Page 1

LocoMatic™ type3 ELECTRIC Sound & Control

for AC or DC track power by

Instructions rev 1.2

CAUTION:

this device can be damaged by static discharge.

please exercise care during installation to avoid this

possibility. discharge yourself to an electrical ground

(outlet cover screw) before removing this device from

its anti-static bag. please read instruction sheet

completely before attempting to install and operate

this product.

AC or DC TRACK POWERED SOUND & CONTROL

SYSTEM - ELECTRIC LOCOMOTIVES

OVERVIEW:

have not previously been available in the model train industry.

DC operators should operate in LocoMatic™ COMMAND

CONTROL only. If operated with variable DC track power in

standard mode, then normal AC like sequencing will occur with

either a Horn or Bell constantly operating (unless switch 3 is set

on for calf mode). Conventional AC operation follows the usual

sequence of forward - neutral - reverse - neutral - forward

sequence pattern except that the initial state is switch selectable

for either start in forward or start in neutral. A locomotive can

also be switch locked in the forward position to accomodate

operation under automated situations. An additional direction

switch is provided so that if several locomotives are run in a

multiple unit lash-up simply set this switch on each locomotive to

specify which direction is forward. Recordings of actual diesel

locomotives, were digitized, to be reproduced by the

microprocessor sound system so that the sounds you hear will

be as prototypically correct as possible. Sounds produced

include user controlled horn and bell, periodic air system release,

brake release and diesel prime mover sound automatically

adjusted to speed and load conditions. The prime mover sound

can also be user forced to its full throttle position. This sound /

control system also incorporates provisions for directional head

and back up lights, also marker lights as well as other lighting,

including roof top strobes. Most lighting can also be manually

controlled by means of the LocoMatic™ controller. The

LocoMatic™ controller is also used to activate optional electric

coil couplers (requires additional item 501 and coil couplers) for

remote uncoupling of the locomotive from its train.

This sound / control system can be operated by all known classic

and modern power transformers that output low voltage 6-18

vAC or up to 25vDC to the track and will also operate with Lionel

Trainmaster in conventional mode. See appended instructions

regarding the operation of this sound / control system in

LocoMatic™ command mode simultaneously with Lionel

Trainmaster Command Control.

Additionally the sound / control system will operate with the

LocoMatic™ controller either in conjunction with your

transformer or independently with a fixed voltage supplied

through the LocoMatic™ controller to the track.

If all you want are sounds, merely connect the speaker and track

power inputs. As long as the internal e-unit remains in sync with

the LocoMatic™ sound/control systems e-unit the sounds will be

produced in sync with the locomotive.

This sound / control system includes features that

INSTALLATION INSTRUCTIONS:

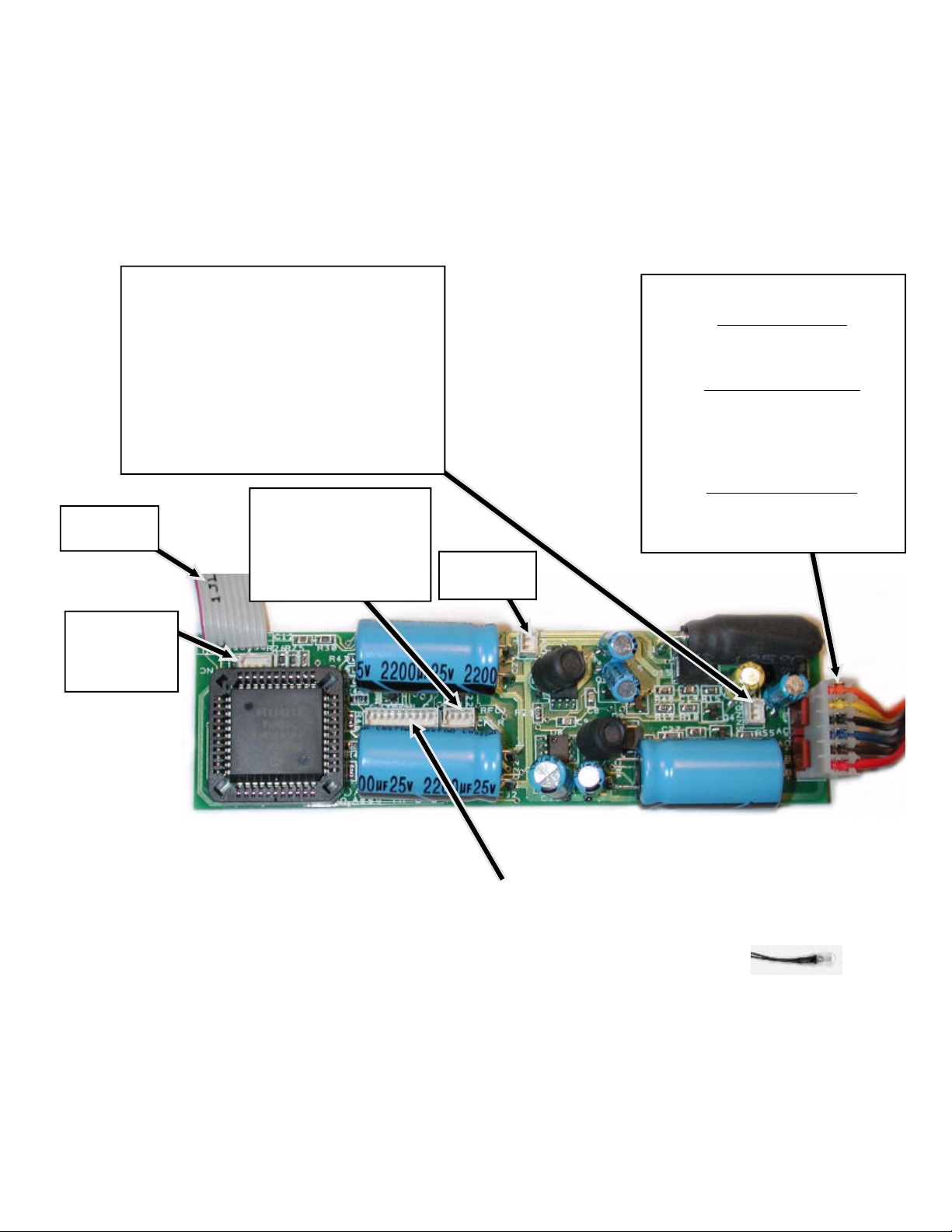

consists of a main printed circuit board with an additional small

circuit board attached by a wire harness. Also included are two 5

volt light bulbs (item #756), one 0.1 mfd capacitor, two 2 pin, and

a 9 pin connector.

Refer to pages 6 and 7 to familiarize yourself with the connectors

and controls on the sound / control board. Before proceeding

with the installation, read the balance of the instructions carefully

so you will be completely familiar with what is required and what

sounds you should hear.

The main circuit board measures 1.25"w x 4.5"l x 0.8"h and

should be mounted where space permits using the double sided

tape attached to the circuit board. The small circuit board (13/16"

x 39/64"), called the sw/vol board, contains the volume control

and 6 switches. It should be mounted so that the controls are

accessible either through the frame or via a hatch or a hole in the

body shell. Double sided tape is supplied to mount this board.

Other double sided tape or small screws may also be used to

mount the sw/vol board. Be certain that the components on the

circuit boards or traces do not come in contact with any metal

objects as such contact can destroy the sound / control system.

