Dalsa Genie HM640, Genie HM1024, Genie HM1400, Genie HM1400 XDR, Genie HC640 User Manual

...

Genie™ HM/HC Series

Camera User’s Manual

Genie Framework 1.80

HM640

HM1024

HM1400

HM1400 XDR

HC640

HC1024

GigE Vision Area Scan Camera

CA-GENM-HUM00

www.imaging.com

HC1400

© 2010 DALSA

All information provided in this manual is believed to be accurate and reliable. No responsibility is assumed by

DALSA for its use. DALSA reserves the right to make changes to this information without notice. Reproduction of

this manual in whole or in part, by any means, is prohibited without prior permission having been obtained from

DALSA.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and other

countries. Windows, Windows XP, Windows Vista, Windows 7 are trademarks of Microsoft Corporation.

All other trademarks or intellectual property mentioned herein belong to their respective owners.

Document Date: October 13, 2010

Document Number: CA-GENM-HUM00

*CA-GENM-HUM00*

About DALSA

DALSA is an international high performance semiconductor and electronics company that designs, develops,

manufactures, and markets digital imaging products and solutions, in addition to providing wafer foundry services.

DALSA Digital Imaging offers the widest range of machine vision components in the world. From industry-leading

image sensors through powerful and sophisticated cameras, frame grabbers, vision processors and software to easyto-use vision appliances and custom vision modules.

DALSA is a public company listed on the Toronto Stock Exchange under the symbol “DSA”.

Based in Waterloo, ON, Canada, the company has operations in Montreal, QC; Bromont, QC; Colorado Springs,

CO; Eindhoven, NL; Munich, Germany and Tokyo, Japan.

Contents

GENIE HM/HC SERIES OVERVIEW ......................................................................................................7

DESCRIPTION ............................................................................................................................................7

Genie Application Advantages.......................................................................................................... 8

PRODUCT PART NUMBERS ........................................................................................................................9

CAMERA PERFORMANCE SPECIFICATIONS ..............................................................................................10

Certifications...................................................................................................................................11

Vibration and Shock Certifications................................................................................................. 11

SUPPORTED INDUSTRY STANDARDS........................................................................................................11

GENIE HM/HC SERIES SENSOR OVERVIEW ............................................................................................12

HM/HC Series Sensor Global Specifications..................................................................................12

Model Specific Specifications .........................................................................................................13

Genie HM/HC Series Responsivity .................................................................................................14

Genie HM/HC Series Effective Quantum Efficiency....................................................................... 15

Genie HM/HC Series Sensor Cosmetic Specifications ...................................................................15

APPLICATION DEVELOPMENT OVERVIEW ...............................................................................................17

Sapera LT Library with optional Processing..................................................................................17

GigE Vision Compliant Environment .............................................................................................18

INSTALLING THE GENIE CAMERA....................................................................................................19

WARNING! (GROUNDING INSTRUCTIONS) ............................................................................................... 19

GIGE NETWORK ADAPTER GUIDELINE ...................................................................................................19

Supported Network Configurations ................................................................................................19

INSTALLATION OVERVIEW & PREPARATIONS .........................................................................................20

Network and Computer Overview................................................................................................... 20

Installation Overview...................................................................................................................... 21

Preventing Operational Faults due to ESD ....................................................................................21

SAPERA LT LIBRARY INSTALLATION ...................................................................................................... 22

GENIE CD PACKAGE INSTALLATION .......................................................................................................23

Procedure........................................................................................................................................23

GigE Server Verification.................................................................................................................23

CONNECT THE GENIE CAMERA ...............................................................................................................24

Connectors ...................................................................................................................................... 24

Status LED Codes ...........................................................................................................................25

Typical LED States on Power Up ........................................................................................................... 25

Genie IP Configuration Sequence ..................................................................................................26

GigE Server Status..........................................................................................................................26

OPTIMIZING THE NETWORK ADAPTER USED WITH GENIE ....................................................................... 27

Running the Network Configuration Tool.......................................................................................27

UPDATING GENIE FIRMWARE..................................................................................................................28

QUICK TEST WITH CAMEXPERT ..............................................................................................................29

Bayer CFA Decoder........................................................................................................................30

About the User-Defined Camera Name ..........................................................................................30

SILENT INSTALLATION OF GENIE FRAMEWORK.......................................................................................31

OPERATIONAL REFERENCE................................................................................................................33

CAMERA AND SENSOR INFORMATION .....................................................................................................33

Access Via CamExpert....................................................................................................................33

Power-up Configuration (Saved User Settings)..............................................................................34

Genie HM-HC Series-GigE Vision Camera Contents 1

Power-up Parameter List......................................................................................................................... 35

Power-up Control via Sapera LT or GigE Vision Compliant Applications............................................. 35

Camera Information via Sapera LT or GigE Vision Compliant Applications................................36

SENSOR CONTROLS .................................................................................................................................37

Sensor Parameters: Controls Via CamExpert ................................................................................ 37

Gain and Black Level Controls.......................................................................................................39

Gain and Offset Control via Sapera LT or GigE Vision Compliant Applications..........................39

Partial Scan—Window ROI ............................................................................................................40

Maximum Frame Rate (fps) Examples (model HM1400/HM1400XDR/HC1400)................................. 40

Maximum Frame Rate (fps) Examples (model HM1024/HC1024 – 8-bit only)..................................... 41

Maximum Frame Rate (fps) Examples (model HM640/HC640 – 8-bit only)......................................... 41

Partial Scan (horizontal cropping)........................................................................................................... 42

Window ROI Control via Sapera LT or GigE Vision Compliant Applications...............................43

CamExpert Image Buffer and ROI Parameters ..............................................................................44

Binning............................................................................................................................................ 45

Binning Control via Sapera LT or GigE Vision Compliant Applications....................................... 46

TRIGGER MODES..................................................................................................................................... 46

EXPOSURE CONTROLS.............................................................................................................................47

Free-running Programmable Exposure.......................................................................................... 47

External Trigger Programmable Exposure ....................................................................................48

External Trigger Level-controlled Exposure ..................................................................................49

Exposure Controls via Sapera LT or GigE Vision Compliant Applications...................................50

SYNCHRONIZATION TIMING ....................................................................................................................51

Synchronous Mode.......................................................................................................................... 51

Reset Mode...................................................................................................................................... 52

Synchronization Mode via Sapera LT or GigE Vision Compliant Applications............................. 52

CAMEXPERT I/O CONTROLS DIALOG...................................................................................................... 53

GENERAL INPUTS .................................................................................................................................... 54

External Input Signal Opto-coupler & Debounce Circuit ..............................................................54

General Inputs: Settings Via CamExpert........................................................................................ 54

Input Controls via Sapera LT or GigE Vision Compliant Applications .........................................55

STROBE AND GENERAL OUTPUTS............................................................................................................56

General Outputs: Settings via CamExpert......................................................................................56

Open and Close Output Settings ............................................................................................................. 57

Strobe On Start of Exposure Event Mode ............................................................................................... 57

Pulse On Valid Trigger Event Mode....................................................................................................... 58

Pulse On Invalid Trigger Event Mode..................................................................................................... 58

Pulse On Start of Readout Event Mode................................................................................................... 59

