Dallas Semiconductor DS2407P, DS2407 Datasheet

DS2407

DS2407

Dual Addressable Switch Plus

1K–Bit Memory

FEATURES

• Open drain PIO pins are controlled and their logic

level can be determined over 1–Wire

closed–loop control

TM

bus for

• Dual Channel operation (TSOC package)

• PIO pin channel A sink capability of 50 mA at 0.4V with

soft turn–on; channel B 8 mA at 0.4V

• Maximum operating voltage of 13V at PIO–A, 6.5V at

PIO–B

• 1024 bits user–programmable OTP EPROM

• 7 bytes of user–programmable status memory to con-

trol the device

• Multiple DS2407s can be identified on a common

1–Wire bus and be turned on or off independently of

other devices on the bus

• Unique, factory–lasered and tested 64–bit registra-

tion number (8–bit family code + 48–bit serial number

+ 8–bit CRC tester) assures error–free selection and

absolute identity because no two parts are alike

• On–chip CRC16 generator allows detection of data

transfer errors

• Built–in multidrop controller ensures compatibility

with other MicroLAN

TM

products

• Reduces control, address, data, programming and

power to a single data pin

• Directly connects to a single port pin of a microproces-

sor and communicates at up to 16.3k bits/s

• Low cost TO–92 or 6–pin TSOC surface mount

package

• 1–Wire communication operates over a wide voltage

range of 2.8V to 6.0V from –40°C to +85°C

• Supports Conditional Search with user–program-

mable condition

• V

bondout for optional external supply to the device

CC

(TSOC package only)

• Hidden Mode; the device will respond only to a Match

ROM command or a Conditional Search when in this

mode.

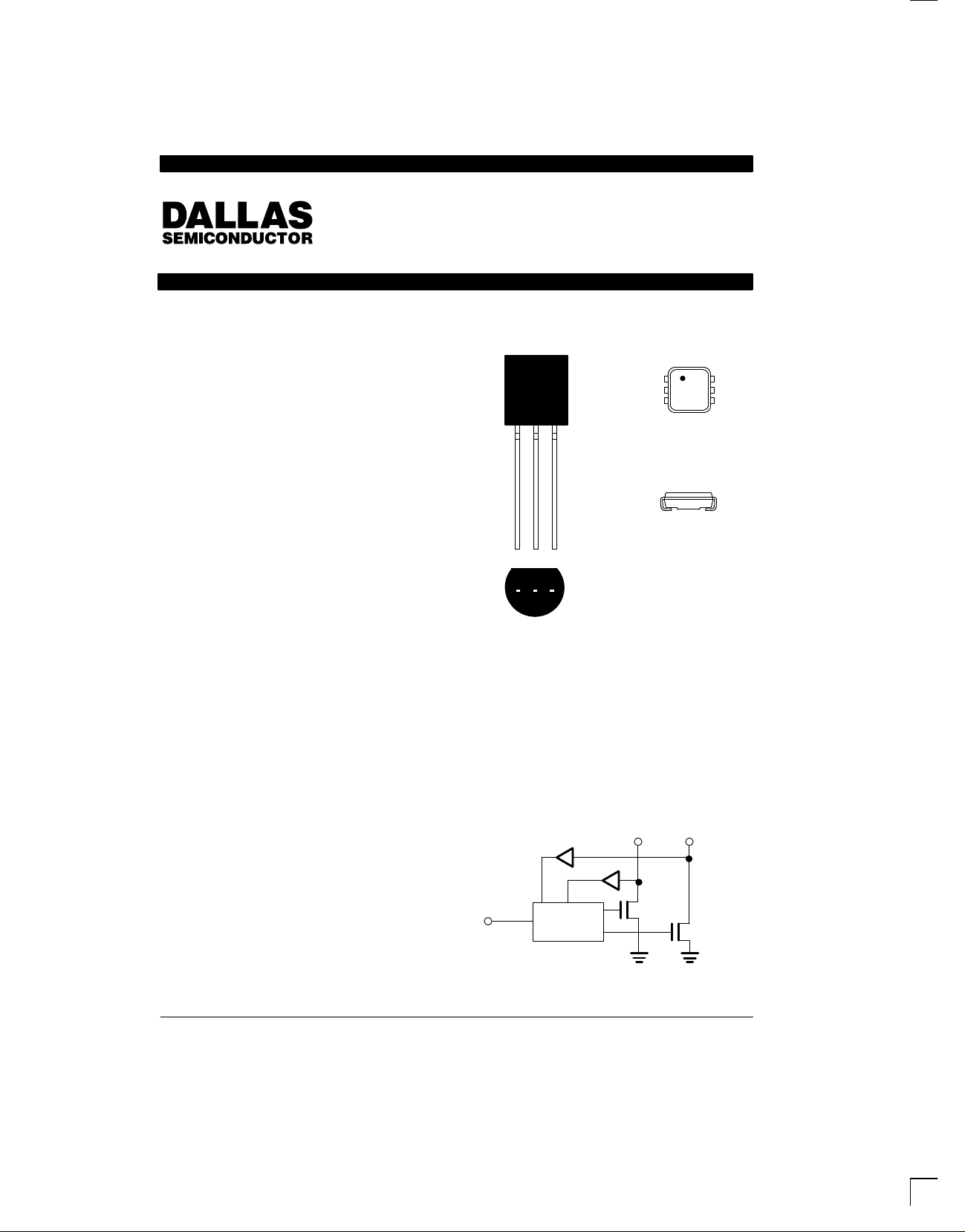

PIN ASSIGNMENT

TO–92

DALLAS

DS2407

123

321

BOTTOM VIEW

See Mech. Drawings

Section

See Mech. Drawings

PIN DESCRIPTION

TO–92 TSOC

Pin 1 Ground Ground

Pin 2 Data Data

Pin 3 PIO–A PIO–A

Pin 4 –––– V

Pin 5 –––– NC

Pin 6 –––– PIO–B

DATA

1–WIRE

PROTOCOL

CC

PIO–A

TSOC PACKAGE

6

1

5

2

4

3

TOP VIEW

3.7 X 4.0 X 1.5 mm

SIDE VIEW

Section

PIO–B

012099 1/31

DS2407

ORDERING INFORMATION

DS2407 TO–92 package

DS2407P 6–pin TSOC package

DS2407T Tape & Reel version of DS2407

DS2407V Tape & Reel version of DS2407P

DS2407X Chip Scale Pkg., Tape & Reel

ADDRESSABLE SWITCHTM DESCRIPTION

The DS2407 Dual Addressable Switch Plus Memory is

a pair of open drain N–channel transistors that can be

turned on or off via the 1–Wire bus. Alternatively, either

open drain output can serve as a logic input that can be

monitored via the same 1–Wire bus. In addition, the

device has 1024 bits of EPROM to store relevant

information such as switch function, physical location,

etc. The device is addressed by matching its individual

64–bit factory–lasered registration number. The 64–bit

number consists of an 8–bit family code, a unique 48–bit

serial number, and an 8–bit cyclic redundancy check.

