher pressure will create a false sealing effect in

assemblies with lip-seals. The unit has a leak if the pressure gauge

reading on your leak check fitting starts to fall after the gearbox has

been pressurized and allowed to equalize. Leaks will most likely occur

at the pipe plugs, the main seal or wherever O-rings or gaskets are

located. The exact location of a leak can usually be detected by

brushing a soap and water solution around the main seal and where

the O-rings or gaskets meet on the exterior of the unit and then

checking for air bubbles. If a leak is detected in a seal, O-ring, or

gasket, the part must be replaced and the unit rechecked. Leak test at

10 psi for 20 minutes. If the assembly has brakes do not plug any of

the brake ports as this may be an alternate leak path. Also if the

assembly does not have a brake that port needs to be sealed as there

are not brake seals.

Model Code

Leak Test Tool

C017A1

T-226231

9

Tightening and Torquing Bolts

If an air impact wrench is used to tighten bolts, extreme care should

be taken to ensure the bolts are not tightened beyond their specified

torque. The following steps describe how to tighten and torque bolts

or socket head cap screws in a bolt circle.

1)

Tighten (but do not torque) bolt “A” until snug.

2)

Go to the opposite side of the bolt circle and tighten bolt “B” until

equally snug.

3)

Crisscross around the bolt circle and tighten the remaining bolts.

4)

Use a torque wrench to apply the specified torque to bolt “A”.

5)

Using the same sequence, crisscross around the bolt circle and

apply an equal torque to the remaining bolts.