LIGHTING INSTALLATION:

middle of the main circuit board. This connector supplies an

output of 5 volts for lighting applications as follows:

1 ....... Red .......... +5 volts

2 ...... Orange ..... +5 volts

3 ...... White ....... Lmp F ....... automatic / manually* controlled

headlight

4 ....... Blue ......... Lmp R ....... automatic / manually* controlled

back up light

5 ...... Yellow ...... Mkr F ........ automatic / manually* controlled

forward marker lights

6 ....... Brown ...... Mkr R ........ automatic / manually* controlled

rear marker lights

7 ...... Violet ....... Aux 1 ........ manually* controlled as desired

8 ....... Gray ........ Aux 2 ........ manually* controlled as desired.

Aux 1 & 2 can be number boards, ditch

lights or other lighting depending on

equipment on specific locomotives.

9 ....... Green ....... Cab 2 ........ primary use is for rooftop strobe

or mars lighting.

*requires LocoMatic™ Controller.

SPEAKER INSTALLATION:

mounted as per available space bearing in mind that sound

reproduction is enhanced when a speaker is properly enclosed

and baffled. The speaker is to connect to a 2 pin connector

located near the center edge of the main circuit board.

The speaker generally should be mounted so that the sound can

actually "get out" of the locomotive. A hole in the floor or fuel tank

is acceptable but open grills or a doorway may be a better choice

as the sound can exit upward rather than down toward the track.

In some cases, particularly with plastic body shells, just mounting

the speaker against the shell, preferably with a few openenings

1

This sound / control system

The 9-pin connector is located in the

The 8 ohm speaker should be

Page 2

at the front of the speaker, will be adequate as the vibrations of

the shell can enhance the sound. Enclosing the speaker in a

chamber will also enhance sound reproduction. A very simple

enclosure can be made with a tube. It is usually best to seal the

end of the tube, so there are no air passages to the rear of the

speaker, thus creating a sound chamber. By carefully sealing all

openings it may be possible to use the entire body shell as a

sound chamber. A simple wall behind the speaker may be all that

is possible or perhaps all that is needed.

Speakers can be attached with double sided tape, glue or "hot

melt". Enclosures can be made with plastic, wood, card stock or

even metal. Film cans or medicine bottles make excellent sound

chamber enclosures for small diameter speakers. Attachment

with "hot melt" is advantageous as the "hot melt" can be used as

a gap filler when creating an enclosure.

Speaker enclosure is an art and experimentation is definitely in

order for your installation so as to gain the maximum benefit of

the superb sound quality available in this sound system. Observe

the installation example pictures for more ideas.

OPTIONAL ITEMS INSTALLATION:

One 3 pin connector,

located next to the 9 pin lighting header, is provided to operate

optional coil couplers. The mate for this is on optional item #501,

double relay board for use with coil couplers. This board can also

be wired as a power booster for any lighting or auxillary function.

A typical use would be to turn on and off a smoke unit. Wiring for

this is provided in item 501's instructions.

This sound / control system also has a 2 pin connector that can

be used to add an optional battery backup. The battery must be

an 8.4 volt high capacity rechargeable type. Our Item #647 is

specified for this unit. Once installed with the sound / control

system, the battery will be charging whenever there is track

power "on". When track power turns "off", the battery will remain

in circuit for about 30 seconds and then automatically turn "off"

(providing sufficient charge exists in the battery). Battery backup

is not generally necessary as this sound / control system has

storage capacitors that are adequate to keep the sound system

functioning during normal power "off" for direction sequencing.

In LocoMatic™ COMMAND MODE, a battery backup is definitely

not needed as full voltage track power is "on" continuously.

Under this operating mode it is suggested that no battery be

installed or that if a battery is in circuit you limit operation to not

more than a continuous 4 hours so that you do not overcharge

the battery.

SOUNDS REPRODUCED:

HORN

is user activated in several ways. It can be activated by

the whistle switch or button on transformers so equipped or

by a separate sound activation button. The horn can also be

activated by the HORN button on the LocoMatic™ controller.

The horn will play as long as the switch or button is held on.

A manual switch allows the horn and bell to be deactivated

so that, for multiple locomotive operation, only the lead

locomotive's horn and bell will sound. When operating in

LocoMatic™ command mode, only the LocoMatic™

controller will activate the horn.

BELL

is user activated by the bell control on transformers so

equipped or by a separate sound activation button wired to

do so. The BELL can also be activated by the BELL button

on the LocoMatic™ controller. The BELL sound will latch

"on" when the bell control is activated and will latch "off"

when the control is again activated. When deactivating, the

BELL will stop at the end of a ring. BELL sound can also be

requested when electric cooling fans sound has been turned

"off". Again, a manual switch allows the bell to be deactivated

for multiple locomotive operation. When operating in

LocoMatic™ command mode, only the LocoMatic™

coontroller will activate the Bell.

BRAKE RELEASE

sound is produced when the locomotive

changes from neutral to a movement direction and will

always precede locomotive movement.

COOLING FANS (ELECTRIC)

sounds range from idle slow to

full rpm when in a direction and back to stopped when

entering neutral with a small pause after the locomotive

motor power has stopped. In neutral or with no power to the

motor the sound system will produce no sounds. When a

movement direction is selected and the speed control is

advanced to put the locomotive in motion, a brake release

will sound (see above) and the cooling fans will accelerate to

full rpm. Depressing the ALT / FORWARD button on the

LocoMatic™ controller will direct the sound system to

energize or de-energize the cooling fans regardless of motor

voltage. Depressing the ALT / FORWARD button again will

release the sound system to return to the correct cooling fan

setting. This feature allows the operator to manually force

the cooling fans "ON" in a standing train. is user activated in

several ways. It can be activated by the whistle switch or

button on transformers so equipped or by a separate sound

activation button. The horn can also be activated by the

HORN button on the LocoMatic™ controller. The horn will

play as long as the switch or button is held on. A manual

switch allows the horn and bell to be deactivated so that, for

multiple locomotive operation, only the lead locomotive's

horn and bell will sound. When operating in LocoMatic™

command mode, only the LocoMatic™ controller will activate

the Horn.

LIGHTING FEATURES:

The sound / control system has outputs

at 5 volts available for head lights, back up lights, front and rear

marker lights, two auxillary lights, and a strobe or mars function

(only certain units have this selectable).

The sound / control system allows lighting that is directional so

that the forward headlight and the rear marker lights will

illuminate when the locomotive is in forward motion. When the

locomotive is in reverse motion the rear headlight and forward

marker lights can illuminate. The headlights, marker lights and

auxillary lights can also be manually operated by means of the

LocoMatic™ controller.

Two 5 volt light bulbs are included with this sound / control

system and additional 5 volt bulbs are available in (Item 756).

These are high intensity, low current, bulbs and are ideal for

headlights. For interior or other lighting locations it is suggested

that 2 bulbs be wired in series to afford a lower light level.

In most cases, marker lights have been represented by LED

devices usually wired in parallel. LED marker lights will function

best with this sound / control system if they are rewired in series

with each other and in series with a 68 ohm 1/4 watt resistor. In

2

Page 3

some cases, 1.5 volt bulbs have been used for marker lights and

/ or headlights. There are many variations of these 1.5 volt bulbs

dependent on current draw, but generally if two bulbs are wired

in series and in series with a 100 ohm 1/4 watt resistor they will

function properly with this sound / control system. See item# 382

for 1.5v lamps.