Communication with the DS2407 follows the standard

Dallas Semiconductor 1–Wire protocol and can be

accomplished with a single port pin of a microcontroller.

Multiple DS2407 devices can reside on a common

1–Wire bus creating a MicroLAN. The network controller circuitry is embedded within the chip including a

search algorithm to determine the identity of each

DS2407 on the network. The open drain outputs (PIO

pins) for each DS2407 on the MicroLAN can be independently switched on or off whether there is one or

many devices sharing the same 1–Wire bus. The logic

level of the PIO pins for each device on the MicroLAN

can also be individually sensed and reported to the bus

master. The device also supports a Conditional Search

command to identify and access devices that qualify for

certain user–specified conditions. Qualification may be

the status of a PIO–pin, the state of the output transistor

or a latched activity flag.

OVERVIEW

The DS2407 Dual Addressable Switch Plus Memory

provides a means for assigning an electronically readable identification to a particular node or location with

additional control capability provided by two open–drain

N–channel MOSFETs that can be remotely switched

and sensed via communication over the 1–Wire bus

(Figure 1). The DS2407 contains a factory–lasered registration number that includes a unique 48–bit serial

number, an 8–bit CRC, and an 8–bit family code (12h).

The 64–bit ROM portion of the DS2407 not only creates

an absolutely unique electronic identification for the

device itself but also is a means to locate and obtain or

change the state of the switches that are associated

with the 64–bit ROM.

The device derives its power entirely from the 1–Wire

bus by storing energy on an internal capacitor during

periods of time when the signal line is high and continues to operate off of this “parasite” power source during

the low times of the 1–Wire line until it returns high to

replenish the parasite (capacitor) supply. For applications in feeder–networks where the low–times of the

1–Wire line may be very long, the V

pin may be con-

CC

nected to an external voltage supply to operate the

device.

The DS2407 uses the standard Dallas Semiconductor

1–Wire protocol for data transfers (Figure 2), with all

data being read and written least significant bit first.

Communication to and from the DS2407 requires a

single bi–directional line that is typically a port pin of a

microcontroller. The 1–Wire bus master (microcontroller) must first issue one of five ROM function commands: 1) Read ROM, 2) Match ROM, 3) Search ROM,

4) Skip ROM, or 5) Conditional Search ROM. These

commands operate on the 64–bit lasered ROM portion

of each device and can singulate a specific device if

many are present on the 1–Wire line as well as indicate

to the bus master how many and what type of each

device is present. After a ROM function command is

successfully executed, the open–drain outputs can be

switched or sensed, or the contents of the memory can

be read or written via the 1–Wire bus. Writing the 1024

bits of data memory or writing to the EPROM sections of

the status memory requires a 12V programming pulse.

When programming the DS2407, only EPROM–based

devices are allowed to be present on the 1–Wire line.

012099 2/31

DS2407

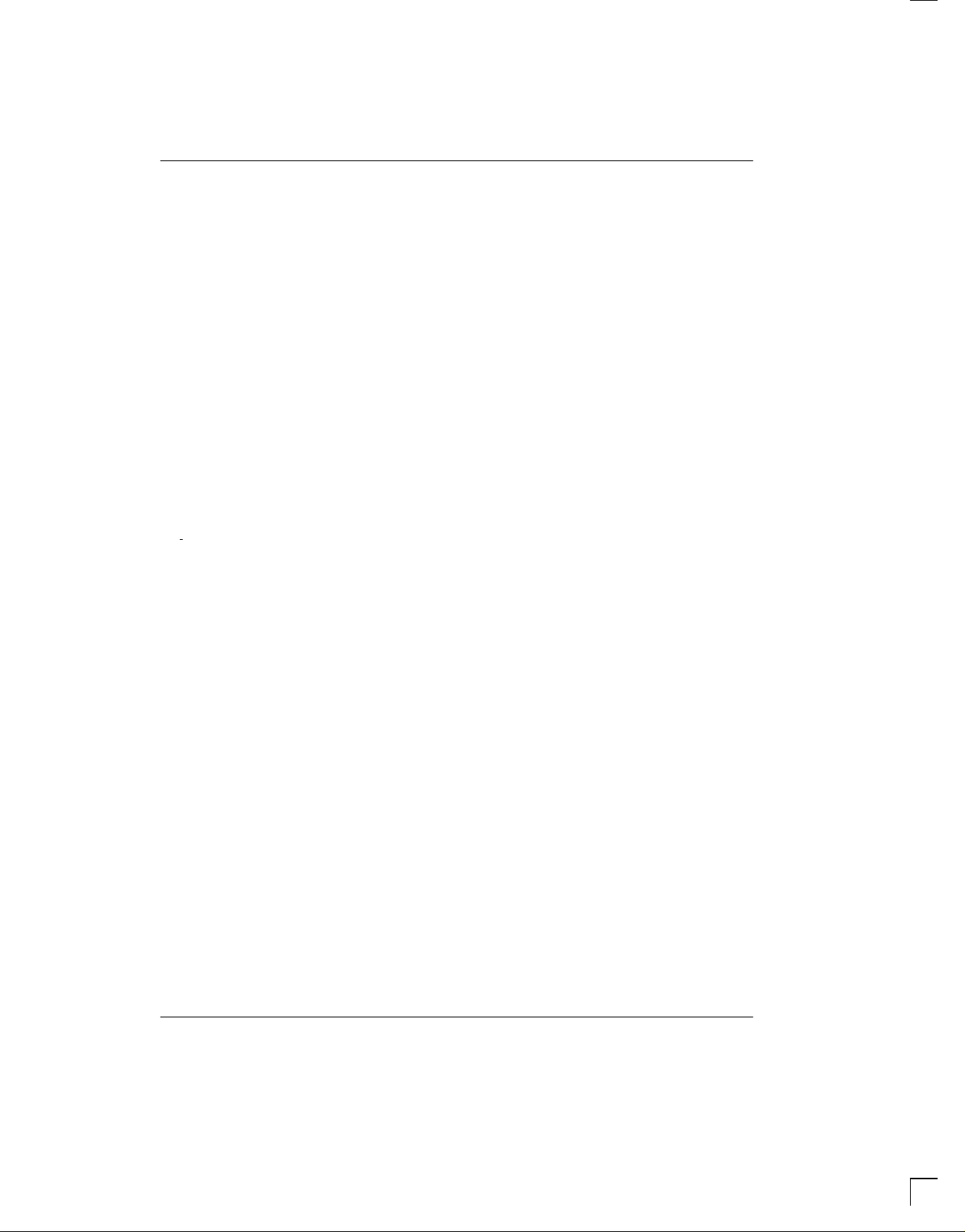

64–BIT LASERED ROM

Each DS2407 contains a unique ROM code that is 64

bits long. The first eight bits are a 1–Wire family code.