Pulse On End of Readout Event Mode.................................................................................................... 59

Pulse On End of Acquisition Event Mode............................................................................................... 60

Pulse On Input 1 or Input 2 Event Modes ............................................................................................... 60

Output Control via Sapera LT or GigE Vision Compliant Applications ........................................61

GENIE PROCESSING FEATURES................................................................................................................61

Lookup Table (LUT) .......................................................................................................................61

LUT Control via Sapera LT or GigE Vision Compliant Applications ............................................ 62

Flat Field (Image Shading) Correction ..........................................................................................63

Information on the Flat Field Data File................................................................................................... 63

Important Factors about Flat Field Processing ........................................................................................ 63

Important Factors about the Flat Field Data (TIF) File ........................................................................... 64

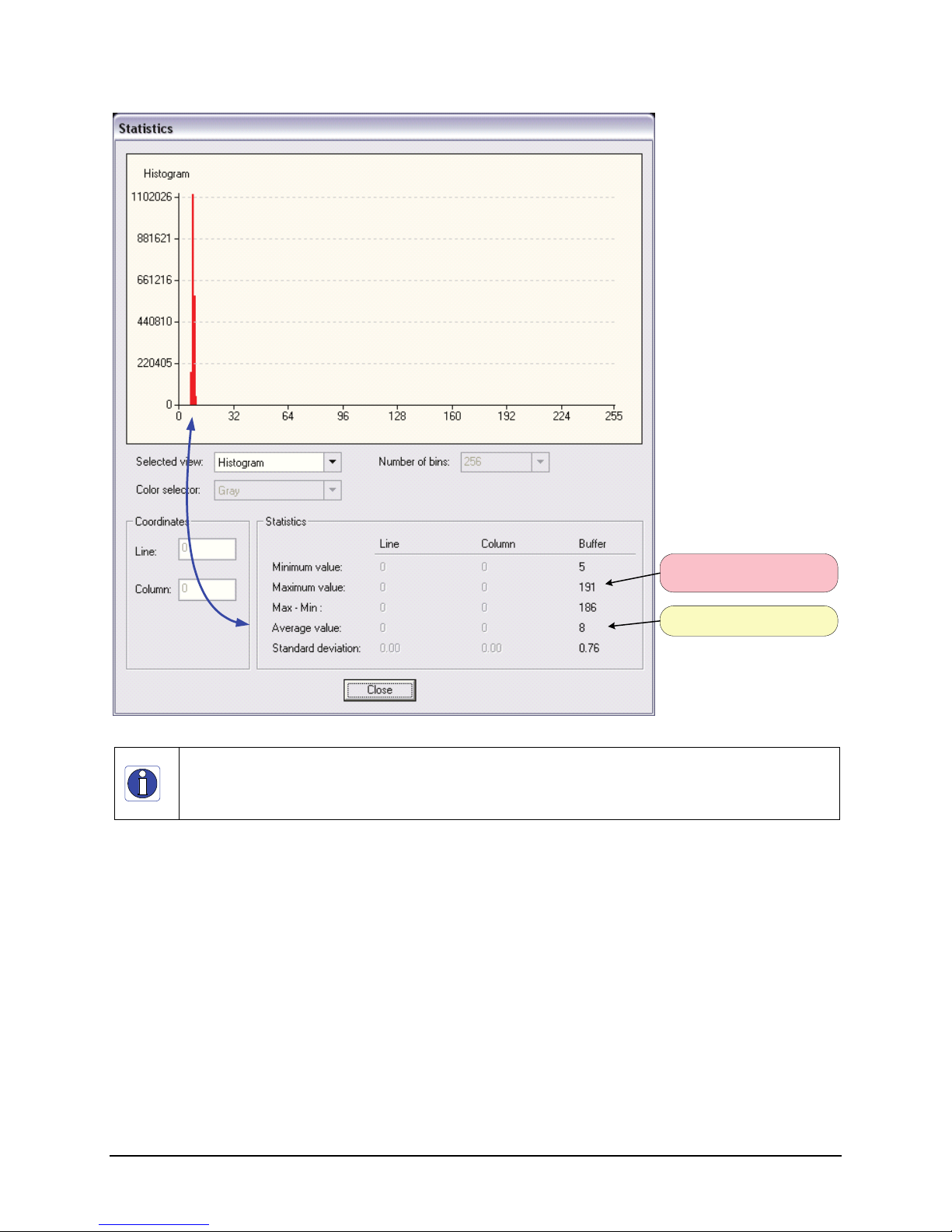

Set up Dark and Bright Acquisitions with the Histogram Tool............................................................... 64

Flat Field Correction Calibration Procedure ........................................................................................... 66

Using Flat Field Correction..................................................................................................................... 68

Flat Field Correction Control via Sapera LT or GigE Vision Compliant Applications.................68

Image Flip.......................................................................................................................................69

Internal Image Test Patterns ..........................................................................................................70

Test Image Select via Sapera LT or GigE Vision Compliant Applications.....................................71

EVENTS ...................................................................................................................................................71

2 Contents Genie HM-HC Series-GigE Vision Camera

Sapera Callbacks ............................................................................................................................71

Event Selection via GigE Vision Compliant Applications ..............................................................72

USING CAMEXPERT TO SET NETWORK CONTROLS & GIGE VISION PARAMETERS ..................................73

CamExpert GigE Vision Parameters ..............................................................................................73

Network Controls via Sapera LT or GigE Vision Compliant Applications ....................................75

SAPERA SUPPORTED FEATURES LIST ......................................................................................................76

Accessing Features with Sapera++ LT ..........................................................................................76

Feature Type STRING.....................................................................................................................77

Feature Type ENUM....................................................................................................................... 77

Feature Type INT32........................................................................................................................79

Feature Type BOOL........................................................................................................................80

Feature Summary List by Function Group .....................................................................................81

Device ..................................................................................................................................................... 81

User Defined Buffers .............................................................................................................................. 81

Sensor...................................................................................................................................................... 81

Sensor Exposure...................................................................................................................................... 82

Acquisition ROI ...................................................................................................................................... 82

Binning Control....................................................................................................................................... 82

LUT Control............................................................................................................................................ 82

Flat Field Control .................................................................................................................................... 82

Trigger Control........................................................................................................................................ 83

I/O Control .............................................................................................................................................. 83

Time Stamp Control................................................................................................................................ 83

Network Parameters ................................................................................................................................ 84

User Options............................................................................................................................................ 84

Feature Interdependence Diagrams ...............................................................................................85

Trigger Enable - TRUE........................................................................................................................... 86

Trigger Enable - FALSE ......................................................................................................................... 86

Output Selector........................................................................................................................................ 87

Vertical Binning...................................................................................................................................... 87

Horizontal Binning.................................................................................................................................. 88

Pixel Format............................................................................................................................................ 88

Network Configuration Mode ................................................................................................................. 89

Miscellaneous Dependencies ................................................................................................................. 89

Accessing the Genie User Buffer ....................................................................................................90

NETWORK OVERVIEW & TOOLS.......................................................................................................93

GENIE IP CONFIGURATION MODE DETAILS ............................................................................................93

Link-Local Address (LLA)...............................................................................................................93

DHCP (Dynamic Host Configuration Protocol).............................................................................94