Because of size considerations a single 1.5 volt bulb may have

been used for a headlight or backup light. In this case, again

dependent on current draw of the bulb, you can generally use

about a 220 ohm 1/4 watt resistor in series with a single bulb for

satisfactory function with this sound / control system.

Each of the lighting outputs is designed for a 60 milliamp load

and should not exceed 120 milliamps or damage will occur to

the lighting output. The cumulative output should be less than the

total current capacity of the lighting regulator which is 1/2 Amp.

Should this 1/2 Amp capacity be exceeded the lamps may

become somewhat dimmed or the regulator itself may shut down.

If this situation occurs, it may be necessary to turn "off" one or

more of the lighting functions so the total current is less than the

1/2 Amp capacity.

MANUAL ADJUSTMENTS:

There are six switches and a volume

control on the small circuit board which should be mounted as

space permits and is still accessible. It is suggested that the

volume control be set at about the 10 o'clock position for

comfortable listening. High volume settings may prematurely

damage the speaker. This is especially true for EMD type prime

mover sound systems. The six switches are normally set to the

"off" position and select the following operations:

OFF ON

Switch 1 ---------- start in

forward .................... neutral

Switch 2 ---------- sequencing

normal .................. lock in start position

Switch 3 ---------- horn & bell

can sound ................. do not sound

Switch 4 ---------- forward coupler

operational .............. deactivated

Switch 5 ---------- rear coupler

operational .............. deactivated

Switch 6 ---------- forward direction is to locomotive

front .......................... rear

Switches 3 thru 6 are used primarily when two or more

locomotives are operated together. You can turn off the horn and

bell in the trailing locomotives and deactivate the couplers

between locomotives so that only the couplers at the front and

rear are operational. If any of the locomotives are actually facing

to the rear, Switch 6 on such locomotives allows operation in

concert with other locomotives facing forward. When Switch 6

changes forward to rear all directional functions such as

headlights, marker lights and couplers are switched also. If you

are not using the coupler functions, switches 5 and 6 should be

set ON to turn off the coupler sound and activation.

OPERATION USING A TRANSFORMER:

With this sound /

control system installed, your locomotive will operate in the same

manner as other locomotives when using a transformer to vary

speed. When power is applied the locomotive will come "on" in

either the forward or neutral position as you have selected.

Momentary interuptions of power will allow the locomotive to

sequence through the usual direction positions. Sequencing can

be accomplished either by a direction switch or by turning the

speed control to "off" and then back "on".

Power interuptions for direction sequencing should be momentary

only. If power remains "off" for more than a short time it is

possible that the stored energy will be used up and the sound /

control system will shut down. When power then returns the

system will come "on" in its initial start position. If you prefer to

employ a battery back up to maintain sound during more

extended power "off" situations, provisions are there to connect a

rechargable 9 volt (8.4 volt actual) battery (item 647).

If your transformer includes whistle or bell controls, or if you have

provided sound activation buttons, you will be able to sound the

horn or the bell with these controls whenever there is power to

the track. The horn will sound as long as you hold the control

"on". The bell control is a push "on", push "off".

An added feature of this sound / control system involves the way

the motor is driven. If track power is set high while in neutral and

you sequence to a direction, the locomotive will gradually

increase its speed rather than jump directly to the high speed.

This type of operation not only looks better but also results in less

strain on the entire motor / gear drive system and is less likely to

cause derailments of the locomotive or its train.

The LocoMatic™ controller contains ten operating buttons and is

usable either in conjunction with your regular transformer or as an

independent control with a fixed voltage applied to the track. The

LocoMatic™ controller is a pass through type of device which is

wired between your transformer and the track. It will not interfere

with track power passing through it when not in use (you do not

have to disconnect it for operating standard type trains). Some of

the buttons cause activation as long as they are held "on" while

others work in a push-on, push-off mode. A pause of a few

seconds is required between pushes. The lower right hand

button, labled 'ALT', is the alternate button which provides a

second function to each of the other nine buttons. When using an

alternate function it is suggested that the ALT button be held

depressed and then another button be pressed. For example;

pressing the COUPLER button will operate the trailing coupler

while pressing ALT / COUPLER will operate the leading coupler.

Not all of the buttons will have alternate functions on all

locomotives.

The ten LocoMatic™ controller buttons perform the following:

BELL .............................. turns bell "on" or "off"

ALT / BELL ..................... restores automatic directional lighting

Note: lighting is directional until a request is

made via the LocoMatic™ controller for a

manual activation. Lighting functions will then

remain manual via the LocoMatic™ controller.

Pressing ALT / BELL will allow all lighting

functions to return to directional operation at

the next direction request.

HEADLIGHT ................... turns front headlight "on" or "off"

ALT / HEADLIGHT ......... turns rear headlight "on" or "off"

MARKERS ..................... turns front marker lights "on" or "off"

ALT / MARKERS ............ turns rear marker lights "on" or "off"

AUX ............................... turns front aux lights "on" or "off"

3

Page 4

ALT / AUX ...................... turns rear aux lights "on" or "off"

COUPLER ...................... activates the locomotive's trailing

coupler

ALT / COUPLER ............ activates the locomotive's leading

coupler

HORN ............................. activates the horn

ALT / HORN ................... activates STROBE or MARS lights

FORWARD ..................... forward motion overiding sequencing

ALT / FORWARD ........... activates / stops electric cooling fan

sound

REVERSE ...................... reverse motion overiding sequencing

ALT / REVERSE ............ forces automatic electric cooling fan

sound "on" or "off"

SLOW ............................ neutral position overiding sequencing

ALT / SLOW ................... neutral position or emergency stop

ALT ................................. alternate button for second functions.

When using this button in conjunction with

another button, press and hold this button first.

Operation using the LocoMatic™ controller with your transformer:

As previously stated, a locomotive with this sound / control

system installed will operate with your transformer in the same

manner as other locomotives, but you will have the advantage of

additional features available with the LocoMatic™ controller.

The horn and bell can be activated by either your transformer

controls or by the LocoMatic™ controller. If the bell is turned "on"

by your transformer it can be turned "off" by either your

transformer or by the LocoMatic™ controller, but if the bell is

turned "on" by the LocoMatic™ controller it must also be turned

"off" by the LocoMatic™ controller.

You can manually operate any of the lighting features on your

locomotive, that you have connected to the sound / control

system, by use of the LocoMatic™ controller. Once you have

selected any manual lighting, all automatic directional operation

is overidden, however you can return to directional lighting at any

time by using the ALT / BELL button.

Mars / Strobe Lighting Effects with the LocoMatic™ Controller:

This LocoMatic™ Sound & Control System is equipped with a

Mars or Strobe lighting effect. They are selected with the

LocoMatic™ controllers Alt-Horn button.

To activate the Mars light press and release the Alt-Horn button.

If the headlight is on, then the Mars light effect will start. If the

Headlight is off the Mars light effect will start when the Headlight

comes on. When the Mars light is on and the Headlight goes off,

as in normal sequence operation, the Mars light will also go off. If

you want the Mars light to stay on, merely enter manual lighting

operation by turning on the Headlight. Since the Mars light

follows the headlight operation, A-A operation is not

compromised when selection switch 6 is placed ON. This way

only the locomotive with the Headlight on will have the Mars light

operational.

To activate the Strobe light function press and release the

Alt-Horn button twice, with a pause between presses. The first

activation starts the Mars light. The second activation starts the

Strobe light. The Strobe light operates whenever the LocoMatic™

Sound & Control System remains powered.

