MotionVision®

CA-D6-xxxxW

High-Speed Area Scan Cameras

Camera User’s Manual

03-32-00225

rev 06

Printed 03/18/99 10:00 AM

2 CA-D6-xxxxW User’s Manual

CA-D6-xxxxW Camera User’s Manual Document Number 03-32-00225

Revision Level 06

© 1998 DALSA Inc. All i nformation provided in this manual is believed to be accurate and

reliable. No responsibility is assum ed by DALS A for its use. DALSA reserves the right to make

changes to this information without notice. Reproduct i on of this manual in whole or in part, by

any means, is prohibited without prior permission having been obtai ned from DALSA INC.

About DALSA

DALSA specializes in the manufacture, design, research and development of high perf ormance

solid state CCD im age sensors and modular cam eras. DALSA cameras provi de the highest

spatial resolution at t he hi ghest data transfer speed of any k nown product s in the industry.

DALSA’s CCD image s ensors and cameras are used worldwide in docum ent scanning, image

capture, surveillance, process monitoring and manufacturing inspecti on. DALSA also develops

customized products for specific customers and applications .

All DALSA products are manufactured using the lat est state-of-the-art equipment to ensure

product reliability. All electronic m odules and cameras are subjected to a 24 hour burn-in test.

For further information not i ncluded in this manual, or for information on DALSA’ s extensive line

of image sensing product s, please call:

North America

DALSA INC.

605 McMurray Road

Waterloo, ON,

CANADA

N2V 2E9

Phone: 519 886 6000

FAX: 519 886 8023

website: www.dalsa.com

Europe

DALSA GmbH.

Breslauer Str. 34

D-82194, Gröbenzell (Munich)

GERMANY

Phone: +49-8142-46770

FAX: +49-8142-467746

TURBOSENSOR™, QUIETSENS OR™, DDBS™, DOBS™ and DUBS™ are regis tered

trademarks of DALS A INC.

Schneider Optics and CORION are t rademarks of their respective holders.

TM

Our symbol represents a cross-section of the c ont rol circuitry basic to all

DALSA image sensors.

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 3

CA-D6-XXXXW U SER’ S M ANUAL

Contents

1.0 Introduction to the CA-D6 5

1.1 Camera Highlights...........................................................................................5

1.2 Image Sensor.................................................................................................. 5

1.3 Camera Performance Specifications...............................................................7

1.4 CCD Camera Primer .......................................................................................8

2.0 Camera Hardware Interface 9

2.1 Installation Overview.......................................................................................9

2.2 Input/Output.....................................................................................................9

2.3 Connectors, Pinouts, and Cables..................................................................10

2.4 Power Supplies ............................................................................................. 11

2.5 User Bus (Inputs) .......................................................................................... 12

2.6 Data Bus........................................................................................................15

2.7 Timing............................................................................................................ 16

2.8 Multi-Camera Operation................................................................................18

3.0 Optical and Mechanical Considerations 19

3.1 Mechanical Interface.....................................................................................19

3.2 Optical Interface............................................................................................20

3.3 EMC Operation.............................................................................................. 23

4.0 Troubleshooting 25

4.1 Common Solutions........................................................................................25

4.2 Specific Solutions.......................................................................................... 27

4.3 Product Support ............................................................................................ 29

Appendix A: EIA-644 Reference 31

Appendix B: EMC Declaration of Conformity 35

Index 37

DALSA INC. 03-32-00225-06

4 CA-D6-xxxxW User’s Manual

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 5

C HAPTER 1

1.0 Introduction to the CA-D6

1.1 Camera Highlights

• 260x260 or 532Hx516V pixels, 10 µm squ are with 100% fill factor

• Frame transfer architecture and pixel resetno shut t e r required

• 4 outputs at 25 MHz: frame rat es to 955 or 262 frames/sec

• 8 bit digital data in EIA-644 (LVDS differe ntial) format

• Separate connectors for power, control and data

• “Snapshot” operation

• Vertical antiblooming

• Operation verified to limits set in EMC standards IEC 1000-4-2; 1995, 1000-4-3;

1995, 1000-4-4; 1995, and CISPR-22.

The CA-D6-xxxxW cameras use DALSA’s patented modular architecture. This

system of connecting circuit module s through standardized bu sses allows

DALSA to build a high performance modular camera using the reliability,

flexibility, and cost-effectiveness of high-volume interchangeable parts. Within

the camera, a timing board (PB-D6-X205) generate s al l internal timing an d a

driver board (PB-D6-A198) provides bias voltages and clocks to t h e CCD image

sensor. Two A/D boards (PB-xxD344) proce ss the video and an output board

(PB-xx-X733) filters the power lines.

1.2 Image Sensor

The CA-D6-xxxxW use the IA-D6 family of image sensors. Available in 260x260

and 532x516 arrays, the sensors have 10 µm square pixels with 100% fill factor.

The IA-D6 image sensors use a frame transfer architecture, providing on-chip

storage.

DALSA INC. 03-32-00225-06

6 CA-D6-xxxxW User’s Manual

6I

OS4

Figure 1. IA-D6-0256 Image Sensor

VPS

VPS

269 Rows

or

525 Rows

260 Columns

or

532 Columns

OS1

6I

CRLAST

VPS

6I

4 CCD Readout Shift Registers

OS2

Note:

All readout shift registers have the same

clocks and outpu t structure as OS1.

6I

OS3

6 isolation CCD cells

6I

Figure 2. CA-D6 Camera Spectral Response

1.4

]

)

2

m

1.2

c

/

J

n

(

1.0

/

N

0.8

D

[

y

t

i

0.6

v

i

s

n

0.4

o

p

s

0.2

e

R

0

Wavelength (nm)

Responsivity

800600400 500 700 900

1000

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 7

1.3 Camera Performance Specifications

Table 1. CA-D6-xxxxW Performance Specificati ons

Calibration Conditions Units Min. Typ. Max.