The next 48 bits are a unique serial number. The last

eight bits are a CRC of the first 56 bits. (See Figure 3.)

The 1–Wire CRC of the lasered ROM is generated using

the polynomial X

about the Dallas Semiconductor 1–Wire Cyclic Redundancy Check is available in the Book of DS19xx

iButton Standards. The 64–bit ROM and ROM Function

Control section allow the DS2407 to operate as a

1–Wire device and follow the 1–Wire protocol detailed in

the section “1–Wire Bus System”. The functions

required to read and write the data and status memory

of the DS2407 and to access the switches are not

accessible until the ROM function protocol has been

satisfied. This protocol is described in the ROM functions flow chart (Figure 12). The 1–Wire bus master

must first provide one of the five ROM function commands. After a ROM function sequence has been successfully executed, the bus master may then provide

any one of the memory function commands specific to

the DS2407 (Figure 6).

8

+ X5 + X4 + 1. Additional information

MEMORY

The DS2407 contains two memory sections, Data

Memory and Status Memory. The data memory consists

of 1024 bits of one–time programmable EPROM organized as 4 pages of 32 bytes each. The size of the

device’s status memory is 8 bytes. The first seven bytes

of status memory (addresses 0 to 6) are also realized as

EPROM. The eighth byte (address 7) consists of SRAM

cells which shadow the contents of address 6 each time

the device powers up. The complete memory map is

shown in Figure 4. The 8–bit scratchpad is an additional

register that acts as a buffer when writing the memory.

Data is first written to the scratchpad and then verified

by reading a 16–bit CRC from the DS2407 that confirms

proper receipt of the data and address. If the buffer contents are correct, a programming pulse should be

applied and the byte of data will be written into the

selected address in memory. This process insures data

integrity when programming the memory . The details for

reading and programming the EPROM portions of the

DS2407 are given in the Memory Function Commands

section.

