DANA Spicer Drive Axles Service Manual

Spicer

®

Drive Axles

Service Manual

AXSM0029

September 2007

General Information

General Information

The description, testing procedures, and specifications contained in this service publication were current at the time of printing.

Dana reserves the right to discontinue or modify its models and/or procedures and to change specifications at any time without

notice and without incurring obligation.

The recommendations of the vehicle manufacturer should be considered as the primary source of service information regarding

this Spicer product. This manual is intended to be used as a supplement to such information.

Any reference to brand names in this publication is made simply as an example of the types of tools and materials recommended

for use and, as such, should not be considered as an endorsement. Equivalents, if available, may be used.

IMPORTANT NOTICE

This symbol is used throughout this

publication to call your attention to areas

in which carelessness or failure to follow

specific procedures may result in

personal injury and/or component

malfunction or damage.

Anyone departing from the

instructions contained in this

publication through procedures

used or choice of tools, materials

and parts may jeopardize his personal

safety and/or the safety of the vehicle user.

Always use genuine Spicer replacement parts.

WARNINGS: Used in areas

where failure to follow listed

procedures creates a high

probability of personal injury

to the servicing technician.

CAUTIONS: Used in areas

where failure to

procedures may cause personal

injury due to component

damage or subsequent malfunction.

follow listed

Table of Contents

Electric Shift System

Introduction

Electric Shift System . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mechanical Operation . . . . . . . . . . . . . . . . . . . . . . . . 2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Shift Unit Removal/Disassembly

Remove Shift Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remove Slider Block . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remove Circuit Board and Motor . . . . . . . . . . . . . . . 9

Remove Gear and Cam Pins . . . . . . . . . . . . . . . . . . 10

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sealing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shift Unit Assembly/Installation

Install Cam Pins and Gear . . . . . . . . . . . . . . . . . . . . 11

Install Slider Block. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install Shift Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Shift Unit Retrofit Kits

Retrofitting Instructions. . . . . . . . . . . . . . . . . . . . . . 16

Air Shift System

Air Shift System

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Air Shift Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Description and Operation (Shift Unit) . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Shift Unit Removal/Disassembly

Remove Shift Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Disassemble Shift Unit . . . . . . . . . . . . . . . . . . . . . . 22

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Shift Unit Assembly/Installation

Assemble Shift Unit. . . . . . . . . . . . . . . . . . . . . . . . . 24

Install Shift Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Air Shifter Valve Removal/Disassembly

Remove/Disassemble Air Shifter Valve . . . . . . . . . . 26

Inspection/Lubrication . . . . . . . . . . . . . . . . . . . . . . 26

Air Shifter Valve Assembly/Installation

Assemble/Install Air Shifter Valve . . . . . . . . . . . . . . 27

Servicing Other Electric System Components

Installation of Improved Motor Housing Cover

(Production units effective December 1989) . . . . . . 17

Speedometer Adapter . . . . . . . . . . . . . . . . . . . . . . . 18

Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Servicing Other Air System Components

Quick Release Valve . . . . . . . . . . . . . . . . . . . . . . . . 28

Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Servicing Other Air System Components

Additional Service Information . . . . . . . . . . . . . . . . 29

Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . 29

i

Introduction

Electric Shift System

The service procedures and specifications in this publication

cover the current Spicer 2-Speed Axle Shift Systems.

Maintenance and overhaul instructions for the Spicer 2-Speed

Axle carriers are covered in the publications listed on the back

cover.

This manual includes information on two types of Shift Systems currently in use for Spicer 2-Speed Axles; Electric and

Air.

Spicer 2-Speed Axles are driver-controlled by means of a shift

unit operated from the vehicle cab. These shift units are activated by air or electric power depending on the convenient

source in the chassis.

Because of this variation, this publication is divided into two

major segments: Electric Shift System for hydraulic-brake

chassis and Air Shift System for air-brake chassis.

Electrical Operation

Note: For component identification and wiring schematic,

refer to illustrations on pages 1, 2, 3, and 4.

Unit in Low Range Shifting to High Range

Current flows through upper contact

cont

acts of high-range switch, and motor to ground which

starts the motor rotating. Current also continues from common motor terminal through low-range switch and to ground

through the resistor.

When motor starts, rotation of the gear allows cam ramp to

apply pressure on low-range cam pin, which allows low range

switch to open. The path to ground (through resistor) is open

and the diode prevents speedometer adapter solenoid from

being energized.