Persistent IP.................................................................................................................................... 95

SAPERA CAMEXPERT GUIDE .............................................................................................................. 97

USING CAMEXPERT WITH GENIE HM/HC CAMERAS ..............................................................................97

CamExpert Panes............................................................................................................................98

CamExpert LUT Controls ............................................................................................................... 99

Bayer CFA Decoder Setting..........................................................................................................100

Bayer Conversion Algorithms............................................................................................................... 101

TECHNICAL SPECIFICATIONS.......................................................................................................... 103

MECHANICAL SPECIFICATIONS .............................................................................................................103

Genie 3D View with C-mount and CS-mount ...............................................................................103

Genie C-mount and CS-mount Mechanical Specifications...........................................................104

Genie 3D View with Right-angle C-mount and CS-mount............................................................105

Genie Right-angle C-mount and CS-mount Mechanical Specifications .......................................106

Additional Notes on Genie Mechanical ........................................................................................107

SENSOR ALIGNMENT SPECIFICATION ....................................................................................................107

Genie HM-HC Series-GigE Vision Camera Contents 3

CONNECTORS........................................................................................................................................108

12-Pin Hirose Connector Signal Details ......................................................................................108

Genie Signal Electrical Details.....................................................................................................109

External Inputs ...................................................................................................................................... 109

External Outputs.................................................................................................................................... 111

RJ45 LAN Ethernet Connector Details.........................................................................................111

CAMERA STATUS LED.......................................................................................................................... 112

OPTICAL CONSIDERATIONS...................................................................................................................112

Illumination................................................................................................................................... 112

Light Sources ................................................................................................................................112

Filters............................................................................................................................................113

Lens Modeling...............................................................................................................................113

Magnification and Resolution.......................................................................................................113

LENS SELECTION OVERVIEW ................................................................................................................114

Lens Mount ...................................................................................................................................114

Lens Sensor Size............................................................................................................................114

Comparison of a 2/3 Inch and 1 Inch Lens used with a Genie HM 1400.............................................. 116

Lens Sensor Size vs. Genie HM model................................................................................................. 116

Additional Lens Parameters (application specific).......................................................................117

SENSOR HANDLING INSTRUCTIONS .......................................................................................................117

Electrostatic Discharge and the Sensor........................................................................................ 117

Protecting Against Dust, Oil and Scratches .................................................................................118

Cleaning the Sensor Window ........................................................................................................ 118

Environment..................................................................................................................................118

RUGGEDIZED RJ45 ETHERNET CABLES.................................................................................................119

C/CS-MOUNT NIR AND UV FILTER .....................................................................................................120

Back Focal Variance when using a Filter ....................................................................................121

COMPUTER REQUIREMENTS FOR GENIE CAMERAS................................................................................122

Host PC System............................................................................................................................. 122

Ethernet Switch Requirements ......................................................................................................122

IEEE 802.3x Pause Frame Flow Control............................................................................................... 122

Ethernet to Fiber-Optic Interface Requirements ..........................................................................123

EC & FCC DECLARATION OF CONFORMITY .........................................................................................124

TROUBLESHOOTING............................................................................................................................125

OVERVIEW ............................................................................................................................................125

Problem Type Summary................................................................................................................125

Verifying Network Parameters......................................................................................................127

Before Contacting Technical Support ................................................................................................... 127

INSTALLATION ISSUES AND FUNCTIONAL PROBLEMS............................................................................127

The Windows Firewall Service Can Not Start ..............................................................................127

DEVICE AVAILABLE WITH OPERATIONAL ISSUES.................................................................................. 128

Firmware Updates ........................................................................................................................128

Power Failure During a Firmware Update–Now What? .............................................................128

Cabling and Communication Issues .............................................................................................128

Acquisition Error without Timeout Messages...............................................................................129

No camera exposure when expected ..................................................................................................... 129

Camera is functional but frame rate is lower than expected.................................................................. 129

Camera acquisition is good but frame rate is lower than expected........................................................ 129

Camera is functional, frame rate is as expected, but image is black ..................................................... 130

Other Problems or Issues..............................................................................................................130

Random Invalid Trigger Events ............................................................................................................ 130

Minimum Sapera Version Required...................................................................................................... 130

DALSA CONTACT INFORMATION....................................................................................................131

GENIE SALES INFORMATION .................................................................................................................131

4 Contents Genie HM-HC Series-GigE Vision Camera

GENIE TECHNICAL SUPPORT .................................................................................................................132

GLOSSARY OF TERMS .........................................................................................................................133

INDEX........................................................................................................................................................137

Genie HM-HC Series-GigE Vision Camera Contents 5

6 Contents Genie HM-HC Series-GigE Vision Camera

Genie HM/HC Series Overview

Description

The Genie HM/HC camera family form a series of affordable, easy to use digital cameras specifically engineered for

industrial imaging applications requiring high frame rates. Genie cameras combine standard gigabit Ethernet

technology with the DALSA Trigger-to-Image-Reliability framework to dependably capture and transfer images

from the camera to the host PC.

The Genie HM camera series provides monochrome acquisition while the HC camera series, using the same sensor

with a Bayer filter, provides color acquisition.

All Genie cameras are supported by DALSA Sapera™ LT software libraries featuring CamExpert for simplified

camera set-up and configuration. Sapera LT is field proven in thousands of robust industrial applications. Hardware

independent, Sapera LT delivers the same reliable performance regardless of the image acquisition device being

used. This unique feature allows OEM’s to start using the Genie without re-writing applications developed for

DALSA frame grabbers. In addition, Sapera LT includes powerful diagnostics and setup utilities for application

development, custom camera configurations and system deployment.

Genie HM-HC Series-GigE Vision Camera Genie HM/HC Series Overview 7

Genie Application Advantages

Compact, rugged design

GigE Vision 1.0 compliant

Gigabit Ethernet (GigE) interconnection to a computer via standard CAT5e or CAT6 cables

Supports connection to the host computer NIC through a GigE network switch

Available in multiple resolutions

Monochrome or color acquisition

High frame rates relative to similar products

Digital binning for increased sensitivity

Lookup table pre-processing

Real-time shading correction (i.e. Flat Field processing)

Horizontal Flip function

Supports several trigger modes for image capture control

2 opto-isolated inputs

2 opto-isolated outputs

Native Trigger-to-Image Reliability design framework

Visual status LEDs on camera back plate

1µs internal timer or external events can timestamp images

Supported by Sapera™ LT software libraries

8 Genie HM/HC Series Overview Genie HM-HC Series-GigE Vision Camera

Product Part Numbers

This manual covers the Genie HM and HC models summarized below. See "Camera Performance Specifications"

on page 10 for each Genie model.