10

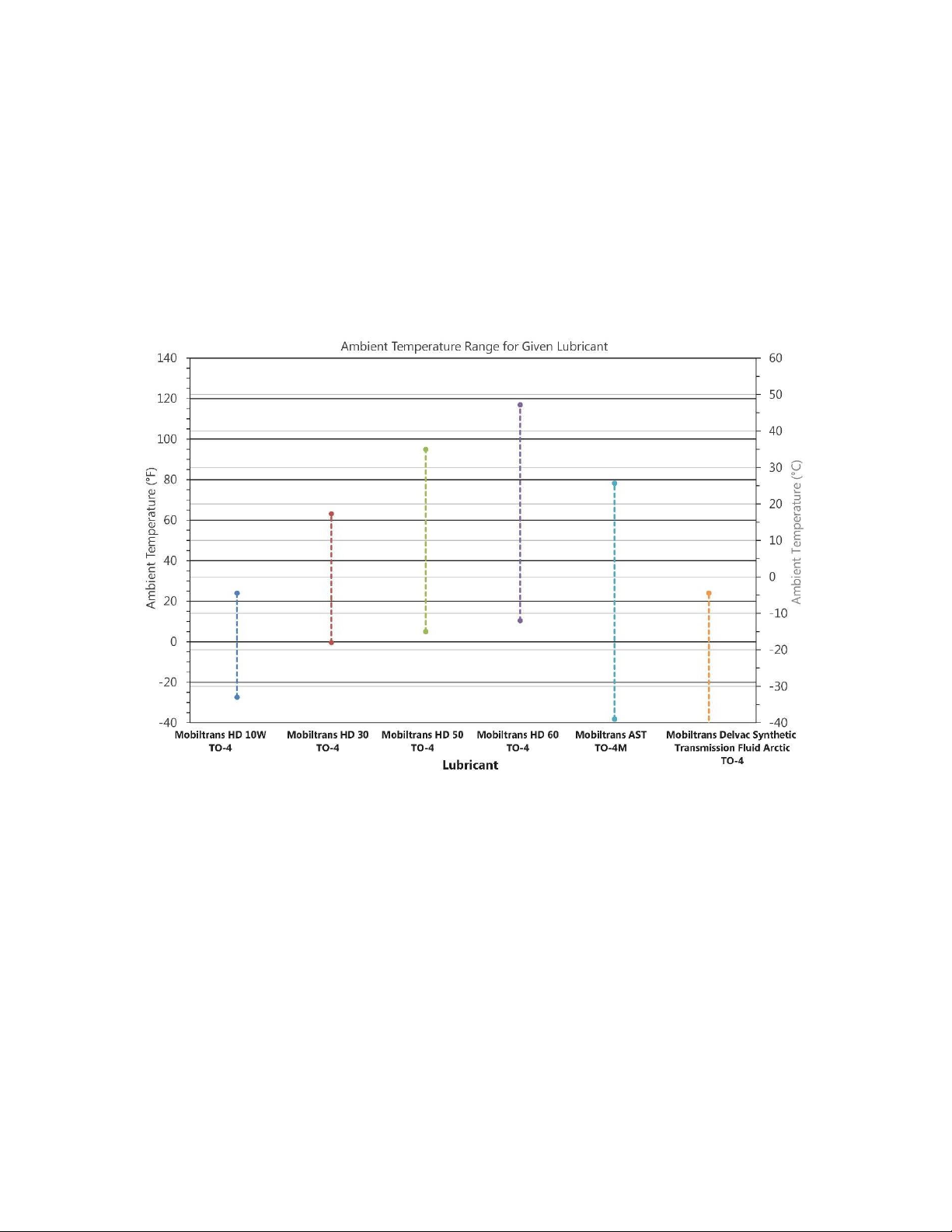

Lubrication Information

General Properties The lubricant used in most Torque-Hub® drives should be petroleum

based gear fluid containing anti-oxidation, anti-foaming and extreme

pressure additives. The lubricant should have a minimum viscosity

index of 95 cst and maintain a minimum viscosity of 40 cst under

normal operating conditions. Some applications require special

considerations; consult the machine manufacturer and Fairfield for

more additional information.

The table below lists the recommended lubricants for various ambient

operating temperatures. Contact Fairfield for other options.

Maintenance An initial oil change should be made after the first 50 hours of

operation. Subsequent oil changes should be made at 1,000 hour

intervals or annually, whichever comes first.

Oil temperatures should be not higher than 200°F for continuous

operation, and no higher than 225°F for intermittent operation. For

special applications, high horsepower, high speeds or wide

temperature changes, please consult Fairfield.

Oil Fill Level When the Torque-Hub® unit is mounted horizontally, unless otherwise

specified, the gearbox should be filled with oil to the “fill-line”, which is

below center, or approximately 50 oz. (1479 cc) with brakes, and 56

oz. (21656 cc) without brakes. Actual oil volume will vary with motor

make and model. Vertically mounted Torque-Hub® units may require

special lubrication procedures. Please contact Fairfield for vertically

mounted applications.

