Dallas Semiconductor DS18B20Z, DS18B20X, DS18B20 Datasheet

r

www.dalsemi.com

2

3

4

7

PRELIMINARY

DS18B20

Programmable Resolution

®

1-Wire

Digital Thermomete

FEATURES

Unique 1-Wire interface requires only one

port pin for communication

Multidrop capability simplifies distributed

temperature sensing applications

Requires no external components

Can be powered from data line. Power supply

range is 3.0V to 5.5V

Zero standby power required

Measures temperatures from -55°C to

+125°C. Fahrenheit equivalent is -67°F to

+257°F

±0.5°C accuracy from -10°C to +85°C

Thermometer resolution is programmable

from 9 to 12 bits

Converts 12-bit temperature to digital word in

750 ms (max.)

User-definable, nonvolatile temperature alarm

settings

Alarm search command identifies and

addresses devices whose temperature is

outside of programmed limits (temperature

alarm condition)

Applications include thermostatic controls,

industrial systems, consumer products,

thermometers, or any thermally sensitive

system

PIN ASSIGNMENT

DALLAS

DS1820

1 2 3

NC

NC

V

DD

DQ

VDD

GND

DQ

8-Pin SOIC (150 mil)

PIN DESCRIPTION

GND - Ground

DQ - Data In/Out

V

NC - No Connect

- Power Supply Voltage

DD

BOTTOM VIEW

1 2 3

DS18B20 To-92

Package

1

8

6

5

DS18B20Z

NC

NC

NC

GND

DESCRIPTION

The DS18B20 Digital Thermometer provides 9 to 12-bit (configurable) temperature readings which

indicate the temperature of the device.

Information is sent to/from the DS18B20 over a 1-Wire interface, so that only one wire (and ground)

needs to be connected from a central microprocessor to a DS18B20. Power for reading, writing, and

performing temperature conversions can be derived from the data line itself with no need for an ex ternal

power source.

Because each DS18B20 contains a unique silicon serial number, multiple DS18B20s can exist on the

same 1-Wire bus. This allows for placing temperature sensors in many differ ent places. Applications

where this feature is useful include HVAC environmental controls, sensing temperatur es inside buildings,

equipment or machinery, and process monitoring and control.

1 of 27 050400

DS18B20

DETAILED PIN DESCRIPTION Table 1

PIN

8PIN SOIC

5 1 GND Ground.

42DQData Input/Output pin. For 1-Wire operation: Open

33VDDOptional VDD pin. See “Parasite Power” section for

DS18B20Z (8-pin SOIC): All pins not specified in this table are not to be connected.

PIN

TO92 SYMBOL DESCRIPTION

drain. (See “Parasite Power” section.)

details of connection. VDD must be grounded for

operation in parasite power mode.