Camera Resolution Pixel size

Genie HM640 640 x 480 7.4 x 7.4 µm 301 fps @ 8-bit

Genie HM1024 1024 x 768 7.4 x 7.4 µm 136 fps @ 8-bit

Genie HM1400 1400 x 1024 7.4 x 7.4 µm

Genie HM1400 XDR

extended dynamic range

Genie HC640 640 x 480 7.4 x 7.4 µm 301 fps @ 8-bit

Genie HC1024 1024 x 768 7.4 x 7.4 µm 136 fps @ 8-bit

Genie HC1400 1400 x 1024 7.4 x 7.4 µm

1400 x 1024 7.4 x 7.4 µm

(free running / flat field off)

fps

75 fps @ 8-bit

37 fps @ 10-bit

75 fps @ 8-bit

37 fps @ 10-bit

75 fps @ 8-bit

37 fps @ 10-bit

Product Number

CR-GM00-H640x

CR-GM00-H102x

CR-GM00-H140x

CR-GM01-H140x

CR-GC00-H640x

CR-GC00-H102x

CR-GC00-H140x

Lens Mount Option

C-Mount = 0

The last digit of the Genie product number defines the mechanical lens mount.

(see Mechanical Specifications)

C-Mount downward right angle = 2

CS-Mount downward right angle = 3

CS-Mount = 1

Software Product Number

Genie Framework composed of the Sapera network Imaging Package, Genie Imaging

Driver and latest Genie Firmware. Required installation.

Sapera Runtime including CamExpert Included and installed if desired

GenICam™ support (XML camera description file) Embedded within Genie

Sapera LT version 6.10 or later (Sapera 7 required for 64-bit support):

Provides everything you will need to develop imaging applications

Sapera documentation in compiled HTML help, and Adobe Acrobat® (PDF) formats.

Sapera Processing Imaging Development Library (sold separately):

Includes over 600 optimized image processing routines.

Included with Genie distribution

CD

OC-SL00-0000000

(sold separately)

Contact Sales at

DALSA

Genie Cables & Accessories (sold separately) Product number

Genie I/O and Power breakout cable (Hirose to Euroconnector) CR-GENC-IOP00

Tripod mount bracket (mount to Genie top or bottom—provides ¼-20 socket) CA-GENA-BRA00

Industrial type CAT 6 cable assembly:

Molded shroud with top/bottom thumbscrews on one end with standard Ethernet RJ45

clip on other. Available in various lengths.

See "Ruggedized RJ45 Ethernet Cables" on page 119.

C-mount NIR/UV filter available from Midwest Optical Systems.

See "C/CS-Mount NIR and UV Filter" on page 120.

CA-GENL-BP550

Genie HM-HC Series-GigE Vision Camera Genie HM/HC Series Overview 9

Camera Performance Specifications

Specifications for each available sensor are listed after the general Genie camera specifications.

Camera Controls

Synchronization Modes Free running

External triggered

Software trigger (through Ethernet)

Exposure Modes Programmable in increments of 1µs

minimum 10µs in Reset Mode or 56µs in Synchronous Mode

maximum is 4 seconds

Pulse controlled via Trigger pulse width.

Trigger Input Opto-isolated, 2V to 12V typical, 2mA min.

Debounce range from 1µs up to 255µs

Strobe Output

Features

LUT 8-bit (HM models) / 10-bit (only HM1400 and HM1400 XDR)

Flip Real-time horizontal flip (All HM models)

Binning Digitally based: Horizontal (2 pixel) and Vertical (2 line) (All HM models)

Timestamp 1µs internal timer or external signal to timestamp images and events

Test image Internal generator with choice of static and shifting patterns

User settings Select factory default or one user camera configuration

Output opto-isolated:

Aligned to the start of exposure with a programmable delay, duration and polarity

Note: LUTs are not available on the HC models.

Note: Flipping is not available on the HC models.

Note: Binning is not available on the HC models.

Optical Interface

Back Focal Distance—C-Mount 17.52 mm

Back Focal Distance—CS-Mount 12.52 mm

Mechanical Interface

Camera Size 29(H) x 44(W) x 67(L) in mm, ( see Mechanical Specifications )

Mass < 125g (no lens)

Power connector 12 pin male Hirose

Ethernet connector RJ45

Electrical Interface

Input Voltage xx-GM0x-xxxxx models +11 to +25.2 Volts DC at 0.6 Amp minimum

(over voltage–reverse voltage protected)

xx-GENx-xxxxx models +11 to +13 Volts DC at 0.6 Amp minimum (legacy models)

Power Dissipation < 4W

Operating Temperature 0 to 45°C (at front plate)

Relative Humidity 5% to 90% non-condensing (operating)

Output Data Configuration Gigabit Ethernet (IEEE 802.3)

Data and Control GigE Vision compliant at 1000 or 100 Mbps

10 Genie HM/HC Series Overview Genie HM-HC Series-GigE Vision Camera

Certifications

CE

FCC

RoHS

EN55022, class A, Radio Disturbance Characteristics

EN61000-4-2, Electrostatic discharge immunity test

EN61000-4-3, Radiated, radio-frequency, electromagnetic field immunity test

EN61000-4-4, Electrical fast transient/burst immunity test

EN61000-4-6, Immunity to conducted disturbances, induced by radio-frequency fields

Part 15, class A

see "EC & FCC Declaration of Conformity" on page 124

Compliancy as per European directive 2002/95/EC

(applies to camera part numbers CR-GENx-xxxxx)

Vibration and Shock Certifications

Test (while operating) Standard Description

Sinusoidal vibrations with identification

of critical frequencies

Random vibrations MIL-STD-810E (1989)

Shocks IEC 68-2-27 (1987)

IEC 68-2-6 (1995)

Test Fc

method 514.4

Category 10

Test Ea and guide

Frequency range: 10 to 2000 Hz

Amplitude: 5 m/s

Sweep rate: 1 octave per minute

Duration: 1 sweep cycle (to and fro)

Levels and frequencies:

2

0.04 g

/Hz from 20 to 1000 Hz

-6 dB/oct. from 1000 to 2000 Hz

Duration: 1 hour

Shape: half-sine

Amplitude: 75 g

Duration: 3 ms

Number: 3 shocks (+) and 3 shocks (-)

2

Supported Industry Standards

Genie cameras are 100% compliant with the GigE Vision 1.0 specification

which defines the communication interface protocol used by any GigE

Vision device. The device description and capabilities are contained in an

XML file. For more information see:

http://www.machinevisiononline.org/public/articles/index.cfm?cat=167

Genie cameras implement a superset of the GenICam™ specification which

defines device capabilities. This description takes the form of an XML

device description file respecting the syntax defined by the GenApi module

of the GenICam™ specification. For more information see

www.genicam.org.

Genie HM-HC Series-GigE Vision Camera Genie HM/HC Series Overview 11

Genie HM/HC Series Sensor Overview

The sensor description below provides a specification table and response graphics. The graph describes the sensor

response to different wavelengths of light (excluding lens and light source characteristics). Visible light spans

wavelengths between about 390 - 780 nanometers. Wavelengths below 390 nm are termed ultra-violet while those

above 780 nm. are termed infra-red. The peak response is around 600 nanometers.