Motor rotation continues to shift axle to high range. As shift is

completed, cam ramp of gear releases high-speed cam pin to

open high-range switch and creates an open circuit to turn off

power to motor. Motor rotation is stopped quickly by means

of dynamic braking through resistor.

of control switch, closed

If, during rotation, driver decides to switch back to low range,

continues to turn.

motor

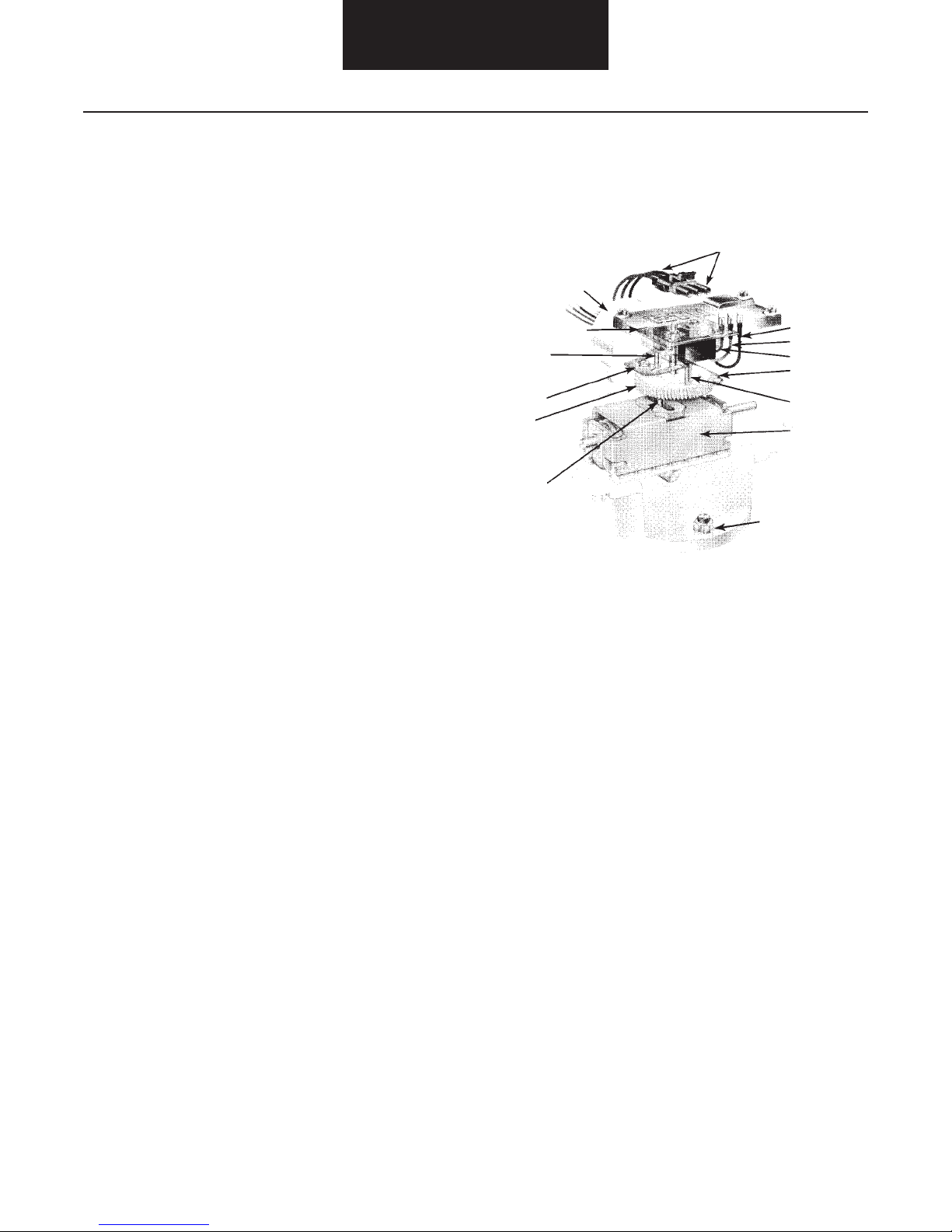

ELECTRIC SHIFT UNIT CUTAWAY

Motor

Circuit Board

Assembly

Cam Pin

(Low Range)

Switch

Spring

Gear

Gear Pin

(Eccentric)

Wiring Harness

and Connector

Black Wire

Green Wire

Red Wire

Worm Gear

Cam Pin

(High Range)

Slider

Block

Flat Washer

(0.100",

2.54 mm

thick)

Opening of high-range switch has no effect since motor is

now being powered by the circuit from control switch,

through diode and low-range switch to ground at motor. In

this instance, motor continues to turn until cam pin opens

low-range switch to turn off power to motor.

