Evaluates: MAXQ3210

MAXQ3210 Evaluation Kit

______________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Rev 0; 6/06

General Description

The MAXQ3210 evaluation kit (EV kit) is a proven platform to conveniently evaluate the capabilities of the

MAXQ3210 voltage regulator microcontroller. The kit

contains the MAXQ3210 with pins brought out to headers, JTAG programming interface, 9V battery clip,

piezoelectric horn, and pushbuttons and LEDs to control and display board operation. With the included

power supply, software, serial-to-JTAG interface board,

and an RS-232 cable connected to a personal computer, the kit provides a completely functional system ideal

for evaluating the capabilities of the MAXQ3210.

♦ MAXQ3210 EV Kit Board with Processor and

3.57MHz Crystal Installed

♦ Serial-to-JTAG Interface Board and JTAG Cable

♦ MAXQ3210 Evaluation Kit CD-ROM

Features

♦ Easily Loads Code Using Bootstrap Loader and

Serial-to-JTAG Interface Board

♦ JTAG Interface Provides In-Application

Debugging Features

Step-by-Step Execution Tracing

Breakpointing by Code Address, Data Memory

Address, or Register Access

Data Memory View and Edit

♦ 9V Battery Clip for Use with MAXQ3210 Voltage

Regulator

♦ Piezoelectric Horn with Optional Volume

Adjustment Jumpers

♦ Evaluation Kit Board can be Powered Directly

Over JTAG Interface

♦ Processor Clock can be run from Crystal or RC

Oscillator Circuit

♦ Direct LED Drive from Port Pin P0.7

♦ 32-Step Digital Potentiometer for Experimenting

with On-Board Comparator

♦ Pushbutton Switches for Reset and Interrupt

Generation

♦ Prototyping Area Including +5V Rail and Ground

♦ Test/Expansion Header Includes All Device GPIO

and Piezoelectric Driver Pins

♦ Board Schematics Included to Provide a

Convenient Reference Design

Evaluation Kit Contents

Ordering Information

PART DESCRIPTION

MAXQ3210-KIT Evaluation Kit for MAXQ3210

SERIAL DEBUG PORT

JTAG INTERFACE

CABLE

RESET

INTERRUPT

SWITCH

MAXQ3210

LEDs

PIEZO HORN

9V BATTERY CONNECTOR

9V POWER CONNECTOR

JTAG INTERFACE BOARD

5V POWER CONNECTOR

Figure 1. MAXQ3210 Evaluation Kit Setup

MAXQ is a registered trademark of Maxim Integrated Products, Inc.