HM/HC Series Sensor Global Specifications

Item / Feature Specification

Imager Features Global Shutter, Exposure Control, Anti-Blooming

Sensor DALSA IA-G5 Area Array

Minimum Frame Rate (free-running) 0.1 fps (one frame every 10 seconds)

Maximum Frame Rate (free-running) Dependent on Genie HM/HC model (see Partial Scan—Window ROI)

Minimum Exposure 10μs when using reset exposure mode (triggered)

56μs when using synchronous exposure mode (free running)

Maximum Exposure ( 1 / frame rate ) - 10μs

Internal Trigger to Start of Exposure 100μs

Horizontal Line Time HM640/HC640 6.7μs

HM1024/HC1024 10.3μs

HM1400/HC1400 (8-bit) 14μs

HM1400/HC1499 (10-bit) 22.3μs

Pixel Size 7.4µm x 7.4µm

Pixel Format 8-bit all models

10-bit available only with HM1400/HM1400 XDR and HC1400

Bayer Mosaic Arrangement

(HC models only)

Shutter Full frame electronic shutter

Gain Range 0dB to +12dB

The HC color camera models have a Bayer filter applied to the

CMOS sensor to allow for color separation. Each individual

pixel is covered by either a red, green, or blue filter. The camera

outputs raw color data--no color interpolation is performed. Full

RGB images can be obtained by performing color interpolation

on the frame grabber or host PC.

12 Genie HM/HC Series Overview Genie HM-HC Series-GigE Vision Camera

Model Specific Specifications

HM1400-XDR Typical Min. Units Notes

Output Dynamic Range 55.3 53.9 db With FFC (Factory calibrated)

Maximum Achievable SNR 51.6 51.1 db With FFC (Factory calibrated)

Full Well Capacity 60 000 electron

Responsivity 12 DN/(nJ/cm2) @ 600 nm , 1 x Gain

HM1400/HC1400 Typical Min. Units Notes

Output Dynamic Range 48.2 47.5 db With FFC (Factory calibrated)

Maximum Achievable SNR 48.3 47.6 db With FFC (Factory calibrated)

Full Well Capacity 24 000 electron

Responsivity 30.6 DN/(nJ/cm2) @ 600 nm, 2.55 x Gain

HM1024/HC1024 Typical Min. Units Notes

Output Dynamic Range 47.5 45.7 db With FFC (Factory calibrated)

Maximum Achievable SNR 47.1 45.9 db With FFC (Factory calibrated)

Full Well Capacity 24 000 electron

Responsivity 30.6 DN/(nJ/cm2) @ 600 nm, 2.55 x Gain

HM640/HC640 Typical Min. Units Notes

Output Dynamic Range 47.5 45.5 db With FFC (Factory calibrated)

Maximum Achievable SNR 47.2 45.9 db With FFC (Factory calibrated)

Full Well Capacity 24 000 electron

Responsivity 30.6 DN/(nJ/cm2) @ 600 nm, 2.55 x Gain

Genie HM-HC Series-GigE Vision Camera Genie HM/HC Series Overview 13

Genie HM/HC Series Responsivity

Note: DALSA recommends using a 700nm cutoff filter with the HC color series cameras since the

blue and green color filters become transparent above 700nm.

14 Genie HM/HC Series Overview Genie HM-HC Series-GigE Vision Camera

Genie HM/HC Series Effective Quantum Efficiency

The following quantum efficiency graph describes the fraction of photons at each wavelength that contribute charge

to the pixel.

Genie HM/HC Quantum Efficiency (%) Curve

70. 0%

60. 0%

50. 0%

40. 0%

30. 0%

20. 0%

10. 0%

0. 0%

400 500 600 70 0 800 900 1000

Wave length ( nm)

Genie HM/HC Series Sensor Cosmetic Specifications

The following table lists the current cosmetic specifications for the DALSA sensor used in the Genie HM/HC series.

Blemish Specifications Maximum Number of Defects

Hot/Dead pixel defects 2

Single pixel defects 100 for HM series

25 for each individual color (R, G1, G2, B) for HC series

Clusters defects 0

Column defects 0

Row defects 0

Note: All of the sensor and camera cosmetic specifications are with factory flat-field correction turned on. There are

no pre-flat-field camera cosmetic specifications.

Genie HM-HC Series-GigE Vision Camera Genie HM/HC Series Overview 15

Definition of cosmetic specifications

Hot/Dead pixel defect:

Pixel whose signal, in dark, deviates by more than 400DN (10-bits) from the mean.

Single pixel defect:

Pixel whose signal, at nominal light (illumination at 50% of the linear range), deviates by more than ±30% from

the mean.

Cluster defect:

A grouping of more than 8 pixel defects.

Column defect:

A column which has more than 8 consecutive pixel defects.

Row defect:

A horizontal grouping of more than 8 consecutive pixel defects.

Test conditions

Digital gain = 1X

Nominal light = illumination at 50% of saturation

Temperature of camera front plate is 40°C

16 Genie HM/HC Series Overview Genie HM-HC Series-GigE Vision Camera

Application Development Overview

Sapera LT Library with optional Processing

Sapera LT is a powerful development library for image acquisition and control. Sapera LT provides a single API

across current and future DALSA hardware. Sapera LT delivers a comprehensive feature set including program

portability, versatile camera controls, flexible display functionality and management, plus easy to use application

development wizards.

Sapera Processing is a comprehensive set of C++ classes for image processing and analysis. Sapera Processing

offers highly optimized tools for image processing, blob analysis, search (pattern recognition), OCR and barcode

decoding.

The following is a Sapera application functional block diagram. The Genie Framework installation includes the

Genie driver and the Sapera Network Imaging Package.

Network

Configuration Tool

smart DHCP

Server

single GigE Vision

(optional)

Camera

User’s Sapera

Application

Sapera LT SDK

Genie Driver

Control

GigE Server

GVCP

GigE Vision

Control

Protocol

Ethernet Network Interface Card

Alternatively via a switch

CamExpert

Sapera Network

Images

Imaging Driver

GVSP

GigE Vision

Stream

Protocol

Sapera LT

Genie

Framework

Sapera

Network

Imaging

Package

To multiple GigE

Vision Cameras

Genie HM-HC Series-GigE Vision Camera Genie HM/HC Series Overview 17

GigE Vision Compliant Environment

The GigE Vision Compliant XML device description file is embedded within Genie firmware allowing GigE Vision

Compliant applications to know Genie capabilities immediately after connection.

18 Genie HM/HC Series Overview Genie HM-HC Series-GigE Vision Camera

Installing the Genie Camera

Warning! (Grounding Instructions)

Static electricity can damage electronic components. Please discharge any static electrical charge by touching a

grounded surface, such as the metal computer chassis, before performing any hardware installation.

If you do not feel comfortable performing the installation, please consult a qualified technician.

GigE Network Adapter Guideline

If the computer to be used with the Genie camera does not have a Gigabit network adapter or second built in Gigabit

NIC, a PCI bus Gigabit Network Interface Card (NIC) needs to be installed. Typically under Windows, the PCI

Gigabit NIC is recognized automatically when Windows boots. An example of a high performance NIC is the Intel

PRO/1000 MT adapter.

Review the NIC documentation concerning any special driver required for Windows. Install the PCI bus Gigabit

NIC as described by the NIC manufacture's documentation.

The Genie camera has been tested with a variety of Gigabit network adapters, both built into the system

motherboard and as third party PCI adapters.

Supported Network Configurations

The Genie obtains an IP address using the Link Local Address (LLA) or DHCP, by default. A LLA IP address is

obtained in about 6 seconds with Microsoft Vista/7 or in about 1 minute with Microsoft XP. If required, a persistent

IP address can be assigned (see "Running the Network Configuration Tool" on page 27).