To turn all Mars and Strobe lighting effects off, merely press and

release the Alt-Horn button a third time.

The optional electric coil couplers are activated ONLY by the

LocoMatic™ controller. There is a brief waiting time between

coupler activations and a minimum of 8 volts on track is

necessary (unless your couplers do not function smoothly). The

couplers can be activated either in neutral or in a motion direction

as you prefer.

With the LocoMatic™ controller in place it is no longer necessary

to follow the forward - neutral - reverse - neutral - forward

sequence. If you are in NEUTRAL and wish to go forward,

depress and release the FORWARD button. The locomotive will

accellerate in the forward direction to the speed set by track

voltage. You can actually set the speed control at a fixed voltage

and operate the locomotive with just the FORWARD, REVERSE

and SLOW buttons. The sound / control system has incorporated

a momentum feature that will gradually increase speed to the the

set voltage rather than just jump to that speed. The FORWARD

button will result in a gradual increase in speed up to the preset

voltage in the forward direction. The SLOW or ALT / SLOW button

will return the locomotive to neutral. The REVERSE button will

result in a gradual increase in speed up to the preset voltage in

the reverse direction. The momentum feature will also work with

the direction control on your transformer if you prefer to employ

usual sequencing.

If there seems to be a lack of response to the buttons on the

LocoMatic™ controller it is generally due to either poor electrical

contact between the pick up rollers and wheels and the track

because of dirt, or the lack of a choke (see "supplemental note"

below) in series with something that is getting its power from the

track.

In summary, a locomotive with this unique sound / control system

installed and with the LocoMatic™ controller will function in the

same manner as other locomotives, has the added benefit of very

smooth slow speed operation with momentum acceleration and

has sequence overide so that you can select the direction of

motion as you desire.

LocoMatic™ COMMAND CONTROL

In addition to all of the previously described features this sound /

control system will operate independently with a fixed 10 to 18

volts AC, or up to 25 volts DC, passing through the LocoMatic™

controller to the track. To enter the LocoMatic™ COMMAND

MODE all power to the locomotive must be "off" and all stored

energy exhausted. Once you are sure that all power is gone, set

Switch 1 to select neutral start and set Switch 2 to lock. With the

locomotive locked to start in neutral, full LocoMatic™ COMMAND

MODE is entered as soon as track power is applied. Turn the

speed control on your transformer to output approximately 10

to18 volts and you are ready to operate in LocoMatic™

COMMAND MODE. UNDER NO CIRCUMSTANCES SHOULD

THE TRANSFORMER VOLTAGE IN THIS OPERATING MODE

EXCEED 20 VOLTS AC, 26 VOLTS DC.

With the fixed voltage on track in this operating mode all lights

when turned "on" including lighting in passenger cars or other

equipment will be at full illumination.

The horn, bell, lighting and coupler controls function as before

4

Page 5

except that the locomotive will no longer respond to the whistle

and bell controls on your transformer. Lowering the voltage on

your transformer will only effect a reduction in the top speed

possible.

The FORWARD, REVERSE and SLOW buttons are now speed

and direction controls. Press and release either FORWARD or

REVERSE and your locomotive will begin in that direction. With

each, approximately 1/2 second, momentary button activation

the speed will increase one step through a total of 24 steps.

Holding a button "on" will continuously increase through the

steps to full speed. To slow down you can activate or hold the

SLOW button through the steps to a stop. You can also slow

down by using the opposite direction button. If the locomotive is

in forward direction and you hold the REVERSE button, the

locomotive will slow to a stop and then accelerate in reverse.

Similarly, if running in reverse, holding the FORWARD button will

result in a slow to stop and then an acceleration in forward. The

ALT / SLOW button results in an emergency stop.

If there seems to be a lack of response to the buttons on the

LocoMatic™ controller it is generally due to either poor electrical

contact between the pick up rollers and wheels and the track

because of dirt, or the lack of a choke (see "supplemental note"

below) in series with something that is getting its power from the

track.

NOTE: regarding multiple unit lashups - because of the

possibility of lack of response due to poor electrical contact it is

suggested that you do not attempt control changes to multiple

units while such locomotives are on track areas of poor contact

such as switches or crossings. If a multiple unit locomotive loses

synchronization between units either increase to full speed or

come to a full stop to restore synchronization.

Operating a locomotive, with this sound / control system

installed, under LocoMatic™ COMMAND CONTROL is simply

the use of the buttons on the LocoMatic™ controller to

implement the desired motions and sounds.

****** SUPPLEMENTAL NOTE ******

The signals generated by the LocoMatic™ controller may be

adversely affected by any powered device that is connected to

the track at the same time that the LocoMatic™ controller is

functional. This would include track powered accessories, lighted

cars or a lighted or powered locomotive operating from the same

transformer that is passed through the LocoMatic™ controller.

To eliminate this possibility it is required that all accessories be

independently powered by a separate transformer or

transformers. Lighted cars or other lighted or powered

locomotives that will be operating with a locomotive with this

sound / control system installed MUST BE MODIFIED by

installation of a choke in series between track pick up and the

lights and/or motor.

The most common installation would be to locate the wires

coming from the center rail rollers (3 rail operators) or right rail (2

rail operators) and disconnect them from the present location.

Connect these wires to one end of the choke and then connect

the other end of the choke to the same location that the wires

were originally connected to. Be sure to properly insulate your

connections and to mount the choke so that it does not move.

Double sided mounting tape makes a simple and neat

installation.

In some situations for two rail operators, it may be simpler to

connect the choke between the lamp base and the proper rail

previously going to the lamp base. Either method is acceptable

as long as the choke is in series between the track and the load

and the bases of each car are not connecting to each other with

metal couplers.

APPENDIX:

simultaneous operation of a LocoMatic™

compatible locomotive with a lionel trainmaster™ command

equipped locomotive. Since both of these control systems can

function with a fixed AC voltage it becomes possible to operate

simultaneously and independently with both systems on the

same track if certain conditions are met.

The fixed voltage power to the Lionel Trainmaster Command

System must be passed through the LocoMatic™ controller

before being connected to the track. The LocoMatic™ controller

does not interfere with the Lionel Trainmaster Command Control

System. All Command equipped locomotives or other devices

that are common to the fixed voltage power supply will require

the installation of a choke in series with power pick up. This

series connection can be made either on the center rail pick up

or on the ground, whichever is easier. Refer to SUPPLEMENTAL

NOTE, for additional information.

With the above installation completed and track power "on", the

Lionel Command equipped locomotive is operational via the

Trainmaster Command Control System. Another locomotive,

equipped with a LocoMatic sound / control system in the

LocoMatic™ COMMAND MODE, can also be operated at the

same time on the same track via the LocoMatic™ controller.

Motor Problems:

If your locomotive reset's to the forward

position when operating in standard mode, or lurches

intermittently when operating in LocoMatic™ command mode,

you will need to install a choke in series with each motor lead to

eliminate large motor noise from becoming fed back to the sound

system. The chokes functions best when placed at or as near to

the motor as possible. Chokes from item 702 or 703 can be used

in most cases. There is on board filtering for this problem but it is

best handled at the motor brushes. This is also why a capacitor

is placed across the motor brushes as shown in the wiring

instructions. This only happens with motors that produce severe

spikes or generate RF when operating.

