Page 1

IN LOCOMOTIVE ELECTRIC SOUND SYSTEM

for various track power by

CAUTION:

this possibility. Discharge yourself to an electrical ground (outlet cover screw) before removing this device from

its anti-static bag. Please read instruction sheet completely before attempting to install and operate this

product. Save the anti-static bag for possible reuse of storing or shipping the sound unit!

OVERVIEW: This device is an electronic, self contained, sound system for installation in model

electric locomotives that are designed to operate with conventional DC track power, digital (DCC)

or other types of command control systems including radio with either track or battery power, also

as a stationary sound unit. Because of its dimensions (2.7" x 0.9" x approx. 0.5" high) the sound

system may be limited to installations in some powered units making the need for use of a

"dummy" unit or a trailing car. An alternative installation under the layout is also possible including

the use of our TRAK-DT devices to switch the sound through multiple speakers so as to follow

the movement of the train. A drawing for this application is in our Model Railroaders Wiring Guide.

An on/off switch (not included) must be used to power the sound unit on and off in some

applications. The audio amplifier can produce one watt of power which is in excess of what most

small speakers can handle. The speaker impedance must be 8 ohms or higher. Sound volume is

adjustable. Refer to our catalog for available speakers. If space permits, the optional oval

speakers (Items 662, 664, 665), which are higher wattage speakers, are the best choice.

Sounds produced include user controlled horn, bell f orce cooling fans and main sounds on/off

(leaves the main sounds off while allowing for horn and bell operation). Non-user co ntrollable

sounds brake release and electric cooling fans sound. These automatically operate. The cooling

fans can be manually controlled.

This sound system, when used with conventional DC track power, requires the use of our

LocoMatic™ Controller (Item 755) to operate the horn, bell, force co oling fans, and main sounds

on/off. DCC and other command control operators can use remote functions on their systems to

activate the same functions. For stationary installations, these functions can be accessed by

switches. Radio control with fixed track power or on board batteries would be similar to DCC

installations and large gauge (where you ride the locomotive) would be similar to a stationary

installation.

INSTALLATION INSTRUCTIONS: The sound system consists of a printed circuit board, a

speaker, five 2-pin connectors with wires and two 3-pin connectors with wires. A CHOKE (item 70

or 703 depending on motor power requirements), no t included, is required for DC track power

installations.

Refer to the drawing on page 2 to familiarize yourself with the connectors and controls on the

sound board. Then refer to the specific instruction sheets for the type of installation you intend to

make. Before proceeding with the installation read the balance of the instructions carefully so you

will be completely familiar with what is required and what sounds you should hear.

The circuit board should be mounted so that at minimum, the volume control is accessible either

through the frame or via a hatch or a hole in the locomotive body shell. Be certain that the

components on the circuit board do not come in contact with any metal objects as such contact

can destroy the sound system. The speaker should be mounted as per available space bearing in

mind that sound reproduction is enhanced when a speaker is properly enclosed and baffled.

If a DC locomotive is not moving, there is no track power, therefore to have sound it is necessary

to have a separate power supply for the sound system. For in locomotive use, this separate

supply is a battery. We suggest the use of one 9 volt or 6 AA or 6 AAA batteries in series to

maximize volume potential and battery life. Rechargeable batteries can be used. When

connecting the battery (DC) power leads be absolutely certain that w ires connect to the proper

DC input leads.

This device can be damaged by static discharge. Please exercise care during installation to avoid

DCv3 rev8

If any connections are not done properly, especially the power connections, you will damage the

sound system. This type of damage is not covered under any warranty. The sound system is

thoroughly tested and inspected before packing to insure proper fu nction. There is a minimum

charge of $35.00 plus s/h for repair.

SOUND INFORMATION:

Cooling Fans (Electric): sounds range from idle (silent - no fans operate when not running) to

full fan rpm. With no power to the track / motor the sound system will produce no sounds. As a

throttle is advanced to put the locomotive in motion, a brake release will sound (see below) and

the electric fans will accelerate to full rpm. With our LocoMatic™ Controller (#755), activating the

ALT and F3 buttons simultaneously (and then releasing) will direct the sound system to ramp the

fans to full RPM regardless of track / motor voltage. Activating both buttons again will release the

sound system to return to the correct fan setting. This feature allows the simulation of more

cooling when sitting after a heavy load run or "pumping air" in a standing train. This full fan RPM

feature is available to other users either by a switch or with a remote function. The cooling fans,

air pops, and brake release sounds can be turned off without turning off the sound system. This

way you can still activate the Horn and Bell. With our LocoMatic™ Controller, use ALT F4 as a

push on, push off. For other receivers or stationary, a function or single pole switch will suffice.

BRAKE RELEASE: sound is produced when the throttle is advanced from the idle position. This

brake release should always precede locomotive movement. For DC operators, this requires

approximatly 1.5 to 2 volts of input voltage to sense a running mode for the brake release to

sound.

HORN: sound is controlled by the HORN button on the LocoMatic™ Controller, by a momentary

push button or by remote function, dependent upon the type of installation. The HORN will sound

as long you are holding the control on. This will allow you to actually play the sound as on a real

locomotive. DCC and similar systems will have a sound delay equivalent to system response

time.

BELL: sound is controlled by the BELL button on the LocoMatic™ Controller, by a toggle switch

or by remote function, dependent upon the type of installation. The sound system includes a

routine which ignores intermittent BELL requests, resulting in a delay when activating or

deactivating the BELL. With the LocoMatic™ Controller you depress and release the BELL button

to turn on the BELL and then again depress and release the button to turn the BELL off. Toggle

switch or remote function control does not require the PUSH ON - PUSH OFF sequence.