The LLA m

After an address is chosen, the link-local process sends an ARP query with that IP onto the network to see if it is

already in use. If there is no response, the IP is assigned to the device, otherwise another IP is selected, and the ARP

is repeated. Note that LLA is unable to forward packets across routers.

Alternatively, if a DHCP server is present on the network, the Genie is going to issue a DHCP request asking for an

IP address. The DHCP server will then provide the Genie an IP address. The DALSA Network Configuration tool,

installed with the DALSA Network Imaging Package, can also function as the DHCP server (refer to the DALSA

Network Imaging Package user's manual).

ethod automatically assigns the Genie with a randomly chosen address on the 169.254.xxx.xxx subnet.

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 19

Installation Overview & Preparations

The Genie camera installation generally follows the sequence described below. Detailed installation instructions

follow this overview. This section also provides important information to prevent operational faults due to ESD

(electrostatic discharge) in Genie installations.

Network and Computer Overview

Genie needs to connect to a computer with a GigE network adapter, either built in on the computer

motherboard or installed as a third party PCI adapter.

Laptop computers with built in GigE network adapters may still not be able to stream full frame rates from

Genie, especially when on battery power. Thorough testing is required with any laptop computer to determine

the maximum frame rate possible (refer to the DALSA Network Imaging Package user's manual).

Genie also can connect through a Gigabit Ethernet switch. When using VLAN groups, the Genie and

controlling computer must be in the same group (refer to the DALSA Network Imaging Package user's

manual).

If Genie is to be used in a Sapera development environment, Sapera LT needs to be installed, either before or

after the Genie software package. If Genie will be used in a GigE Vision Compliant environment, Sapera or

Sapera runtime is not required and you need to follow the installation instructions of the third party GigE

Vision compliant package.

Install the Genie Framework software package if not using a third party GigE Vision compliant package.

Also install Sapera Run-time with CamExpert to control the Genie.

The Windows Firewall exceptions feature is automatically configured to allow the Sapera GigE Server to pass

through the firewall.

Computers with VPN software (virtual private network) may need to have the VPN driver disabled in the NIC

properties. This would be required only on the NIC used with the Genie. Testing by the user is required.

20 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Installation Overview

Before connecting power to the camera, test all power supplies. Power supplies must meet the requirements

defined in section "Genie Signal Electrical Details" on page 109. Apply power to the cam

Connect Genie to the computer GigE network adapter or to the Ethernet switch via a CAT5e or CAT6 Ethernet

cable. Note: cable should not be less than 1 meter (3 feet) long or more than 100 meters (328 feet) long.

Check the diagnostic LED which will be initially red then switch to flashing blue while waiting for IP

configuration. See "Status LED Codes" on page 25 for Geni

Look at the small camera icon added to the Windows tray (next to the clock). Ensure the Genie camera has

been found (right click the icon and select Status).

A new Genie installation typically requires a firmware update. See the procedure "Updating Genie Firmware"

on page 28.

Use Cam

the Genie to internal test pattern. See "Sapera CamExpert Guide" on page 97.

Set

trigger sources, etc. Test with CamExpert.

Expert (installed either with Sapera or Sapera runtime) to test the installation of the Genie camera. Set

up the other components of the imaging system such as light sources, camera mounts, optics, encoders,

e LED display descriptions.

era.

Preventing Operational Faults due to ESD

Genie camera installations which do not protect against ESD (electrostatic discharge) may exhibit operational faults.

Problems such as random packet loss, random camera resets, and random loss of Ethernet connections, may all be

solved by proper ESD management.

The Genie camera when used with a simple power supply and Ethernet cable, is not properly connected to earth

ground and therefore is susceptible to ESD caused problems. An Ethernet cable has no ground connection and a

power supply's 0 volt return line is not necessarily connected to earth ground.

DALSA has performed ESD testing on Genie cameras using an 8 kilovolt ESD generator without any indication of

operational faults. The two following methods, either individually or together will prevent ESD problems.

Method 1: Use a shielded power supply cable where the shield is connected to earth ground at the supply end

and to the Hirose connector shell at the Genie end. The Genie case is now properly connected to earth ground

and can withstand ESD of 8 kilovolts, as tested by DALSA.

Method 2: Mount the Genie camera on a metallic platform which has a good connection to earth ground.

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 21

Sapera LT Library Installation

Note: to install Sapera LT and the Genie device driver, logon to the workstation as an administrator or with an

account that has administrator privileges.

When Sapera application development is performed on the same computer that the Genie is connected to, the Sapera

Development Library (version 6.20 or later) must be installed. Else, Sapera LT is not required to control the Genie

camera.

Insert the DALSA Sapera CD-ROM. If AUTORUN is enabled on your computer, the DALSA installation

menu is presented.

If AUTORUN is not enabled, use Windows Explorer and browse to the root directory of the CD-ROM.

Execute launch.exe to start the DALSA installation menu and install the required Sapera components.

The installation program will prompt you to reboot the computer.

Continue with the Genie CD Package Installation described next.

Refer to Sapera LT User’s Manual

concerning application development with Sapera.

22 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Genie CD Package Installation

The Genie Framework software package and Sapera runtime provides all components required to control the Genie

with the supplied CamExpert tool. Genie Framework software components include the Network Imaging driver

(refer to the DALSA Network Imaging package manual), the Sapera GigE server, and CamExpert (if Sapera LT

library is not installed).

Note: If Sapera application development is required, install Sapera (6.20 or later) as described in the previous

section.

Procedure

Insert the DALSA Genie CD-ROM. If AUTORUN is enabled on your computer, the Genie installation menu is

presented.

If AUTORUN is not enabled, use Windows Explorer and browse to the root directory of the CD-ROM.

Execute launch.exe to start the installation menu and install the Genie software components.

Click to install the Genie Framework Software which includes the Network Imaging driver, and the Sapera

GigE server.

The procedure will prompt for acceptance of the installation folder for the Genie files.

If desired, click to install Sapera LT run-time which includes CamExpert. Follow the on screen prompts and

reboot when the installation is complete.

GigE Server Verification

After a successful Genie Framework package installation, the GigE Server icon is visible in the desktop taskbar tray

area. After connecting a camera (see following section), allow a few seconds for the GigE Server status to update.

The Genie camera must be on the same subnet as the NIC to be recognized by the GigE Server.

Device Available Device IP Error Device Not Available

GigE Server

Tray Icon:

The normal GigE server tray

icon when the Genie device is

found. It will take a few

seconds for the GigE Server to

refresh its state after the Genie

has obtained an IP address.

The GigE server tray icon

shows a warning when a device

is connected but there is some

type of IP error.

If you place your mouse cursor on this icon, the GigE Server will display the number of GigE Vision devices found

by your PC. Right click the icon and select status to view information about those devices. See "Running the

work Configuration Tool" on page 27 and "Troubleshooting" on page 125for m

Net

A red X will remain over the

GigE server tray icon when the

Genie device is not found. This

indicates a major network

issue. Or in the simplest case,

the Genie is not connected.

ore information.

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 23

Connect the Genie Camera

Connect a power supply to the Genie camera and an Ethernet cable from the Genie to the host computer. Once

communication with the host computer is started the automatic IP configuration sequence will assign an LLA IP

address as described in section "Genie IP Configuration Sequence" on page 26, or a DHCP IP address if a DHCP

s present on your network. Note that the DALSA Network Configuration tool can enable the DALSA smart

server i

DHCP server.