DUAL MOTORS: When connecting to a locomotive with dual

motors, the motors are normally connected in parallel from the

factory. The filter capacitor should be placed on the motor

brushes closest to the LocoMatic™board. If the locomotive has

DC can motors, try connecting the motors in series instead of

parallel. Most locomotives have an extremely high rate of speed.

By connecting the motors in series not only reduces the top end

speed of the locomotive but also results in a lower motor current

consumption with better locomotive low end performance! To

make a series connection, simply place one power lead on the

motor#1 brush, then take the other brush lead to motor#2's

brush. The other power lead then connects to the other motor#2

brush. If the motors rotate opposite of each other simply reverse

the brush leads of the motor that rotates opposite of the direction

you want the locomotive to go when in the forward state.

5

Page 6

COMMON HORN SIGNALS

SOUND

short .......................... apply brakes, stop

2-long ........................ release brakes, proceed

long, 3-short .............. flagman protect rear of train

4 or 5 long ................. recall flagman

2-short ....................... acknowledgment

3-short ....................... back up movement

4-short ....................... call for signals

short, long ................. inspect train line for leak or brakes

2-long, short .............. approaching meet or wait point

2-long, short, long ..... approaching grade crossings

continuous long ......... approaching stations or junctions

successive shorts ...... alarm for something on track

INDICATION

sticking

installation - speaker & sw/vol board

LocoMatic™

SwVol Board

Selector Switch & Volume Control Board.

Mount with tape supplied in a convenient location, or use

other double sided tape, or small screws. Be sure not

to allow any metal parts to contact any parts or traces

on the board, this will damage the system. This board

is connected to the Main Board with a 9 pin wire

harness to allow for a more convenient placement.

Rotating the "VOL" (volume) control clockwise will

increase the volume. A complete counter-clockwise

rotation will yield no sound!

Note: It is possible to destroy a standard round speaker

when operating at higher volumes. This is especially

true with EMD type sound systems. The sound system

contains a 1 watt audio amplifier and the standard

speaker is capable of sustaining 0.2 watts continuous.

The standard speaker is a high efficiency type. You can

connect two standard speakers in series to obtain

higher volumes with less damage to the speakers.

Volume control

Selector switches

Standard round speaker

when soldering wires to rear

of speaker, care must be

taken so that the wires do not

come in contact with the

speakers metal frame!

Mounting Templates for LocoMatic™ SwVol Board

Actual size mounting template to assist in mounting the switch / volume (sw/vol-h) control board.

6

Page 7

installation - connections to main board

LocoMatic™ Main Board

The main board is supplied with double sided tape

especially made to be electrically insulated, non

absorbent to moisture, anti-fungal, etc.. To mount the

board find and clean (possibly with alcohol to remove

grease) a location. Peel the tape cover off. Press to

secure in place. More tape can be obtained as item 388.

The small connectors are handled better using a tweezers

or small needle nose pliers to place the connectors

together. When seperating the connectors DO NOT pull

on the wires! Instead, slide a tweezers (or small flat

screwdriver between the top connectors lip and the board

mate. Care must be taken when handling these small

connectors.

Auxillary Backup Battery input

Use only item #647 rechargeable battery! Item

#578 contains connector snaps with wires.

Item #579 contains mounting clips or use Item

#388 double sided foam tape.

Connect the red wire to the red battery clip

wire and the gray wire to the black battery clip

wire. Insulate the connection properly. DO

NOT get these wires reversed, severe damage

to the battery / unit / and you can occur!

to Sw/vol-h

board

SYNC input

not used with

Diesel sound

systems

Coupler Outputs

1 .... Red ..... +5 volts

2 .... Black .... Front

3 .... White ... Rear

for use with item#501 only!

Main Power / Motor Connections

Motor Brushes

1 ....... Red

2 ....... Brown

Track Power Input

3 ....... Blue 3rail - center roller pu

2rail - left rail pickup

4 ....... Black 3rail - chassis pickup

2rail - right rail pickup

Motor Field Wires

5 ....... Yellow

6 ....... Orange

Speaker

connection

LocoMatic™

type 3

Main Board

Lighting Outputs:

each output shown, as described in the main text, is capable of driving

one 60 milliamp load. This load may be a light bulb, as supplied, LED's

(with limiting resistor), or a series of light bulbs. Item #756 contains more

lamps as provided. More detailed optional connections exist on the

following pages.

Connect the proper wires to supplied lamps as described. Insulate

properly. As with any connections, an improperly or uninsulated wire

touching the frame or other wire will damage the unit! Any damage as

such is not covered under warranty. When connecting the lamps to the

common +5v power, split the load between the two wires (red & orange).

Use one for the front lights and the other for the rear lights. If any

switched lamp output no longer operates, this is a sign that the output

was either overloaded or came in contact with another wire. A short

between wires to the lamp is also a overload. This would indicate a need

for repair and has to be returned. Again, this type of failure is not covered

under warranty since it is due to improper handling during installation.

Lighting Outputs

1 .... Red ....... +5 volts

2 .... Orange .. +5 volts

3 .... White ..... Lmp F

4 .... Blue ....... Lmp R

5 .... Yellow .... Mkr F

6 .... Brown .... Mkr R

7 .... Violet ..... Aux 1

8 .... Gray ...... Aux 2

9 .... Green .... Cab 2 ..... primary use is for rooftop strobe

or mars lightingif applicable.

7

.Item # 756

5 Volt, 60 milliamp

high intensity lamp.

