Dallas Semiconductor DS2437 Datasheet

r

www.dalsemi.com

DS2437

Smart Battery Monito

FEATURES

PIN ASSIGNMENT

Unique 1-Wire® interface requires only one

port pin for communication

Provides unique 64-bit serial number to

battery packs

Eliminates thermistors by sensing battery

temperature on-chip

On-board A/D converter allows monitoring of

battery voltage for end-of-charge and end-ofdischarge determination

DQ

NC

VAD

NC

VSENS+

VSENS-

NC

AGND

See Mech. Drawings Section

1

2

3

4

5

6

7

8

16-PIN SSOP

16

15

14

13

12

11

10

VDD

NC

NC

X1

NC

X2

NC

9

GND

On-board integrated current accumulator

facilitates gas gauging

Real-time clock in binary format

40-byte nonvolatile user memory available for

storage of user data such as gas gauge and

manufacturing information

Operating range -40°C to +85°C

Applications include portable computers,

portable/cellular phones, consumer

electronics, and handheld instrumentation

PIN DESCRIPTION

DQ - Data In/Out

VAD - General A/D input

VSENS+ - Battery current monitor input (+)

VSENS- - Battery current monitor input (-)

NC - No connect

GND - Digital Ground

AGND - Analog Ground

X2 - Connection for 32.768 kHz XTAL

X1 - Connection for 32.768 kHz XTAL

VDD - Power Supply (2.7V to 10.0V)

DESCRIPTION

The DS2437 Smart Battery Monitor provides several functions that are desirable to carry in a battery

pack: a means of tagging a battery pack with a unique serial number; a direct-to-digital temperature

sensor which eliminates the need for thermistors in the battery pack; an A/D converter which measures

the battery voltage and current; an integrated current accumulator, which keeps a running total of all

current going into and out of the battery; a real-time clock; and 40 bytes of nonvolatile EEPROM

memory for storage of important parameters such as battery capacity, capacity remaining, and indication

of battery cycling.

Information is sent to/from the DS2437 over a 1-Wire interface, so that only one wire (and ground) needs

to be connected from a central microprocessor to a DS2437. This means that batter y packs need only

have three output connectors: battery power, ground, and the 1-Wire interface.

Because each DS2437 contains a unique silicon serial number, multiple DS2437s can exist on the same

1-Wire bus. This allows multiple battery packs to be charged or used in the system simultaneously.

1 of 31 070600

DS2437

Applications for the smart battery pack monitor include portable computers, portable/ cellular telephones,

and handheld instrumentation battery packs in which it is critical to monitor real-time battery

performance. Used in conjunction with a microcontroller in the batter y pack or host system, the DS2437

provides a complete smart battery pack solution that is fully chemistry-independent. The customization

for a particular battery chemistry and capacity is realized in the code programmed into the

microcontroller and DS2437 EEPROM, and only a software revision is necessar y should a desi gner wish

to change battery pack chemistry.

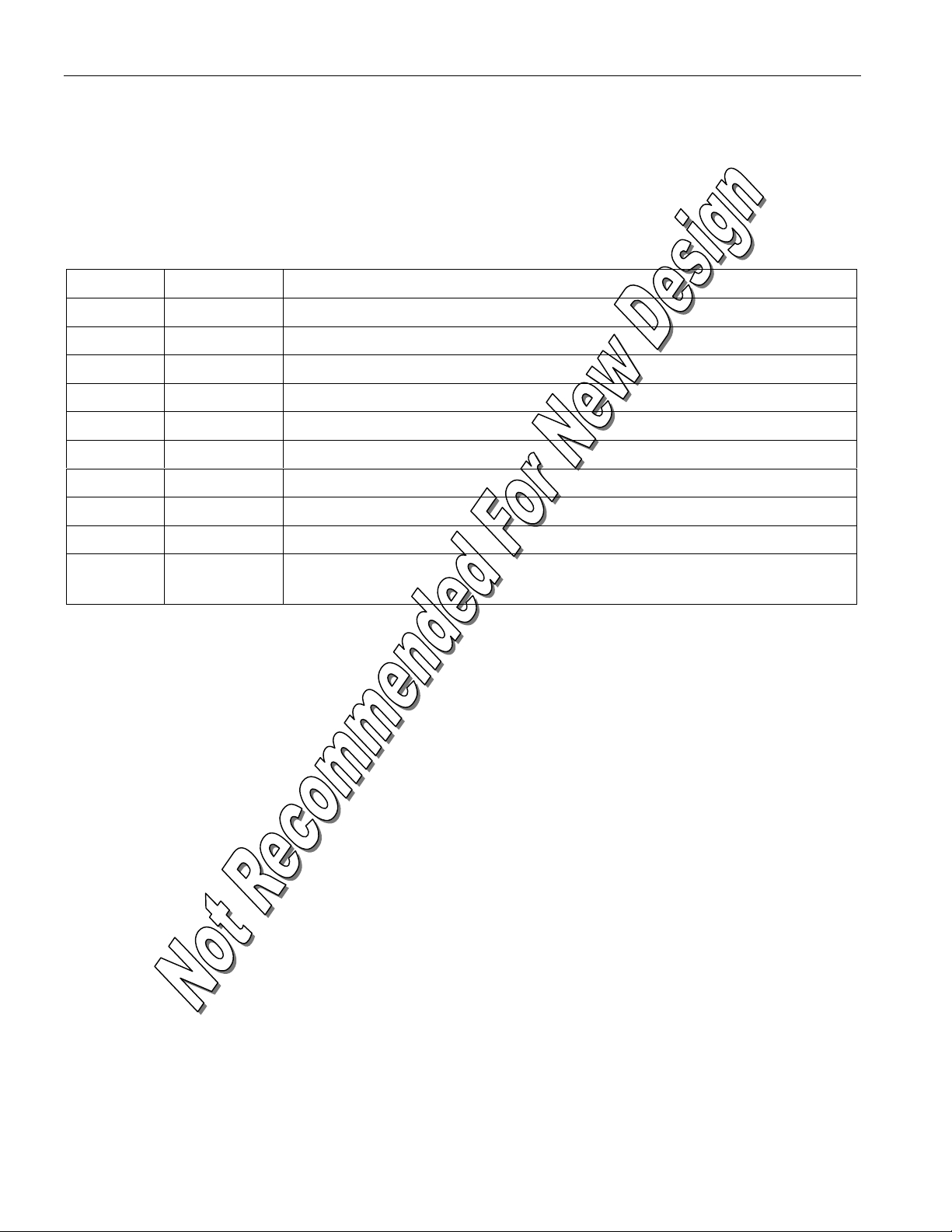

DETAILED PIN DESCRIPTION

PIN SYMBOL DESCRIPTION

1DQData Input/Out: for 1-Wire operation: open drain

3 VAD ADC Input: input for general purpose A/D

5VSENS+Battery Input: connection for battery current to be monitored (see text)

