DANA DI-100F User Manual

Inversed Fluoresence Microscope

This manual is written for Metallurgical Microscope of DI-100F ..For safety and for

exerting the best performance, making you familiar with the instrument entirely, it is

strongly recommended that you read this manual carefully before using the microscope.

DI-100F

USER MANUAL

1

Content DI-100F

Contents…………………………………………………………………… 1

User Notices………………………………………………………………… 2

1.Components Name……………………………………………………… 4

2.Assembly………………………………………………………………… 5

2.1 Installment figure……………………………………………………… 5

2.2 Installment steps…………………………………………………… 6

3.Adjustment and opertation…………………………………………… 11

3.1 Lamp adjustment for fluorescence observation ………………… 11

3.2 Lamp adjustment for biological observation……………………… 17

4Microscope photography and video…………………………………… 19

4.1Microscope Photography……………………………………………… 19

4.2 Microscope Video…………………………………………………… 20

5.Technical Specifications………………………………………………… 21

5.1 Outfit………………………………………………………………… 21

5.2 Objective Specification…………………………………………… 23

6.Troubleshooting………………………………………………………… 24

2

Notices DI-100F

Symbol

Meaning

The surface is very hot, not touch by your hands

Before using ,please read the instruction carefully, improper operation will result in

bodily injure or instruction malfunction.

The main switch on

The main switch off

Safety Note

1. The epi-fluorescent attachment is a precise instrument. Open the box carefully, and avoid

dropping the accessories to ground and causing damage to them.

2. Do keep the instrument out of direct sunlight, high temperature or humidity, dusty and

virations.

3. Make certain that the burner is installed correctly and all cords are connected firmly.

4. Do not open the lamp housing while it is turned on or for at least 10 minutes after it has

been turned off. Lamp housing parts are extremely hot and cause burns if touched.

5. Always be sure to ground (earth) the equipment.

6. Verify that the voltage and the frequency of the AC mains outlet match the setting of the

voltage switch and the frequency switch on the rear of the power supply unit.

7. Always use the power cord provided and make sure that the main switch is moved to

“O”(OFF) before connecting the power cord plug to the wall outlet.

8. To prevent any hazard, always turn the main switch on the power supply unit to “O”

(OFF), unplug the power cord plug from the mains outlet before replacing the burner or

the fuse, and wait for at least 10 minutes before replacing the burner. (Be sure to use a

GCQ-100 mercury burner.)

9. To prevent obstruction of the air flow, it is important to leave enough space around and

above the lamp housing.

Safety Symbol

3

DI-100F

Maintenance and Storage

1. Clean all glass components by wiping gently with gauze. To remove fingerprints or oil

smudges, wipe with gauze slightly moistened with a mixture of ether (70%) and

alcohol (30%).

Since solvents such as ether and alcohol are highly flammable, they must be

handled carefully. Be sure to keep these chemicals away from open flames or potential

sources of electrical sparks-for example, electrical equipment that is being switched on

or off. Also remember to always use these chemicals only in a well-ventilated room.

2. Do not attempt to use organic solvents to clean the non-optical component of the

equipment. To clean these, use a lint-free, soft cloth lightly moistened with a diluted

neutral detergent.

3. Do not disassemble any part of the power supply unit as malfunction or damage may

occur.

4. In order not to impair the safety of the equipment, replace the burner when the counter of

NFP-1 indicates “100.00” hours. To prevent any hazard, always turn the main switch on the

power supply unit to “O” (OFF), unplug the power cord plug from the mains outlet, and

wait for at least 10 minutes before replacing the burner. High-pressure gas is sealed within

the mercury burner. Thus, if it is continued to be used after its service life expectancy, the

glass tube may deform and may sometimes rupture.