SPEAKER MOUNTING: The speaker generally should be mounted so that the sound can

actually "get out" of the locomotive. A hole in the floor or fuel tank is acceptable but open grills or

a doorway may be a better choice as the sound can exit upward rather than down toward the

track. In some cases, particularly with plastic body shells, just mounting the speaker against the

shell will be adequate as the vibrations of the shell can enhance the sound. Enclosing the

speaker in a chamber will also enhance sound reproduction. A very simple enclosure can be

made with a tube. The longer the tube the better the speaker will reproduce low frequency sound

which is inherent in electric cooling fanss. It is usually best to seal the end of the tube, so there

are no air passages to the rear of the speaker, thus creating a sound chamber. By carefully

sealing all openings it may be possible to use the entire body shell as a sound chamber. A simple

wall behind the speaker may be all that is possible or perhaps all that is needed.

Speakers can be attached with double sided tape, with glue or with "hot melt". Enclosures can be

made with plastic, wood, card stock or even metal. Film cans or medicine bottles make excellent

sound chamber enclosures for small diameter speakers. Attachment with "hot melt" is

advantageous as the "hot melt" can be used as a gap filler when creating an enclosure.

A second speaker, wired in series with the main speaker, can also enhance sound quality and will

1

Page 2

permit a higher volume without damage to the individual speakers. A tube with a speaker at each

end or a speaker in a doorway at each end of a body shell is an excellent approach. A four

speaker approach will yield the highest volume while still maintaining the 8 ohm minimum

requirement. Drawings for this are included in the speaker instructions.

Speaker enclosure is an art and experimentation is definitely in order for your installation so a s to

gain the maximum benefit of the superb sound quality available in this sound system.

GENERAL OPERATING INFORMATION:

VOLUME ADJUSTMENT: should be set as desired for your application. Please remember that

the amplifier can produce more power than a small speaker can handle and that the sound will be

louder if the speaker is properly enclosed and baffled. If you are using batteries, the louder the

volume the shorter the battery life.

NOTCH ADJUSTMENT: full clockwise for standard 12 volts to the track / motor. Rotate the

control CCW for all other operators using higher motor voltages. This control will have no real

effect in this system but must be set correctly for higher motor voltages.