The factory defaults for Genie is Persistent IP disabled and DHCP enabled with LLA always enabled as per the

GigE Vision specification. For additional information see "Genie IP Configuration Mode Details" on page 93. See

he next section "Connectors" on page 24 for an overview of the Genie interfaces.

t

Connectors

The Genie has only two connectors:

A single RJ45 Ethernet connector for control and video data transmitted to/from the host computer Gigabit

NIC. See "Ruggedized RJ45 Ethernet Cables" on page 119 for secure cables.

A si

The Genie has one multicolor LED to provide a simple visible indication of camera state (see figure below and

section "Status LED Codes" on page 25). Addi

The following figure of the Genie back end shows connector and LED locations. See "Mechanical Specifications"

on page 103 for det

ngle 12-pin Hirose male connector for camera power plus trigger, strobe and general I/O signals. The

suggested female cable mating connector is Hirose model HR10A-10P-12S.

tionally the RJ45 has two LEDs for network status conditions.

ails on the Genie connectors and camera mounting dimensions.

Genie – Rear View

24 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Status LED Codes

The camera is equipped with a LED to display the operational status of the camera. When more than one condition

is active, the LED color indicates the condition with the highest priority (such as an acquisition in progress has more

priority than a valid IP address assignment). The following table summarizes the LED states and corresponding

camera status.

LED State Definition

LED is off No power to the camera

Steady Red Camera not initialized **

Slow Flashing Red Camera initialization problem **

** Often there is no serious problem with the Genie hardware.

Wait 2-5 minutes for the Genie to load internal default firmware,

then follow these instructions (see Updating Genie Firmware).

Slow Flashing Blue Waiting for an IP address

Fast Flashing Blue Ethernet cable disconnected (no link)

Steady Blue IP address assigned;

no application connected to the camera

Steady Green Application connected

Slow Flashing Green Triggered acquisition in progress

Fast Flashing Green Free-running acquisition in progress

Once the Genie has its RJ45 connected to a network, the Status LED will turn to steady blue when the IP address is

assigned. Only at this time will it be possible by the GigE Server or any application to communicate with the

camera.

Note: Even if the Genie has obtained an IP address, it might be on a different subnet than the NIC it is attached to.

Therefore, if the Genie LED is blue but an application such as CamExpert can not see it, this indicates a network

configuration problem. See the troubleshooting section in this manual.

Typical LED States on Power Up

The following LED sequence occurs when the Genie is powered up connected to a network with installed Genie

Framework software.

Red

power connected

Flashing Blue

waiting for IP

Blue

IP assigned

Green

application

connected

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 25

Genie IP Configuration Sequence

The Genie IP (Internet Protocol) Configuration sequence to assign an IP address is executed automatically on

camera power-up or when connected to a network. As a GigE Vision compliant device, Genie attempts to assign an

IP address as follows.

For any GigE Vision device, the IP configuration protocol sequence is:

Persistent IP (if enabled)

DHCP (if a DHCP server is present such as the DALSA Smart DHCP server)

Link-Local Address (always enabled)

The factory defaults for Genie is Persistent IP disabled and DHCP enabled with LLA always enabled as per the

GigE Vision specification. For additional information see "Genie IP Configuration Mode Details" on page 93.

GigE Server Status

Once the Genie is assigned an IP address (its Status LED is steady blue) the GigE server tray icon will not have a

red X through it, indicating that the Genie device was found. It might take a few seconds for the GigE Server to

refresh its state after the Genie has obtained an IP address.

Right-click the GigE Server tray icon to open the following menu.

Click on Show Status to open a window listing all devices connected to the host system. Each GigE device is listed

by name along with important information such as the assigned IP address and device MAC address. The screen

shot below shows a connected Genie with no networking problems.

In the event that the device is physically connected, but the Sapera GigE Server icon is indicating that the connected

device is not recognized, click Scan Network to restart the discovery process. Note that the GigE server

periodically scans the network automatically to refresh its state. See "Troubleshooting" on page 125 for net

problems.

work

26 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Optimizing the Network Adapter used with Genie

Most Gigabit network interface controllers (NIC) allow user modifications to parameters such as Adapter Buffers

and Jumbo Frames. These should be optimized for use with the Genie during the installation. Refer to the DALSA

Network Imaging package manual for optimization information.

Running the Network Configuration Tool

The Network Configuration tool provides information and parameter adjustments for network adapters installed in

the system and any connected GigE Vision camera without use of any Windows Control Panel application. This tool

allows you to:

Activate the Network Imaging driver use for image acquisition on any NIC or disable the imaging driver

for any NIC not used with a GigE Vision camera.

Change the Auto Discovery Interval from the default of 15 seconds.

Configure the Windows firewall exception list.

Configure the NIC and camera IP settings.

Assign a User-Defined name to a connected camera.

Assign a Persistent IP address to a camera instead of the default DHCP/LLA assigned address.

Easily Configure the NIC as a DHCP server for connected GigE Vision camera.

Important: Any changes made with this tool will update the Genie flash memory. Do not remove power from the

Genie camera for a minimum 10 seconds. Then cycle the Genie power to load the new flash settings.

Refer to the DALSA Network Imaging package manual for more detailed information on using this tool. As shown

below, the Network Configuration tool can quickly verify and modify the network configuration of the imaging

system.

Run the tool from the Windows Start menu: Start•Programs•DALSA Sapera Network Imaging Package•Dalsa

Network Configuration Tool. Verify the camera appears as a child of the NIC card it is connected to. By default

the Genie camera is identified by its serial number if no user-defined name has been assigned.

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 27

Updating Genie Firmware

The Genie firmware may need to be updated to correspond with the currently installed Genie software framework.

After installing the new Genie software package and Genie camera, update the firmware by following this

procedure.

Important: Make sure that no Sapera application (such as CamExpert) is controlling the Genie camera.

Start the DALSA Device Manager program from the windows start menu:

Start•Programs•DALSA•Genie•Firmware Update.

The right hand column shows whether a firmware update is Required or Not Required.

If an update is required, click on the Automatic button. The Update Firmware manager dialog opens and the

new firmware version is written to the Genie camera.

The manual button allows the user to select from multiple Genie firmware configuration files – if such files

become available for future operational modes.

The firmware update is complete when the lower message output area says "Device reset complete". Close the

Device Manager program.

28 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Wait for the GigE Server to find the Genie again, then run CamExpert to test the Genie operation (as described

below).

Important: If the Genie power is accidentally cut off during the firmware update (such as a electrical source

power failure or human error), the Genie is easily recovered. See "Power Failure During a Firmware Update–Now

Wha

t?" on page 128.

Quick Test with CamExpert

When the Genie camera is directly connected to a Gigabit network adapter on a host computer or via a network

switch, testing the installation with CamExpert is a straightforward procedure.

Start Sapera CamExpert by double clicking the desktop icon created during the Genie software installation.

CamExpert will search for installed Sapera devices. In the Device list area on the left side, the connected Genie

camera is shown or will be listed in a few seconds after CamExpert completes the automatic device search

(device discovery).