4

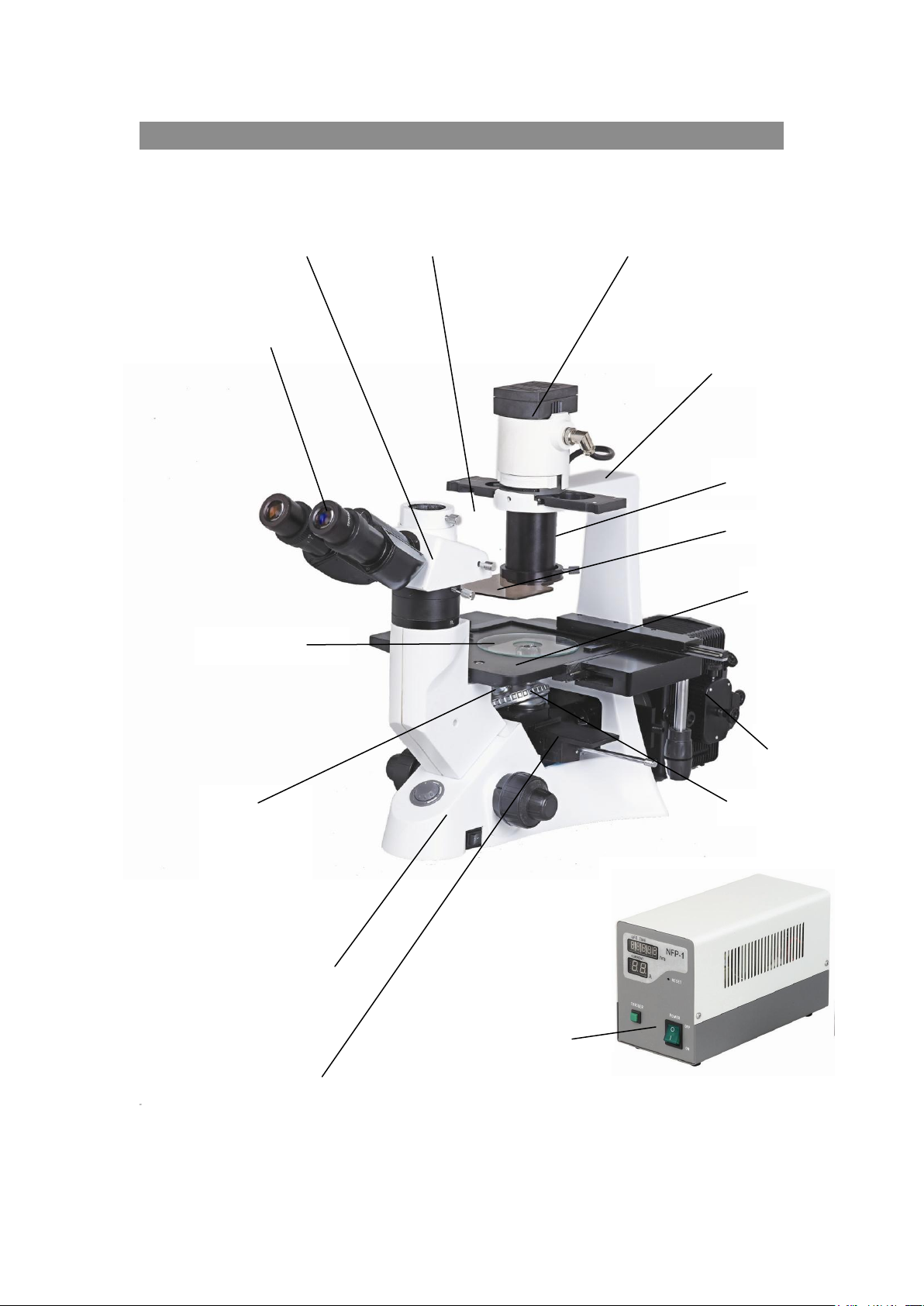

1.Components name DI-100F

Condenser

Illumination bracket

eyepiece

Stage inserted plate

Stage

Body

nosepiece

Objectives

。 4×

。 10×

。 20×

。 40×

NFP-1 Fluorescence power supplier

Protection barrier

B excitation G excitation

l

DI-100F inverted fluorescence microscope

Trinocular tube head Phase contrast slider Lamp

reflected fluorescence units

5

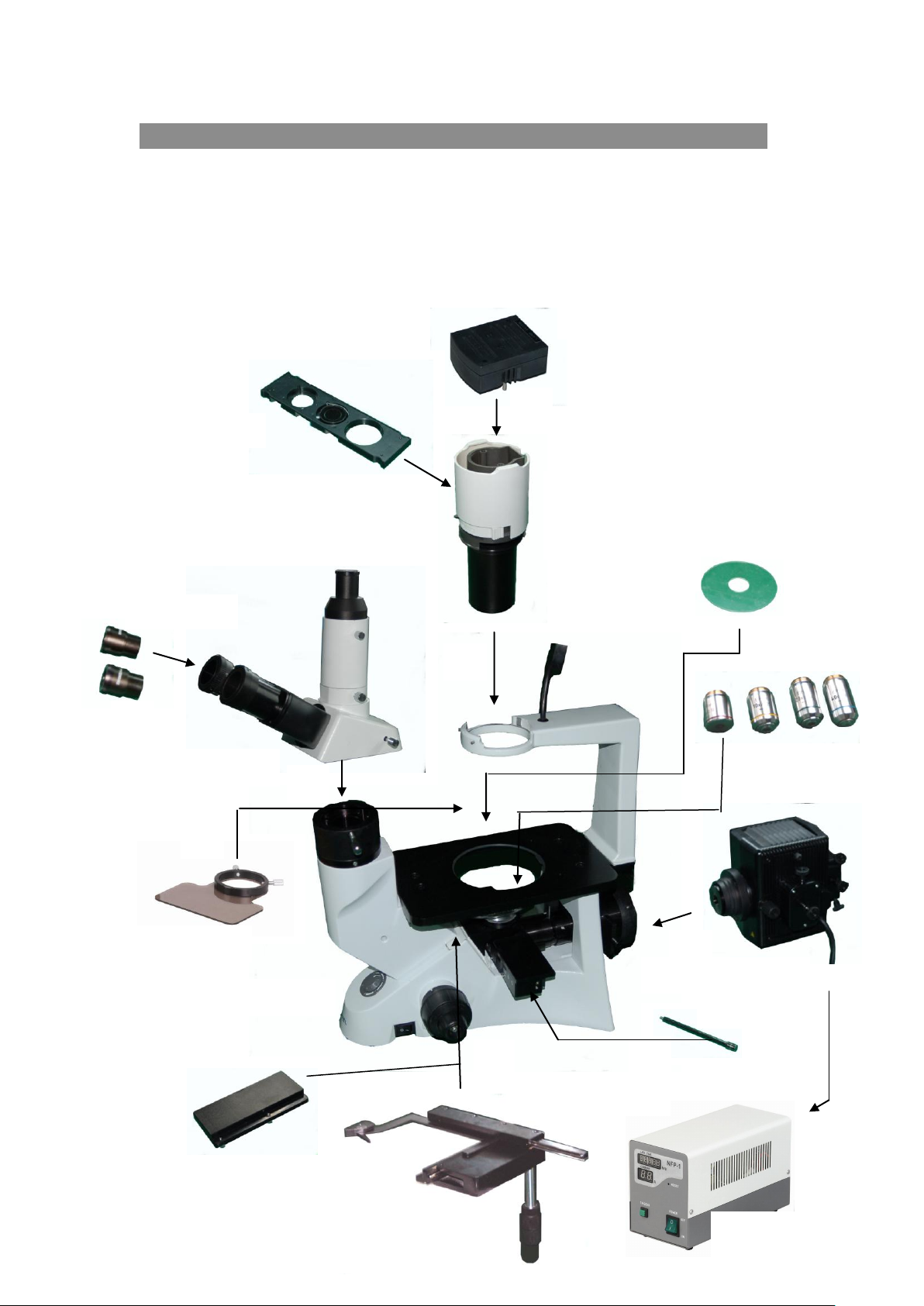

2Installation DI-100

① ② ④

③

⑤ ⑥ ⑦

⑧

Condenser

illumination unit

Phase contrast slider

Lamp house

Eyepiece

Trinocular tube

Objectives

Glass stage

Power supply unit

Mechanical ruler

Body Stand

Stage lengthen splint

⑨

Power supply

⑩

⑾

⑿

Lever

Protection barrier

2.1 Installing diagram

The following figure shows the installation sequence of the components. The number in the

figure shows the installation steps.