6VSENS-Battery Input: connection for battery current to be monitored (see text)

8 AGND Analog Ground: must be at the same potential as GND

9 GND Digital Ground: must be at the same potential as AGND

11 X2 Crystal Input: connection for 32.768 kHz for RTC operation

13 X1 Crystal Input: connection for 32.768 kHz for RTC operation

16 V

2, 4, 7, 10,

DD

NC

VDD Pin: input supply voltage

No Connect

12, 14, 15

OVERVIEW

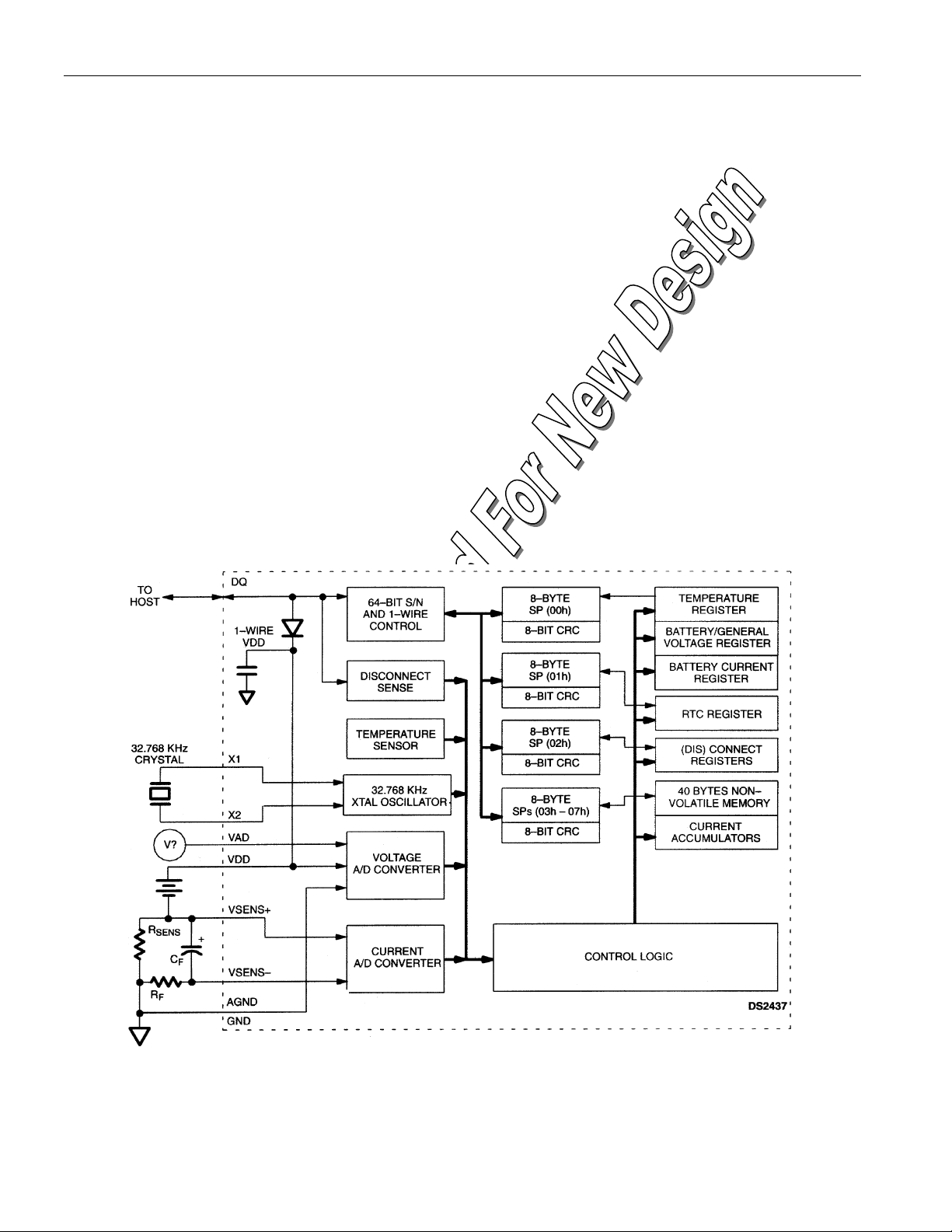

The block diagram of Figure 1 shows the seven major components of the DS2437:

1. 64-bit lasered ROM

2. temperature sensor

3. battery voltage A/D

4. battery current A/D

5. current accumulators

6. real-time clock

7. 40-byte nonvolatile user memory

Each DS2437 contains a unique 64-bit lasered ROM serial number so that several battery packs can be

charged/monitored by the same host system. Furthermore, other Dallas products featuring the same

1-Wire bus architecture with a 64-bit ROM can reside on the same bus; refer to the Dallas "Automatic

Identification Data Book" for the specifications of these products.

Communication to the DS2437 is via a 1-Wire port. With the 1-Wire port, the memory and control

functions will not be available until the ROM function protocol has been established. The master must

first provide one of four ROM function commands: 1) Read ROM, 2) Match ROM, 3) Search ROM, or 4)

Skip ROM. These commands operate on the 64-bit lasered ROM portion of each device and can singulate

a specific device if man y are present on the 1-Wire line as well as indicate to the bus maste r how many

and what types of devices are present. After a ROM function sequence has been successfull y executed,

the memory and control functions are accessible and the master may then provide any one of the six

memory and control function commands.

2 of 31

DS2437

Control function commands may be issued which instruct the DS2437 to perform a temperature

measurement or battery voltage A/D conversion. The result of these measurements will be placed in the

DS2437’s memory map, and may be read by issuing a memory function command which reads the

contents of the temperature and voltage registers. Additionally, the charging/discharging battery current is

measured without user intervention, and again, the last completed result is stored in DS2437 memory

space. The DS2437 uses these current measurements to update thre e current a ccumulators: one stor es net

charge for gas gauge calculations, the second accumulates the total charging current over the life of the

battery, and the remaining accumulator tallies battery discharge current. The real time clock data, which

can be used in calculating battery self-discharge or time-related charge termination limits, also resides in

the DS2437 memory map and can be extracted with a control function command. The nonvolatile user

memory of the DS2437 consists of 40 bytes of EEPROM. These locations may be used to store any data

the user wishes and are written to using a memory function command. All data and commands are read

and written least significant bit first.