Page 8

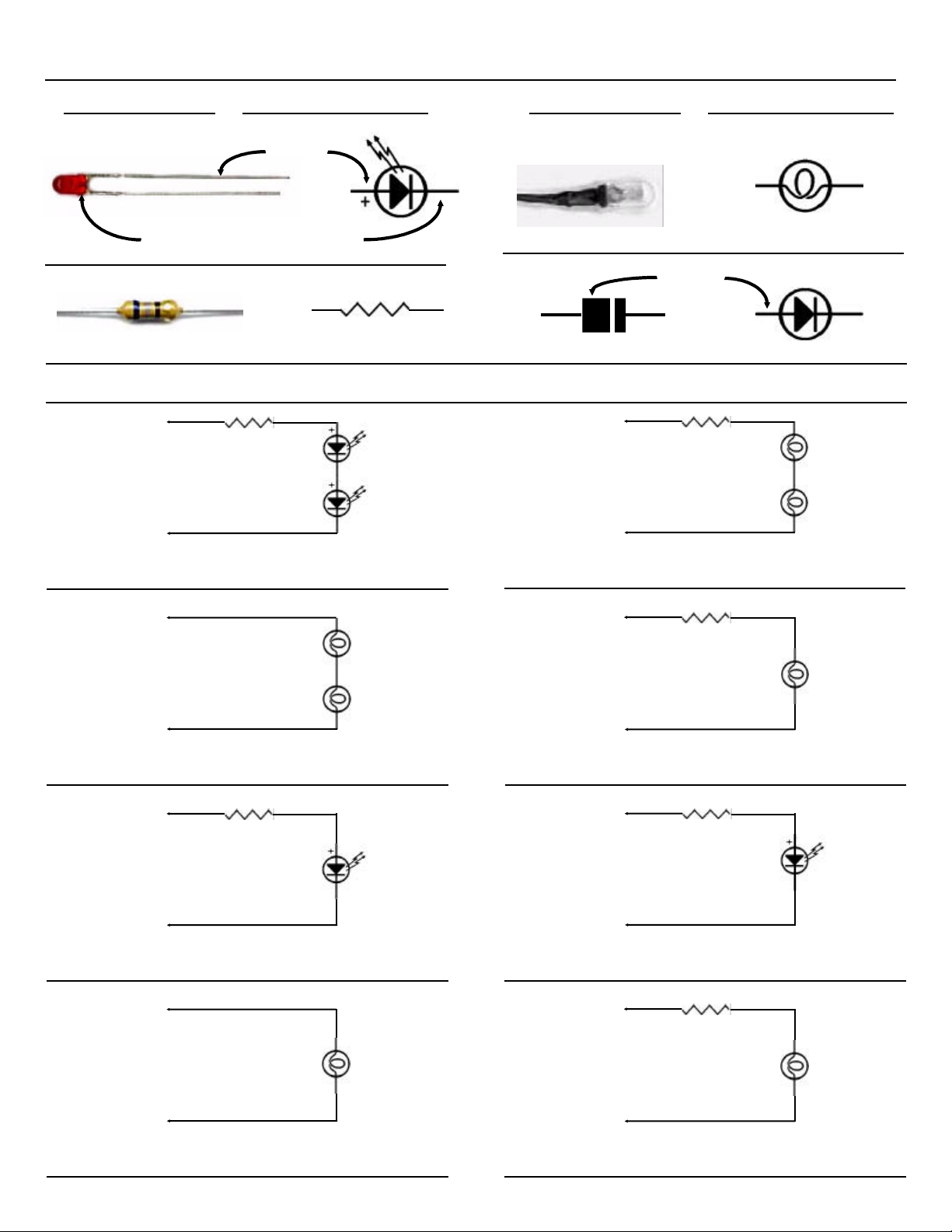

Electical parts and their symbols

Physical

shown larger than actual size

shown larger than actual size

Red or Orange Wire

Wires from:

Marker Rear or

Marker Front

Yellow or Brow Wire

Electrical symbol

anode

(light emitting diode)

LED

flat side = short lead = cathode

resistor

Wiring various Lighting Effects

68 ohm

(blue, gray, black)

Marker Indicators

( LED's )

Physical

shown larger than actual size

Red or Orange Wire

Wires from:

Marker Rear or

Marker Front

Yellow or Brow Wire

light bulb

anode

diode

100 ohm

(black, brown, brown)

Electrical symbol

Marker

Indicators

(1.5volt,

15milliamp,

lamps )

Wiring LED's as Marker Lights

Red or Orange Wire

Wires from:

Cab 1 or

Aux 1 or

Aux 2

Violet or Gray Wire

Cab Interior

#383 or #756

Wiring light bulbs in series as Interior Lights

Red or Orange Wire

100 ohm

Wires from:

Cab2 - Strobe

Green Wire

(black, brown, brown)

Strobe Lamp

Wiring an LED as a Strobe Light

Red or Orange Wire

Wires from:

lmp F

lmp R

White or Blue Wire

#756 lamps

as supplied or

order extras)

(use Item

Lamps)

( LED)

5 volt lamp

(use Item

Wiring 1.5v Light bulbs as Marker Lights

Red or Orange Wire

220 ohm

(red, red, brown)

Wires from:

Any Lighting

Output

appropriate Wire

Wiring 1.5v Light bulb for any use

Red or Orange Wire

68 ohm

(blue, gray, black)

Wires from:

Any Lighting

Output

appropriate Wire

Wiring WHITE LED instead of lamps

Red or Orange Wire

220 ohm

(red, red, brown)

Wires from:

Any Lighting

Output

appropriate Wire

Cab Interior

(1.5volt,

15milliamp,

Lamp)

White LED for

Headlight

(item#536 or

item#537)

a 68 ohm

resistor is OK

for this

application.

Cab Interior

( Lamps )

Wiring 5v Light bulb as headlight

8

Wiring 5v Light bulb for any use

Page 9

AC track power installation - Series Motor / Track connections

Main Power / Motor Connections

Place 0.1mfd capacitor

(chicklet) across

motor brushes.

Motor Brushes

1 Red

2 Brown

1

2

Track Power Input

3 ...... Blue (3 rail ........ center roller pickup)

(2 rail ....... right rail pickup)

4 ...... Black (3 rail ........ chassis pickup)

(2 rail ......... left rail pickup)

3

4

5

6

Motor Field Wires

5 ..... Yellow

6 ...... Orange

If the engine does not have a chassis (outside rail) pickup from each

truck you should add one to prevent intermittent track pickup from

occuring. Adding multiple center rail pickups will also help.

Help for Am Flyerl series motors.

the wires are normally terminated. Colors indicated are those

that match the LocoMatic™ board connector and not the

locomotives existing wires.

Field1 - connect original

red to Yellow (5)

Field2 - connect original

black to Orange (6)

This picture shows where

Brush1 - connect

original yellow

to Brown (2)

Brush2 - connect

original green

toRed (1)

Help for Lionel series motors.

early Lionel. Right is later series motor style. It is always better to add a ground wire to both outside rail pickups and the chassis. When more

than one center roller is available always connect to both, also secure the center pin from rotating with the roller.

Colors indicated are those that match the LocoMatic™ main board connector and not the locomotives existing wires.

These pictures show where the grounded field wire needs to be broken from the chassis for the motor power. Left picture is

Field - Orange

(previously connected to the

chassis pickup ground lug above)

Brush - Brown

Field - Yellow

Field - Orange

Brush - Brown

Track Input - Black

Brush - Red

NOTE: pictures do not depict the

0.1mfd capacitor across the

motor brushes as shown in

wiring diagram above. This

needs to be done!

(chassis pickup)

Track Input - Black

(chassis pickup)

Brush - Red

Track Input - Blue

(from roller pickup)

Track Input - Blue

(from roller pickup)

9

Field - Yellow

(previously connected to the

chassis pickup ground lug above)

Page 10

track power installation - DC Motor / Track connections

Main Power / Motor Connections

Place 0.1mfd capacitor

(chicklet) across

motor brushes.

Motor Brushes

1 ...... Red

2 ...... Brown

3 rail operators: If the engine does not have a

chassis (outside rail) pickup from each truck you

should add one to prevent intermittent track pickup

from occuring. Adding multiple center rail pickups will

also help.

2 rail operators: If the engine does not have a pickup

wire for each rail, you should add one. DO NOT rely

on proper pickup through the wiping action of a truck

against the chassis for a proper pickup.

Multiple motors: when more than one motor is

present you may want to wire them in series to

reduce the top end speed. This is especially true of

most 3 rail chassis since the gear ratio is higher than

neccessary. Place the capacitor shown on the motor

brushes closest to the connection of the power feeds

(red & brown) from the main board. If placing motors

in series, either place one capacitor on each motor or

connect to wire splice at closest motor to power feed.

Track Power Input

3 ...... Blue (3 rail ........ center roller pickup)

(2 rail ....... right rail pickup)

4 ...... Black (3 rail ........ chassis pickup)

(2 rail ......... left rail pickup)

connect wires together

5 ..... Yellow

6 ...... Orange

1

2

3

4

5

6

Main Power / Motor Connections using series diodes to drop motor speed

Place 0.1mfd capacitor

(chicklet) across

motor brushes.