2 _____________________________________________________________________

Evaluates: MAXQ3210

MAXQ3210 Evaluation Kit

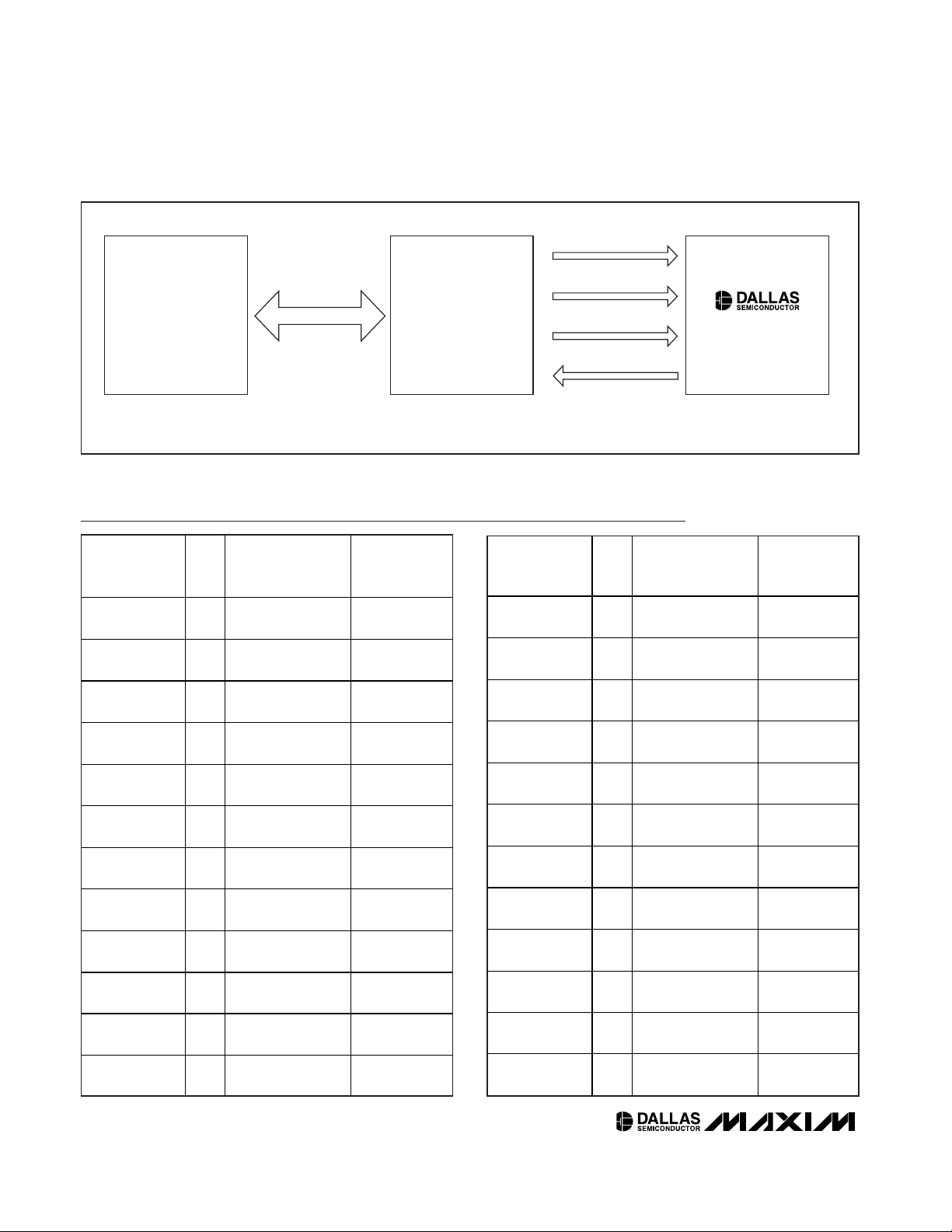

TEST MODE SELECT

JTAG/TAP

INTERFACE

RS-232

INTERFACE

SERIAL-TO-JTAG

INTERFACE

ADAPTER

WINDOWS

PC

SERIAL

(COM)

PORT

TEST CLOCK

TEST DATA IN

TEST DATA OUT

MAXQ3210

Figure 2. Serial-to-JTAG Interface

Component List

DESIGNATION

QTY

DESCRIPTION

SUPPLIER/

PART

NUMBER

C1, C2, C3

10µF, 20V tantalum

capacitors

Panasonic

ECS-T1DX106R

C4

Empty capacitor

footprint (0805)

—

C5, C6

22pF ±10%, 10V

capacitors (0805)

Generic

C7, C8

100nF ±10%, 10V

capacitors (0805)

Generic

C9

2nF, 10V capacitor

(0805)

Generic

D1, D2, D3

Red surface-mount

LEDs

Dialight

597-3001-1xx

JU1, JU3–JU13

2-pin NO (1 x 2,

0.1”) jumpers

3M

929834-02-02

JU2

3-pin NO (1 x 3,

3M

929834-02-03

J1

9V battery clip

Keystone

1294

J2

DC power jack

(2mm)

CUI Inc.

PJ-002A

J3

2 x 5, 0.100”

spaced header

3M

929836-02-05

J4

2 x 20, 0.100”

spaced header

3M

929836-02-20

DESIGNATION QTY DESCRIPTION

SUPPLIER/

PART

NUMBER

3

1

2

2

1

3

12

1

0.1”, 2 of 3) jumper

1

1

1

1

PT1 1

R1 1

R2 1

R3 1

R4, R5 2

R6 1

R7 1

R8, R9, R10 3

R11, R12, R13 3

R14 1

SW1, SW2 2

TP1, TP2, TP3 3

Piezoelectric horn

(high volume)

1.2kΩ, 1/8W

resistor (0805)

510Ω, 1/8W resistor

(0805)

Empty resistor

footprint (0805)

1kΩ, 1/2W resistors

(2010)

68kΩ, 1/8W resistor

(0805)

470kΩ, 1/8W

resistor (0805)

10kΩ, 1/8W

resistors (0805)

1kΩ, 1/8W resistors

(0805)

30kΩ, 1/8W resistor

(0805)

S P S T- N O m om entar y

p ushb utton

1 x 2 (0.100”

spaced) test points3M929834-02-02

CUI Inc.