PARASITE POWER

The block diagram (Figure 1) shows the parasite-powered circuitry. This circuitry “steals” power

whenever the DQ pin is high. DQ will provide sufficient power as long as the specified timing and

voltage requirements are met (see the section titled “1-Wire Bus System”). The advantage of parasite

power is that the ROM may be read in absence of normal power, i.e., if the battery pack is completely

discharged.

DS2437 BLOCK DIAGRAM Figure 1

3 of 31

DS2437

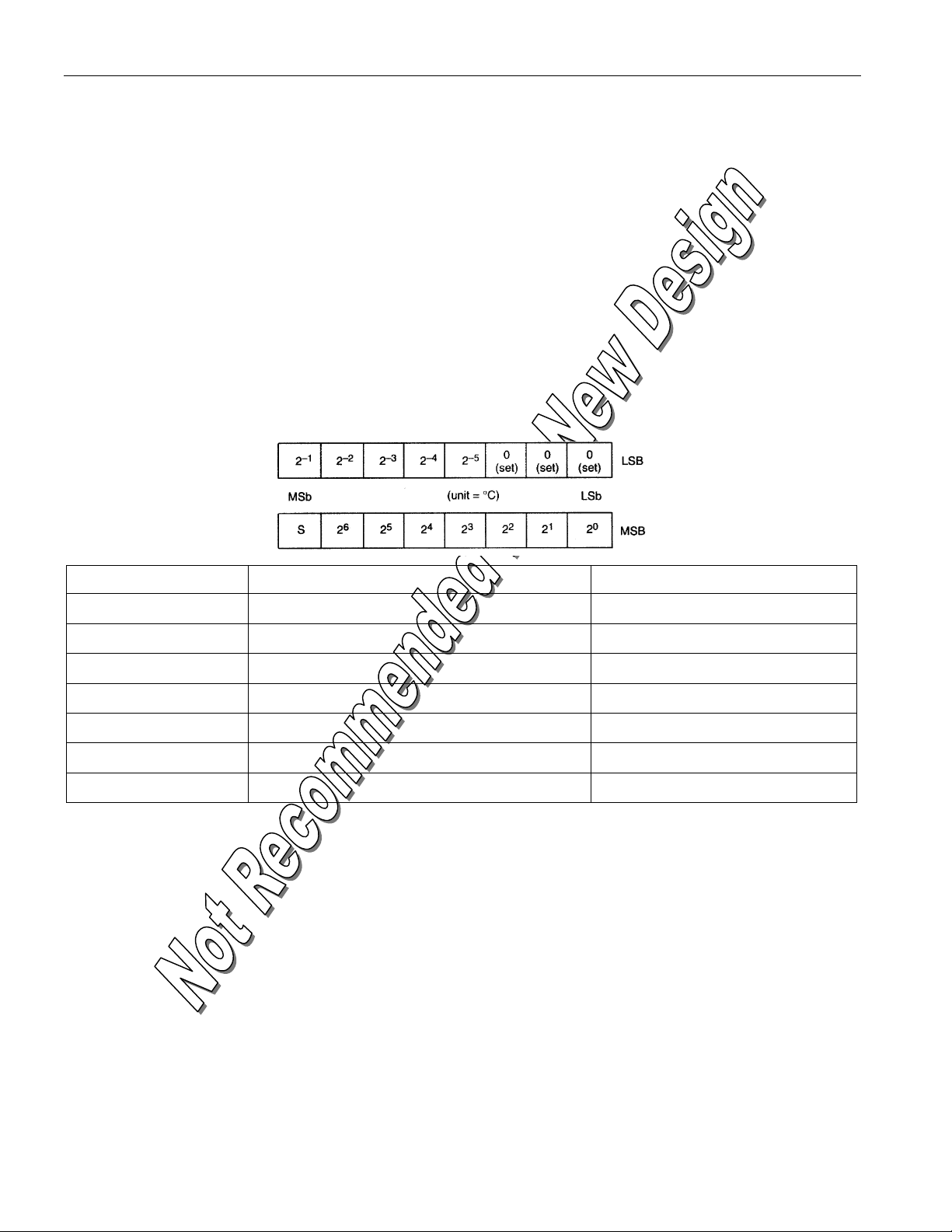

OPERATION – MEASURING TEMPERATURE

The DS2437 measures temperatures through the use of an onboard prop rietary temperature measurement

technique.

The temperature reading is provided in a 13-bit, two’s complement reading, which provides 0.03125°C of

resolution. Table 1 describes the exact relationship of output data to measured temperature. The data is

transmitted serially over the 1-Wire interface. The DS2437 can me asure temperature over the range of

-55°C to +125°C in 0.03125°C increments. For Fahrenheit usage, a lookup table or conversion factor

must be used.

Note that temperature is represented in the DS2437 in terms of a 0.03125°C LSb, yielding the following

13-bit format. The 3 least significant bits of the temperature register will always be 0. The remaining 13

bits contain the two’s complement representation of the temperature in °C, with the MSb holding the sign

(S) bit. See “Memory Map” section for the TEMPERATURE REGISTER address location.

Temperature/Data Relationships Table 1

TEMPERATURE DIGITAL OUTPUT (Binary) DIGITAL OUTPUT (Hex)