Motor Brushes

1 ...... Red

2 ...... Brown

Track Power Input

3 ...... Blue (3 rail ........ center roller pickup)

(2 rail ....... right rail pickup)

4 ...... Black (3 rail ........ chassis pickup)

(2 rail ......... left rail pickup)

Series Diode drop

1

2

3

4

5

6

Use 6 ampere diodes (item 375) for heavy

motor loads, 1 ampere diodes (item 374)

for lighter motor loads (as in newer 'S'

gauge equipment) . One or more diodes can

be used. As shown, two diodes are used

yielding a 1.5 volt drop. This is also a drop in

voltage going to the DC motor, thus lowering

it's RPM for a given voltage. By adding more

diodes in series you can effectively reduce

the top end speed of any locomotive and

make a jack rabbit engine more tolerable

without effecting the sound system.

:

Series Diode drop

5 ..... Yellow (to anode '+' )

6 ...... Orange (to cathode '-' )

When more than one motor is in a locomotive you can either leave them in parallel, as originally wired, or place

Note:

them in series to reduce the top end speed. Remember, the power stage is rated for 3 amperes. Higher load

current will damage the electronics. In general, most newer locomotives with dual motors are only consuming 3

amperes. If in doubt you can always place a fuse in series with a motor brush wire.

10

Page 11

Although the following sample installations show diesel

locomotives all is applicable to Electric's

no lights Headlight Headlight and

Number Boards

Sample installation - Am. Flyer GP-7

Rear Marker

Lights and

Number Boards

Number Boards

and Interior

Lights

Marker Lights

When mounting in a GP-7, things get a bit tight. Shown is how to place the main board. The sw/vol board may be placed so

that the controls show through the bottom where the reversing unit lever was already punched out as shwon below. The

speaker chamber could be made towards the front of the engine, possibly utilizing the cab area by the windows.

11

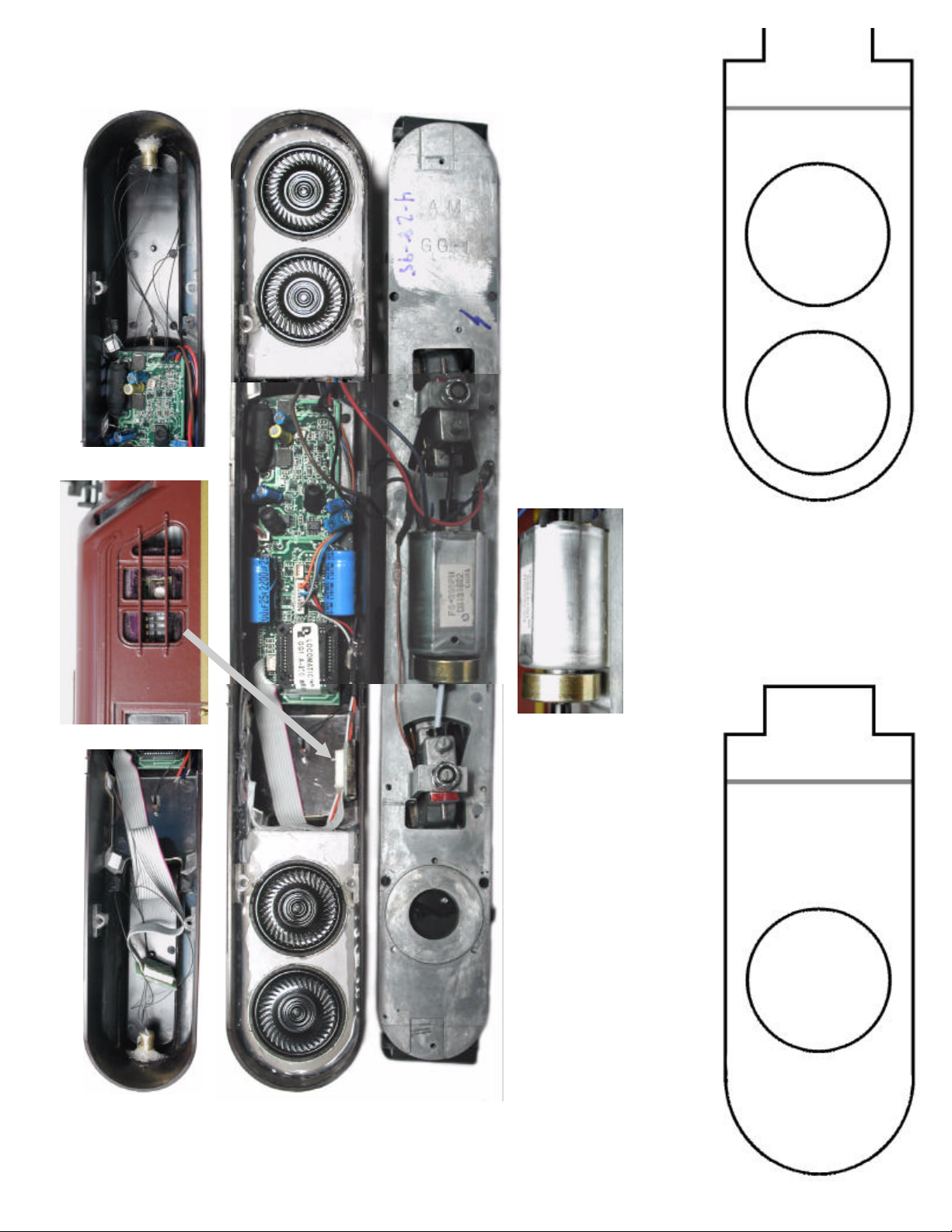

Page 12

American Models GG-1 LocoMatic™ Type3 Installation

mounting template.

them and glue onto a stiff cardboard. Cut out the speaker

circles. Fold on the gray line. Mount the speakers with a glue.

Secure the entire unit inside the shell completely sealing the

Use the cutout templates below for speaker mounting. Copy

edges as shown. Hot Melt was used for the installation.

1.5" speakers (item

When installing four

1/16" thick tape.

change motor mout to

Double Speaker

the speaker insert.

#661) wire in series

parallel as shown in

wire them in series.

polarity in all cases!

Observe the speaker

For two 1.5" speakers,

12

Single Speaker

mounting template.

sided tape and mount board flush to the roof top. Also

clearance for the drive box stud (or remove the stud).

Study the pictures for wire, lamps, sw/vol, and speaker

remove the one 2200mfd capacitor, as shown, to obtain

To mount sound unit you must remove the 1/8" double

The sw/vol board was mounted with double sided tape

placement.

placed on the front side of the board and then made

Headlights were mounted using a brass tube as a shroud.

black with a marker. Carefully fold the gray flat wire to fit.

Page 13

Sample installation - Short GG-1

Place 1/16" tape on board to prevent motor / chassis from

shorting to board.

Make spacers, with slot guides to hold board, to raise

board brom bottom to clear wires.

Position board on angle to clear shell / chassis and

motors when swung to full extent (motors move to

negotiate tight curves).

Use a non-conductive glue to hold board on spacers.

"Quick Grag" works well for this. Make rear support

bracket to keep board from tipping.

Install lamps in parrallel for illumination of the markers.

Then cover the lamps with foil tape to prevent light from

seeping through.

Install speaker in enclosed tube flush to the inside ceiling.

Coil couplers could also be added but would need addition

modifications to the coupler pockets for installation and item #501.

An easy location for the sw/vol board is

near the previous lockout switch

location.

If opening the chassis for the sw/vol, do

this first before mounting the main

board.