Unit in High Range Shifting to Low Range

Current flows through control switch lower contact to energize speedometer adapter solenoid and through the diode and

low-range switch to common motor terminal and ground at

motor. Motor starts rotating. Current also flows through

closed contact of high-range switch and to ground through

resistor. Once gear rotates enough to apply cam pin pressure

on the high switch, circuit to ground through resistor is open

As moto

r rotation continues to shift axle to low range, gear

rotates and releases cam pin on low-range switch to open

switch and open motor circuit. Motor power is turned off.

Once again, the resistor portion of the circuit provides braking

to stop motor quickly.

If, during motor rotation, driver decides to shift back to high

range, the motor continues to turn. Opening of low-range

switch has no effect since motor is now being powered

through control switch. In this instance, motor continues to

turn until gear rotation opens high-range switch to open

motor circuit.

.

1

The shift unit always remains synchronized with position of

driver's control switch.

Electric Shift System

Mechanical Operation

Low to High Range or High to Low Range

When shifting axle range either up or down, motor starts and

turns worm gear shaft. The gear assembly (which is meshed

with worm gear) turns and moves eccentric pin in slot area of

slider block.

Since driving torque holds shift fork and swivel block of the

slider block assembly in place, linear motion of slider block is

translated into compression of the internal spring.

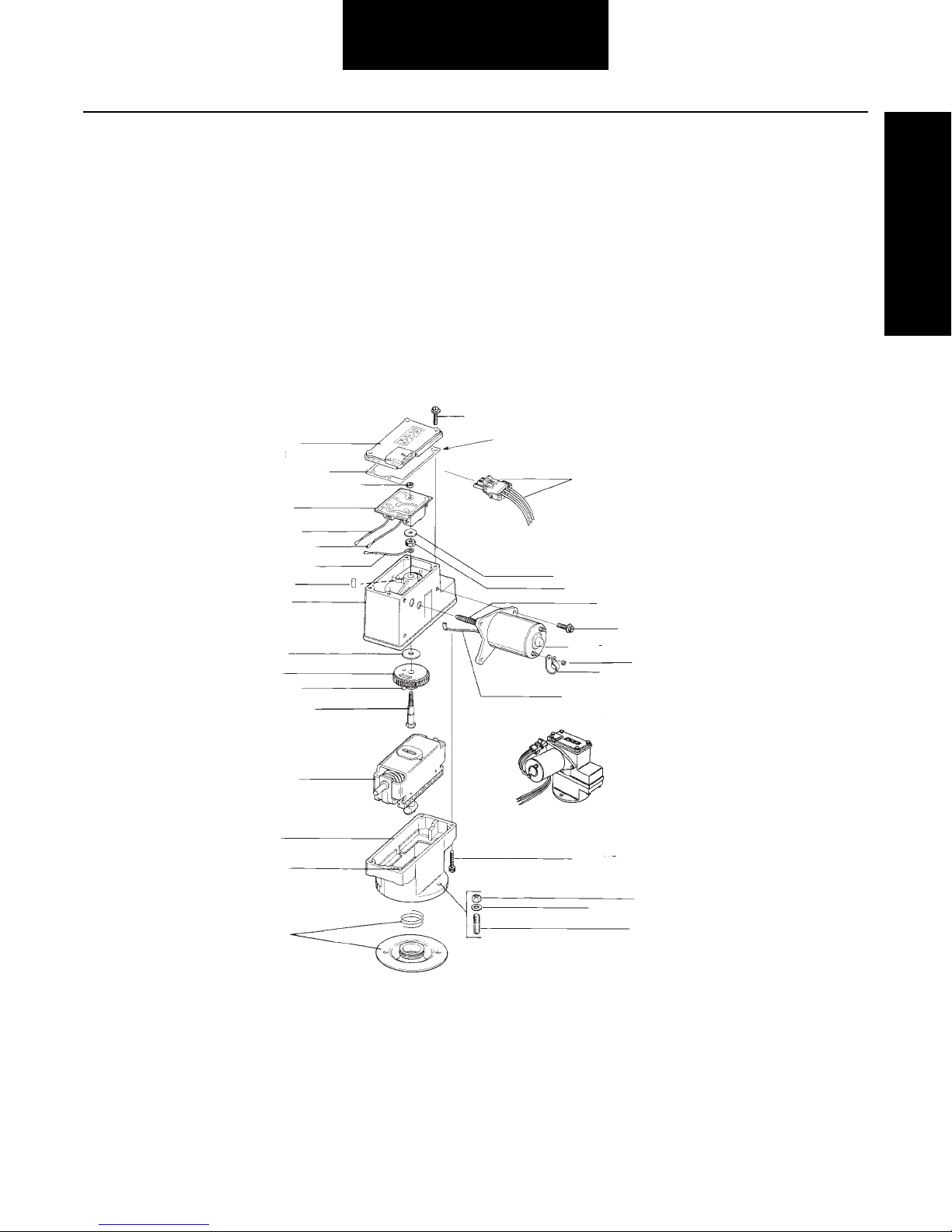

ELECTRIC SHIFT UNIT

Housing Cover

Cover Gasket

Nut (Circuit Board)

Circuit Board Assembly

Red Wire

Black Wire

Green Wire

Cam Pin

Motor Housing

Gear Washer

Gear

Gear Pin

Gear Shaft

As motor shuts off at 180º of gear rotation, a break in torque

by driver allows spring force (stored in the slider block

assembly) to move the swivel pin and shift fork in appropriate

direction for axle range change.

When opposite axle range is selected by driver, the process is

repeated by motor turning another 180º in same direction. In

this case though, eccentric pin movement creates block

spring compression in the opposite direction.

Cover Screw

Cover Gasket

(See Note below)

Wiring Harness

and Connector

Board Flat Washer

Nut (Gear Shaft)

Worm Gear

Motor Screw

Motor Assembly

Nut

Cable Clip

Motor Lead Wire

General Information

Slider Block &

Shaft Assembly

Base Housing

Dowel Pin

Seal & Spring

Note: The new improved housing cover does not require a

gasket (see page 17).

Electric Shift Unit Assembly

Housing Screw

Flat W

Nut

asher (0.100", 2.54 mm thick)