Select the Genie camera device by clicking on the camera user-defined name. By default the Genie camera is

identified by its serial number. The Genie status LED will turn green, indicating the CamExpert application is

now connected.

Click on the Grab button for live acquisition (the Genie default is Free Running mode). Focus and adjust the

lens iris. See "Operational Reference" on page 33 for inform

camera.

The following figure shows CamExpert with the Genie generating a diagonal test pattern. Select this via the

Test Image Selector drop menu from the Sensor Parameters tab.

ation on CamExpert parameters with the Genie

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 29

Bayer CFA Decoder

For the HC camera models, to view the acquisition display in color set the Bayer CFA Decoder to Software from

the CamExpert Pre-Processing menu.

About the User-Defined Camera Name

The Genie can be programmed with a user-defined name to aid identifying multiple cameras connected to the

network. For instance, on an inspection system with 4 cameras, the first camera might be labeled “top view”, the

second “left view”, the third “right view” and the last one “bottom view”. The factory default user name is set to

match the camera serial number for quick initial identification. Note that the factory programmed Genie serial

number and MAC address are not user changeable.

When using CamExpert, multiple Genie cameras on the network are seen as different "Genie_M640_x" devices as

an example. Click on a Genie device user name to select it for control by CamExpert.

An imaging application uses any one of these attributes to identify a camera: its IP address, MAC address, serial

number or User Name. Some important considerations are listed below.

Do not use the camera's IP address as identification (unless it is a persistent IP) since it can change with each

power cycle.

A MAC address is unique to a single camera, therefore the control application is limited to the vision system

with that unique camera if it uses the camera's MAC address.

The User Name can be freely programmed to clearly represent the camera usage. This scheme is recommended

for an application to identify cameras. In this case, the vision system can be duplicated any number of times

with cameras identified by their function, not their serial numbers or MAC address.

30 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Silent Installation of Genie Framework

The Genie Framework installation can be integrated within a developer's installation procedure. The silent

installation mode allows the Genie Framework installation to proceed without the need for mouse clicks from a

user.

Two steps are required:

Preparation of a response file to emulate a user.

Invoking the Genie Framework installer with command options to use the prepared response file.

Creating the Response File

An installer response file is created by performing a Genie Framework installation with the command line switch

"-r". The response file is automatically named setup.iss which is saved in the \windows folder. One simple

method is to execute the Framework installer from within a batch file. The batch file will have one command line.

As an example, using the executable file name for Framework version 1.40, the command line is:

"Genie_1.40.00.0222 Release.exe" –r

Important: The executable name is enclosed in quotation marks. This is required because of the space characters in

the Genie Framework file name.

Running a Silent Mode Installation

A Genie Framework silent installation, whether done alone or within a larger software installation requires the

Genie Framework executable and the generated response file setup.iss.

Execute the Framework installer with the following command line (using version 1.30 as an example):

"Genie_1.40.00.0222 Release.exe" -s -f1".\setup.iss"

where in this example, the switch –f1".\setup.iss" specifies that the setup.iss file is in the same folder as the

Framework installer.

Genie HM-HC Series-GigE Vision Camera Installing the Genie Camera 31

32 Installing the Genie Camera Genie HM-HC Series-GigE Vision Camera

Operational Reference

Camera and Sensor Information

Camera and sensor information can be retrieved via a controlling application. Parameters such as camera model,

firmware version, sensor characteristics, etc. are read to uniquely identify the connected Genie device.

All these features, with the exception of the DeviceUserId, are read-only. Sapera LT or GigE Vision Compliant calls

are used to retrieve this information and correctly identify the camera along with its characteristics.

Following is an overview of CamExpert displaying this information followed by tables with the feature name

associated to Sapera LT and to GigE Vision Compliant development environments.

Access Via CamExpert

The Camera Information Parameters tab groups information specific to the individual Genie camera.

Genie HM-HC Series-GigE Vision Camera Operational Reference 33

Read Only Parameters

Parameter Description

Device Vendor Name For the Genie HM series, this is always DALSA.

Device Model Name Displays the device model name

Device Version Displays the device version which includes the firmware release and build.

Firmware Version Displays the currently loaded firmware version manufacturer's code.

Device ID Displays the factory set camera serial number.

MAC Address Displays the unique MAC (Media Access Control) address of the Genie camera.

User Set Parameters

Parameter Description

Device User ID Specifies a user written ID, of up to 15 characters, for the Genie camera.

By default, this field is set to the serial number of the camera.

Power-up Configuration

Click Setting to open the Power-up configuration dialog box which allows you to specify

camera power-up configuration. For more information, see "Power-up Configuration" on page

34.

Power-up Configuration (Saved User Settings)

The Power-up configuration dialog allows you to specify the camera configuration to load when powering-up the

camera. The Genie camera flash memory contains two possible configuration settings; the Factory Default (neutral

parameters and in free run mode), and a user-defined Camera Configuration 1. The Camera Power-up

configuration drop-down list box allows you to select either the Factory Default or a user specified camera

configuration file. To save the current CamExpert settings to the camera user-defined (Camera Configuration)

setting, click Save. To view in CamExpert a camera configuration file currently saved in the camera, select the

configuration file in the Load configuration from Camera drop-down list, and click Load. See the parameter list

below.

34 Operational Reference Genie HM-HC Series-GigE Vision Camera

Power-up Parameter List

The user-defined Camera Configuration saves in camera memory features that can be configured by the user. The

following table lists most of these parameters.

Parameter Description

ROI Region of interest used to crop the image.

Pixel Format Defines the pixel format.

Frame Rate Defines the frame rate for free run mode. (see note below)

Exposure Control mode Defines the exposure mode (Programmable or Pulse Controlled)

Exposure duration Defines the exposure duration for Programmable mode. (see note below)

Exposure synchronization Synchronous or Reset synchronization mode.

Gain Defines the sensor analog Gain factor, initially set to 0.0 dB.

Black Level Defines the sensor analog Black level factor, initially set to 0.

Flip Horizontal flip: Off or On (HM models only)

Image source Defines the image source as the sensor or one of the stored image patterns.

Trigger enable Free-running or triggered.

Trigger source Selects the trigger input (input pin or software).

Trigger delay Defines the delay from input trigger to exposure start.

GPI settings Defines the operational mode of the general input pins.

GPO settings Defines the operational mode of the general output pins

LUT Lookup Table function On or Off plus the LUT data. (HM models only)

Flat Field Correction FFC function On or Off plus the offset/gain data. (see warning below)

Note: Maximum frame rates and exposure durations saved previously with Genie Framework 1.40 may be

slightly reduced by Framework 1.50, to improve acquisition robustness.

Warning: Non-typical or invalid Flat Field data, either from a faulty calibration setup or uploaded by the user,

may cause an error when trying to save the User Settings Power-up Parameters. Such "flawed" Flat Field data is

useable during camera operation but cannot be sufficiently compressed to be saved as a user setting.

Power-up Control via Sapera LT or GigE Vision Compliant Applications

Sapera

Genie HM-HC Series-GigE Vision Camera Operational Reference 35

Genie Sapera parameters for Power-up Configuration:

Power-upConfig = {Factory Default = 0, Camera Configuration 1 = 1}

SaveCameraConfigurationSelector = {Camera Configuration 1 = 1}