Frame Rate (FVAL) Hz

256x256 Hz 955

512x512 Hz 262

Data Rate (STROBE) MHz 25

Halogen light source

Specification Units Min. Typ. Max.

Saturation Output Ampl itude DN 243 248 254

Photoresponse Non-Uniformi ty (PRNU) DN (rms) 1.2 1.8

PRNU with exposure control DN (rms) 1.6 2.4

Fixed Pattern Noise (FPN) DN (rms) 0.5 0.75

Output Gain Mismatch DN 1.5 3.0

Mean Output Offset DN 4 5 8

Random Noise DN (rms) 0.45 0.75

Noise Equivalent Exposure pJ/cm

Saturation Equivalent Exposure nJ/cm

Responsivity DN/(nJ/cm2)1.34

Dynamic Range ratio 325:1 540:1

Supply Current (256/512)

+15.0 V mA 300/350 350/400

+5.0 V mA 900/1200 950/1300

+5.0 V mA 1000/1300 1050/1400

-5.0 V mA 200/230 250/280

Operating Temperature °C0 50

2

2

336

181.4

Notes

DN = digital numbers, als o known as “levels” (0-255 for 8-bit systems).

All cameras use s ensor grade 01. Other grades also available. Contact DALSA for information.

1. DC light source, bulb color temp 3150K, 750nm cut of f filter.

2. Measured at 20%, 50% and 80% of VSAT.

3. Measured at 50% of VSAT.

4. Unterminated outputs.

5. Terminated outputs.

Notes

1

Notes

2

2

3

1

4

5

Table 2. IA-D6 Sensor Cosmetic Specifications

Specification IA-D6 Grade

01

a Number of first & last columns excluded 1

b Number of first & last rows excluded 1

c Max. # of single pixel blemishes 10

d Max. # of cluster blemishes 0

e Max. size of clusters (# of adjacent pixels) NA

f Max. # of column defects 0

g Blemish variation from mean at 50% VSAT

h Blemish variation f rom average dark level (DN) 5

DALSA INC. 03-32-00225-06

±10%

8 CA-D6-xxxxW User’s Manual

1.4 CCD Camera Primer

How CCD Image Sensors Work

In a CCD camera such as the CA-D6-xxxxW, a CCD image sensor converts

photons (light) into el ectrons (electricity). When photons hit an image sensor, an

electron is released, and the sensor adds this electric charge to the charge it has

already collected. This is called charge integration. The brighter your light

source, the more photons available for the sensor to integrate, and the smaller

the amount of time required to collect a given amount of charge.

The way photosensitive elements (pixels)

on CCD image sensors colle c t charge has

often been compared to buckets filling

with water. From this analogy comes the

term “full-well capacity,” meaning the

maximum charge (number of electrons) a

pixel can hold without “spilling” charge

onto adjacent pixels.

As light energy hits an array of pixels, the pixels collect charge. At certain

intervals, a frame transfer sensor such as the IA-D6 transfers its collected charge

from the active, photosensitive region to a light-shielded storage region. Then it

transfers the charge, line by line, to one or more readout registers, which feed

each pixel’s charge from the image sensor into an output node that con verts the

charges into voltages.

After this transfer and

conversion, the

voltages are amplified

to become the camera’s

analog output. In

digital output cameras,

the camera’s analog-todigital (A/D) board

converts voltages to

digital number s (0-255

for 8-bit cameras).

These digital numbers

are what the camera

outputs as data to a frameg rabber.

For more information on terms and concepts from the digital imaging industry, see

DALSA’s current Databook Glossary, CCD Technology Primer, and Application Notes.

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 9

C HAPTER 2

2.0 Camera Hardware Interface

2.1 Installation Overview

In order to set up your camera, you should take these steps:

1. Decide on modes of operation—will you use USR_EN?

2. Test and connect powe r supplies.

3. Test and connect User Bu s c o ntrol signals from framegrabber.

4. Test and connect data sig n als output from camera.

You must also set u p the other components of your system, including light

sources, framegrabbers, camera mounts, heat sinks, host c o mputers, optics, and

so on.

2.2 Input/Output

DALSA INC. 03-32-00225-06

10 CA-D6-xxxxW User’s Manual

2.3 Connectors, Pinouts, and Cables

DB50F—Data BusOS1/OS2 and OS3/OS4

Camera connector uses crimp labeling convention for pin numbers

2( )

2( )

34

Crimp

label

Solder

label

Mating Part: Amphenol 17D-D50P (solder pi n) with shell 17-1657-50

34

3( )

18

1( )

1

Cable: 26 AWG 100Ω shiel ded t wisted pair

Note on DB50 connectors: There are several standard ways to number the pins of DB50 connectors.

The connectors on the back of the camera use the “crimp” convention, but many shielded connectors

used to control EMI/EMC (including the Amphenol part listed here) use the “solder” convention. To help

you translate between numbering conventions, this pinout table lists both. The signals are located on the

same physical pins in both cases, but the STROBE pin is numbered 37 under the “crimp” convention and

13 under the “solder” convention.