+125°C

+25.0625°C

+1/2°C

0°C

-1/2°C

-25.0625°C

-55°C

01111101 00000000 7D00h

00011001 00010000 1910h

00000000 10000000 0080h

00000000 00000000 0000h

11111111 10000000 FF80h

11100110 11110000 E6F0h

11001001 00000000 C900h

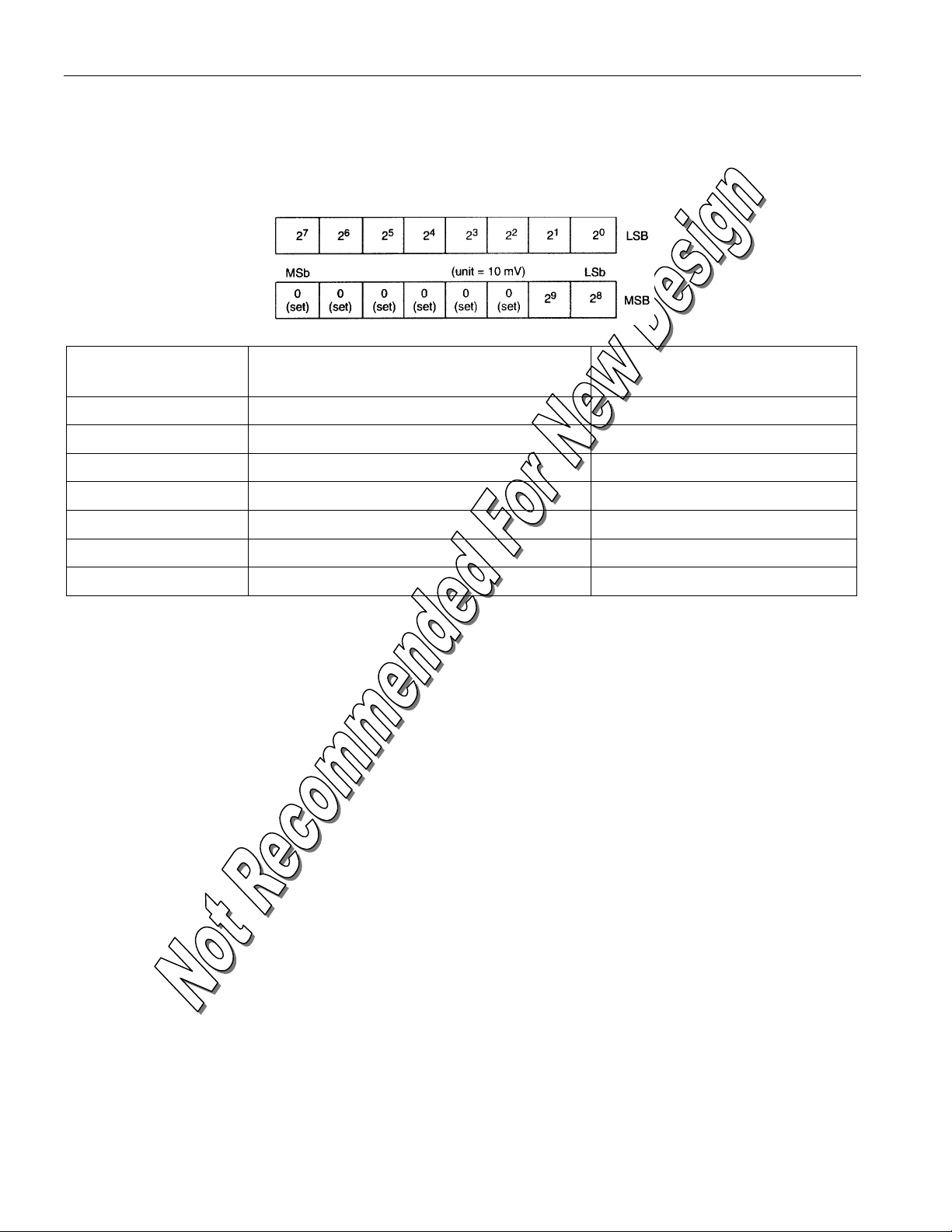

OPERATION – MEASURING BATTERY VOLTAGE

The on-board analog-to-digital converter (ADC) has 10 bits of resolution and will perform a conversion

when the DS2437 receives a command protocol (Convert V) instructing it to do so. The result of this

measurement is placed in the 2-byte VOLTAGE REGISTER. The range for the DS2437 ADC is 0V to

10V; this range is suitable for NiCd or NiMH battery packs up to six cells and for lithium ion battery

packs of two cells. The full-scale range of the ADC is scaled to 10.23V, resulting in a resolution of 10

mV.

While the ADC has a range that extends to 0V, it is important to note that the battery voltage can also be

the supply voltage to the DS2437. As such, the accuracy of the ADC begins to degrade below battery

voltages of 2.7V, and the ability to make conversions is limited by the operating voltage range of the

DS2437.

4 of 31

DS2437

Voltage is expressed in this register in scaled binary format, as outlined in Table 2. Note that while codes

exist for values below 2.7V, accuracy of the ADC and the limitation on the DS2437’s supply voltage

make it unlikely that these values would be used in actual practice. See “Memo ry Map” section for the

VOLTAGE REGISTER address location.

Voltage/Data Relationships Table 2

BATTERY

VOLTAGE DIGITAL OUTPUT (Binary) DIGITAL OUTPUT (Hex)

0.01V 0000 0000 0000 0001 0001h

2.7 0000 0001 0000 1110 010Eh

3.6V 0000 0001 0110 1000 0168h

5V 0000 0001 1111 0100 01F4h

7.2V 0000 0010 1101 0000 02D0h

9.99V 0000 0011 1110 0111 03E7h

10V 0000 0011 1110 1000 03E8h

For applications requiring a general purpose voltage A/D converter, the DS2437 can be configured so that

the result of a Convert V command will place the scaled binary representation of the voltage on the V

AD

input (as opposed to the VDD input) into the VOLTAGE REGISTER in the same format described in

Table 2. Depending upon the state of the configuration register, either (but not both) the VDD or V

AD

voltage will be stored in the VOLTAGE REGISTER upon receipt of the Convert V command. Refer to

the description of the Configuration Register in the Memory Map section for details. If the VAD input is

used as the voltage input, the A/D will be accurate for 0V < VAD < 2VDD over the range 2.7V < VDD <

5.0V. Recall that the battery voltage A/D (V

input) loses accuracy as VDD falls below 2.7V. This

DD

feature gives the user the ability to have a voltage A/D that meets spec accurac y for inputs over the entire

range of 0V < V

< 10V for VDD = 5.0V.

AD

OPERATION – MEASURING BATTERY CURRENT

The DS2437 features a sigma-delta A/D converter that effectivel y measures the current flow into and out

of the battery pack. It does so in the background at a rate of 32 measurements/sec; thus, no command is

required to initiate current flow measurements. However, the DS2437 will only perform current A/D

measurements if the IAD bit is set to 1 in the CONFIGURATION REGISTER. The DS2437 measures

current flow in and out of the battery through the VSENS pins; the voltage from the VSENS+ pin to the

VSENS- pin is considered to be the voltage across the current sense resistor, R

terminal may be tied directly to the cell side of the R

filter between the other side of R

capacitor (C

), the filter cutoff is approximately 32 Hz. The current A/D measures at a rate of 32 times

F

and VSENS-. Using a 47 kΩ=(max) resistor (RF) and a 0.1 µF

SENS

resistor, we recommend using an RC low pass

SENS

per second, or once every 31.25 ms. This filter will capture the effect of many current spikes and will thus

allow the current accumulators to accurately reflect the total charge which has gone into or out of the

battery.