Stud

2

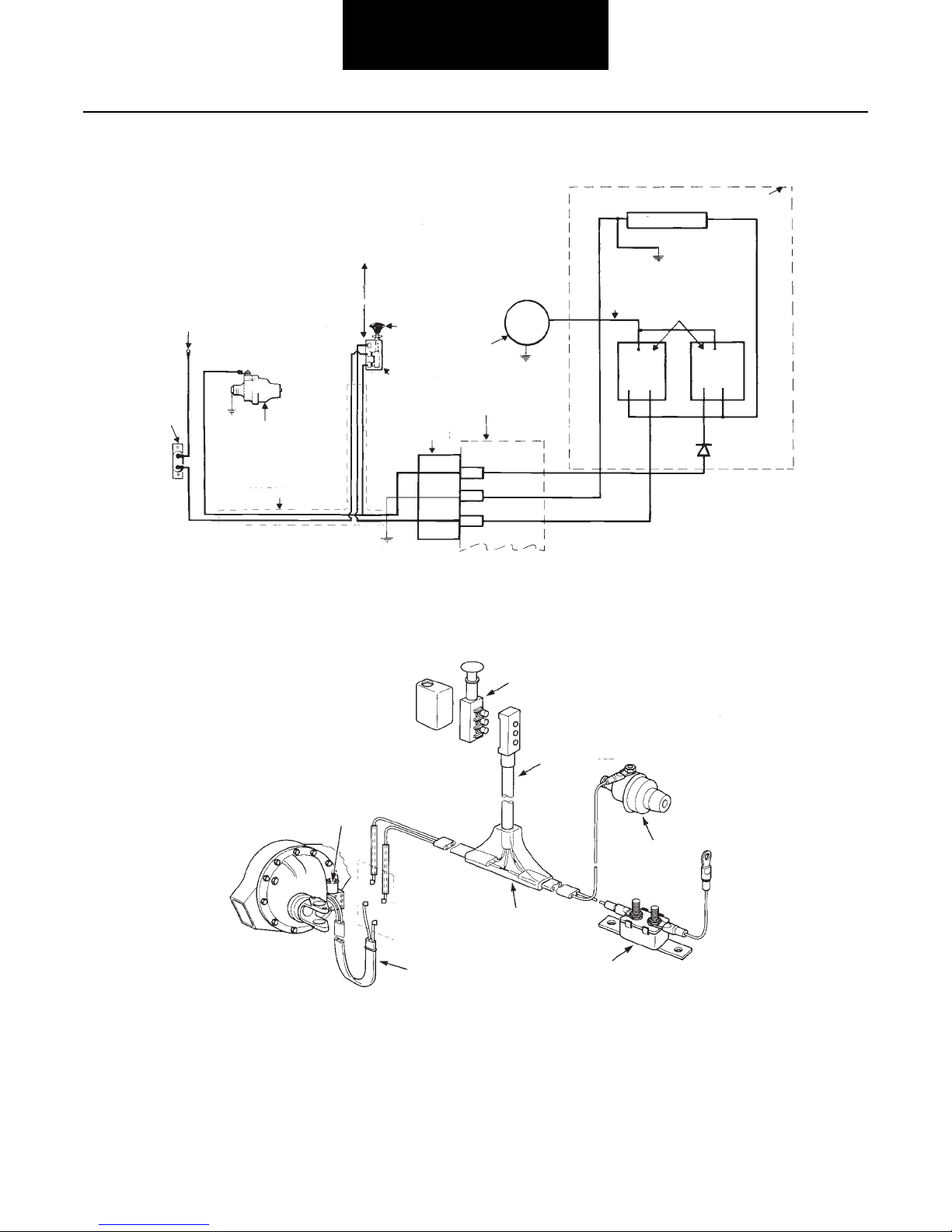

Shift System Electrical Wiring Schematic

Electric Shift System

Circuit Board

Resistor

Up-High

Power Source

(Ignition or

Accessory Switch)