11

DISASSEMBLY

12

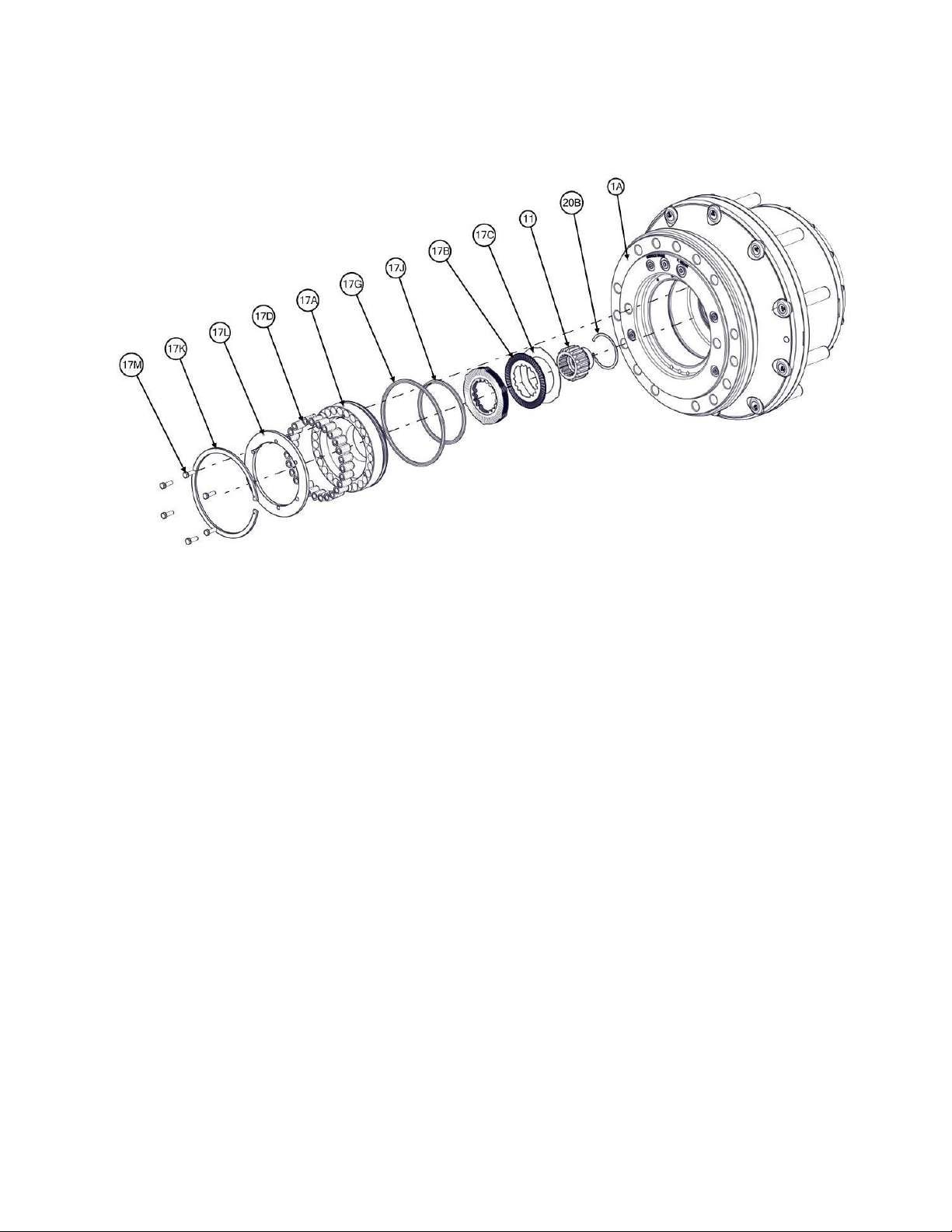

Park Brake Disassembly

1)

Place the gearbox flange up on the bench. Install M6-1.0x20 Bolts (17M) thru the Pressure Plate (17L)

into the Piston (17A). Tighten the bolts evenly to compress the Brake Springs (17D).

2)

Carefully remove the Retaining Ring (17K). Remove the Piston (17A), this may be done by applying

low air pressure to the “PARK” pressure port on the Spindle (1A).

3)

Remove the Quad-rings (17G) and (17J) from the grooves in the Spindle (1A) bore.

4)

Remove the Brake Stators (17C) and Brake Rotors (17B).

5)

Remove the M6-1.0x20 Bolts (17M) from the Piston (17A) slowly and evenly to relieve the spring

pressure. Remove the Pressure Plate (17L) and Springs (17D).

6)

Remove the Coupling (11) with the Retaining Rings (20B) and (20C).

This concludes the Brake Disassembly.