50( )

50

48( )

49( )

33

17

Crimp

Label

1 1 OSBD7 3 18 OS2D6 2 34 OS2D7B

4 2 OS2D6B 6 19 OS2D5B 5 35 OS2D5

7 3 OS2D4 9 20 OS2D3 8 36 OS2D4B

10 4 OS2D3B 12 21 OS2D2B 11 37 OS2D2

13 5 OS2D1 15 22 OS2D0 14 38 OS2D1B

16 6 OS2D0B 18 23 FVALB 17 39 FVAL

19 7 USR_EN 21 24 OS1D7 20 40 USR_ENB

22 8 OS1D7B 24 25 OS1D6B 23 41 OS1D6

25 9 OS1D5 27 26 OS1D4 26 42 OSID5B

28 10 OS1D4B 30 27 OS1D3B 29 43 OS1D3

31 11 OS1D2 33 28 OS1D1 32 44 OS1D2B

34 12 OS1D1B 36 29 OS1D0B 35 45 OS1D0

37 13 STROBE 39 30 LVAL 38 46 STROBEB

40 14 LV A LB 42 31 not used 41 47 not used

43 15 not used 45 32 not used 44 48 not used

46 16 not used 48 33 not used 47 49 not used

49 17 not used 50 50 not used

Solder

Label

Signal

Crimp

Label

Solder

Label

Signal

Crimp

Label

Solder

Label

Signal

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 11

DB15M—Power DB15F—Control

Mating Part: Amphenol 17D-A15S

with shell 17-1657-15

Cable: 22 AWG min. shielded

Pin Signal Pin Signal Pin Signal Pin Signal

1 DGND 9 +5V Digital

2 +5V Digital 10 DGND

3 not used 11 not used

4 -5V Digital 12 not used

5 Not used 13 -5V Analog

6 +15V 14 AGND

7 +15V 15 +5V Analog

8AGND

2.4 Power Supplies

See section 1.3 for power requirements.

When setting up the camera’s power supplies, follow these guidelines:

• Do not use the shield on a multi-conductor cable for ground.

• Connect separate supplies at the source and at the camera.

• Use separate leads for better noise immunity.

The companies listed below make power supplies that meet the camera’s

requirements, but they should not be considered the only choices. Many high

quality supplies are available from other vendors. DALSA assumes no

responsibility for the use of these supplies.

Mating Part: Amphenol 17D-A15P

with shell 17-1657-15

Cable: 22 AWG min. shielded

1 not used 9 not used

2 not used 10 not used

3 not used 11 not used

4 EXSYNCB 12 EXSYNC

5 PRIN 13 PRINB

6 future use 14 future use

7 not used 15 not used

8 not used

• Uniforce, 408-946-3864 (CA, USA) • Power-One, 805-987-8741 (CA, USA)

• Vision 1, 406-585-7225 (MT, USA) • Tectrol Inc., 416-630-4026 (ON, CAN)

• Xantrex, 206-671-2966 (WA, USA)

DALSA INC. 03-32-00225-06

12 CA-D6-xxxxW User’s Manual

2.5 User Bus (Inputs)

The User Bus uses a DB25 connec tor and includes the man datory control signal

EXSYNC and optional sig nal PRIN. These signals must be suppli ed from your

framegrabber to the c am era using EIA-644 (differential) form at, which requires

the use of twisted pair cable. DALSA recommends shielded cables. Maximum

cable lengths depe nds on environmental fac tors and EIA-644 limitations. See

Appendix A.

EXSYNC—Triggers Frame Readout

EXSYNC is an optional sig nal used to control the c amera’s frame rate. When

EXSYNC is left unconnected or connected to logic LOW, the camera outputs data

at its maximum frame rate (free-run mode). When EXSYNC is toggled, its falling

edge triggers frame readout; in this mode its frequency determines the camera’s

frame rate (FVAL frequency). The delay between the falling edge of EXSYNC

and the first valid pixel varies with model and is shown on the timing diagram

(section 2.9).

Minimum EXSYNC high or low time: 100 ns.

• DB15 Pins—EXSYNC: 12; EXSYNCB: 4.

Note: Restricting EXSYNC to logic HIGH prevents frame readout.

PRIN—Controls Electronic Shuttering

PRIN is an optional si gnal that can shorten the effective exposure time by

resetting the pixels (draining accumulated charge) on the image sensor between

EXSYNC-triggered frame readouts. PRIN is active when connected to logic LOW;

exposure effectively begins on the rising edge of PRIN. If PRIN is unconnected or

connected to logic HIGH, the integration time is maximized; if it is connected to

logic LOW the sensor collects no image information. The PRIN pulse width must

be 6.5±1µs. During the frame transfer period, the camera ignores PRIN inputs.

• DB15 pins: PRIN 5; PRINB 13.

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 13

Application Tip: Combining Input Signals for

Exposure Control and “Snapshot” Operation

When used together, EXSYNC and PRIN can give very precise control over

exposure and image capture. The examples below illustrate some camera

operating options.

Figure 3 depicts the operation of the camera when EXSYNC is kept low and

PRIN high at all times. The camera operates at its maximum frame rate with the

maximum exposure time, which is defined as the time from the end of one frame

transport to the beginning of the next frame transport.

Figure 3. Free-Run Mode

exposure time

EXSYNC

MODE

frame

transport

frame readout

frame

transport

frame readout

PRIN

Figure 4 depicts the operation of the camera when the EXSYNC signal frequency

is user controlled. The frame rate is variable and depends solely on the EXSYNC

rate. Keeping PRIN high maximizes the time the sensor is exposed to light. The

exposure time is defined from the end of one frame transport to the beginning of

the next frame tr ansport.

Figure 4. User-Controlled EXSYNC

exposure time

EXSYNC

MODE

PRIN

frame

transport

frame readout

frame

transport

frame readout

DALSA INC. 03-32-00225-06

14 CA-D6-xxxxW User’s Manual

Figure 5 shows the oper ation of the camera when EXSYNC and PRIN are both

user controlled. The start of the exposure time depends on the rising edge of

PRIN in combination with the falling edge of EXSYNC. The exposure time is

defined from the rising edge of PRIN to the falling edge of EXSYNC. PRIN must

be kept low for 6.5±1µs to drain all charge that was previously coll ected. Note

also that the camera will ignore PRIN inputs during frame readout.