Circuit

Breaker

Speedometer

Adapter

Wiring

Harness

Range

Down-Low

Range

Electrical Shift System Major Components

Switch Knob

Control Switch

Wiring

Harness

Connector

Ground

Motor

Housing

Cover

Ground

Black

Green

Red

Shift Unit Switch

Black

Ground

High

Range

NC NO

Switches

Low

Range

NO NC

Diode

Plug and Cable

Assembly

Electric

Shift Unit

Speedometer

Adapter

Front Wiring

Harness

Rear Wiring

Harness

Circuit Breaker

or Fuse

3

Electric Shift System

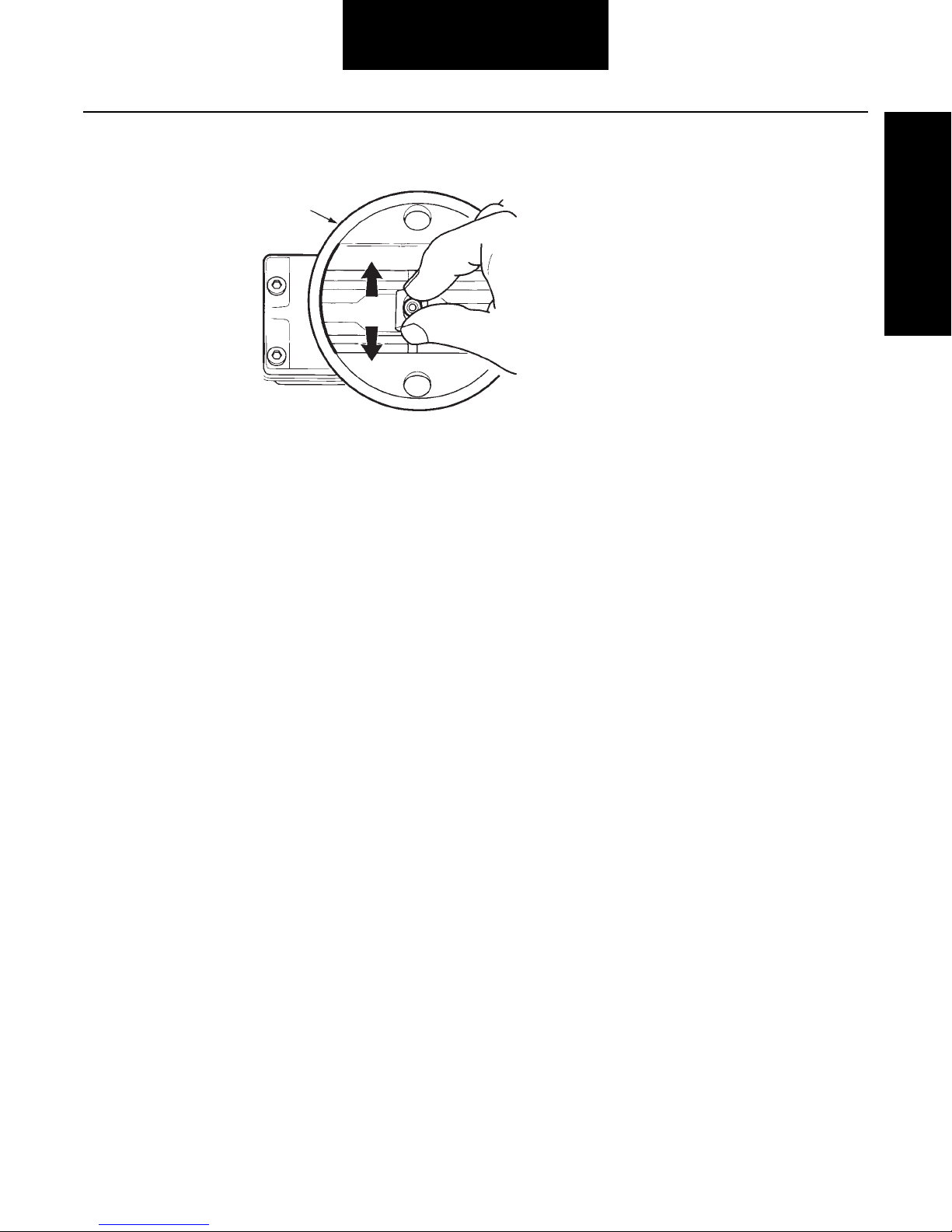

Slider Block Inspection Procedure

Bottom of

Base Housing

General Information

• Remove shift unit from axle.

• Move slider block from side to side.

Make sure slider block moves freely

in housing.