012099 3/31

DS2407

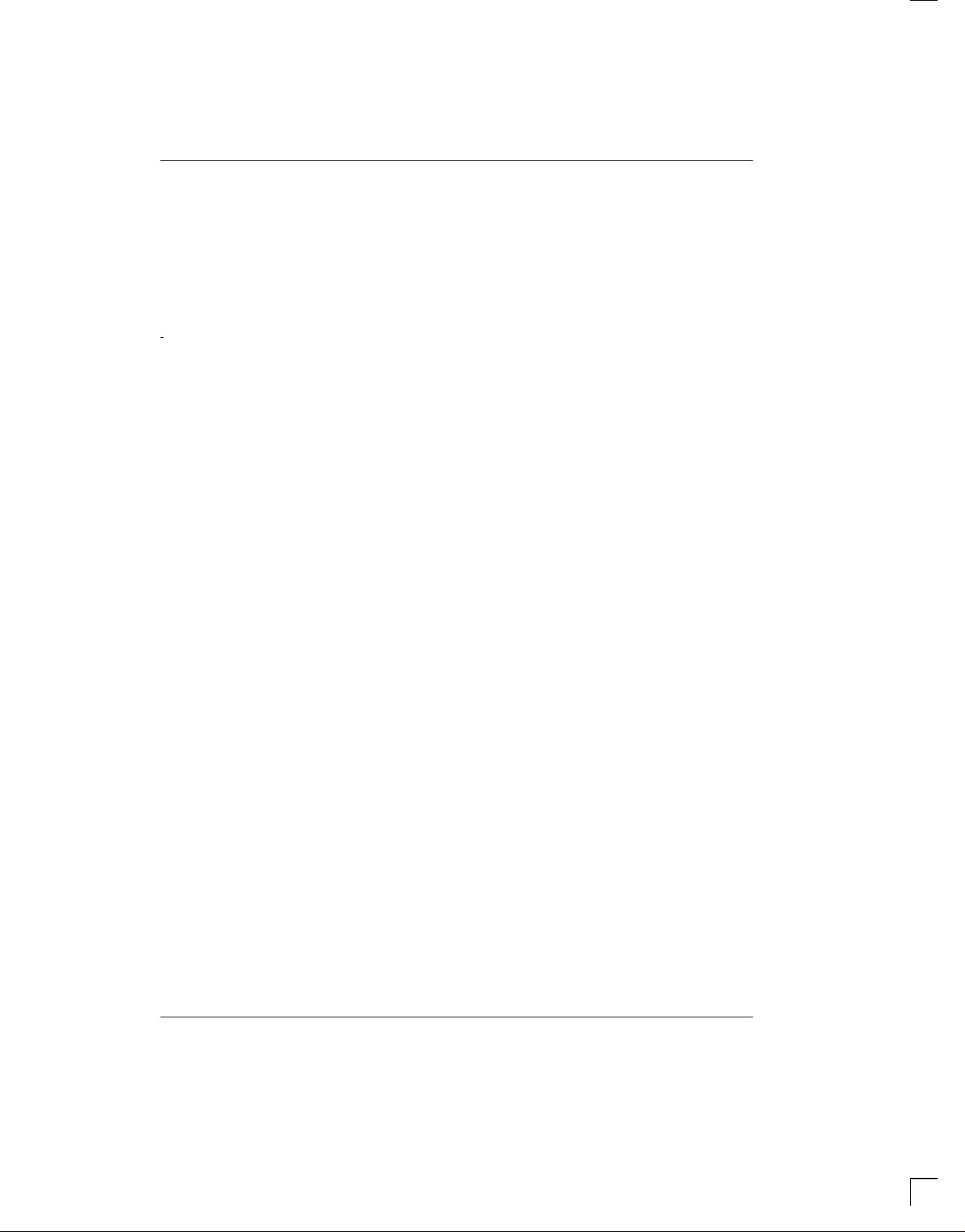

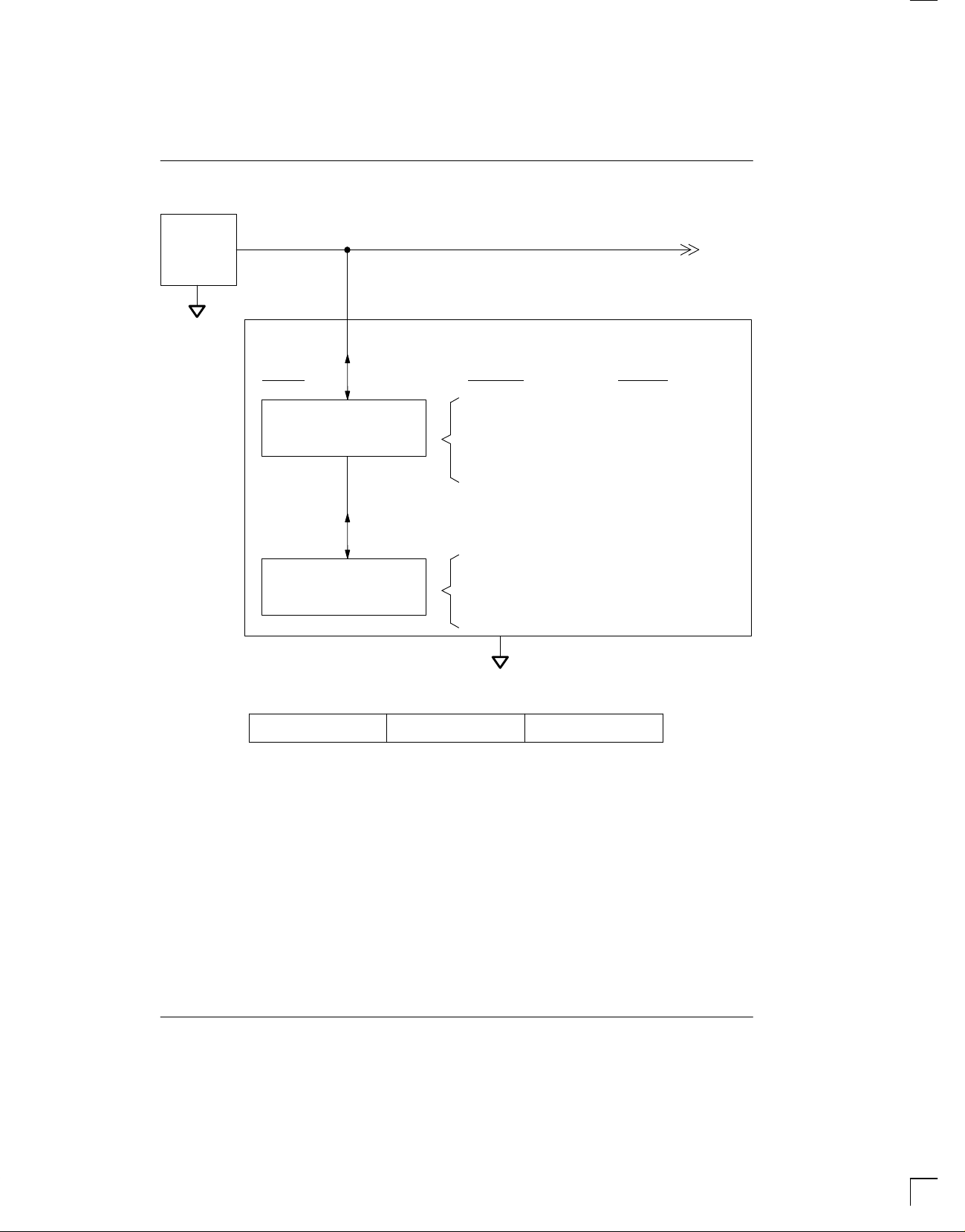

DS2407 BLOCK DIAGRAM Figure 1

PARASITE POWER

INT VDD

VDD

PROGRAM

VOLTAGE

DETECT

DATA1–WIRE BUS

1–WIRE FUNCTION

CONTROL

MEMORY

FUNCTION

CONTROL

16–BIT CRC

GENERATOR

DATA MEMORY

1024–BIT EPROM

(4 PAGES OF 32 BYTES)