Figure 5. User-Controlled EXSYNC and PRIN

exposure time

EXSYNC

MODE

PRIN

frame

transport

frame readout

frame

transport

frame readout

For “snapshot” operation (see Figure 6), you can use a combination of EXSY NC

and PRIN to trigger image capture from external event. The CA-D6 can remain in

a wait state until it receives a combination of EXSYNC and PRIN.

During the wait st ate, the EXSYNC and PRIN signals mu st be high (meaning the

camera is continually integrating incident light). To begin the effective exposure

period, PRIN must be toggle low for 6.5± 1 µs and then high. After the desired

exposure (e.g. 20 ms) EX SYNC must go low, and the exposed frame is tran sferred

and output.

cont’d...

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 15

exposure

Figure 6. Event-Triggered Image Capture

Trigger event

exposure time

EXSYNC

MODE

PRIN

Note that to have the camera react to an external event, your imaging system

must detect th e event and then send the appropriate EXSYNC and PRIN signals

to the camera to cause it to capture images.

2.6 Data Bus

Digital Data

See section

2.3 for pinouts.

IMPORTANT:

This camera’s

data is valid on

rising

the

of STROBE,

unlike previous

DALSA

cameras, which

used the falling

edge.

edge

The CA-D6-xxxxW provides 4 channels of 8 bits of data in EIA-644 differential

format at 25 MHz.

To help clock digital data into framegrabbers, the camera outputs clocking

signals STROBE, LVAL, and FVAL.

STROBE

STROBE is a pixel clock signal for digital data. It is continuous, toggling even

when data is not valid. Digital data is valid on its rising edge with LVAL and

FVAL high.

LVAL

LVAL high with FVAL high indicates the camera is outputting a valid line of

pixels. Between valid lines within a frame, LVAL goes low for 29 inactive pixels

(0256 model) or 47 inactive pixels (0512 model).

wait state

frame

transport

frame readout

FVAL

FVAL high indicates the camera is outputting a valid frame of data.

DALSA INC. 03-32-00225-06

16 CA-D6-xxxxW User’s Manual

USR_EN—Input for Multiplexing

USR_EN is an input used during camera multiplexing. When multiple cameras

share the same data bus, their digital dat a outputs can be placed into tri-state by

connecting USR_EN to logic LOW. Connecting USR_EN to logic HIGH activates

a camera’s outputs. USR _EN is an optional signal; if n o t using USR_EN, conne ct

it to logic HIGH and USR_ENB to logic LOW.

2.7 Timing

When exposed to light, the sensor collec ts charge. The EXSYNC control signal

(input from framegrabbe r) triggers the transfer and readout of the charge. The

FVAL output goes high to indicate a valid frame; the LVAL output goes high for

each of the lines that make up the frame. LVAL goes low between the lines of a

frame. The STROBE signal is a pixel clock; digital data is valid on its rising edge.

After a frame is read out, t h e FVAL signal goes low and the sensor collects charge

for the next frame.

Figure 7. CA-D6-xxxxW Overall Timing

EXSYNC

FVAL

LVA L

STRO BE

OS1

OS2

OS3

OS4

1

2

3

4

NOTES:

Position o f th e first valid pixel (v alid o n the of ST RO BE)

Dimensions of single frame 4x(260 lines of 65 pixels) 4x(516 lines of 133 pixels)

1

1

EXSYNC minimum pulse width 100ns 100ns

2

2 EXSYNC to FVAL 1542 STROBEs 7136

3

3 F VA L to LVAL 22 ST RO BEs 22 S TRO BEs

4

4 EXSYNC to first valid pixel 1564 STROBEs 7158 STROBEs

5

5 LVAL HIGH 65 STROBEs 133 STROBEs

6

6 Between lines: LVAL LOW 29 STROBEs 37 STROBEs

7

↓↓

7 LVAL to FVAL 15 STROBEs

8

8 Minimum time between frames 1715 STROBEs 7461 STROBEs

↑

↑

1

N/4+1

N/2+1

3N/4+1

5

LINE 1 LAST LINE

rising edge

0256 0512

6

N/4

N/2

3N/4

N

STRO BEs

15 STROBEs

8

7

IMPORTANT:

This camera’s data is

rising

valid on the

edge

of STROBE, unlike

previous DALSA

cameras, which used

the falling edge.

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 17

Figure 8. CA-D6-xxxxW Detailed Timing

Symbol Description Min. Typ. Max. Unit

T

LSW

T

LSZW

T

SETUP

T

HOLD

T

PL

T

EL

↑LVAL to ↓STROBE

↓LVAL to ↓STROBE

Data setup 18 23 28 ns

Data hold 12 17 22 ns

PRIN pulse 5.5 6.5 7. 5

EXSYNC pulse 100 ns

-2 0 2 ns

-2 0 2 ns

µs

DALSA INC. 03-32-00225-06

18 CA-D6-xxxxW User’s Manual

USR_EN

2.8 Multi-Camera Operation

Camera Multiplexing

Camera multiplexing puts multiple cameras on the same data bus. All the

multiplexed cameras are spliced into the same data cable; this is possible because

the camera’s output line drivers can be tri-stated. The usu al c o ntrol signals can be

spliced on a single cabl e, but they can al so be kept separate for each camera. The

cameras do not require synchronized control signals because only one camera

can be active at any one time—a camera becomes active when you supply it with

a differential USR_EN signal. Each multiplexed camera must receive its own

USR_EN signal from a separate differential pair from a EIA-644 line driver.