4

Electric Shift System

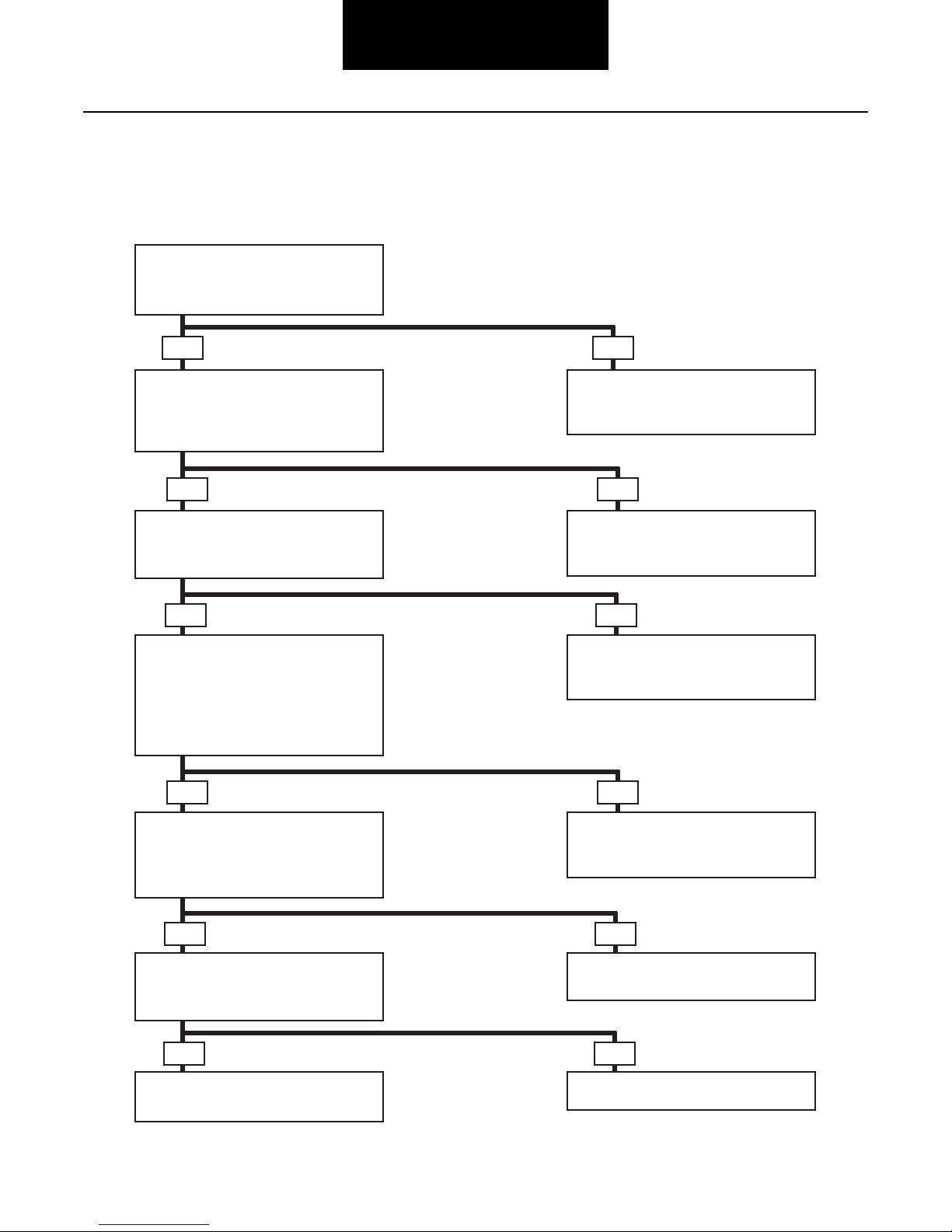

Troubleshooting

Troubleshooting Guide

This chart begins with an improperly operating shift unit. Use with illustrations on pages 3, 4 and 6 to help isolate the problem.

Follow the possible solutions as an aid to system repair.

Axle doesn’t shift ranges.

• Check the circuit breaker.

• Is the circuit breaker closed?

NoYes

Check for power at the shift unit

connector.

• Is there a voltage reading of 9V

or more?

Remove shift unit from axle and

apply voltage.

• Does unit shift properly?

Inspect slider block from bottom

of shift unit. See page 4

• Check to see if slider block is loose

or missing.

• Is slider block in good operating

condition?

Inspect appearance of shift fork

and check fit with depth card.

• Does the fork match the depth

card output? (See page 6)

• Reset circuit breaker or

replace fuse.

• Repeat troubleshooting procedure.

NoYes

• Check the battery, cab switch,

wire harness, and connectors.

• Repeat troubleshooting procedure.

NoYes

• Disassemble and service shift unit.

(See page 8)

• Repeat troubleshooting procedure.

NoYes

• Replace slider block assembly

(See page 8)

• Repeat troubleshooting procedure.

Remove and inspect axle shift parts.

• Are engagement surfaces severely

worn, chipped or broken?

Yes

• Replace worn components.

• Repeat troubleshooting procedure.

5

NoYes

• Rework or replace shift fork.

• Repeat troubleshooting procedure.