STATUS MEMORY

7 BYTES EPROM

1 BYTE SRAM

64–BIT LASERED

ROM

8–BIT

SCRATCHPAD

012099 4/31

PIO–A

PIO–B

PIO

CONTROL

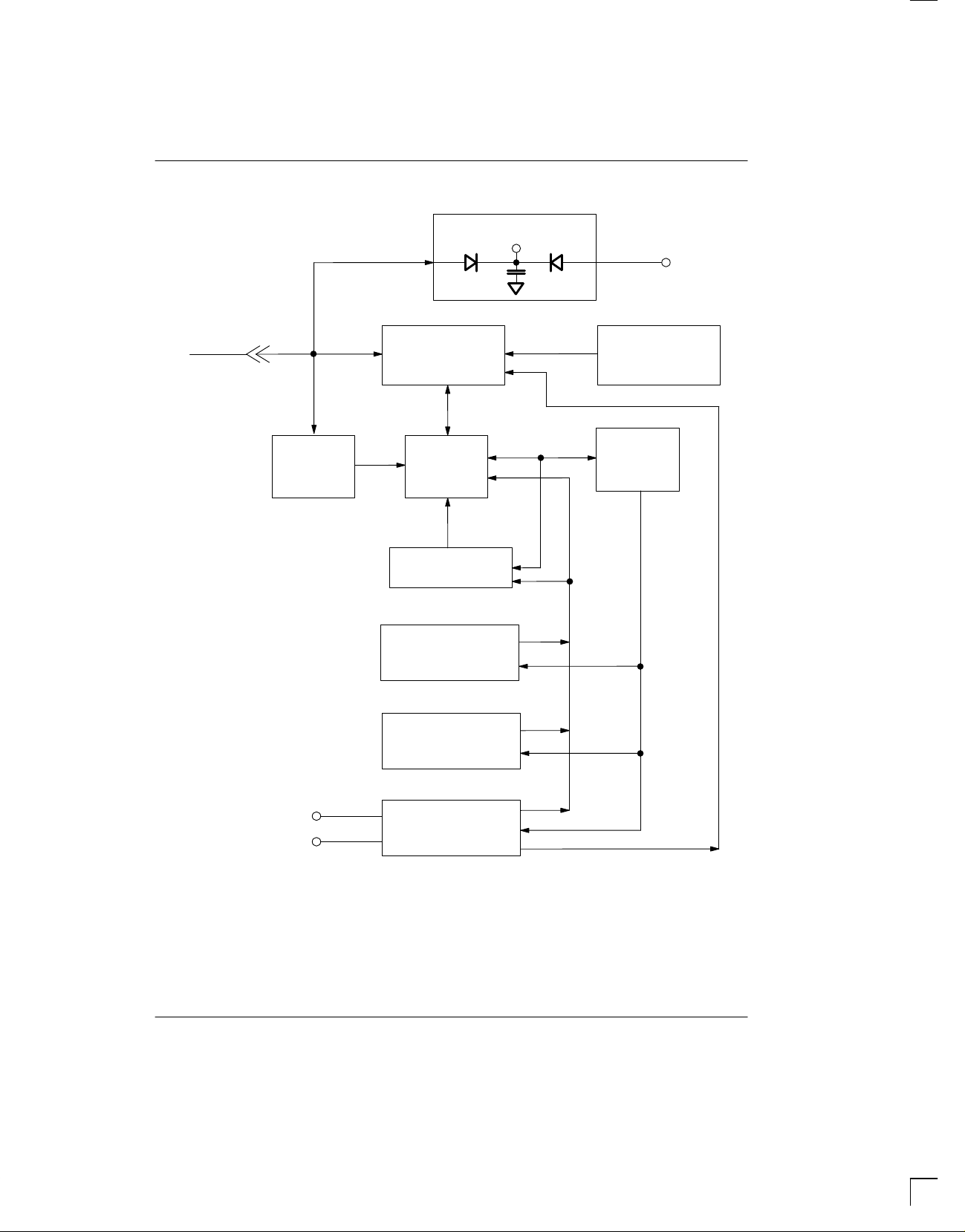

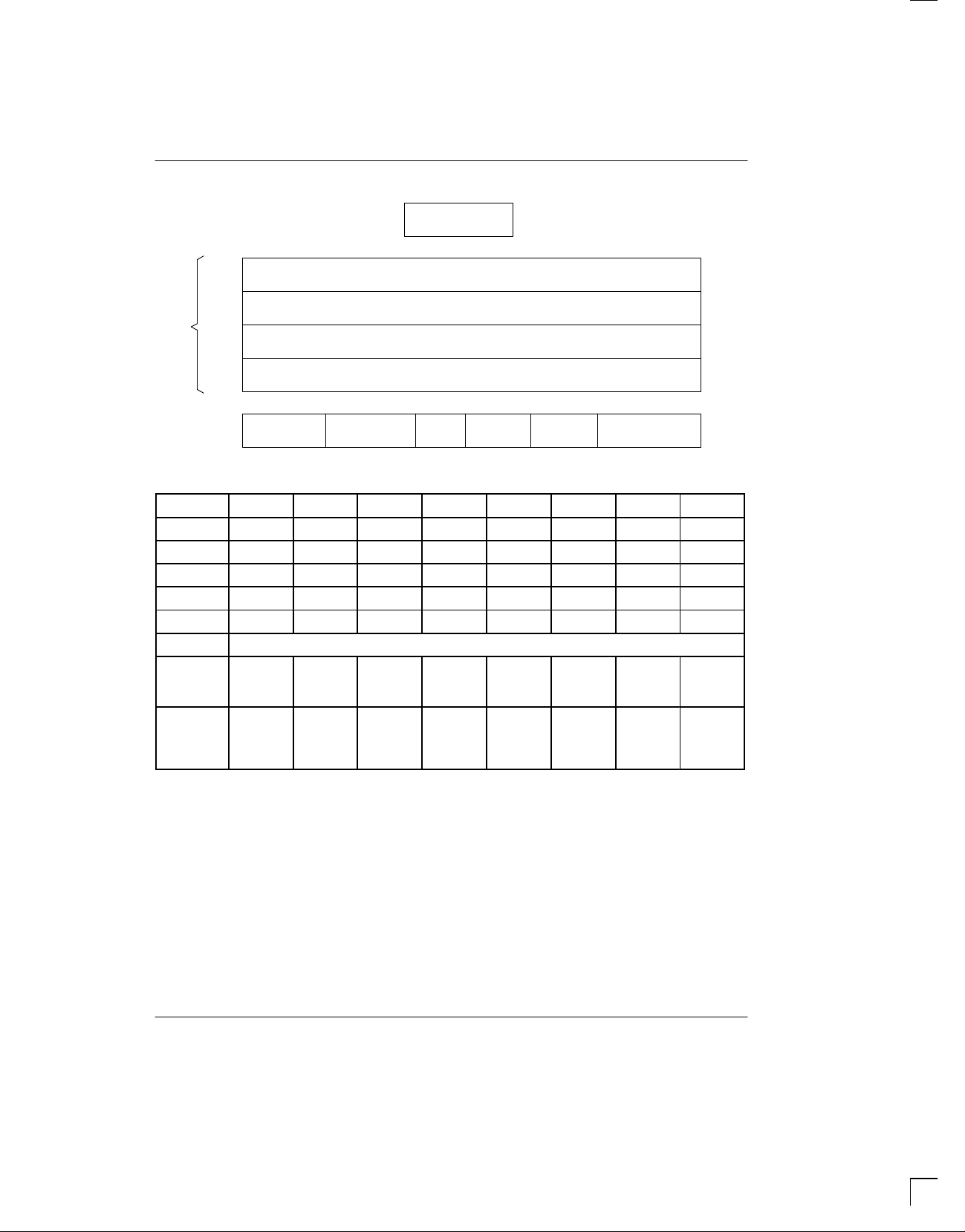

HIERARCHICAL STRUCTURE FOR 1–WIRE PROTOCOL Figure 2

DS2407

BUS

MASTER

1–WIRE BUS

COMMAND

LEVEL:

1–WIRE ROM FUNCTION

COMMANDS (SEE FIGURE 12)

DS2407 SPECIFIC

MEMORY FUNCTION

COMMANDS

(SEE FIGURE 6)

DS2407

AVAILABLE

COMMANDS:

READ ROM

MATCH ROM

SEARCH ROM

SKIP ROM

CONDITIONAL 64–BIT ROM,

SEARCH ROM CONDITIONAL SEARCH

WRITE MEMORY 1024–BIT EPROM

WRITE STATUS

READ MEMORY

READ STATUS

EXT. READ MEMORY

CHANNEL ACCESS PIO CHANNELS

DATA FIELD

AFFECTED:

64–BIT ROM

64–BIT ROM

64–BIT ROM

N/A

SETTINGS AT ST A TUS

MEMORY LOCATION 7,

DEVICE/CHANNEL STATUS

STATUS MEMORY

1024–BIT EPROM

STATUS MEMORY

1024–BIT EPROM

OTHER

DEVICES

64–BIT LASERED ROM Figure 3

8–Bit CRC Code 48–Bit Serial Number 8–Bit Family Code (12H)