CEP-1172

Generic

Generic

—

Generic

Generic

Generic

Generic

Generic

Generic

Omron

B3FS-1000

_____________________________________________________________________ 3

Detailed Description

This evaluation kit must be used with the following documents:

• MAXQ3210 Data Sheet

(www.maxim-ic.com/MAXQ3210)

• MAXQ Family User’s Guide

(www.maxim-ic.com/MAXQUG)

• MAXQ Family User’s Guide: MAXQ3210/MAX3212

Supplement (www.maxim-ic.com/MAXQ32xxSUP)

The MAXQ3210 EV kit board is fully defined in the

schematics provided in the EV kit CD-ROM. However, a

short description of the major components and connectors of the boards follows.

Power Supplies

There are three ways to set up power supplies when

using the MAXQ3210 EV kit. The two boards that

require power supplies are the MAXQ3210 EV kit board

and the serial-to-JTAG interface board.

Running Both Boards from

Separate Power Supplies

To run each of the boards from its own power supply,

connect supplies as follows.

• Connect a 5V, ±5% regulated DC wall supply (center post positive) to the J2 power plug of the serialto-JTAG interface board.

• Connect a 9V, ±5% regulated DC wall supply (center post positive) to the J2 power plug of the

MAXQ3210 EV kit board, OR insert a 9V battery into

clip J1 of the MAXQ3210 EV kit board.

• Connect a jumper across pins 1 and 2 of jumper

JU2 on the MAXQ3210 EV kit board.

Note: When using two power supplies in this manner, the JU1 jumper on the MAXQ3210 EV kit board

must be DISCONNECTED.

Running Both Boards from a Single Power Supply

If the serial-to-JTAG interface board is being used, a

single power supply can be used to power both boards

as follows.

• Connect a 5V, ±5% regulated DC wall supply (center post positive) to the J2 power plug of the serialto-JTAG interface board.

• Connect the JH3 jumper on the serial-to-JTAG interface board.

• Connect the JU1 jumper on the MAXQ3210 EV kit

board.

• Connect a jumper across pins 2 and 3 of JU2 on the

MAXQ3210 EV kit board.

Note: Do not connect a power supply to the J1 plug

on the MAXQ3210 EV kit when powering the boards

in this manner.

Running the MAXQ3210 EV Kit Board

from a Single Power Supply

If the MAXQ3210 has already been programmed using

the JTAG interface, it is possible to disconnect the serial-to-JTAG board and power up the MAXQ3210 EV kit

board on its own. This simply executes the previously

loaded firmware, with no possibility of in-application

load or debugging.

• Connect a 9V, ±5% regulated DC wall supply (center post positive) to the J2 power plug of the

MAXQ3210 EV kit board, OR insert a 9V battery into

clip J1 of the MAXQ3210 EV kit board.

• Connect a jumper across pins 1 and 2 of JU2 on the

MAXQ3210 EV kit board.

The power pins for the MAXQ3210 EV kit are connected to the on-board power supplies by jumpers as

shown in Table 1.

Evaluates: MAXQ3210

MAXQ3210 Evaluation Kit

Component List (continued)

DESIGNATION

QTY

DESCRIPTION

SUPPLIER/

PART

NUMBER

U1

MAXQ3210 voltage

regulator

microcontroller

MAXQ3210-EJX

U2

MAX5160 digital

potentiometer

MAX5160LEUA

Y1

Citizen

HC49US3.5795

45MABJ

1

1

1 3.5795MHz crystal

Evaluates: MAXQ3210

Additional Hardware Features

Most of the additional hardware on the MAXQ3210 EV

kit, such as the piezoelectric horn, LED and digital

potentiometer, can be enabled or disabled by setting

or removing jumpers. Disabling unused hardware frees

up the associated port pins for other uses.

Using the RC Oscillator Clock Option

To run the MAXQ3210 EV kit using the RC oscillator,

remove the crystal at Y1, close jumper JU3, and populate R3 and C4 with appropriate components. (Refer to

the MAXQ3210 data sheet for appropriate resistor and

capacitor values for a given frequency.)