Common Horn signals

SOUND

short .............................. apply brakes, stop

2-long ............................ release brakes, proceed

long, 3-short .................. flagman protect rear of train

4 or 5 long ..................... recall flagman

2-short ........................... acknowledgment

3-short ........................... back up movement

4-short ........................... call for signals

short, long ..................... inspect train line for leak or brakes sticking

2-long, short .................. approaching meet or wait point

2-long, short, long ......... approaching grade crossings

continuous long ............. approaching stations or junctions

successive shorts .......... alarm for something on track

INDICATION

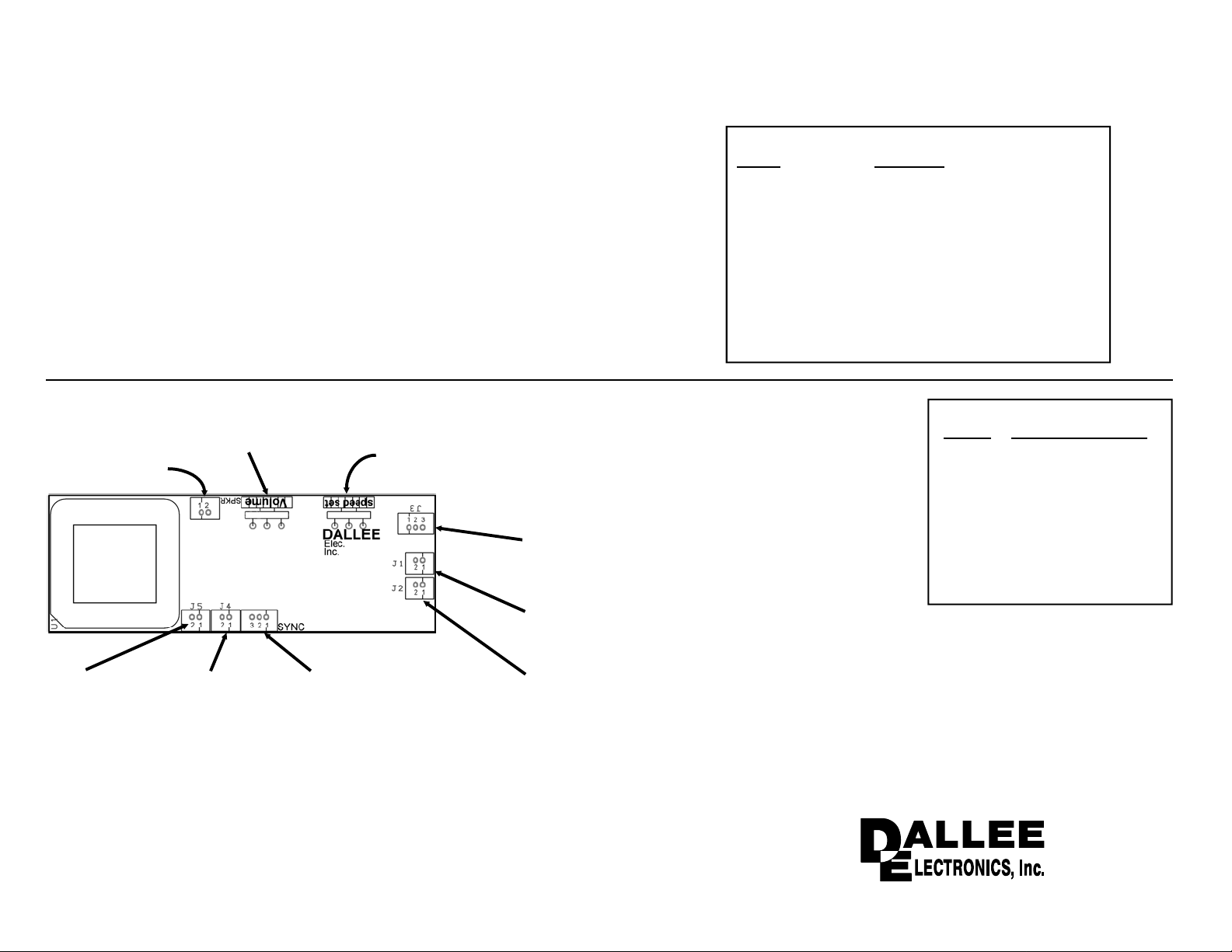

Volume Control

Notch Control

Speaker Output

Motor Select (J5)

1 - force Cooling

Fans (red)

2 - motor sound

OFF (gray)

NOTE: The speaker impedance should be kept near or above 8

ohms, therefore four 8 ohm speakers in a series/parallel

configuration is acceptable since it yields 8 ohms total

impedance. If you care to use two 8 ohm speakers you must

place them in SERIES.

Remote Input (J4)

1 - Horn (red)

2 - Bell (gray)

See pg10 for use with

Electric Sound systems .

This system features an optically coupled motor

input sensor. This means that any connection to

J3 pins 1, 2, and 3, do not electrically connect

to any other power to the board!

J3 connections:

1 - track RF input (RED)

2 - Motor 1 (BLACK)

3 - Motor 2 (WHITE)

J1 connections:

1 - DCC rail 1 ....... also AC input 1 ......... (RED)

2 - DCC rail 2 ....... also AC input 2 ......... (GRAY)

J2 connections:

1 - DC power "+" (RED)

2 - DC power "–" (GRAY)

When connecting DC power to the sound unit be absoloutly

sure that the "+" and "–" are connect correctly! If not, you

will either burn out the sound unit or the supply feeding it.

This is not covered under warranty!