. While the VSENS+

SENS

5 of 31

DS2437

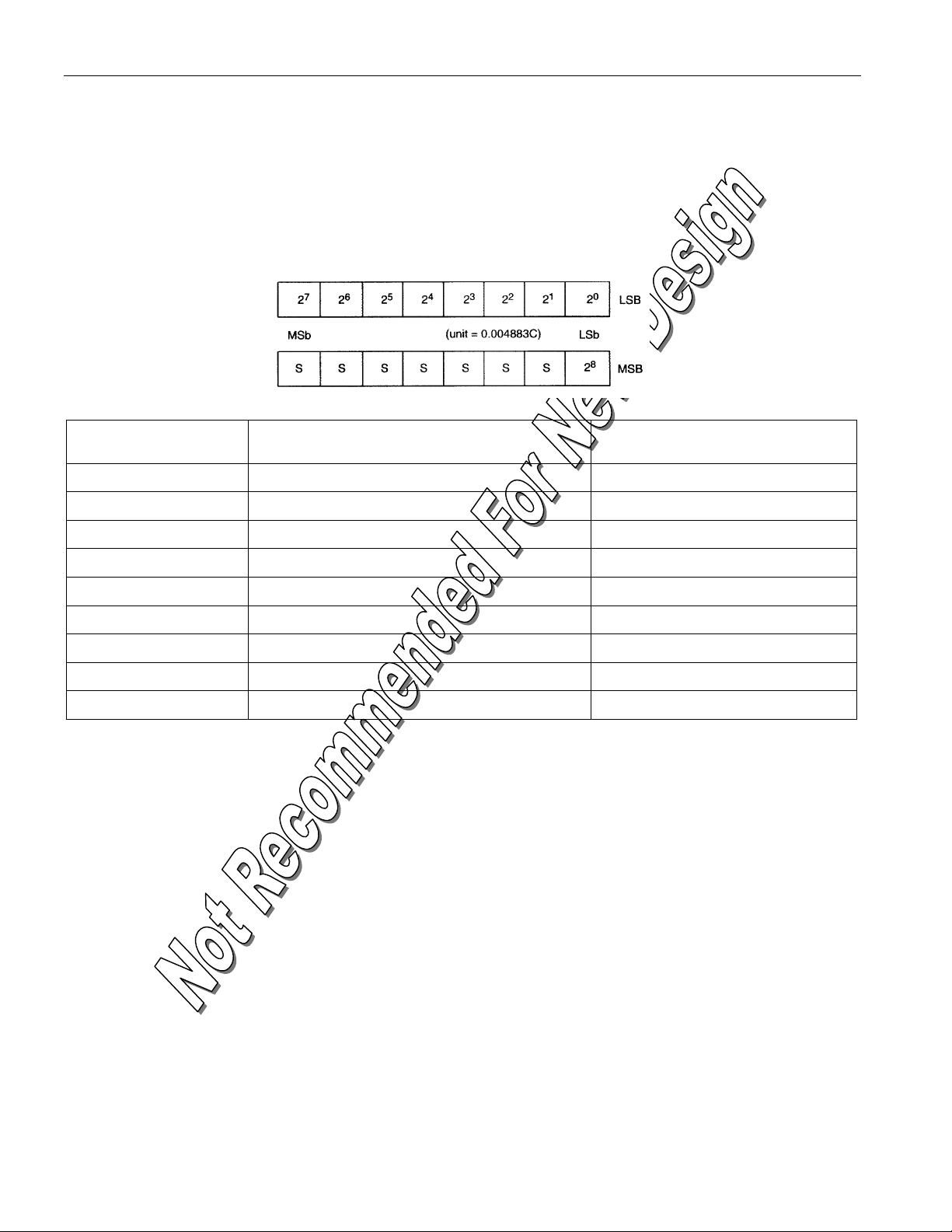

The current is measured by the ADC with a signed 10-bit (0.004883C) resolution, and the last completed

measurement is placed in the CURRENT REGISTER in a sign-extended 2’s-complement format. This

register is scaled such that a count of 20510 corresponds to a current level of 1C. Thus, the range of

current flow that can be measured is from -2.5C (discharging) to +2.5C (charging). The si gn (S) of the

current measurement, indicating charge or discharge, resides in the seven most significant bits of the

CURRENT REGISTER, as shown in Table 3. See “Memory Map” section for the CURRENT

REGISTER address location.

Current/Data Relationships Table 3

BATTERY

CURRENT DIGITAL OUTPUT (Binary) DIGITAL OUTPUT (Hex)

+2.495C 0000 0001 1111 1111 01FFh

+2.002C 0000 0001 1001 1010 019Ah

+1.25C 0000 0001 0000 0000 0100h

+1.001C 0000 0000 1100 1101 00CDh

0C 0000 0000 0000 0000 0000h

-1.001C 1111 1111 0011 0011 FF33h

-1.25C 1111 1111 0000 0000 FF00h

-2.002C 1111 1110 0110 0110 FE66h

-2.500C 1111 1110 0000 0000 FE00h

For the DS2437 to output current data scaled as in Table 3, the user is responsible for selecting an R

SENS

that will provide a 100 mV drop across it at a 2C rate. However, this value could be changed to

correspond to a different rate as long as this is comprehended by the user’s software in interpreting the

results from the DS2437.

OPERATION – CURRENT ACCUMULATORS

The DS2437 keeps track of the remaining capacity of a battery through the Integrated Current

Accumulator (ICA). The ICA maintains a net accumulated total of current flowing into and out of the

battery; therefore, the reading in this register is an indication of the remaining capacity in a battery and

may be used in performing gas gauge functions. In addition, the DS2437 has a register that accumulates

battery charging (positive) current (CCA) and one that accumulates discharging (negative) current

(DCA). This gives the smart battery system information needed to determine the end of life of a

rechargeable battery, based on total charge/discharge current over its lifetime.

The current measurement described above yields a result of the instantaneous current measured at the

31.25 ms measurement times. This value is then used to increment or decrement the ICA register,

increment the CCA (if current is positive), or increment the DCA (if current is negative).