Before installing, be sure every components is clean, do not score any parts or glass surface.

Keep well with the supplied hexagon wrench. When changing the components, you will need it again。

6

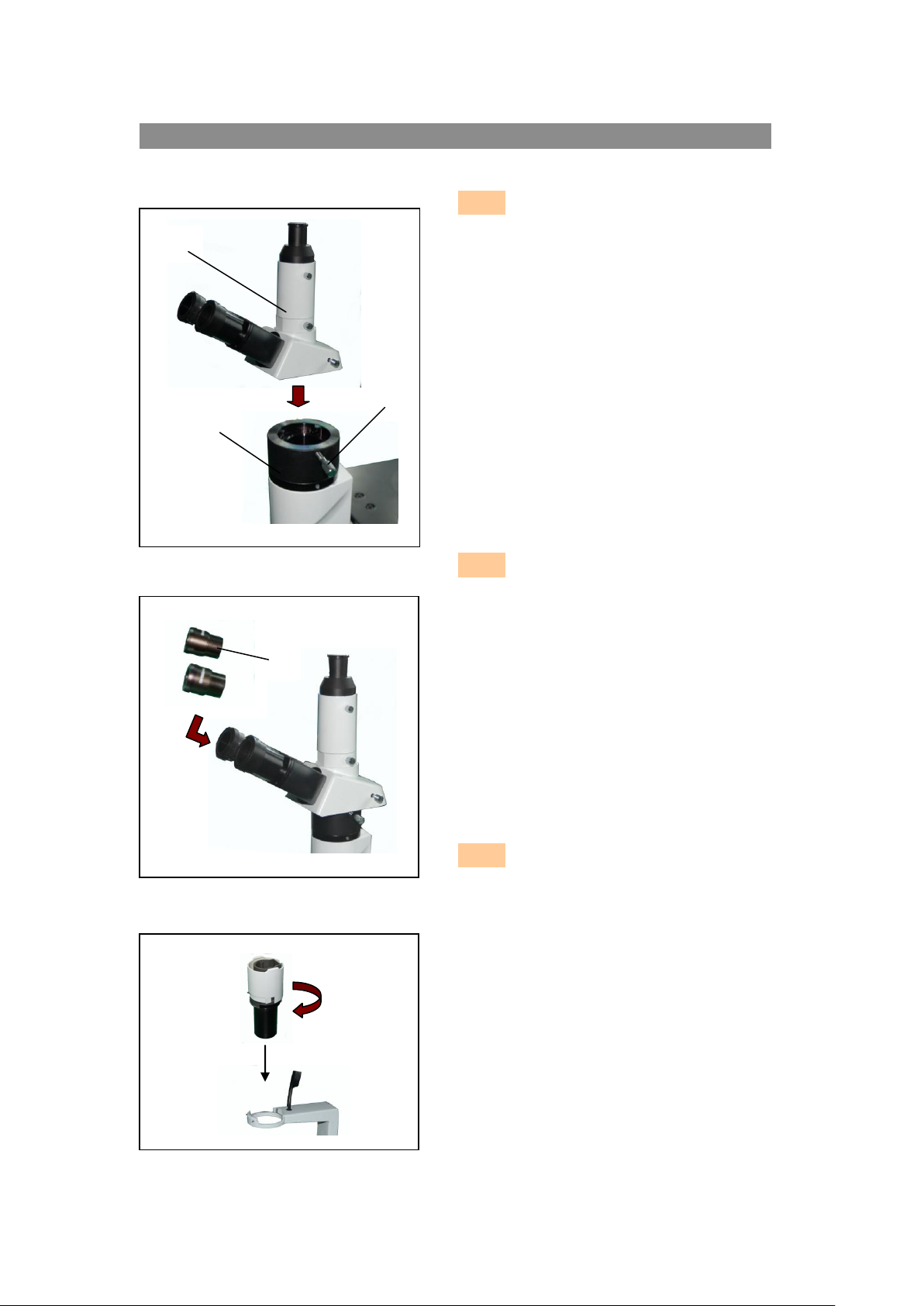

2.2 Installment steps DI-100F

2.2.1 Installing trinocular

head(fig 1)

Loosen the setscrew ② and insert the

trinocular Viewing Head ① into the body

correctly , screw down with bolt③.