SPECIFIC INSTRUCTION SHEETS

PAGE

3, 4, 10 Conventional DC

5, 9, 10 Stationary Sound

6 DCC receiver

7 OTHER receiver

8 with DC Controller

8, 9, 10 aux. Amplifier

10 Manual Speed Control

Remote Volume Control

INSTALLATION TYPE

Dual Conventional DC

Systems

246 W. Main St.

Leola, PA 17540

(717) 661-7041

www.dallee.com

2

Page 3

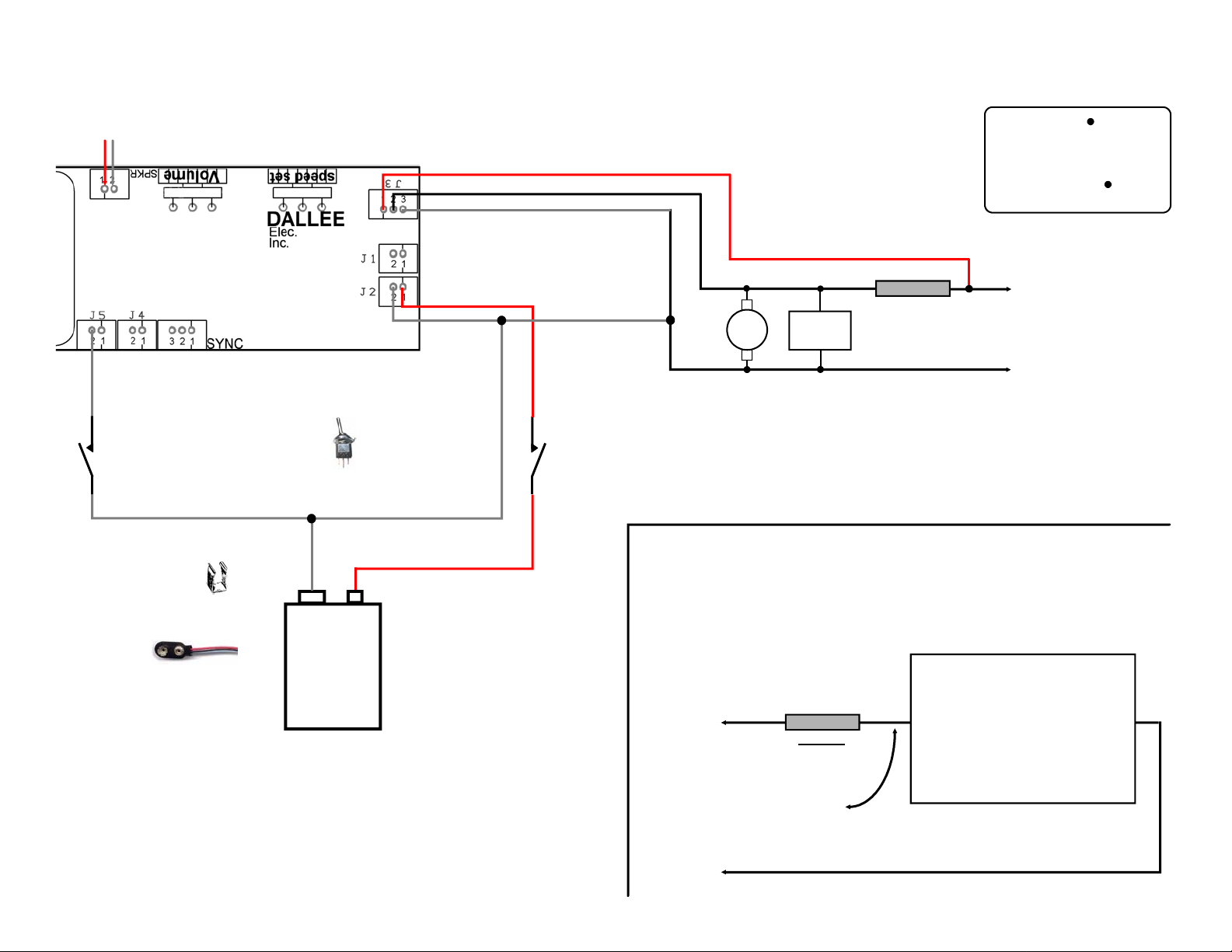

DC track power installation using standard batteries & DALLEE controller #755

speaker

Gray

Optional main

sounds switch

ON / OFF

(shown sound "ON")

Battery Holders

#579 - single 9 volt (shown)

#652 - holds 6 AA

#654 - holds 2 AA

#578 - 9 volt battery snap

connector

Battery power - must not exceed 24 volts DC.

Use one 9 volt battery or a string of 6 AA or

AAA batteries (24 volt DC maximum input). Life

depends on volume setting and speaker

impedance. Typical operation of most sound

systems for one good 9 volt batteries is about 8

hours, AA or larger is well beyond 50 hours!

– +

9V or 6-AA,

or 6-AAA

batteries

Red

Black

White

Red

+

Gray

–

524 SPST switch.

Switch shown in the OFF

position. Drawn as a spst.

ON / OFF

switch

wires with a " " ARE a

connection!

wires crossing over

(without a " ")

DO NOT CONNECT!

Right Rail

pickup

either rail may be used. Right / Left

only used for reference.

DC

motor

lighting

CHOKE *

circuits

Left Rail

pickup

*Larger motors require a larger capacity choke.

Chokes:

Item 702 - 1.5 ampere loads

Item 703 - 5.0 ampere loads

Lighted car / other engines used in consist preperation. You will know if this is necessary

by placing the locomotive / lighted cars on the track and then attempting to blow the

HORN or operate the BELL. If they do not operate with the other items on the track

then you need to do the following. We suggest doing this to all lighted cars or

engines used in the same consist since it lets the signal stay at it's maximum level.

for additional chokes order:

Item 702 for up to 1.5 ampere load

Item 703 for up to 5.0 ampere load

Right Rail

pickup

either rail may be

used. Right / Left

only used for

reference.

CHOKE PACK

looks like coil of wire with a

Formerly right

rail pickup

CHOKE

lead on each end

LOAD

Lighting load, other locomotive in

consist, or other type circuitry

drawing off of track power. As

shown one lead needs to be

disconnected from the rail and a

"CHOKE" needs to be placed in

series with the load. In most cases

the 1.5 ampere (#702) will handle

the load.