6 of 31

DS2437

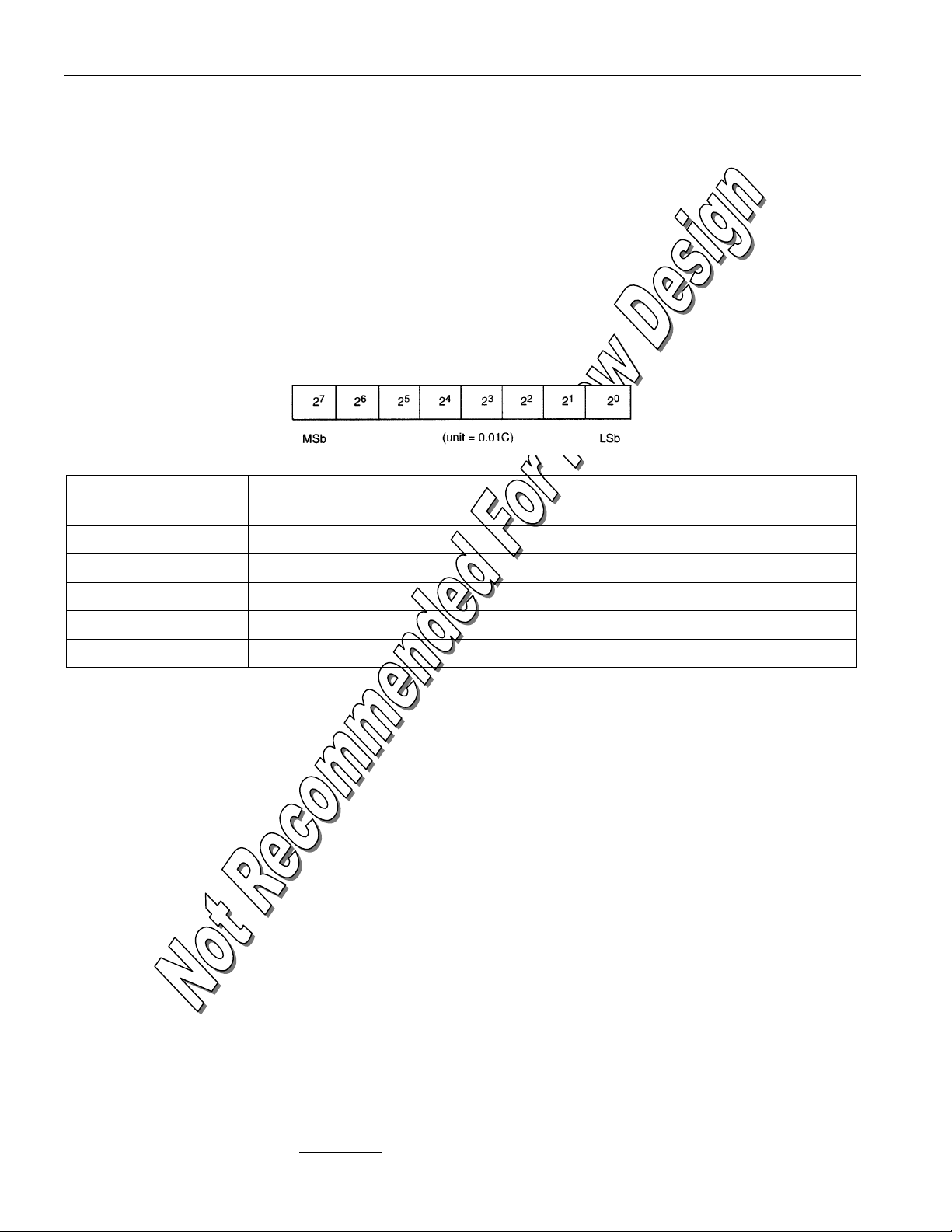

The ICA is a scaled 8-bit (0.01C resolution) volatile binary counter which represents the amount of

capacity remaining in the battery in terms of the full capacity (1C), normalized to a count of 10010. Thus,

an ICA count of 10010 represents 1C of charge or 100% of capacit y or fully charged, while a count of 0

represents 0% of capacity or fully discharged. The ICA will count up to 25510, but will not roll over if

incremented above 2.55C, which should not occur during charging. However, since charging typically

provides the battery with more than its rated capacity, the ICA should be reset to a count of 100

when

10

charging is complete to indicate that the battery is at 100% of capacity and to ensure that later gas gauge

measurements are accurate.

The ICA is only incremented/decremented if the IAD bit is set to 1 in the CONFIGURATION

REGISTER. Refer to the “Memory Map” section for details of device configuration. Table 4 below

illustrates the contents of the ICA. See Memory Map section for the address location of the ICA.

ICA/Data Relationships Table 4

BATTERY

CAPACITY DIGITAL OUTPUT (Binary) DIGITAL OUTPUT (Hex)