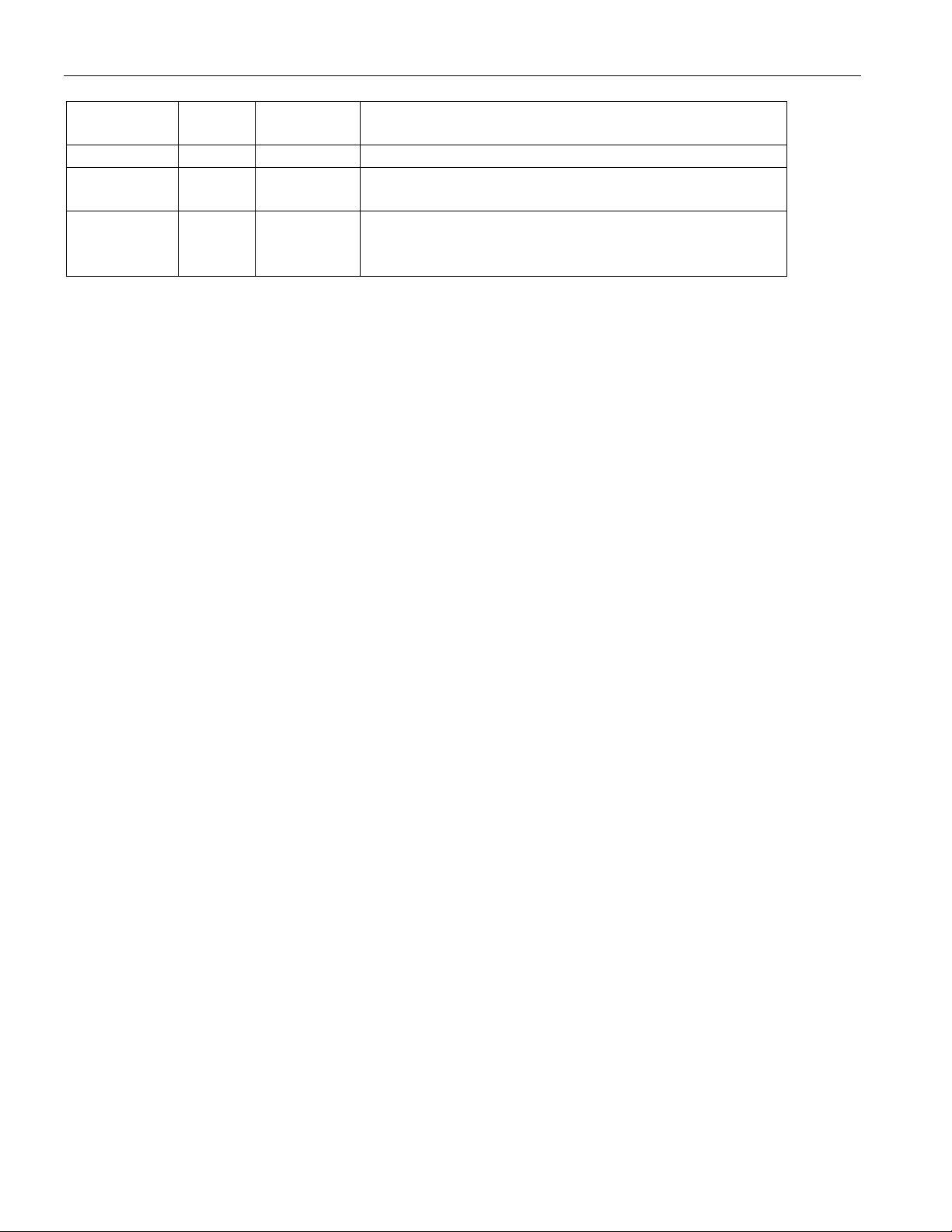

OVERVIEW

The block diagram of Figure 1 shows the major components of the DS18B20. The DS18B20 has four

main data components: 1) 64-bit lasered ROM, 2) temperature sensor, 3 ) nonvolatile temperature alarm

triggers TH and TL, and 4) a configuration register. The device derives its power from the 1-Wire

communication line by storing energy on an internal capacitor during periods of time when the signal line

is high and continues to operate off this power source during the low times of the 1-Wire line until it

returns high to replenish the parasite (capacitor) supply. As an alternative, the DS18B20 ma y also be

powered from an external 3 volt - 5.5 volt supply.