Because the XT/RC bit in the CKCN register is set to 1

(selecting crystal mode) upon power-up, the MAXQ3210

will always come out of power-up and attempt to run

from an external crystal. If the RC circuit option is populated instead, the crystal oscillator does not start, and the

MAXQ3210 continues running on the internal ring oscillator (approximately 8kHz) until the loaded program

firmware sets the XT/RC bit to 0. If the MAXQ3210 is not

loaded, it continues running from the internal ring indefinitely, which means it is running too slowly to communicate using the standard JTAG firmware.

If this occurs, you can communicate with the slow-running MAXQ3210 by loading the jtag_1kHz.hex file

(provided on the EV kit CD-ROM) into the serial-toJTAG board and then using MTK or MAX-IDE as usual.

Note that this version performs the master erase, loading, and debug operations much more slowly than

usual due to the reduced communications speed, so as

soon as you have loaded program firmware into the

MAXQ3210 that sets the XT/RC bit to 0 upon startup,

you can reload the normal serial-to-JTAG board

firmware to go back to normal tools operation.

MAXQ3210 Evaluation Kit

4 _____________________________________________________________________

JUMPER

EFFECT

JU1

REGOUT is not connected to JTAG

5V. (Drive from internal regulator or

bench supply.)

*

JU1

Pins 1 and 2

REGOUT is connected to the 5V

supply from the JTAG board.

JU2

The power supply at J2 is not used.

JU2

Pins 1 and 2

The J2 power supply (which should

be 9V) is connected to the V

BAT

pin.

This configuration should only be

used with the J1 battery clip empty.

JU2

Pins 2 and 3

The J2 power supply (which should

be 5V) is connected to the REGOUT

pin. When using this configuration,

the JU1 jumper must be

disconnected and the J1 battery clip

must be empty.

Table 1. Power-Supply Jumper Settings

JUMPER

WHEN OPEN WHEN CLOSED

JU3 No effect.

The RC oscillator circuit may

be used to drive the

MAXQ3210 clock. To use this

feature, Y1 must be empty, and

R3 and C4 must be populated

with appropriate components.

JU5, JU7,

JU8

The piezoelectric

The piezoelectric horn is

enabled.

JU4, JU6

The piezoelectric

horn operates at

The piezoelectric horn

operates at full volume.

JU9 No effect.

Port pin P0.0 is connected to

pin CS of the MAX5160 digital

potentiometer.

JU10 No effect.

Port pin P1.5 is connected to

pin INC of the MAX5160 digital

potentiometer.

JU11 No effect.

Port pin P0.5 (comparator

input) is connected to the

wiper pin of the MAX5160.

JU12 No effect.

Port pin P1.6 is connected to

pin U/D of the MAX5160 digital

potentiometer.

JU13 No effect.

Port pin P0.7 (LED drive) is

connected to the red LED D3.

Table 2. Other Jumper Settings

* Refer to the MAXQ3210 data sheet for the allowable range of

supply at REGOUT.

SETTING

(No jumper)

connected

(No jumper)

connected

connected

horn is disabled.

reduced volume.

_____________________________________________________________________ 5

Evaluates: MAXQ3210

MAXQ3210 Evaluation Kit

WINDOWS PC

WITH SERIAL

(COM) PORT

(USER SUPPLIED)

POWER SUPPLY

5V DC ±5%

> 300mA

(USER SUPPLIED)

POWER SUPPLY

6V–9V DC

> 300mA

(USER SUPPLIED)

(WHEN NOT USING

JTAG BOARD)

RS-232

J1

SERIAL

JTAG

CONNECTOR

SERIAL-

TO-

JTAG

INTERFACE

BOARD

JTAG

INTERFACE

JTAG

CONNECTOR

J2

P2

J2

SW1 SW2

J4

DEVICE

HEADER

PINS

INTERRUPT RESET

CRYSTAL

9V BATTERY CLIP

PIEZO BUZZER

J3

+5V

GND

PROTOTYPE

AREA

MAXQ3210

Figure 3. MAXQ3210 Evaluation Kit Functional Layout

6 _____________________________________________________________________

Evaluates: MAXQ3210

MAXQ3210 Evaluation Kit

1

TP1

GND

PJ-002A

J2

IN

G1

G2

JU2

JU3

JU2 - 1/2 FOR 9V DC POWER

JU2 - 2/3 FOR 5V DC POWER

CLOSE JU3 AND POPULATE R3, C4

TO USE RC RELAXATION OSCILLATOR

VBAT

VBAT

VCC5

VBAT

VCC5

RED LED

D1

C3

10µF

20V

C1

10µF

20V

R1

1.2kΩ

2

1

TP2

VBAT

2

1

1

1

1

2

1

2

2

VCC5

VCC5

RED LED

D2

C2

10µF

20V

R2

510Ω

R3

EMPTY

C4

EMPTY

1

TP3

+5V

2

1

J1

9V BATTERY CLIP

2

1

2

1

1

2

1

2

2

PLUS

MINUS

1

J3

J4

JU1

HEADER 2x5 (JTAG)