MSB LSBMSBLSB MSBLSB

012099 5/31

DS2407

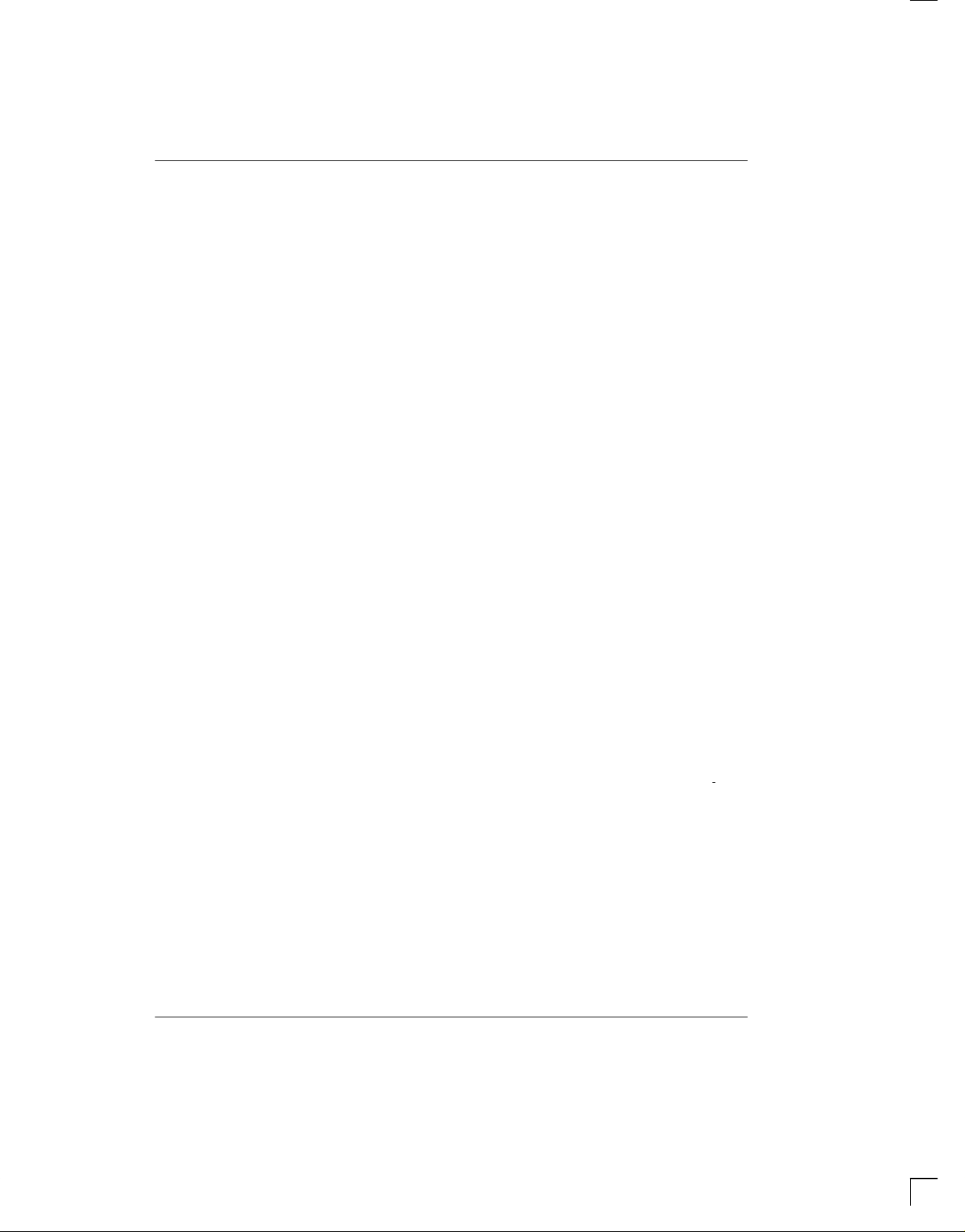

DS2407 MEMORY MAP Figure 4

STARTING

ADDRESS

0000H

0020H

1K BIT

EPROM

0040H

0060H

8–BIT

SCRATCHPAD

32–BYTE FINAL STORAGE EPROM PAGE 0

32–BYTE FINAL STORAGE EPROM

32–BYTE FINAL STORAGE EPROM

32–BYTE FINAL STORAGE EPROM

PAGE 1

PAGE 2

PAGE 3

VALID DEVICE

SETTINGS (SRAM)

POWER–ON

DEFAULT SETTINGS

FACTORY

BYTE

REDIRECITON

BYTES

BIT MAP OF

USED PAGES

WRITE–PROTECT BITS

DATA MEMORY

8 BYTES

STATUS

MEMORY

DS2407 ST ATUS MEMORY MAP Figure 5

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 (EPROM) BM 3 BM 2 BM 1 BM 0 WP 3 WP 2 WP 1 WP 0

1 (EPROM) 1 1 1 1 1 1 Redir. 0 Redir. 0

2 (EPROM) 1 1 1 1 1 1 Redir. 1 Redir. 1

3 (EPROM) 1 1 1 1 1 1 Redir. 2 Redir. 2

4 (EPROM) 1 1 1 1 1 1 Redir. 3 Redir. 3

5 (EPROM) EPROM factory byte

6 (EPROM X Pwr–On

Status

PIO–B

7 (SRAM) Supply

Indication

(read

PIO–B

Channel

Flip–Flop

only)

Pwr–On

Status

PIO–A

PIO–A

Channel

Flip–Flop

Pwr–On

Status

CSS4

CSS4

Channel

Select

Pwr–On

Status

CSS3

CSS3

Channel

Select

Pwr–On

Status

CSS2

CSS2

Source

Select

Pwr–On

Status

CSS1

CSS1

Source

Select

Pwr–On

Status

CSS0

CSS0

Polarity

012099 6/31

DS2407

STATUS MEMORY

The Status Memory can be read or written to indicate

various conditions to the software interrogating the

DS2407. These conditions include special features for

the data memory, definition of the power–on default and

actual settings for the Conditional Search as well as the

channel flip–flops and the external power supply indication. How these functions are assigned to the bits of the

Status Memory is detailed in Figure 5. The channel flip–

flops and power supply indication are also included in

the Channel Info Byte of the Channel Access command

protocol (see Figure 6).