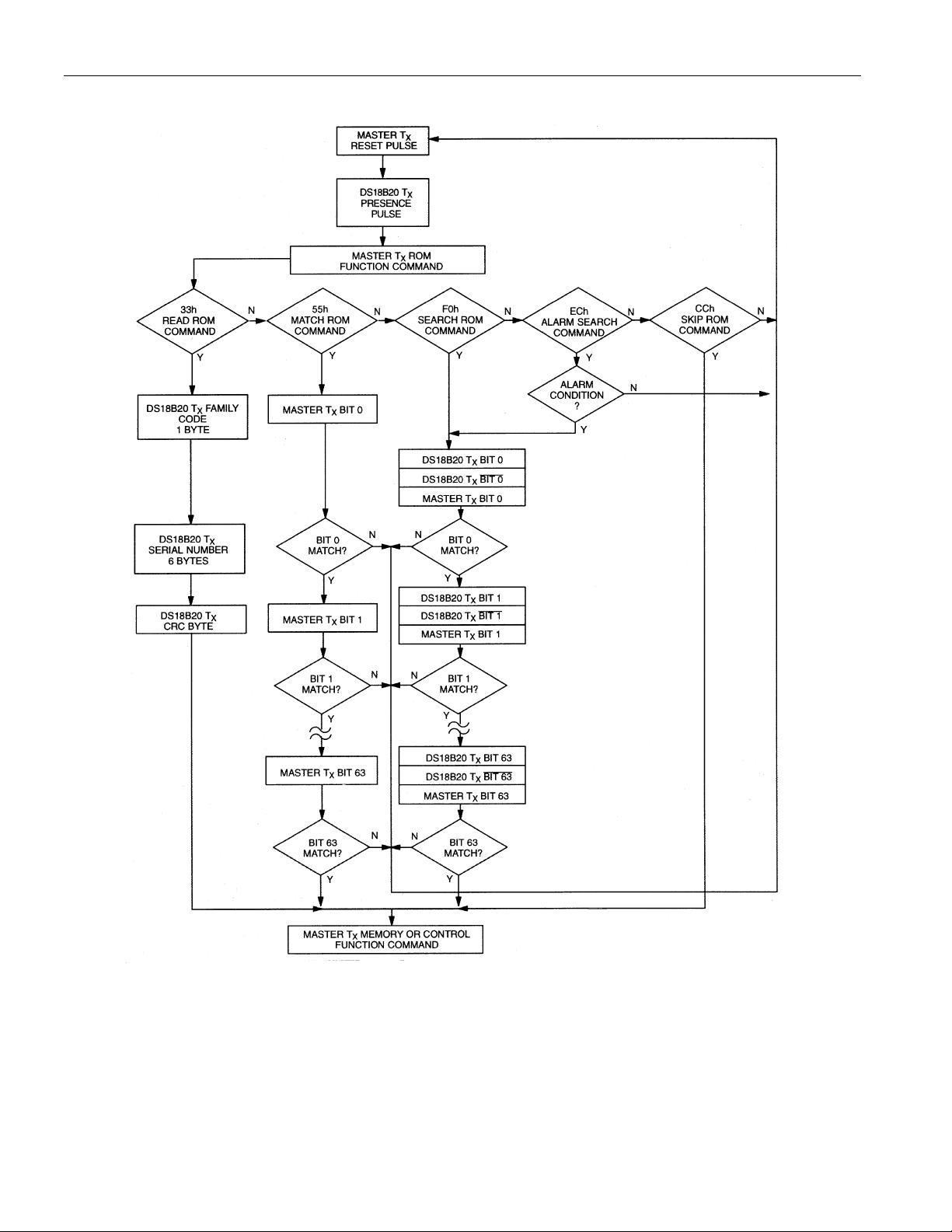

Communication to the DS18B20 is via a 1-Wire port. With the 1-Wire port, the memory and control

functions will not be available before the ROM function protocol has been established. The master must

first provide one of five ROM function commands: 1) Read ROM, 2) Match ROM, 3) Search ROM, 4)

Skip ROM, or 5) Alarm Search. These commands operate on the 64-bit lasered ROM portion of each

device and can single out a specific d evice if many are present on the 1-W ire line as well as indicate to

the bus master how many and what types of devices are present. After a ROM functi on sequence has

been successfully executed, the memory and control functions are accessible and the master may then

provide any one of the six memory and control function commands.

One control function command instructs the DS18B20 to perform a temperature m e asurement. Th e result

of this measurement will be placed in the DS18B20’s scratch-pad memory, and may be read by issuing a

memory function command which reads the contents of the scratchpad memory. The temperature alarm

triggers TH and TL consist of 1 byte EEPROM each. If the alarm search command is not applied to the

DS18B20, these registers may be used as general purpose user memory. The scratchpad also contains a

configuration byte to set the desired resolution of the temperature to digital conversion. Writing TH, TL,

and the configuration byte is done using a memory function command. Read access to these registers is

through the scratchpad. All data is read and written least significant bit first.

2 of 27

DS18B20 BLOCK DIAGRAM Figure 1

G

64-BIT ROM

DQ

AND

1-WIRE PORT

DS18B20

MEMORY AND

CONTROL LOGIC

TEMPERATURE SENSOR

INTERNAL V

V

DD

POWER

SUPPLY

DD

SCRATCHPAD

8-BIT CRC

ENERATOR

HIGH TEMPERATURE

TRIGGER, TH

LOW TEMPERATURE

CONFIGURATION

REGISTER

PARASITE POWER

The block diagram (Figure 1) shows the parasite-powered circuitry. This circuitry “steals” power

whenever the DQ or V

and voltage requirements are met (see the section titled “1-Wire Bus System”). The advantages of

parasite power are twofold: 1) by parasiting off this pin, no local power source is needed for remote

sensing of temperature, and 2) the ROM may be read in absence of normal power.

In order for the DS18B20 to be able to perform accurate temperature conv ersions, sufficient power must

be provided over the DQ line when a temperature conversion is taking place. Since the operating current

of the DS18B20 is up to 1.5 mA, the DQ line will not have sufficient drive due to the 5k pullup resistor.