HEADER 2x20

3

5

7

9

2

4

6

8

10

TCK

TDO

TMS

CLOSE JU1 TO POWER (5V ONLY)

OVER JTAG CONNECTOR

KEY

TDI

GND

P14_TDO

P13_TCK

P12_TMS P11_RST

P10_TDI

2

1

P0.4_VREF

3

P0.3_CMPO

4

P0.2_T2P

5

P0.1_T2PB

6

P0.07P1.68P1.5

9

P1.4_TDO

10

11

12

232422

21

20

19

18

17

16

15

14

13

315

7

9

11

131517

19

21

232527

29

31

33

35

37

39

426

8

10

12

141618

20

22

242628

30

32

34

36

38

40

P1.3_TCK

P0.0

P0.1_T2PB

P0.2_T2P

P0.3_CMPO

P0.4_VREF

P0.5_CMPI

P0.6_INT

P0.7_LED

P1.0_TDI

P1.1_RESET

P1.2_TMS

P1.3_TCK

P1.4_TDO

P1.5

P1.6

HORNS

HORNB

FEED

P0.4_VREF

GND

P0.3_CMPO

P0.2_T2P

P0.1_T2PB

P0.0

P1.6

P1.5

P1.4_TDO

P1.3_TCK

HFXIN

HFXOUT

P0.6_INT

P0.5_CMPI

P0.7_LED

P0.0_TDI

P1.1_RESET

P1.2_TMS

REGOUT

V

DD

HORNS

GND

HORN

HORNB

FEED

REF

RST

VCC5

GND

3

2

221

3

VBAT

1

1

1

2

2

C6

22pF

10V

C5

22pF

10V

11

1

2

C7

100nF

10V

1

2

VCC5

C8

100nF

10V

1

2

2

2

Y1

3.5795MHz

SOCKETED

2

P0.6_INT

P0.5_CMPI

P0.7_LED

P0.0_TDI

P1.1_RESET

P1.2_TMS

VCC5VBAT

HORNS

HORNB

FEED

MAXQ3210

Figure 4. MAXQ3210 Evaluation Kit Power Schematics

Evaluates: MAXQ3210

MAXQ3210 Evaluation Kit

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 _____________________ 7

© 2006 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

is a registered trademark of Dallas Semiconductor Corporation.

INTERRUPT

SW1

JU4

P0.6_INT

HORNS

FEED

3

4

2

VCC5

P.05_CMPI

VCC5

JU9

JU11

JU10

JU12

11

22

2

1

P0.0

P1.5

P1.6

CLOSE JU9, JU10, JU11, JU12 TO

SET COMPARATOR INPUT TO

ADJUSTABLE DIGITAL POT VALUE

CLOSE JU5, JU7, JU8 TO ENABLE PIEZO HORN

CLOSE JU4, JU6 TO ENABLE LOUD VOLUME

CLOSE JU13 TO DRIVE LED WITH P0.7

1

1

2

JU7

R5

1kΩ

1/2W

R6

68kΩ

R14

30kΩ

C9

2nF

CEP-1172

PT1

1

2

1

2

JU6

1

HORNB

2

1M

F

G

122

21

3

1

2

R7

470 kΩ

1

2

R4

1kΩ

1/2W

1

2

1

2

JU5

1

2

JU8

1

2

7

8

VDD

H

L

W

CS

INC

U/D

GND

1

5

6

2

1

2

4

2

2

1

2

1

2

1

2

11 2

R11

1kΩ

R13

1kΩ

RED LED

R10

10kΩ

R9

10kΩ

R8

10kΩ

P0.7_LED

RESET

SW2

P1.1_RST

3

4

2

11 2

R12

1kΩ

MAX5160LEUA

U2

JU13

VCC5

Figure 5. MAXQ3210 Evaluation Kit Demo Components Schematic

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Maxim Integrated:

MAXQ3210-KIT

Loading...

Loading...