USR_EN in logic HIGH activates camera

output. USR_EN in logic LOW puts

outputs in tri-state. Note that toggling

the camera outputs from tri-state to

active requires a small but important

amount of setup and hold time. Be sure to take this time into account when

configuring your system.

max.39 ns

Data

max. 50 ns

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 19

C HAPTER 3

3.0 Optical and Mechanical

Considerations

3.1 Mechanical Interface

The camera’s electroni cs are housed in a rugged an odi zed aluminum case.

Mounting

For maximum stability and best heat sinking, DALSA recommends mounting the

camera by its front plate. There are four M4 ho l es and seven 4-40 UNC hole s

tapped into the front plate for mounting the camera or attaching heat sinking.

Other mounting options include M4 holes on the sides of the camera (stability

increases with nu mber of sides used) and the tripod mount (least stable).

Environment

The camera and cables should be shielded from environmental noise sources for

best operation. The camera should also be ke pt as cool as possible. Moun ting

holes (see above) al low you to attach heat sinking.

DALSA INC. 03-32-00225-06

20 CA-D6-xxxxW User’s Manual

3.2 Optical Interface

Front

plate

Imager

clamp

Die

C-mount

Z-axis

aligner

17.5 mm

The CA-D6-xxxxW camera comes with a mount adapter for C-mount lenses,

which have a back focal di stance of 17.5 mm. Ensure that the image circ l e

diameter of the lens to be used is as great as the diagonal of the imaging region of

the image sensor.

IMPORTANT: The camera’s Z-axis alignment is optimized for the adapter

provided. Do not remove the mount adapter without contacting DALSA first, or

you may misalign your lens.

Illumination

The amount and wavelengths of light required to capture useful images depend

on the particular application. Factors include the nature, speed, and spectral

characteristics of objects being imaged, e xposure times, light source

characteristics, en vironmental and acquisi tion system specifics, and more.

DALSA’s current Databook provides an introduction to this potentially

complicated issue. See “4.Radiometry and Photo Responsivity” and “Cam era

Sensitivities in Photometric Units”.

It is often more important to consider exposure than illumination. The total

amount of energy (which is related to the total number of photons reaching the

sensor) is more important t han the rate at which it arrives. For example, 5 µJ/cm

can be achieved by exposing 5 mW/cm2 for 1 mS just the same as e xposing an

intensity of 5 W/cm

03-32-00225-06 DALSA INC.

2

for 1 µS.

2

CA-D6-xxxxW User’s Manual 21

Light Sources

Keep these guidelines in mind when setting up your light source.

• Halogen light sources generally provide very little blue relative to IR.

• Fiber-optic light distribution systems generally transmit very l ittle blue

relative to IR.

• Some light sources age; over their lifespan they produce less light. This aging

may not be uniform—a light source may produce progressively less light in

some areas of the spectrum but not others.

Filters

CCD cameras are often very responsive to infrared (IR) w avelengths of light. If

you wish to exclude IR, use a “hot m i rror” or IR cutoff filter that transmits visible

wavelengths b ut does not transmit wavelengths ove r 700 µm. Examples are the

Schneider Optics™ B+W 489, which includes a m o unting ring, the CORION™

LS-750, which does not include a mounting ri n g, and the CORION ™ HR-750

series hot mirror.

Lens Modeling

Any lens surrounded by air can be modeled for camera purposes using three

primary points: the first and second principal points and the second focal point.

The primary points for a lens should be available from the lens data sheet or from

the lens manufacturer. Primed quantities denote characteristics of the image side

of the lens. That is, h is the object height and h

′

is the image height.

The focal point is the point at which the image of an infinitely distant object is

′

brought to focus. The effective focal length (f

principal point to the second focal point. The back focal length (BFL) is the distance

from the image side of the lens surface to the second focal point. The object

distance (OD) is the distance from the first principal point to the object.

) is the distance from the second

Figure 9. Primary Points in a Lens System

Magnification and Resolution

The magnification of a l ens is the ratio of the im age size to the object size:

DALSA INC. 03-32-00225-06

22 CA-D6-xxxxW User’s Manual

h

h

f

OD

hhf

OD

10

45

where m is the magnification, h’ is the image height (pixel size)

′

m

=

By similar triangles, the magnification is alternatively given by:

and h is the object height (desired object resolution size).

=

′

=

100

′

′

µ

µmmmmOD

This is the governing equation for many object and image plane

parameters.

450 0 450

OD mm m==(. )

m

These equations can be combined to give their most useful form:

Example: An acquisition system has a 512 x 512 element, 10 µm pixe l pitch area

scan camera, a lens with an effective focal length of 45 mm, and require s that

100µm in the object space correspond to each pixel in the image sensor. Using the

preceding equation , the object distance must be 450 mm (0. 450 m).

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 23

3.3 EMC Operation

The CA-D6 has been design ed for EMC compliance. The test setup shown be low

has been verifie d to the limits set in EMC standards IEC 1000-4-2; 1995, 1000-4-3;

1995, 1000-4-4; 1995, and CISPR-22.

Data Bus: 3M #3750-50, 6’ (1.8m), shielded jacketed twisted pair

Data Bus: 3M #3750-50, 6’ (1.8m), shielded jacketed twisted pair

Data Bus: 3M #3750-50, 6’ (1.8m), shielded jacketed twisted pair

User Bus: 3M #3750-9, 6’ (1.8m), shielded jacketed twisted pair

Power: 18 AWG

Follow these specific guidelines to maximize compliance in your application:

• Keep control and data cables as short as possible.

• Control and data cables must have 95% coverage shields that i n clude braided

wire. Metallic foil shields are insufficient without braided wire.

• Ensure that all cable shields have 360° electrical connection to the connector.