This problem is particularly acute if several DS18B20s are on the same DQ and attempting to convert

simultaneously.

pins are high. DQ will provide sufficient power as long as the specified timing

DD

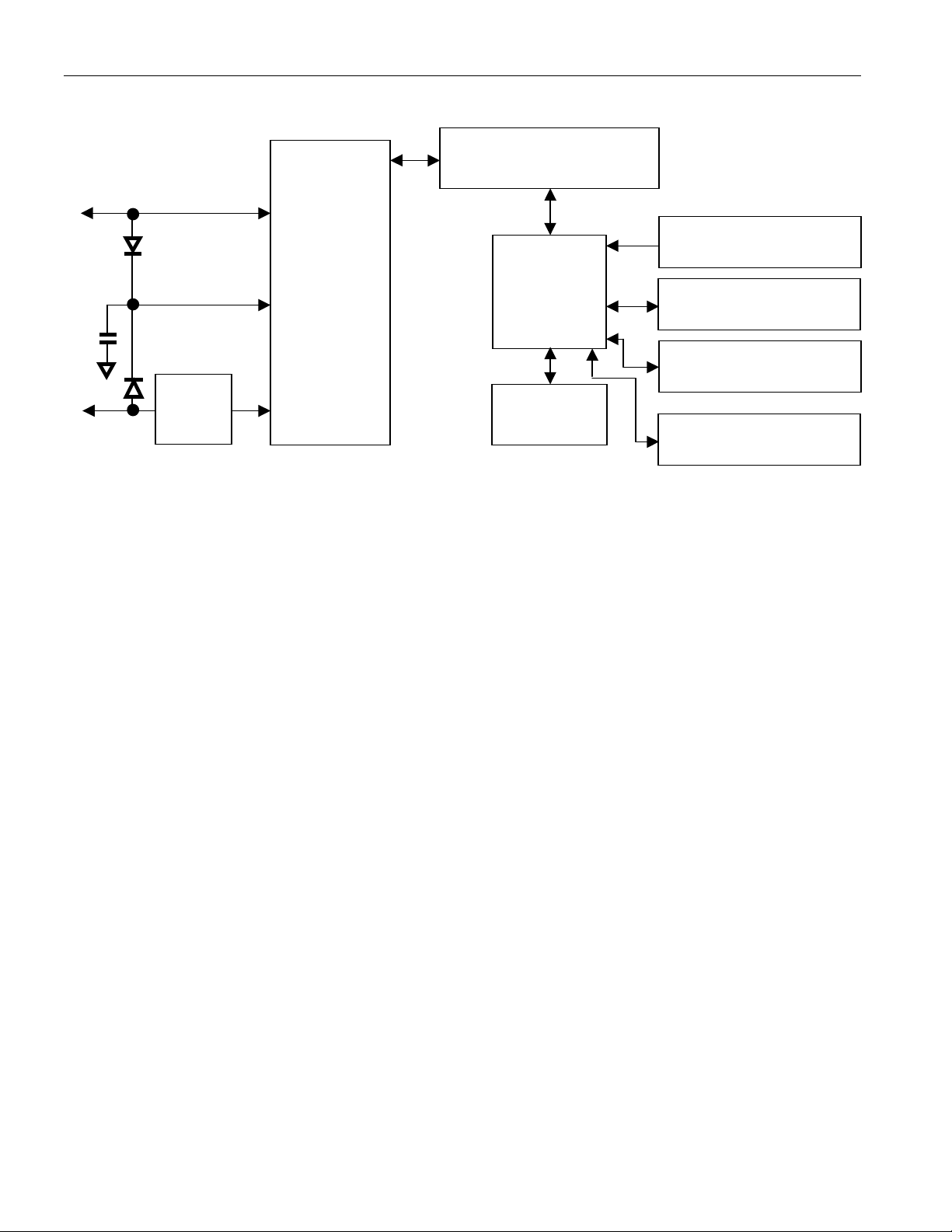

There are two ways to assure that the DS18B20 has sufficient supply current during its active conversion

cycle. The first is to provide a strong pullup on the DQ line whenever temperature conversions or copies

2

to the E

memory are taking place. This may be accomplished by using a MOSFET to pull the DQ line

directly to the power supply as shown in Figure 2. The DQ line must be switched over to the strong pullup within 10 µs maximum after issuing any protocol that involves copying to the E2 memory or initiates

temperature conversions. When using the parasite power mode, the VDD pin must be tied to ground.