Left Rail

Pickup

3

Page 4

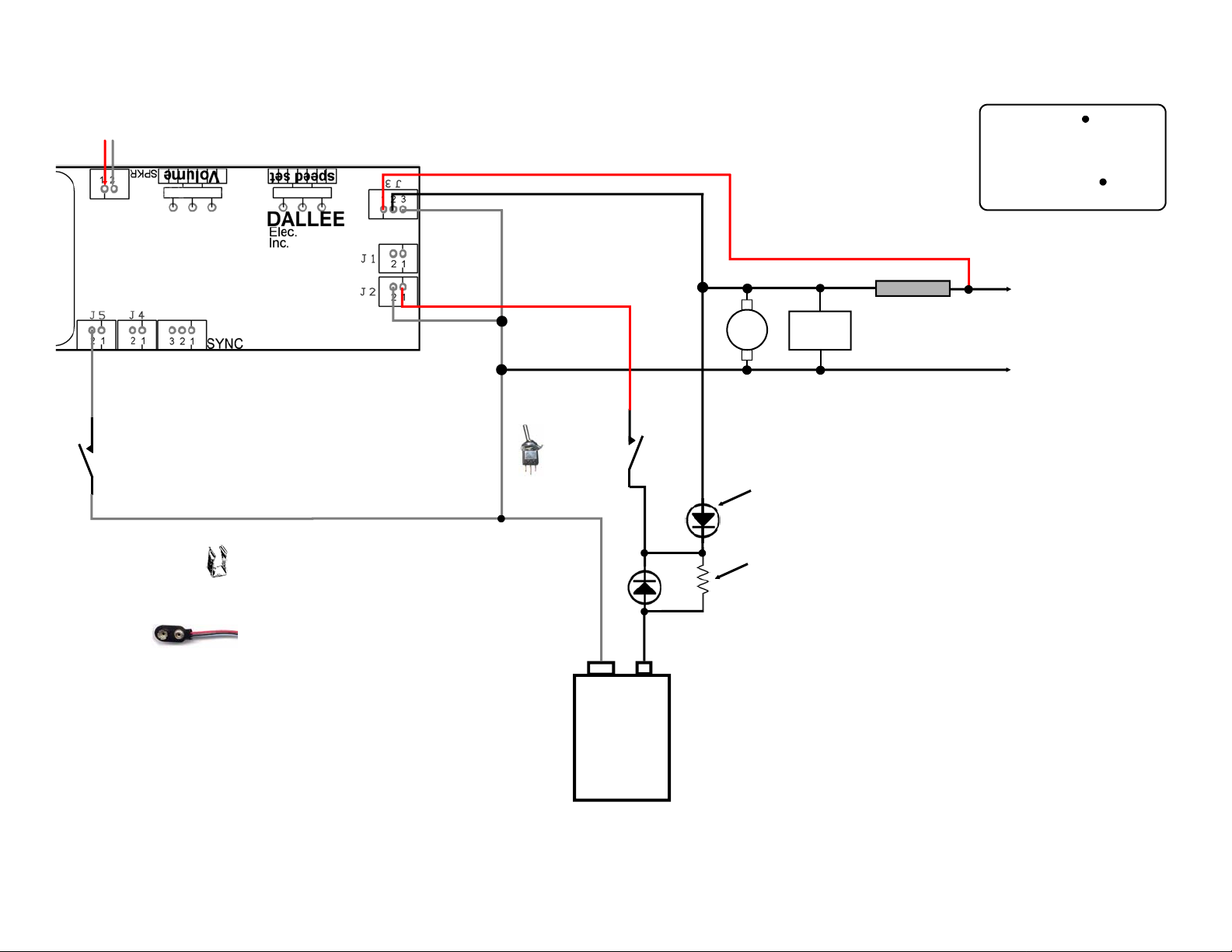

speaker

DC track power installation #2 with DALLEE controller #755.

With rechargeable or standard battery.

When track voltage exceeds battery voltage, the sound system will

operate from track voltage instead of battery voltage.

Red

Black

White

wires with a " " ARE a

connection!

wires crossing over

(without a " ")

DO NOT CONNECT!

Red

+

Gray

–

Gray

Optional main

sounds switch

ON / OFF

(shown sound "ON")

Battery Holders

#579 - single 9 volt (shown)

#652 - holds 6 AA

#654 - holds 2 AA

#578 - 9 volt battery snap

connector

Battery power - must not exceed 24 volts DC.

Use one 9 volt battery or a string of 6 AA or

AAA batteries (24 volt DC maximum input). Life

depends on volume setting and speaker

impedance. Typical operation of most sound

systems for one good 9 volt batteries is about 8

hours, AA or larger is well beyond 50 hours!

524 SPST switch.

Switch shown in the OFF

position. Drawn as a spst.

This diagram allows for the use of rechargeable batteries. When

track voltage exceeds battery voltage, the sound system will operate

from track voltage and the battery will start to charge (when in the

forward direction). If you need to charge the battery fully without the

sound system on, place the locomotive on the track (with the motor

not powered if present) and leave full track voltage on for 14 hours.

The batteries will charge whenever the locomotive track power is

set for the forward condition regardless of the sound system being

on or off. They will not charge when the polarity on the track is set

in reverse. When running in reverse, the sound system will only

operate from the battery. A bridge rectifier could be used instead of

a single diode alleviating this potential problem.

ON / OFF

switch

– +

9V or 6-AA,

or 6-AAA

batteries

Right Rail

pickup

either rail may be used. Right / Left

only used for reference.

DC

motor

lighting

CHOKE *

circuits

Left Rail

pickup

*Larger motors require a larger capacity choke.

Chokes:

Item 702 - 1.5 ampere loads

Item 703 - 5.0 ampere loads

1N4002 or

equivalent diode

(item #374)

If using a standard battery instead of

rechargeable, do not connect/use a resistor!

Resistor needs to be calculated for battery type (you must know

the charge currents of the batteries used) and maximum track

voltage used.

R = (Vtrk max - Vbatt nominal) / battery charge current

For 12 - 14 volt maximum track voltage:

1 - Item #647 (8.4v / 150mahr) rechargeable battery use 380 ohms

(1/4 watt).

6 - Item #648 (1.2v / 700mahr) rechargeable batteries in series, use

100 ohms (1/2 watt).

For 18 volt maximum track voltage:

1 - Item #647 (8.4v / 150mahr) rechargeable battery use 560 ohms

(1/4 watt).

6 - Item #648 (1.2v / 700mahr) rechargeable batteries in series, use

180 ohms (1 watt).

4

Page 5

speaker

Stationary DC power installation using track power for notch setting.

You can also add an auxillary Amplifier, see pages 8, 9, and 10.

Switch key:

S1 - Horn (momentary)

S2 - Bell

S3 - Force Cooling Fans

S4 - Main sounds off

Gray

Red

S4

S3

524 SPST switch.

Switch shown in the OFF position.

Drawn as a spst.

Gray

S2

Red

S1

speaker

Switch key:

S1 - Horn (momentary)

S2 - Bell

S3 - Force Cooling Fans

S4 - Main sounds off

Gray

Red

Gray

Red

#618 SPST momentary

push button switch.

Switch shown in the OFF posi tion.

Black

White

+

–

Red

Gray

ON / OFF

switch

Right Rail

Left Rail

either rail may be used. Right / Left

only used for reference.

524 SPST switch.

Switch shown in the OFF

position. Drawn as a spst.