The first four bits of the Status Memory (address 0, bits 0

to 3) contain the Write Protect Page bits which inhibit

programming of the corresponding page in the 1024–bit

data memory area if the appropriate write protection bit

is programmed. Once a bit has been programmed in the

Write Protect Page section of the Status Memory, the

entire 32 byte page that corresponds to that bit can no

longer be altered but may still be read. The remaining 4

bits of Status Memory location 0 are reserved for use by

the iButton operating software TMEX. Their purpose is

to indicate which memory pages are already in use.

Originally, all of these bits are unprogrammed, indicating that the device does not contain any data. As soon

as data is written to any page of the device under control

of TMEX, the bit inside this bitmap corresponding to that

page will be programmed to 0, marking this page as

used. These bits are application flags only and have no

impact on the internal logic of the DS2407.

The next four bytes of the Status Memory (addresses 1

to 4) contain the Page Address Redirection Bytes which

indicate if one or more of the pages of data in the

1024–bits EPROM memory section have been invalidated by software and redirected to the page address

contained in the appropriate redirection byte. The hardware of the DS2407 makes no decisions based on the

contents of the Page Address Redirection Bytes. Since

with EPROM technology bits can only be changed from

a logical 1 to a logical 0 by programming, it is not possible to simply rewrite a page if the data requires changing or updating. But with space permitting, an entire

page of data can be redirected to another page within

the DS2407. Under TMEX, a page is redirected by writing the one’s complement of the new page address into

the Page Address Redirection Byte that corresponds to

the original (replaced) page. This architecture allows

the user’s software to make a “data patch” to the

EPROM by indicating that a particular page or pages

should be replaced with those indicated in the Page

Address Redirection Bytes.

Under TMEX, if a Page Address Redirection Byte has a

FFh value, the data in the main memory that corresponds to that page is valid. If a Page Address Redirection Byte has some other hex value than FFh, the data in

the page corresponding to that redirection byte is

invalid. According to the TMEX definitions, the valid

data will now be found at the one’s complement of the

page address indicated by the hex value stored in the

associated Page Address Redirection Byte. A value of

FDh in the redirection byte for page 1, for example,

would indicate that the updated data is now in page 2.

Since the data memory consists of four pages only , the 6

most significant bits of the redirection bytes cannot be

programmed to zeros.

Status Memory location 5 is programmed to 00h at the

factory. Status Memory location 6 contains the power–on default settings for the Conditional Search Select

(CSS0 to CSS4, bits 0 to 4) and the PIO channels. The

power–on settings become valid as they are internally

transferred by the device into Status Memory location 7

after the device has powered up and the bus master

sends a ROM Function Command byte for the first time.

The codes for the Conditional Search Settings are

detailed with the description of the Conditional Search

command later in this data sheet. If both CSS1 and

CSS2 in Status Memory Location 7 are set to zero, the

DS2407 will enter a “Hidden Mode” where it will keep its

status but only responds to Match ROM and Conditional

Search. To respond to Conditional Search the polarity

(CSS0) needs to be 1. The “Hidden Mode” can be ended

either by a power–on reset or by matching the device’s

registration number and setting CSS1 or CSS2 to 1.

012099 7/31

DS2407

The output transistors of both channels are controlled

by their channel flip–flops. These flip–flops are accessible through bit locations 5 and 6 of Status Memory

address 7 as well as through the Channel Access command. Setting a channel flip–flop to 0 will make the

associated PIO–transistor conducting or on, setting the

flip–flop to 1 will switch the transistor off. When powering

up, the output transistors of both channels are non–conducting or off. They may change their status as the

user–programmed power–on status is transferred into

Status Memory location 7. Bit 7 of Status Memory Location 7 indicates if the DS2407 is connected to an external power supply. Without external supply this read–

only bit will be 0. If the voltage applied to the V

CC

pin is

high enough to keep the device powered up, this bit will

be 1.

The Status Memory is programmed similarly to the data

memory. Details for reading and programming the status memory portion of the DS2407 are given in the

Memory Function Commands section.

MEMORY FUNCTION COMMANDS

The “Memory Function Flow Chart” (Figure 6) describes

the protocols necessary for accessing the various data

fields and PIO channels within the DS2407. The

Memory Function Control section, 8–bit scratchpad,

and the Program Voltage Detect circuit combine to interpret the commands issued by the bus master and create

the correct control signals within the device. A three–

byte protocol is issued by the bus master. It is comprised

of a command byte to determine the type of operation

and two address bytes to determine the specific starting

byte location within a data field or to supply and

exchange setup and status data when accessing the

PIO channels. The command byte indicates if the

device is to be read or written or if the PIO channels are

to be accessed. Writing data involves not only issuing

the correct command sequence but also providing a

12–volt programming voltage at the appropriate times.

To execute a write sequence, a byte of data is first

loaded into the scratchpad and then programmed into

the selected address. Write sequences always occur a

byte at a time. To execute a read sequence, the starting

address is issued by the bus master and data is read

from the part beginning at that initial location and continuing to the end of the selected data field or until a reset

sequence is issued. All bits transferred to the DS2407

and received back by the bus master are sent least significant bit first.

READ MEMORY [F0h]

The Read Memory command is used to read data from

the 1024–bit EPROM data memory field. The bus master follows the command byte with a two–byte address

(TA1=(T7:T0), TA2=(T15:T8)) that indicates a starting

byte location within the data field. Since the data

memory contains 128 bytes, T15:T8 and T7 should all

be zero. With every subsequent read data time slot the

bus master receives data from the DS2407 starting at

the initial address and continuing until the end of the

1024–bits data field is reached or until a Reset Pulse is

issued. If reading occurs through the end of memory

space, the bus master may issue sixteen additional read

time slots and the DS2407 will respond with a 16–bit

CRC of the command, address bytes and all data bytes

read from the initial starting byte through the last byte of

memory. This CRC is the result of clearing the CRC generator and then shifting in the command byte followed

by the two address bytes and the data bytes beginning

at the first addressed memory location and continuing

through to the last byte of the EPROM data memory.

After the CRC is received by the bus master, any subsequent read time slots will appear as logical 1s until a

Reset Pulse is issued. Any reads ended by a Reset

Pulse prior to reaching the end of memory will not have

the 16–bit CRC available.

Typically the software controlling the device should

store a 16–bit CRC with each page of data to insure

rapid, error–free data transfers that eliminate having to

read a page multiple times to determine if the received

data is correct or not. (See Book of DS19xx i

Standards, Chapter 7 for the recommended file structure to be used with the 1–Wire environment). If CRC

values are imbedded within the data it is unnecessary to

read the end–of–memory CRC. The Read Memory

command can be ended at any point by issuing a Reset

Pulse.