Mill open or drill multiple holes and file

smooth to gain access to the

switches and volume control. If only

the volume control is of importance,

locate suitably about an existing hole.

Be sure that none of the tracks on

the board or switch mounts touch the

chassis. This would permanently

damage the microcontroller and is

not covered under warranty.

Place 1/16" double sided tape on front

side of board and secure in place.

An added touch would be the addition of two interior cab lamps.

These can be accessed from the LocoMatic controller as

Aux1/Aux2. Use Aux1 as the forward cab and Aux2 as the rear

cab. This way you can independently illuminate the proper

operating cab when at idle.

13

Page 14

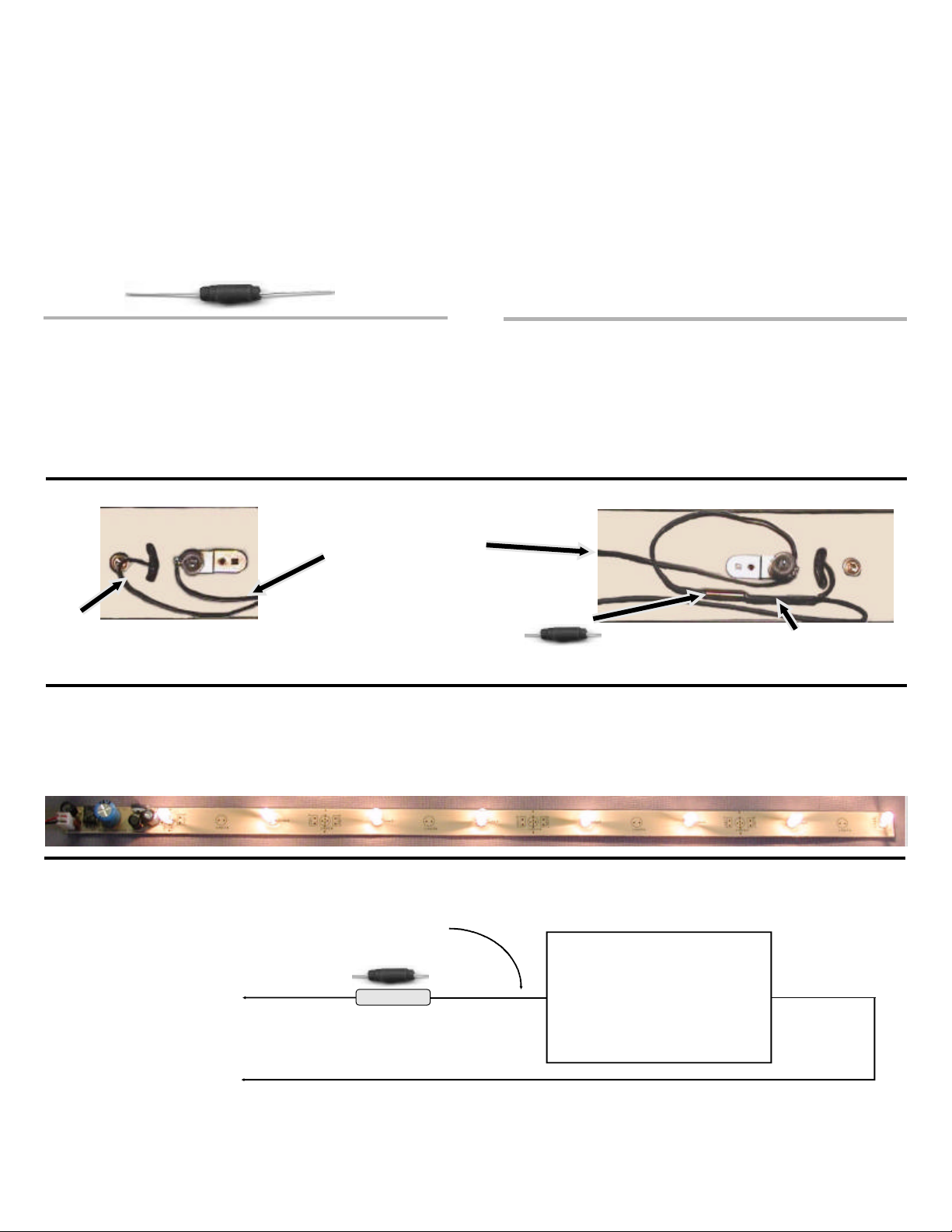

Choke installation

When using other equipment on the same track with the

LocoMatic™ system, it is neccessary to install choke's in

series with the other items drawing power. These other

items could be lighted cars or other engines running in the

consist. This is neccessary to insure proper signal

strength from the LocoMatic™ Controller. Without proper

signal strength, the locomotive could receive improper

instructions or no instructions at all when an operation is

selected from the LocoMatic™ Controller.

CHOKE (Coil)

Input

Output

To install the choke in 3-rail passenger cars with multiple

pickups:

1 ...... remove the existing center roller pickup wires.

2 ...... connect these wires together to form a common wire.

3 ...... place a new wire from one truck roller to the second truck

roller. This will give you better pickup and should be done

on all lighted cars.

4 ...... connect one end of the previous center roller pickup wire

to one end of the choke.

5 ...... connect the center roller jumper wire (the new wire

installed in step #3) to the other end of the choke.

6 ...... be sure to electrically insulate all connections.

To install the choke in other 2-rail lighted cars:

1 ...... locate right rail lamp power feed wire.

2 ...... inside the car, cut the power feed wire making two ends.

3 ...... connect one power feed end to one side of the choke and

connect the other power feed end to the other side of the

choke.

4 ...... be sure to electrically insulate all connections.

one side of passenger car

3-rail choke installation

To install the choke in 2-rail AF lighted cars:

1 ...... locate center lamp power feed wire.

2 ...... inside the car, cut the power feed wire making two ends.

3 ...... connect one power feed end to one side of the choke and

connect the other power feed end to the other side of the

choke.

4 ...... be sure to electrically insulate all connections.

other side of passenger car

lamp power

(from other end of choke - connects

to all input tabs of lamps in car)

center roller pickup

(to other center roller pickup)

choke

center roller pickup

(to other center roller pickup and one side of choke)

alternative lighting

you might also want to consider installing our Adjustable Regulated Lighting board. The RL-ADJ (item 379) comes with 4 lamps but is capable of driving

eight lamps, as shown. You can set the intensity desired (1.25 - 5 volts). It maintains constant voltage to the lamps and has it's own choke so no other

modifications are needed. Simply install the lamps where desired, connect the input power, and peel the tape to secure. The unit can be broken into smaller

strip lengths where needed. Install in cabooses, passenger cars, or buildings. Measures only 1/2" wide. Extra, low voltage lamps, are available (item 383).

basic choke installation diagram

Formerly center rail

or right rail pickup

Center Rail ..... (3 rail)

Right Rail ........ (2 rail)

pickup

Outside Rail .... (3 rail)

Left Rail .......... (2 rail)

pickup

When installing in 2 rail equipment, use all Center Rail

references as Right Rail and all Outside Rail as Left Rail.

choke

LOAD

Lighting load, other locomotive in

consist, or other type circuitry

drawing off of track power. As shown

one lead needs to be disconnected

from the rail and a CHOKE needs to

be placed in series with the load. In

most cases the 1.5 ampere (#702)

will handle the load.

for additional chokes order:

Item 702 for up to 1.5 ampere load

Item 703 for up to 5.0 ampere load

14

Loading...

Loading...