+

–

fixed DC power - must not exceed 24

volts DC. If you have a HUM or

other static noise in the audio output

it is because this power is not

filtered enough. Add a large

electrolytic capacitor (470 mfd @ 25

vDC or larger) across this DC

supplies output (when power is off).

Make sure you observe the polarity

markings of the capacitor !

Stationary AC power installation using track power for notch setting.

You can also add an auxillary Amplifier, see pages 8, 9, and 10.

Black

White

Gray

+

–

Red

Gray

Right Rail

Left Rail

Red

+

extra filter

capacitor observe

polarity !

either rail may be used. Right / Left

only used for reference.

ON / OFF

switch

524 SPST switch.

Switch shown in the OFF position.

Drawn as a spst.

fixed AC power 10 - 18 vAC you MUST

NOT EXCEED 18 volts AC. DC voltage

created from AC is 1.414 X vAC, 18vAC

= 25 vDC !

A HUM in the audio output is because

the DC power is not filtered enough. Add

a large electrolytic capacitor (470 mfd @

25 vDC or larger) across the DC output

as shown (when power is off). Make

sure you observe the polarity markings

of the capacitor !

S4

S3

S2

S1

5

Page 6

DCC receiver installation using motor power for Main Sound activation and

speaker

function control for HORN, BELL, Manual Cooling Fans, Main Sounds ON / OFF

Gray

Red

Gray

S4

S3

S2

Connect S1 thru S4 to function control desired.

You do not need to connect functions you do

not intend on using.

Function key:

Red

S1 - Horn (momentary)

S2 - Bell

S1

S3 - Force Cooling Fans

S4 - Main sounds off

Black

White

Red

Gray

No connection is

required to J2. All of

the sound system

power is supplied

from the track via J1.

DCC

track power input

Connect motor

M

if present

receiver motor leads (Orange / Gray is

standard practice). If you are using a

seperate receiver merely connect the

motor leads to pins 2 (black) and 3

(white) of J3. The sound system presents

a load of 480 to 980 ohms (depends on

speed set control setting).

Make sure that your receiver is operating in

the same step mode as the transmitter !!

S1 - HORN function. Connect to desired

function output of module. Activate low to

play HORN.

Some DCC systems offer a momentary

type function. It is best to use what the

system you are using suggests.

Digitrax - use F2 function

Wangro - use F3 function

S2 - BELL function. Connect to

function output of module.

Activate low to play BELL.

Suggest function as set by DCC

system you are using.

Digitrax - use F1 function

Wangro - use F2 function

S2 -> S4 - function. Connect to extra

function, if desired. When using an extra

receiver you can use either Forward or

Reverse lamp function output of module.

Normally not activated = "high".

Activated = "low" (function ON).

ATTENTION

ALL FUNCTION CONNECTIONS are for OPEN COLLECTOR type FUNCTIONS such as those found on DIGITRAX, LENZ, NCE, and WANGRO receivers. Although there should not be any

problem with any other type, we have not verified it. The sound unit has been designed and operated with WANGRO, DIGITRAX, and LENZ systems to verify DCC operation and compatability.

ADDITIONAL NOTES:

If you feel that you need longer running time when an intermittent track power input occurs simply attach a larger filter capacitor across the DC power leads (J2). Observe proper polarity. The

plus connects to pin 1 (red), minus to pin 2 (gray) - the polarity is very important since some capacitors when connected in reverse can actually blow up like a fire cracker! The larger the

capacitor the longer operating time without track power. A capacitor of 470 mfd @ 25vDC should be sufficient, too large of a value will require a very large surge current when track power is

applied. Some transmitters cannot take the large surge current on startup and will show an overload condition when powering up.

6

Page 7

Other receiver or controller installation using motor power for Main Sound activation and

function control for HORN, BELL, Force Cooling Fans, Main Sounds ON / OFF

speaker

receiver motor leads. Connect

Black

White

Connect motor

M

if present

the motor leads to pins 2

(black) and 3 (white) of J3.

The sound system presents

a load of 480 to 980 ohms

(depends on speed set

control setting).

Function key:

S4

Gray

Red

S3

S2

Gray

Red

S1 - Horn (momentary)

S2 - Bell

S1

S3 - Force Cooling Fans

S4 - Main sounds off

S1 - HORN function. Connect to desired

function output of receiver or

activated switch. Activate low to

play HORN. This needs to be a

momentary operation.

Red

+

Gray

–

Connect S1 thru S4 to function control desired.

You do not need to connect functions you do

not intend on using.

S2 - BELL function. Connect to

function output of

receiver or activated

switch. Activate low to

play BELL.

DC battery power input.

Input voltage of 7 to 24 volts DC. Absoulute maximum

input is 35 volts DC! If the battery supply is not the

same as the receiver supply, connect the gray "-"

wire to the "-" of the receiver supply.

S2 -> S4 - function. Connect to receiver

function or switch, if desired.

Normally not activated = "high".

Activated = "low" (function/switch ON).

If you are using a receiver that

operates higher than 24 volts, it is

necessary to add a 470 ohm, 1/2

watt, resistor in series with one of

the inputs to J3 from the motor lead.

using SIGNAL TRANSISTORS for remote control of the HORN, BELL, and other functions.

C

B

Q1

E

C

B

Q2

E

to Horn input of

sound board

to Bell input of

sound board

These parts can be obtained directly from us but they do

not appear on the price schedule - call or write for prices.