13

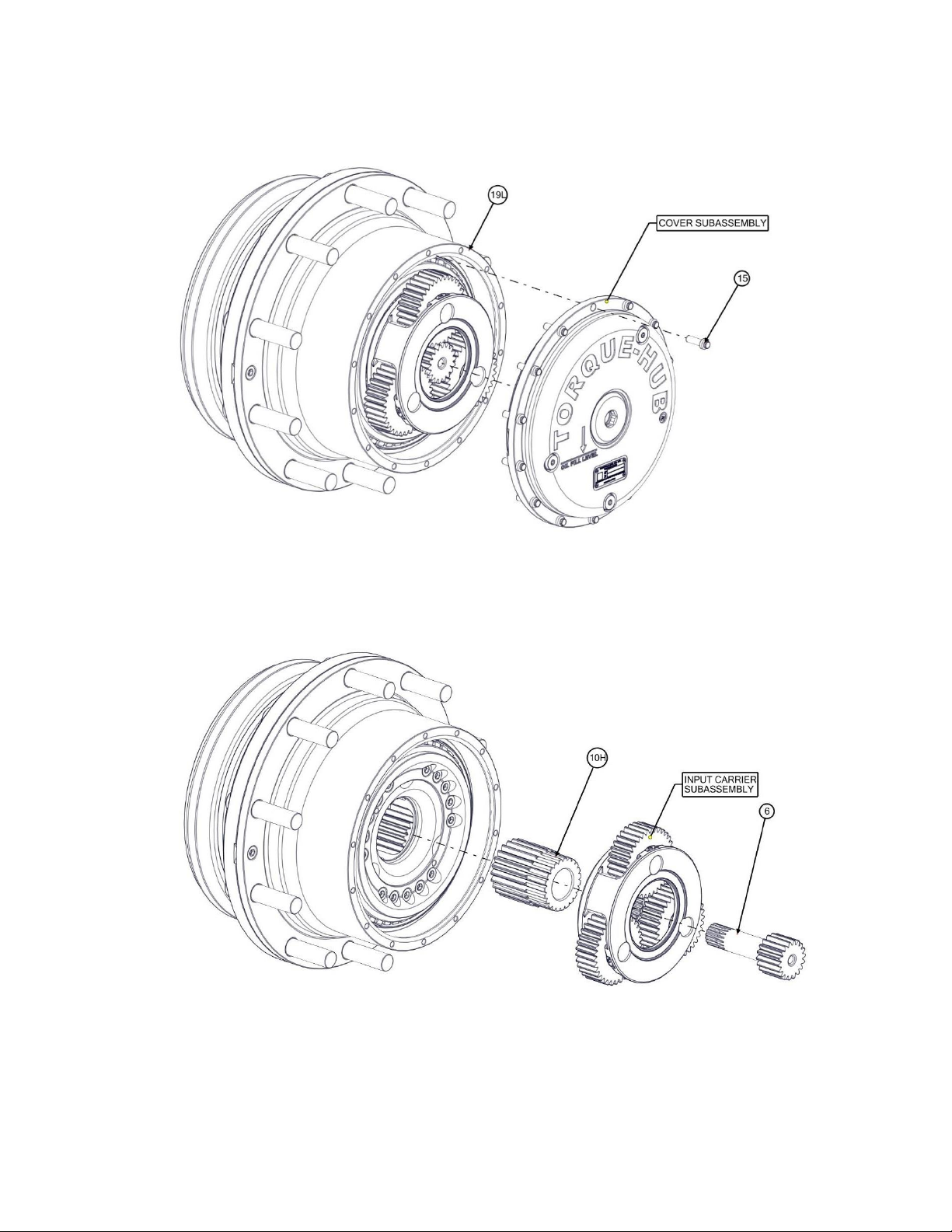

Main Disassembly

1)

Remove Oil Plugs (6H) and drain the oil. Notice the condition of the oil and the volume.

2)

Remove the Bolts (15) from the housing.

3)

Remove the Sun Gear (6).

4)

Remove the Input Carrier Sub-Assembly.

5)

Remove the Sun Gear (10H).