DALSA INC. 03-32-00225-06

24 CA-D6-xxxxW User’s Manual

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 25

C HAPTER 4

4.0 Troubleshooting

The information in this chapter can help you solve problems that may occur

during the setup of your camera. Remember that the camera is part of the entire

acquisition system. You may have to troubleshoot any or all of the following:

• power supplies • cabling

• framegrabber hardware & software • host computer

• light sources • optics

• operating environment • encoder

Your steps in dealing with a technical problem should be:

1. Follow the troubleshooting flowchart (Figure 10 in this chapter).

2. Try the general and specific solutions liste d in sections 4.1 and 4.2.

3. If these solutions do not resolve your problem, see section 4.3 on gett i n g

product support.

4.1 Common Solutions

Connections

The first step in troubleshooting is to verify that your camera has all the correct

connections. Follow the troubleshooting flowchart shown in Figure 10.

Power Supply Voltages

Check for the presence of all analog and digital volt ages at the camera DB25

connector. Verify that all grounds are connected.

EXSYNC

The EXSYNC signal from your framegrabber or camera controller m ust either

toggle or be connected to logic LOW. With EXSYNC restricted to logic HIGH, the

camera will not output any data. Using an oscilloscope, check the camera end of

the control signal cab le and verify that EXSYNC and EXSYNCB toggl e.

DALSA INC. 03-32-00225-06

26 CA-D6-xxxxW User’s Manual

Complete the table in the

g

Figure 10. Troubleshooting Flowchart

START

Check setup

see Chapt er 2

Check power supply.

Are voltages correct?

Yes

Are voltag es

correct at camera end of

power ca bl e?

Yes

Is ± EXSYNC

signal

present?

Yes

Are

± LVAL ,

± STROBE signals

± FVAL ,

present?

No

No

No

No

Yes

Scope the digital

•

video

•

Under varying

illumination, trigger

from LVAL while

looking at each

individu al digital bit .

Does each

ital data bit toggle and

di

are there continuous

STROBE clocks?

Yes

No

Product Support section

and contact your DALSA

representative

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 27

Data Clocking/Output Signals

Verify the presence of all data clocking and output sig nals. Trigger the

oscilloscope from the rising edge of FVAL (ch1; DC coupled). Adjust the

oscilloscope time base to allow for a complete cycle of each signal:

• STROBE—Verify the presence of the STROBE and STROBEB signals. There

should be a continuous clock signal present at the same frequency as your

data rate.

• LVAL—Verify the presence of the LVAL and LVALB signals.

• FVAL—Verify the presence of the FVAL and FVALB signals.

• Digital Output—Use FVAL to trigger the scope sweep. Illuminate the camera

target and check each individual digital output signal on ch2 of the

oscilloscope (±D0 - D7 on the digital output connector). The digital output

data signal should change value when light is blocked from the camera lens.

If any of the above si gnals are missing, cont act DALSA product support.

4.2 Specific Solutions

No Output or Erratic Behavior

If your camera provides no output or behaves erratically, it may be picking up

random noise from long cables acting as antennae. Do not attach wires to unused

pins. Verify that the camera is not receiving spurious MCLK, or USR_EN inputs.

Noisy Output

Check your power supply voltage outputs for noise. Noise present on these lines

can result in poor video quality. Low quality or non-twisted pair cable can also

add noise to the video output.

Dark Patches

If dark patches appear in your output the optics path may have become

contaminated. Clean your lenses and sensor windows with extreme care.

1. Take standard ESD precautions.

2. Wear latex gloves or finger cots

3. Blow off dust using a filtered blow bottle or dry, filtered compressed air.

4. Fold a piece of optical len s c l eaning tissue (approx. 3" x 5") to make a square

pad that is approximately one finger-width

DALSA INC. 03-32-00225-06

28 CA-D6-xxxxW User’s Manual

5. Moisten the pad on one edge with 2-3 drops of clean solvent—either alcohol

or acetone. Do not saturate the entire pad with solvent.

6. Wipe across the length of the window in one direction with the moistened

end first, followed by the rest of the pad. The dry part of the pad should

follow the moistened end. The goal is to prevent solvent from evaporating

from the window surface, as this will end up leaving residue and streaking

behind.

7. Repeat steps 2-4 using a clean tissue until the entire window has been

cleaned.

8. Blow off any adhering fibers or parti c l es using dry, filtered com pre ssed air.

Stuck Bits

If data bits seem to be stuck or do not change, check that the camera is not

saturated by preventing light from entering. Next, disconnect the digital cable

from the camera. Check the digital signals at the output of the camera, ensuring

that the correct values are present. Check all cable connections, especially right at

the connector; poor connections or broken wires will cause randomly changing

bits or stuck bits.

Horizontal Lines or Patterns in Image

Patterns may be caused by low frequency illumination variations. Use a DC or

high frequency light source.

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 29

4.3 Product Support

If the troubleshooting flowchart indicates a problem with your camera, collect

the following data ab out your application an d si tuation and call your DALSA

representative.

Note: You may also want to photocopy this page to fax to DALSA.

Customer name

Organization name

Customer phone number

fax number

Complete Product Model Number

(e.g. CL-C3-1024A-STDJ)

Complete Serial Number

Your DALSA Agent or Dealer

Acquisition System hardware

(framegrabber, host computer, light

sources, etc.)

Acquisition System software

(version, OS, etc.)

Power supplies and current draw

Data rate used

Control signals used in your

application, and their frequency or

state (if applicable)

Detailed description of problem

encountered.