This is possible when both the receiver and sound system are operating

from a common supply. The common supply can be either fixed track

voltage or fixed battery voltage. Since both the sound system and the

receiver are operating on the same supply, the common "—" power

would be the same. This circuit relies on the receiver having a logical

"HI" voltage when the remote functions are activated. Keithco and other

users requiring an inverted signal can use this optional interface circuit.

If you have another function available you could operate another function

such as a forced cooling fans. Connect another transistor as the Horn

and Bell transistors but connect the collector of the transistor to the S3

function input.

HORN function

of receiver

R1

BELL function of

receiver

R2

R1, R2 - 1.0k 1/4 watt (Brown, Black, Red)

Q1, Q2 - 2N4401 or equivalent NPN transistor

2N4401

(front view)

EBC

COMMON of receiver

("-"supply) or J2 pin2 (gray).

These are the same since

both operate from the same

supply.

7

Page 8

Other receiver or controller installation using motor power for Main Sound activation and

switches for HORN, BELL, Force Cooling Fans, Main Sounds ON / OFF

speaker

receiver motor leads. Connect

Black

White

Connect motor

M

if present

the motor leads to pins 2

(black) and 3 (white) of J3.

The sound system presents

a load of 480 to 980 ohms

(depends on speed set

control setting).

Gray

S4

Red

S3

524 SPST switch.

Switch shown in the OFF position.

Red

Gray

S1

S2

Drawn as a spst.

Switch key:

S1 - Horn (momentary)

S2 - Bell

S3 - Force Cooling Fans

S4 - Main sounds off

#618 SPST momentary

push button switch.

Switch shown in the OFF position.

+

–

Red

Gray

DC battery power input.

Input voltage of 7 to 24 volts DC. Absoulute maximum

input is 35 volts DC! If the battery supply is not the

same as the receiver supply, connect the gray "-"

wire to the "-" of the receiver supply.

Auxillary Amplifier connections

"Audio input" Connect to gray wire from sound system speaker output. Do not use the

red speaker wire from the sound system. This wire does not get connected! Either cut or

tape the red wire securely so that it cannot short to something. Never connect either of

the speaker output wires to ground. This will damage the sound system's amplifier and is

not covered under any warranty.

If desired, a speaker can still be connected to the main sound sytem speaker output as

well as another speaker from the amplifier.

auxillary AUDIO AMPLIFIER,

Item #671 or #672

If you are using a receiver that

operates higher than 24 volts, it is

necessary to add a 470 ohm, 1/2

watt, resistor in series with one of

the inputs to J3 from the motor lead.

Amplifier DC input power

Red -> +DC

Black -> ground

This needs to be the same

as the sound system power.

8

Gray

"Audio Input"

1

2

3

Page 9

speaker output

Gray

Using dual sound systems with an auxillary amplifier.

1k, 1/4w

(brn,blk,red)

Switch key:

S1 - Horn (momentary)

S2 - Bell

S3 - Force Cooling Fans

S4 - Main sounds off

Gray

S4

S3

524 SPST switch.

Switch shown in the OFF position.

Drawn as a spst.

Gray

S2

Red

S1

Connect only the switches desired for each sound

#618 SPST momentary

Switch shown in the OFF position.

system. It is best to use one with the prime mover

turned off (S4), using it to produce the Horn and Bell.

The other unit would then produce the prime mover

with only S3, to force N8, utilized. As shown.

speaker output

Gray

Switch key:

S1 - Horn (momentary)

S2 - Bell

S3 - Force Cooling Fans

S4 - Main sounds off

This unit would produce the prime mover sounds.

Gray

Red

S4

S3

524 SPST switch.

Switch shown in the OFF position. Drawn as a spst.

Utilizing S3, force N8, and S4, main sounds off,

as optional connections. The horn and bell

would not be used in this unit since the upper

unit would be producing those sounds.

S1

S2

Horn and Bell

sounds would be

produced by this

sound unit.

push button switch.

Prime mover

sounds would be

produced by this

sound unit.

Black

White

+

–

Black

White

+

–

Red

Gray

Red

Gray

ON / OFF

switch

524 SPST switch.

Switch shown in the OFF position.

Drawn as a spst.

1k, 1/4w

(brn,blk,red)

Black

Audio input. Connect as shown to

resistors and gray speaker wire from

sound system. Do not use the red

speaker wire from the sound system.

This wire does not get connected!

9

track power, receiver motor

Connect motor

M

if present

Red

Gray

Auxillary 11 or 22 watt Audio Amplifier

Red

Black

Gray

More than one power amplifier can be used. To do so

connect the input wires (gray) in parrallel from the

amplifier to the sound systems gray speaker wire or

use one amplifier for each sound system.

DC battery power input.

+

Input voltage of 12 to 24 volts DC.

–

If this is a DCC system, one of the sound

with Treble and Bass controls.

Item 671 - 11watt, 672 - 22 watt.

1

2

3

leads, or whatever you are

using to adjust the prime

mover notches.

Connect to the same power that is

powering the sound system.

units needs to have J1 connected to

the track power and no battery power

or an on/off switch would be

connected. Switch inputs s1 - s4 would

be functions.

8 ohm

speaker

use

Page 10

using dual systems with LocoMatic™ Controller

To strap off the Horn and Bell in an electric unit, connect the

SYNC white wire to the black wire. This will allow only the

prime mover sounds to operate. Cut the white wire off or

remove from the connector.

Refer to page 9 for using two sound units. The top sound unit would be

connected as shown on page 9 without switches S1 and S2. The lower

sound unit, producing the prime mover sounds, would be connected as

shown to the left with nothing connected to J4 or J5.