2.2.2 Installing eyepiece(fig 2)

Insert the eyepiece④ into tube until they

are against.

2.2.3 Installing condenser

set(fig3)

Install the condenser into the right

direction(fig3)。

图 1

Fig 2

②

①

③

④

Fig 3

7

DI-100F

Fig 4

A

2.2.4 Installing lamp house(fig4、fig5)

Insert the plug A into hole A of power cord. then

insert theplug B into the B hole of the condenser

till there are against. (Fig 6)。

2.2.5 Installing phase contrast

plate(fig6、fig7)

1. Keep the slider① face ( the surface which had

character) up towards,。 Every light ring or opening

has its own located position, so you need to move

them until you heard the “clicked” to ensure the ring

or the opening reache the center of the light

path(show as fig 7)。

2. Turn the aperture diaphragm lever ① to

adjust aperture。Turn the diaphragm to a big

aperture when do phase contrast observation。

● The light ring was centered beforehand, so

it needn’t to adjust in the use process.

If the ring is not in the center, you could

adjust by the centering bolt.

● The 10X/20X light ring is worked with the

10X,20X phase contrast objective, while

the opening is used for bright field .

A

B

A B Fig 5

Fig 6

Notices

Requirement :

1. temprature:0℃~40℃,max humidity:85%。

2. high temperature and moisture will damage

instrument and affect performance。

3. keep the instrument from the dust

environment ,and take the dust cover when no

using 。

4. lay the instrument without vibration place。

Fig 7

①

Replace lamp

1. Turn the swith to off position when using or

need replacement.pull out the lamp house and

then the lamp after it is cool down competely。

2. Insert the new lamp softly to prevent damage。

3. Do not touch the lamp by hands to prevent

reducing lamp expectancy or explode。Clean

the fingerprint by wiping slightly moistened

with ether

8

DI-100F

Fig 8

③

②

①

2.2.6 Installing the objective (fig8、fig9)

1. Turning the coarse fusing knob① like the figure

shows till the nosepiece get to its lowest position.

★For ensuring the safety of the instruction

on transportation, the nosepiece is located in the

lowest position and the tension adjustment

collar② is adjusted in a appropriate tight

tension while leaving the factory.

2. Screw the lowest magnification objective on to the

turret from the nearside, then turn the turret

clockwise, mount other objectives according the

magnification sequence of low to high.

◎ Mount objective like this way will make the change

of magnification to be very easy in using.

◎ It also can install the objective through the

stage opening.

★ Clean the objective regularly, the objective used in

the inversed microscope is very sensitivity about

dust.

★ Do cover all the unused holes with turret dust

caps③, to prevent the dust and contamination

entering inside.

★ When operating, use the low magnification objective

(4X or 10X)to search and focus the specimen at

first, then replace the higher magnifications if

necessary.

★ When replace the objective, slowly turning the

nosepiece until you hear “clicked”, that means the

objective enter into the right position—center of

the light path.

2.2.7 Mounting the Mercury Burner (fig10、

fig 11)

1.Loosen the burner socket clamping screw ①, and

remove the burner socket.(fig.1)

2.After removing the foam backstop②, securely insert

the + pole (the wide head) of the specified mercury

burner③ to the lower teminal first and then the –

pole(the thin head) to the upper terminal, then

tighten the two socket clamping screws④.

3.Close the burner socket with burner into the original

position and tighten the socket clamping screw①.

Fig 10

Fig 9

①

Loading...

Loading...