❑ EXSYNC ❑ BIN

❑ MCLK ❑ Other _______

❑ PRIN

please attach description with as

much detail as appropriate

In addition to your local DALSA representative, you may need to call DALSA

Technical Sales Support:

North America

Voice:

Fax:

DALSA INC. 03-32-00225-06

519-886-6000

519-886-8023

Europe

+49-8142-46770

+49-8142-467746

Asia

519-886-6000

519-886-8023

30 CA-D6-xxxxW User’s Manual

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 31

CA-D6-XXXXW U SER’ S M ANUAL

Appendix A: EIA-644 Reference

EIA-644 is an electrical spe c ification for the transmission of digital data. The

standard is available from the EIA (Electronic Industries Association). It defines

voltage level s, expected transmi ssion speeds over various cab le lengths, common

mode voltage operating requirements for t ransmitters and receivers, and input

impedances and sensitivities for receivers. The table below gives a quick

comparison between EIA-644 and RS422 (another different i al standard).

Table 3. RS422 vs. EIA-644

Parameter RS422 EIA-644

Differential Driver Output Voltage ±2-5V ±250-450mV

Receiver Input Threshold ±200mV ±100mV

Data Rate <30Mbps >400Mbps

Supply Current, Quad Driver (no load, static)* 60mA 3.0mA

Prop. Delay of Driver, max.* 11ns 3ns

Prop. Delay of Receiver, max.* 30ns 5ns

Supply Current, Quad Receiver (no load, static)* 23mA 10mA

* based on National Semiconductor DS90C031/2

The standard requires that two wires (e.g. twisted pair) be used to transmit one

signal in a differential mode. This means that one wire will be logic HIGH while

the other wire is logic LOW. Voltage swing between HIGH and LOW is

approximately 350mV, w ith a typical offset of approximately 1.25V. The use of

differential signal tran smission allows the recei ver to reject commo n mode

voltages. This noise rejection improves data integrity and allows cameras to be

installed in an industrial environment.

EIA-644-compatible line receivers and drivers are available from many differe n t

IC manufacture r s in a variety of fabricat i on technologies such as CMOS and

GaAs. The EIA-644 standard does not de fine specific voltages, so it can migrate

from 5V power supplies to 3. 3V and sub-3V. DALSA recommen d s the use of 5V

CMOS line drivers and re c eivers such as National Semiconductor parts

DS90C0C31 quad line driver and DS90C032 quad line receiver .

To achieve full benefit of the common mode rejection, twisted pair cable should

be used for all EIA-644 sign al s. The cable impedance should be 100 Ohms and th e

cable terminate d at the receiving end with a 100 Ohm resistor. All EIA-644 inputs

DALSA INC. 03-32-00225-06

32 CA-D6-xxxxW User’s Manual

MCLK

in a DALSA camera are terminated with 100 Ohms betwee n the (+) and (-) of a

signal. Figure A-1 (a) sh ows an example of an EIA-644 tran smission.

DALSA indicates the (+) signal by the name of the signal; i.e. MCLK, while the (-)

signal is indicated by either an overscore over the name or appending the letter B

to the end of the name; i.e.

as the TTL signal which is sent or received; i.e. when MCLK in the TTL domain is

HIGH then MCLK in the EIA-644 domain is HIGH . The (-) signal has the

opposite sense of the TTL domain signal and so if MCLK TTL is HIGH t hen

MCLKB EIA-644 is LOW. Figure 11 shows the relationship.

Figure 11. EIA-644 Example

or MCLKB. The (+) signal has the same sense

Unused EIA-644 Inputs and Outputs

Unused outputs should be left unconnected. This will reduce power dissipation

within the camera an d reduce radiated emissions.

Unused inputs should also be left unconnecte d ; EIA-644 chips have fail-safe

features that gu arantee a known logic state (HIGH) in faul t conditions

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 33

(unconnected, shorted, or unterminated). Do not connect cables to unused

inputs. Cables can act as anten nae and cause erratic camera behavior.