Track power inputs, as shown on page 3 and 4, will be the same except they

will go to both sound systems J3 connectors.

Battery connections will go to both units DC power input connector, J2.

If you do not care to use an amplifier, you must use two seperate speakers. In

that case, each sound system will have their own speaker. The speaker

connected to the lower sound unit would then produce the prime mover

sounds with air and brake release sounds, and the other speaker, connected

to the upper sound unit, will produce the Horn and Bell sounds.

For extra 2 and 3 pin ultra-miniature connectors, see item's 757 and 758.

They are listed under Accessory Items / Connectors.

adding manual control to the IN LOCOMOTIVE DC SOUND system as a

stationary unit to adjust diesel notches, steam chuff rate, or operate

brake release and cooling fans in electric's.

Connect input power, speaker, and all other connections as shown in stationary or other types of

installations except no input connections should be applied to the DC motor/track input

header (J3) pins 2, or 3. Instead, connections should be done as shown below. All other

input power, speaker, switch connections should be done as before.

Basic setup for both types of operation: Set NOTCH CONTROL (speed set) full CCW. The

potentiometer, transistor, and a knob can be obtained directly from us as item#602 but they

may not appear on the price schedule - call or write for prices.

no connection

Black

White

Red

+

Gray

–

Don't forget to connect either J2 or

J1 to the appropriate power supply.

C

B

E

2N4401 (NPN) or equiv.

External RPM control

potentiometer with knob &

transistor (item #602)

CW

50K

E B C

adding remote volume control when using an Aux illary Amplifier

With single sound systems, connect the gray wire from the speaker output to input "I". Connect

the rest as shown.

If using two sound system as shown on page 9, connect the junction of the two sound systems

to the capacitor as shown on page 9, then merely add the potentiometer as shown. This will only

work properly if the amplifier has an industry standard auxillary input.

I

audio input from

sound system

1 2 3

viewed from front

External Volume control

with knob and capacitor

(item #601)

Remote

volume

control

+

1

3

1 mfd capacitor

Observe polarity!

—›

clockwise

2

Amplifier DC input power

Red -> +DC

Black -> ground

This needs to be the same

as the sound system power.

auxillary AUDIO AMPLIFIER,

Item #671 or #672

Gray

1

2

3

using an Auxillary Amplifier with matching transformer input

10

speaker output

matching transformer

8 - 16

ohms

amplifier input impedance

Amplifier

Input

matching transformers

can be found in many

audio shops. They are

used for power amplifiers

found in car systems.

Page 11

Sample Speaker Installations

For open body shells it is necessary to make a speaker baffle instead of using

the body for a baffle. In both cases, the backside of the speaker is closed off.

Mounting a speaker facing out from

inside of the body. You have to seal

all edges of the speaker for a proper

baffle.

Body shell before speaker installation.

Using the fuel tank as a speaker

baffle is quite easy. In this case the

speaker eminates sound into the

body.

Mounting speaker in hood of engine using a metal grill for the exhaust.

Body shell after speaker installation. Speakers are mounted on a card stock formed

shelf and then hot melted in place. Air space is required between the front of the

speakers and the body bottom but the back of the speaker enclosure is completely

sealed to make a good enclosure / baffle! This type of installation yields more sou nd

per watt than one single speaker.

In the case of a long body, such as the GG1, you can place four speakers inside the

shell. As shown above, the body shell is used as the backside of the baffle The more

speakers, the better the sound (especially when using small speakers as in model

locomotives. Four speakers make an ideal configuration.

11

Page 12

alternative lighting

you might also want to consider installing our Adjustable Regulated Lighting board. The RL-ADJ (item 379) comes with four 2.7v lamps (item 383) but is capable of driving eight lamps, as shown. You can

set the intensity desired (1.25 - 6.2 volts). It maintains constant voltage to the lamps and requires nothing more for our standard DC sound systems or LocoMatic™ compatibility. Simply install the lamps

where desired, connect the input power, and peel the tape to secure. The unit can be broken into smaller strip lengths where needed. All the way down to 2" for the power module. Install in cabooses,

passenger cars, or buildings. Measures only 1/2" wide. Extra, low voltage lamps, are available. We also offer 1.5 volt lamps in various colors. See our Catalog or Web site for more details.

Like the RL-ADJ (item 379), the VRS (item 378) offers the same adjustments in a super small size. It is capable of driving 1/2 ampere of current, like the 37 9. This amounts to eight 2.7v lamps (item 383),

as shown above or our small 1.5 volt lamps as well (see our catalog or w eb site for details on other lamps). You can set the intensity desired (1.25 - 6.2 volts). It maintains constant voltage to the lamps

and requires nothing more for our standard DC sound systems or LocoMatic™ compatibility. Simply install the lamps where desired, connect the input power, and secure the board. There are also no

connections on the back side of this board so it can be mounted flush to any area. Install in cabooses, passenger cars, or buildings. Measures only 1.25" w x 1" l x 0.35" h.

Output can be adjusted from 1.25 to 6.2 volts. Input can be up to 30 volts DC,

DCC, or AC. Powers 30 of our 1.2mm colored 1.5v lamps (Red #384, Yellow

#385, Green #386), 12 #382 lamps, 8 #383 or #756 lamps.

With two diodes and light bulbs, you can also use this module to achieve

directional lighting. The drawing for this is on our web site as well.

12

1.25"w x 1"l x 0.35"h

Loading...

Loading...