Continued on Next Page

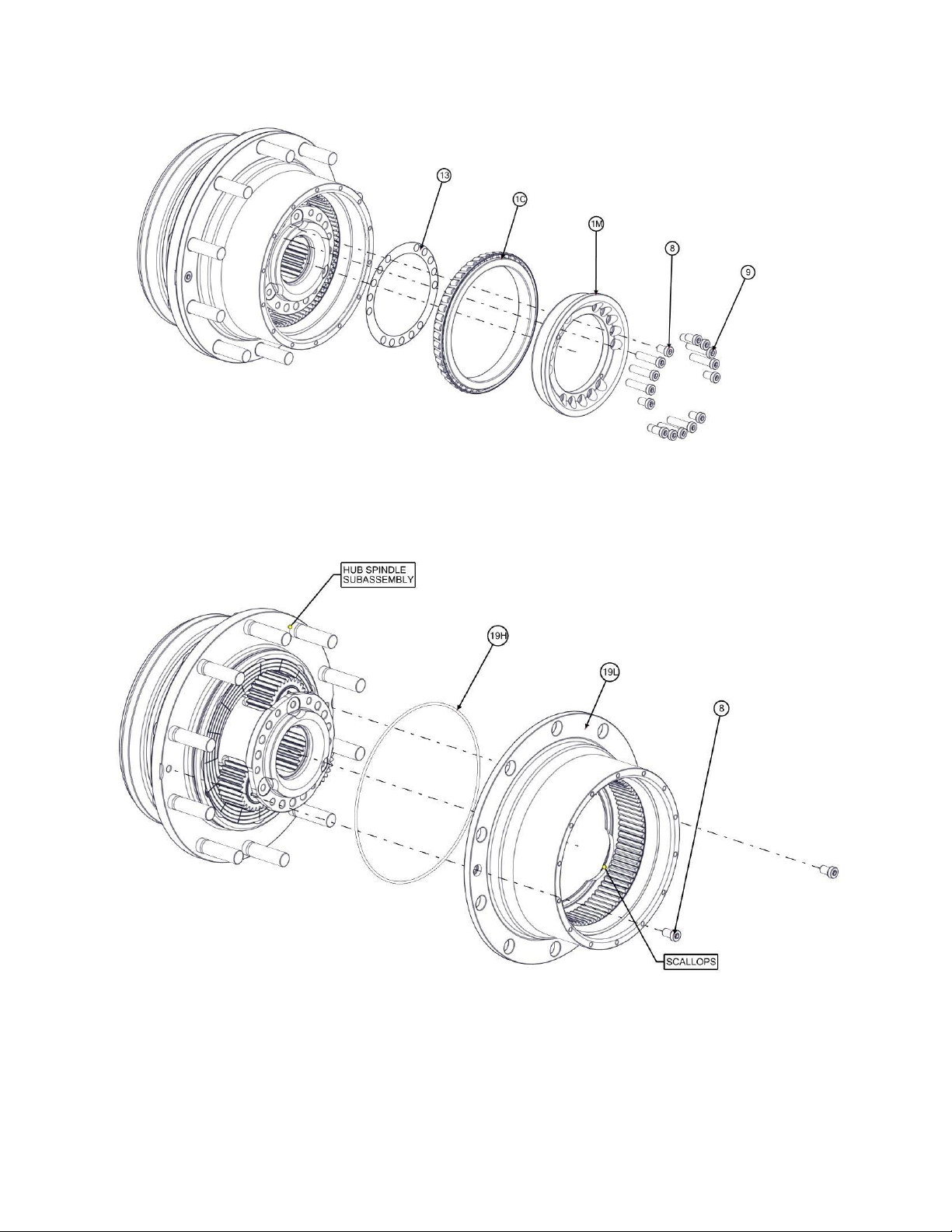

14

6)

Remove Socket Head Bolts (8) and (9). There are two different lengths.

7)

Remove the Bearing Carrier (1M) with the Bearing Cone (1C).

8)

Remove the Shims (13) from the Spindle (1A). Note: the shims can be very sharp.

9)

Remove the Socket Head Screws (8).

10)

Note: The Ring Gear (19L) will need to be rotated to line up the scallops in the brake flange with

the Planet Gears then remove the Ring Gear.

11)

Remove and discard the O-ring (19H) from the groove in the Housing (1G).

Continued on Next Page

Loading...

Loading...