No

End of diagnostics

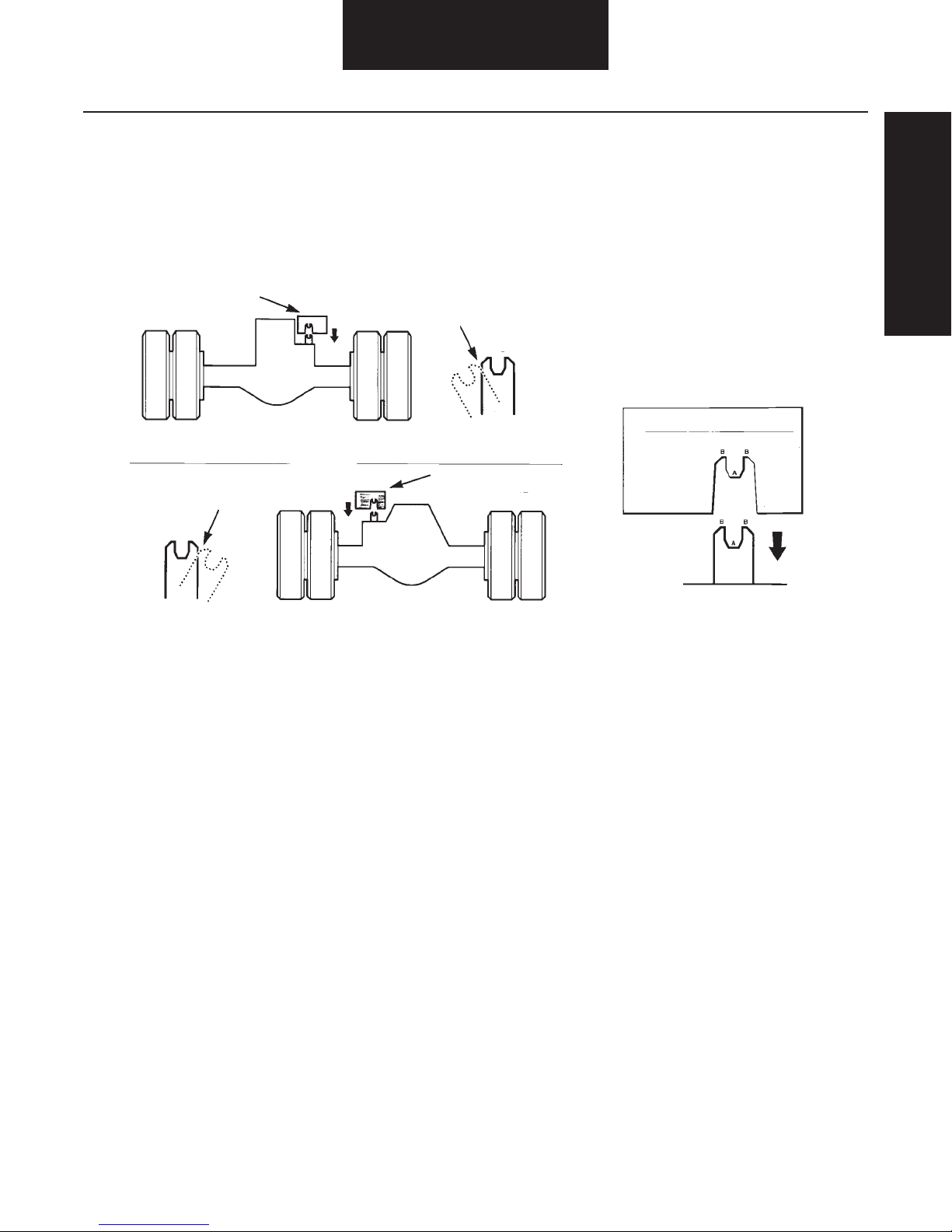

Electric Shift System

Checking Shift Fork Position and Alignment

Electric shift unit failure or shifting problems may be caused

by the shift fork binding on the slider block. Check the shift

fork position and alignment with the Shift Fork Fit-Up card.

Refer to the instructions on the card and the illustration below

to check the shift fork.

Shift Fork Fit-up Card

FORWARD-REAR AXLE

Figure 1

Shift Fork

Range Position

Lo

Hi

Shift Fork

Range Position

Shift Fork

Fit-up Card

If interference at points A and B exists, carefully grind shift

fork until it matches the fit-up card.

Shift Fork Fit-up Card

(Part No. 128039)

Lo

Hi

• Fit-up Card must set flush

on mounting surface of axle

• Shift fork must NOT touch

Fit-up Card at points A and B

2-Speed Shift Fork Fit-Up Card

Procedure:

1. Shift axle to high range so fork is

square to axle face.

2. Remove shift unit and rubber boot.

3. Drop card over shift unit as shown

in (fig. 1) until card touches carrier

surface or interferes with fork.

4. If no interference, fork is OK.

Go to step #6.

5. If card interferes at A or B, care fully grind fork to fit template.

6. Replace boot and reassemble unit.

Printed in U.S.A.

Dana service keeps

you on the road.

For technical assistance call

1-877-777-5360

anywhere in North America

Part no. 128039

10M/1290/MP

Copyright Dana 1991

All right reserved

General Information

REAR-REAR AND SINGLE AXLES

6

Parts Service Kits

Expanded Service Kits

Note: The new

and improved

housing cover

does NOT

require a

gasket

(see page 17).

Electric Shift System

SERVICE KIT NO. DESCRIPTION ITEMS INCLUDED

211319

113745

113746

113759

113753

Circuit Board and Cover Kit

Motor and Lube Kit

Drive Gear and Cam Pin Kit

Slider Block and Lube Kit

Connector and Harness Kit

1-7, 18-19

10, 18-19

5, 9, 12-14, 18

15, 18

20-26

7

Loading...

Loading...