Button

012099 8/31

DS2407

EXTENDED READ MEMORY [A5h]

The Extended Read Memory command supports page

redirection when reading data from the 1024–bit

EPROM data field. One major difference between the

Extended Read Memory and the basic Read Memory

command is that the bus master receives the Redirection Byte (see description of Status Memory) first before

investing time in reading data from the addressed

memory location. This allows the bus master to quickly

decide whether to continue and access the data at the

selected starting page or to terminate and restart the

reading process at the redirected page address.

In addition to page redirection, the Extended Read

Memory command also supports “bit–oriented” applications where the user cannot store a 16–bit CRC with the

data itself. With bit–oriented applications the EPROM

information may change over time within a page boundary making it impossible to include an accompanying

CRC that will always be valid. Therefore, the Extended

Read Memory command concludes each page with the

DS2407 generating and supplying a 16–bit CRC that is

based on and therefore always consistent with the current data stored in each page of the 1024–bit EPROM

data field.

After having sent the command code of the Extended

Read Memory command, the bus master sends a two–

byte address (TA1=(T7:T0), TA2=(T15:T8)) that indicates a starting byte location within the data field. By

sending eight read data time slots, the master receives

the Redirection Byte associated with the page given by

the starting address. With the next sixteen read data

time slots, the bus master receives a 16–bit CRC of the

command byte, address bytes and the Redirection

Byte. This CRC is computed by the DS2407 and read

back by the bus master to check if the command word,

starting address and Redirection Byte were received

correctly.

If the CRC read by the bus master is incorrect, a Reset

Pulse must be issued and the entire sequence must be

repeated. If the CRC received by the bus master is correct, the bus master issues read time slots and receives

data from the DS2407 starting at the initial address and

continuing until the end of a 32–byte page is reached. At

that point the bus master will send sixteen additional

read time slots and receive a 16–bit CRC that is the

result of shifting into the CRC generator all of the data

bytes from the initial starting byte to the last byte of the

current page.

With the next 24 read data time slots the master will

receive the Redirection Byte of the next page followed

by a 16–bit CRC of the Redirection Byte. After this, data

is again read from the 1024–bits EPROM data field

starting at the beginning of the new page. This

sequence will continue until the final page and its

accompanying CRC are read by the bus master.

The Extended Read Memory command provides a

16–bit CRC at two locations within the transaction flow

chart: 1) after the Redirection Byte and 2) at the end of

each memory page. The CRC at the end of the memory

page is always the result of clearing the CRC generator

and shifting in the data bytes beginning at the first

addressed memory location of the EPROM data page

until the last byte of this page. With the initial pass

through the Extended Read Memory flow chart the

16–bit CRC value after the Redirection Byte is the result

of shifting the command byte into the cleared CRC generator, followed by the two address bytes and the

Redirection Byte. Subsequent passes through the

Extended Read Memory flow chart will generate a

16–bit CRC that is the result of clearing the CRC generator and then shifting in the Redirection Byte only. After

the 16–bit CRC of the last page is read, the bus master

will receive logical 1s from the DS2407 until a Reset

Pulse is issued. The Extended Read Memory command

sequence can be ended at any point by issuing a Reset

Pulse.

WRITING EPROM MEMORY

The DS2407 has two independent EPROM memory

fields, Data Memory and Status Memory. The function

flow for writing either field is almost identical. After the

appropriate write command has been issued, the bus

master will send a two–byte starting address

(TA1=(T7:T0), TA2=(T15:T8)) and a byte of data

(D7:D0). A 16–bit CRC of the command byte, address

bytes, and data byte is computed by the DS2407 and

read back by the bus master to confirm that the correct

command word, starting address, and data byte were

received.

012099 9/31

DS2407

If the CRC read by the bus master is incorrect, a Reset

Pulse must be issued and the entire sequence must be

repeated. If the CRC received by the bus master is correct, a programming pulse (12 volts on the 1–Wire bus

for 480 µs) is issued by the bus master. Prior to programming, the entire unprogrammed EPROM memory field

will appear as logical 1s. For each bit in the data byte

provided by the bus master that is set to a logical 0, the

corresponding bit in the selected byte of the EPROM

memory is programmed to a logical 0 after the programming pulse has been applied.

After the 480 µs programming pulse is applied and the

data line returns to the idle level (5 volts), the bus master

issues eight read time slots to verify that the appropriate

bits have been programmed. The DS2407 responds

with the data from the selected EPROM address sent

least significant bit first. This byte contains the bitwise

logical AND of all data ever written to this address. If the

EPROM byte contains 1s in bit positions where the byte

issued by the master contained 0s, a Reset Pulse

should be issued and the current byte address should

be programmed again. If the DS2407 EPROM byte contains 0s in the same bit positions as the data byte, the

programming was successful and the DS2407 will automatically increment its address counter to select the

next byte in the EPROM memory field. The new two–

byte address will also be loaded into the 16–bit CRC

generator as a starting value. The bus master will issue

the next byte of data using eight write time slots.

As the DS2407 receives this byte of data into the

scratchpad, it also shifts the data into the CRC generator that has been preloaded with the current address

and the result is a 16–bit CRC of the new data byte and

the new address. After supplying the data byte, the bus

master will read this 16–bit CRC from the DS2407 with

sixteen read time slots to confirm that the address

incremented properly and the data byte was received

correctly. If the CRC is incorrect, a Reset Pulse must be

issued and the write sequence must be restarted. If the

CRC is correct, the bus master will issue a programming

pulse and the selected byte in memory will be programmed.

Note that the initial pass through the write flow chart will

generate an 16–bit CRC value that is the result of shifting the command byte into the CRC generator, followed

by the two address bytes, and finally the data byte. Subsequent passes through the write flow chart due to the

DS2407 automatically incrementing its address counter

will generate a 16–bit CRC that is the result of loading

(not shifting) the new (incremented) address into the

CRC generator and then shifting in the new data byte.

For both of these cases, the decision to continue (to

apply a program pulse to the DS2407) is made entirely

by the bus master, since the DS2407 will not be able to

determine if the 16–bit CRC calculated by the bus master agrees with the 16–bit CRC calculated by the

DS2407. If an incorrect CRC is ignored and a program

pulse is applied by the bus master, incorrect programming could occur within the DS2407. Also note that the

DS2407 will always increment its internal address

counter after the receipt of the eight read time slots used

to confirm the programming of the selected EPROM

byte. The decision to continue is again made entirely by

the bus master. Therefore if the EPROM data byte does

not match the supplied data byte but the master continues with the write command, incorrect programming

could occur within the DS2407. The write command

sequence can be ended at any point by issuing a Reset

Pulse.

012099 10/31

Loading...

Loading...