2.55C 1111 1111 FFh

1.0C 0110 0100 64h

0.5C 0011 0010 32h

0.1C 0000 1010 0Ah

0C 0000 0000 00h

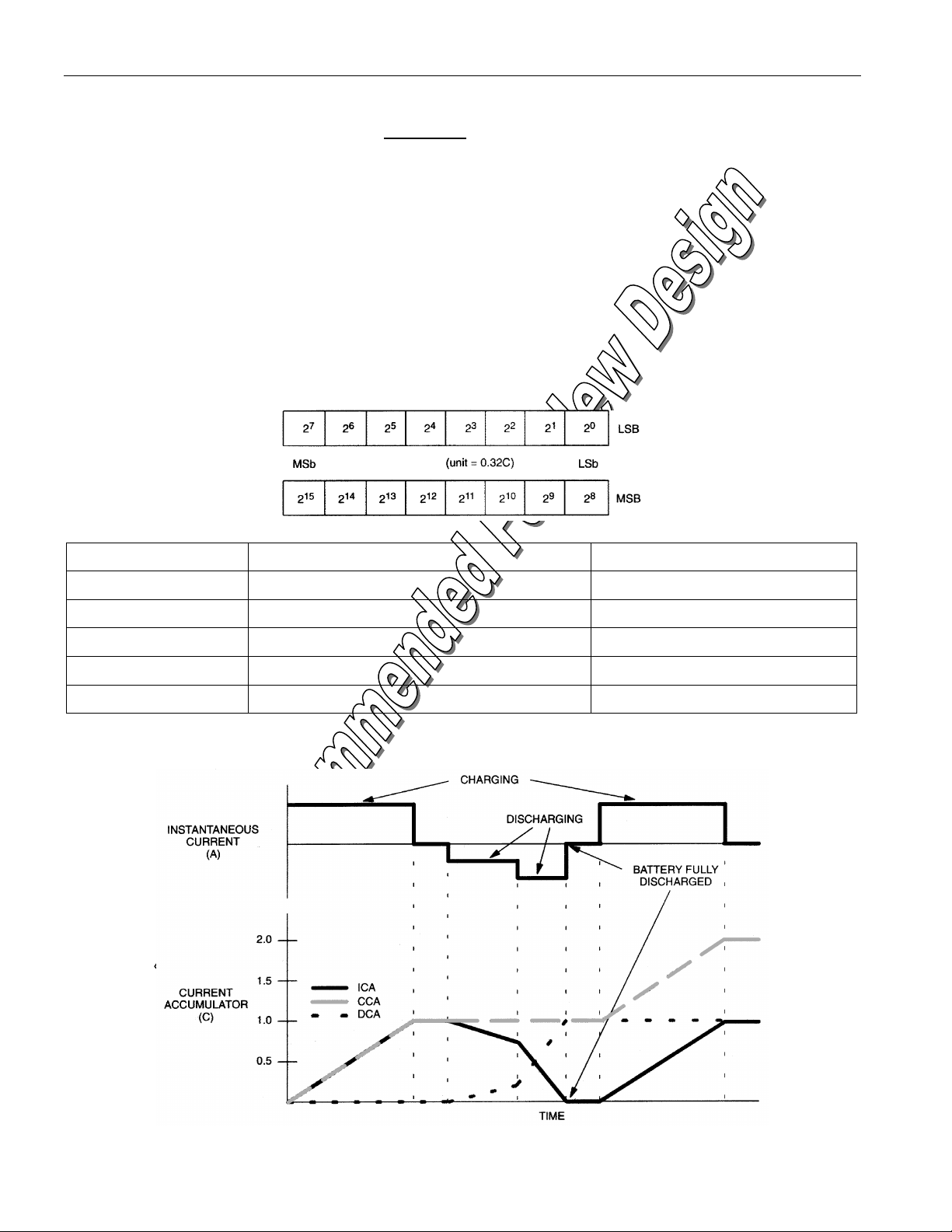

The Charging Current Accumulator (CCA) is a 2-byte (0.32C resolution) nonvolatile read/write counter

which represents the total charging current the battery has encountered in its lifetime. It is only updated

when current through R

is positive; i.e., the battery is being charged. Because this is a nonvolatile

SENS

register, the information will accumulate over the lifetime of the batter y pack and will not be lost when

the battery becomes discharged.

Similarly, the Discharge Current Accumulator (DCA) is a 2-byte nonvolatile counter which represents the

total discharging current the battery has encountered over its lifetime. It features the same resolution as

the CCA and it also is shadowed to EEPROM in the background at the rate of once per 0.32C of

discharge current if the DS2437 is properly configured, thus allowing three EEPROM updates for each

complete discharge cycle of the battery pack. Table 5 illustrates the contents of the CCA/DCA registers.

In reference to the CCA/DCA, the DS2437 can be configured to function in any of three modes. Refe r to

the Memory Map section for details of device configuration and for the address location of the

CCA/DCA.

1. The CCA/DCA is disabled. Charging/discharging current will not be accumulated, thus allowing free

use of EEPROM page 07h otherwise reserved for the CCA/DCA.

2. The CCA/DCA will accumulate charging/discharging current, but the information will NOT be

shadowed to EEPROM. The information could be lost or corrupted upon discharge of the battery

(depending upon the voltage to which discharged battery decays). The memory location is reserved

for the CCA/DCA, and the entire page SHOULD NOT be written to.

7 of 31

DS2437

3. The CCA/DCA will accumulate charging/discharging current, and the counter information will be

shadowed to EEPROM each time the respective counter increments by 0.32C. The memory location

is reserved for the CCA/DCA, and the entire page SHOULD NOT be written to.

Because the user has read/writ e access to the entire EEPROM arr ay, including the CCA/DCA locations,

the user’s software should never allow a write to memory page 07h if the CCA/DCA are used; otherwise

CCA/ DCA information will be overwritten.

Figure 2 below illustrates the activity of the ICA, CCA, and DCA over a sample charge/discharge cycle

of a battery pack, assuming the DS2437 is configured for the ICA to function and the CCA/DCA to

function and shadow data to EEPROM. To simplify the illustration of the accumulators, they are treated

as analog values, although they are digital counters in the DS2437. Note that when the battery becomes

fully discharged, i.e., the ICA value reaches 0, the CCA and DCA register values are maintained.

CCA/DCA Data Relationships Table 5

CCA/DCA DIGITAL OUTPUT (Binary) DIGITAL OUTPUT (Hex)