Cable Lengths

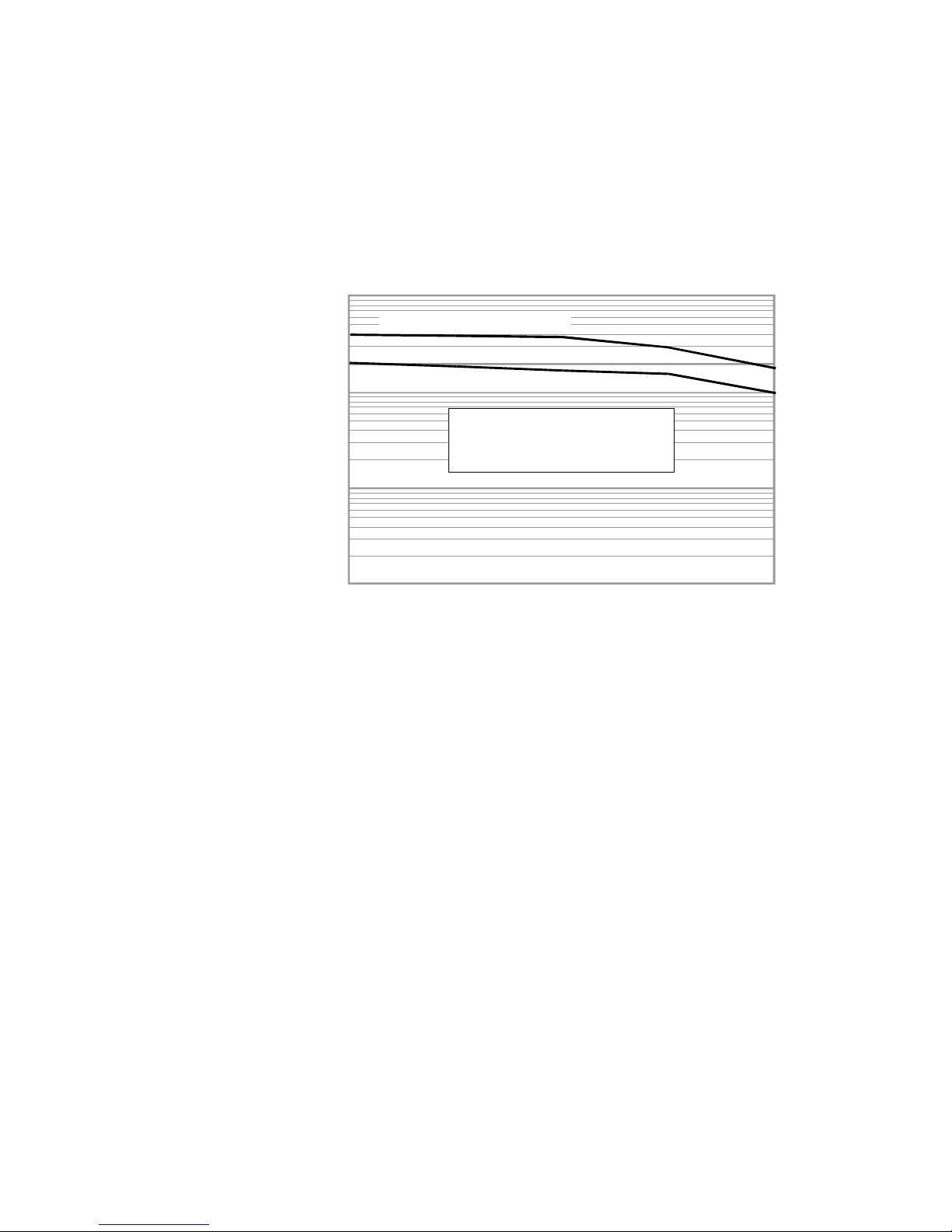

Figure 12 shows a graph of ideal communication data rate vs. cable length for the

EIA-644 standard.

Figure 12. EIA-644 Data Rate vs. Cable Lengt h

1000

20% Jitter Measured at 0V Differential

100

Data Rate (Mbps)

10

1

20% Jitter Measured at ±0100mV Differential

Typical Data Rate vs. Cable Length

(National DS90C031)

1

23510

CAT3 Cable

Cable Length (m)

DALSA INC. 03-32-00225-06

34 CA-D6-xxxxW User’s Manual

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 35

CA-D6-XXXXW U SER’ S M ANUAL

Appendix B:

EMC Declaration of Conformity

We, DALSA INC.

605 McMurray Rd., W aterloo, ON

CANADA N2V 2E9

declare under sole responsibility, that the product(s):

CA-D6-0256W-ECEW

CA-D6-0512W-ECEW

meets the test (limits) for:

Electrostatic Discharge, IEC 1000-4-2; 1995

Radiated Immunity, IEC 1000-4-3; 1995

Burst ELF, Class III, IEC 1000-4-4; 1995

Radiated Emissions, CISPR 22

and therefore correspond(s) to th e regulations of the EU-Directive 89/336/EEC.

Place of Issue

Date of Issue

Name and Signature of

authorized person

This Declaration corresponds to EN 45 014.

DALSA INC. 03-32-00225-06

Waterloo, ON, CANADA

18 November 1997

Brian Doody

Vice-President, Operations

36 CA-D6-xxxxW User’s Manual

03-32-00225-06 DALSA INC.

CA-D6-xxxxW User’s Manual 37

CA-D6-XXXXW U SER’ S M ANUAL

Index

1

100% fill factor • 5

A

A/D boards • 5

About DALSA • 2

asynchronous reset (PRIN) • 12

B

bucket analogy • 8

C

cable lengths • 12

cables • 11

length • 33

CCD image sensors • 8

combining input signals • 13

connectors • 10

cooling • 19

cosmetic specifications • 7

D

DALSA User Bus Standard • 5

dark patches • 27

Data Bus • 15

Digital Data • 15

DN (digital numbers) • 7

driver board • 5

E

EMC compliance • 5, 23

EMC Declaration of Conformity • 35

EMC Operation • 23

environmental considerations • 19

Event-Triggered Image Capture • 15

EXSYNC • 12

troubleshooting • 25

F

fiber-optic light sources • 21

fill factor • 5

Filters • 21

free-run mode • 13

full-well capacity • 8

FVAL • 15

H

halogen light sources • 21

hot mirror • 21

how CCD image sensors work • 8

I

IA-D1 image sensor • 5

Illumination • 20

Input/Output • 9

inputs (user bus) • 12

Installation Overview • 9

integration • 8

interface

mechanical • 19

optical • 20

DALSA INC. 03-32-00225-06

38 CA-D6-xxxxW User’s Manual

Introduction to the CA-D1 • 5

R

L

Lens Modeling • 21

light sources • 21

Logic HIGH and LOW • 31

LVAL • 15

troubleshooting • 27

M

magnification • 21

mechanical interface • 19

mounting • 19

multi-camera operati on • 18

multiplexing, camera • 18

N

noisy output • 27

RS422 reference • 31

S

shuttering, e lectronic (PRIN) • 12

snapshot operation • 15

state diagrams • 16

STROBE • 15

troubleshooting • 27

stuck bits • 28

T

Technical Sales Support • 29

temperature • 19

Timing • 16

timing board • 5

troubleshooting • 25

O

optical interface • 20

P

performance specifications • 7

photosensitive elements (pixels) • 8

pinout

DB25 User Bus • 10

OS1 data • 10

pixels and resolution • 5

power supplies • 11

PRIN • 12

U

user bus • 12

USR_EN • 16, 18

03-32-00225-06 DALSA INC.

Loading...

Loading...