0C 0000 0000 0000 0000 0000h

32C 0000 0000 0110 0100 0064h

64C 0000 0000 1100 1000 00C8h

100C 0010 0001 0011 1000 0138h

20,971 1111 1111 1111 1111 FFFFh

CURRENT ACCUMULATOR ACTIVITY Figure 2

8 of 31

DS2437

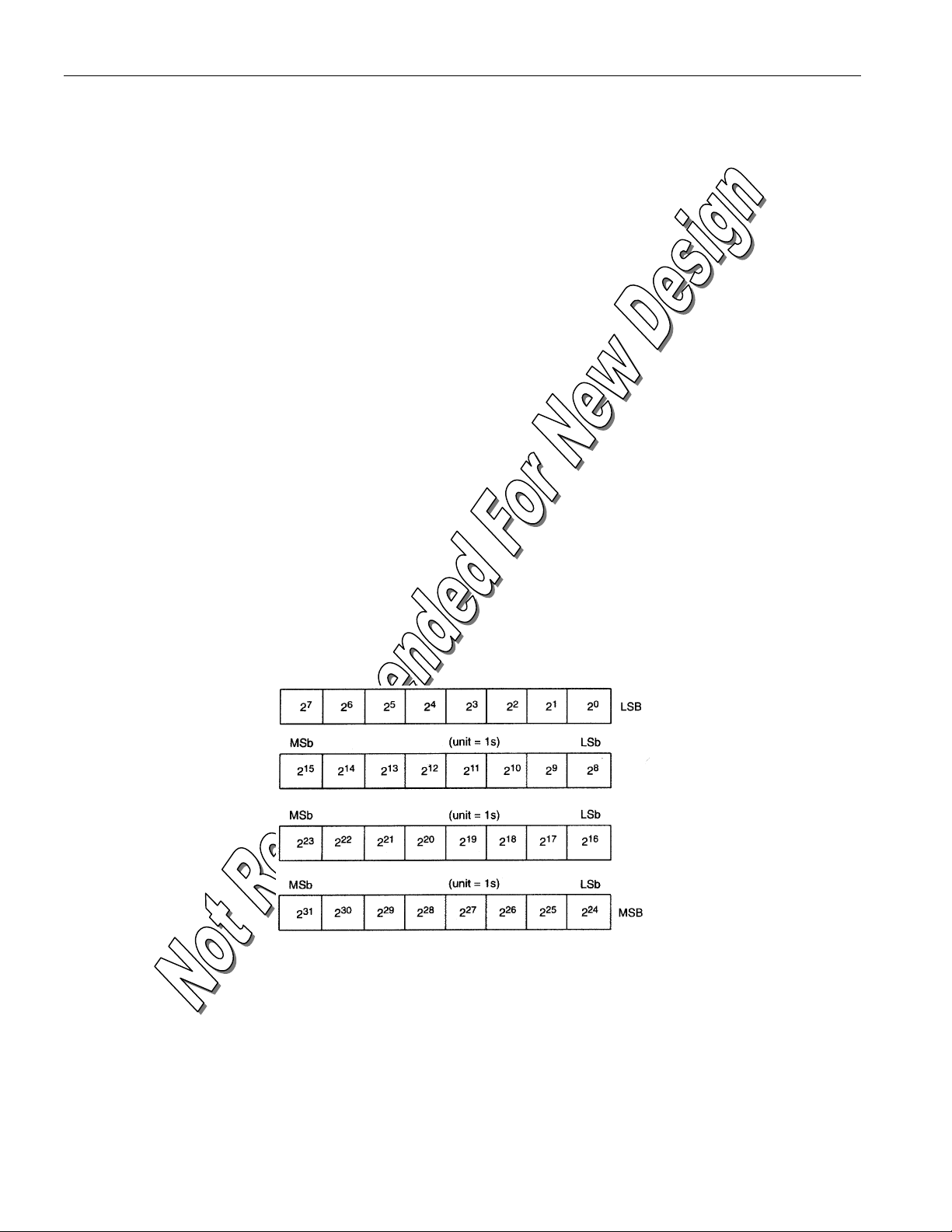

OPERATION – REAL TIME CLOCK

The 32.768 kHz crystal oscillator is used as the time base for the timekeeping fun ctions. The timekeepin g

functions are double-buffered, allowing the master to read time without the data changing while it is

being read. To accomplish this, a snapshot of the counter data is transferred to holding registers which the

user accesses. This occurs after the eighth bit of the Recall Memory command.

The real-time clock is a 4-byte binary counter with a 1-second resolution. The four bytes are a count of

seconds. The real-time clock can accumulate 136 years of seconds before rolling over. Time/date is

represented by the number of seconds since a reference point, which is determined by the user. For

example, 12:00 A.M., January 1, 1970 could be used as a reference point.

Two other time-related functions are available. The first is the DISCONNECT TIMESTAMP, which is

written to by the DS2437 whenever it senses that the DQ line has been low for more than 1 second. This

condition would signal that the battery pack has been removed from the system; the time when that

occurs is written into the DISCONNECT TIMESTAMP register, so that upon replacement into the

system, the system can determine how long the device has been in storage, to facilitate self-discharge

corrections to the remaining battery capacity. After the disconnect has been detected, the DS2437 reverts

to a sleep mode, during which nothing is active except the real time clock.

The other timestamp is the END OF CHARGE timestamp, which is written to by the DS2437 whenever it

senses that charging is finished (when current changes direction). This timestamp allows the user to

calculate the amount of time the battery has been in a discharge or storage state, again to facilitate selfdischarge calculations.

The format of the RTC, Disconnect, and End of Charge registers are as shown in Table 6. Refer to the

“Memory Map” section for the address location of the time-related registers.

Time Data Relationships Table 6

Crystal Selection

A 32.768 kHz crystal, Daiwa Part No. DT26S, Seiko Part No. DS-VT-200 or equivalent can be directly

connected to the DS2437 via pins 11 and 13 (X1, X2). The crystal selected for use should have a

specified load capacitance (CL) of 6 pF. The crystal is connected directl y to the X1 and X2 pins. There is

no need for external capacitors or resistors. Note: X1 and X2 are very high impedance nodes. It is

recommended that they and the crystal be guard ringed with ground and that high frequenc y signals be

kept away from the crystal area. For more information on crystal selection and crystal layout

considerations, please consult Application Note 58, “Crystal Considerations with Dallas Real Time

Clocks.”

9 of 31

DS2437

64-BIT LASERED ROM

Each DS2437 contains a unique ROM code that is 64 bits long. The first 8 bits are a 1-Wire family code

(DS2437 code is 1Eh). The next 48 bits are a unique serial number. The last 8 bits are a CRC of the first

56 bits. (See Figure 3.) The 64-bit ROM and ROM Function Control section allow the DS2437 to oper ate

as a 1-Wire device and follow the 1-Wire protocol detailed in the section “1-Wire Bus System.” The

functions required to control sections of the DS2437 are not accessible until the ROM function protocol

has been satisfied. This protocol is described in the ROM function protocol flow chart (Figure 4). The

1-Wire bus master must first provide one of four ROM function commands: 1) Read ROM, 2) Match

ROM, 3) Search ROM, or 4) Skip ROM. After a ROM function sequence has been successfully executed,

the functions specific to the DS2437 are accessible and the bus master may then provide and one of the

six memory and control function commands.

64-Bit Lasered ROM Figure 3

CRC Generation

The DS2437 has an 8-bit CRC stored in the most significant byte of the 64-bit ROM. The bus master can

compute a CRC value from the first 56 bits of the 64-bit ROM and compare it to the value stored within

the DS2437 to determine if the ROM data has been received error-free b y the bus master. The equivalent

polynomial function of this CRC is:

CRC = X8 + X5 + X4 +1

The DS2437 also generates an 8-bit CRC value using the same polynomial function shown above and

provides this value to the bus master to validate the transfer of data bytes. In each case where a CRC is

used for data transfer validation, the bus master must calculate a CRC value using the polynomial

function given above and compare the calculated value to either the 8-bit CRC value stored in the 64-bit

ROM portion of the DS2437 (for ROM reads) or the 8-bit CRC value computed within the DS2437

(which is read as a 9th byte when a scratchpad is read). The comparison of CRC values and decision to

continue with an operation are determined entirely by the bus master. There is no circuitry inside the

DS2437 that prevents a command sequence from proceeding if the CRC stored in or calculated by the

DS2437 does not match the value generated by the bus master. Proper use of the CRC as outlined in the

flowchart of Figure 6 can result in a communication channel with a very high level of integrity.

The 1-Wire CRC can be generated using a polynomial generator consisting of a shift register and XOR

gates as shown in Figure 4. Additional information about the Dallas 1-Wire Cyclic Redundancy Check is

available in Application Note 27 entitled “Understanding and Using Cyclic Redundancy Checks with

Dallas Semiconductor Touch Memory Products.”

The shift register bits are initialized to 0. Then starting with the least significant bit of the family code,

1 bit at a time is shifted in. After the 8th bit of the family code has been entered, then the serial number is

th

entered. After the 48

bit of the serial number has been entered, the shift register contains the CRC

value.

10 of 31

Loading...

Loading...