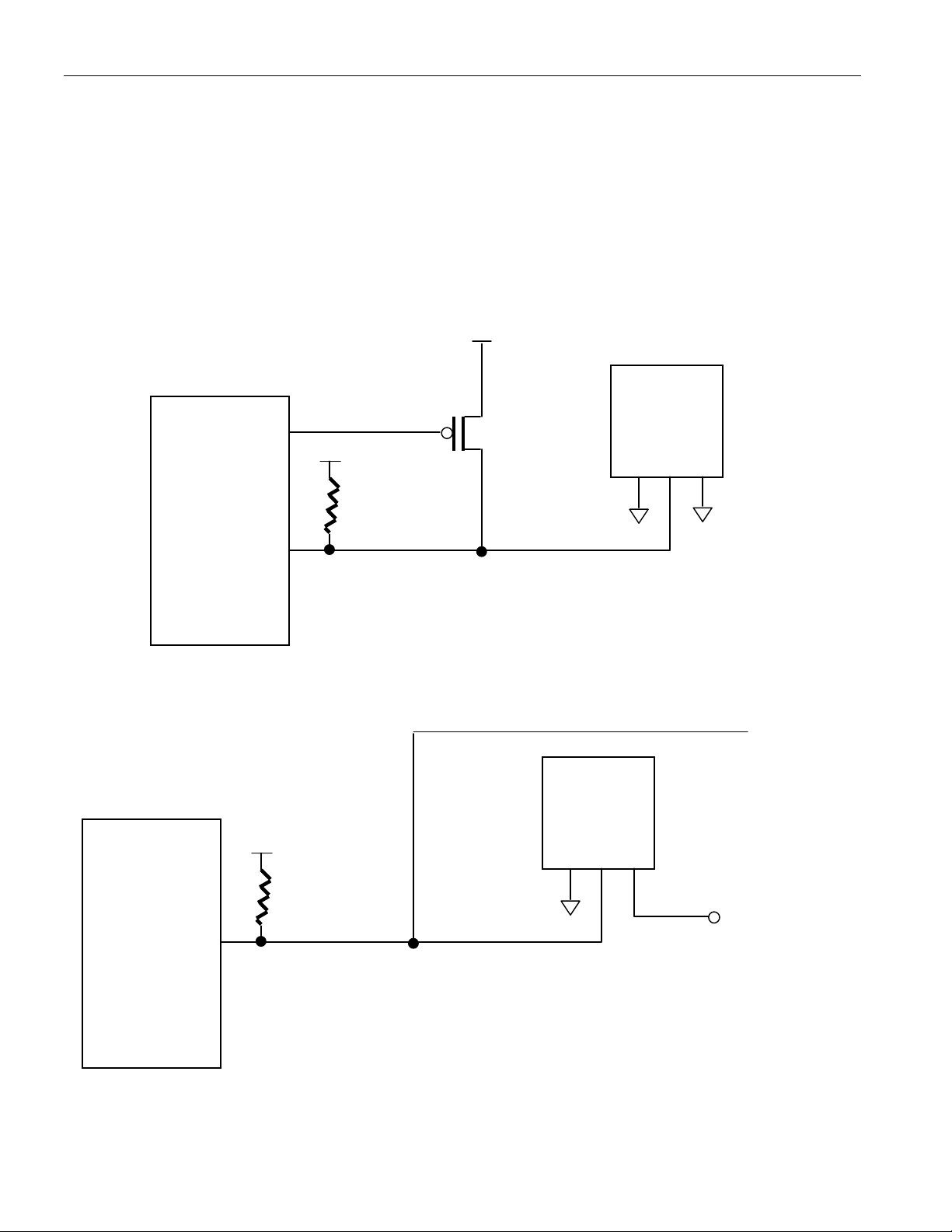

Another method of supplying current to the DS18B20 is through the use of an ex ternal power suppl y tied

to the VDD pin, as shown in Figure 3. The advantage to this is that the strong pullup is not required on the

DQ line, and the bus master need not be tied up holding that line high during temperature conversions.

This allows other data traffic on the 1-Wire bus during the conversion time. In addition, any number of

DS18B20s may be placed on the 1-Wire bus, and if they all use external power, they may all

simultaneously perform temperature conversions by issuing the Skip ROM command and then issuing the

Convert T command. Note that as long as the external power supply is active, the GND pin may not be

floating.

The use of parasite power is not recommended above 100°C, since it may not be able to sustain

communications given the higher leakage currents the DS18B20 exhibits at these temperatures. For

applications in which such temperatures are likely, it is strongly recommended that V

be applied to the

DD

DS18B20.

3 of 27

DS18B20

For situations where the bus master does not know whether the DS18B20s on the bus are parasite

powered or supplied with external VDD, a provision is made in the DS18B20 to signal the power supply

scheme used. The bus master can determine if any DS18B20s are on the bus which require the strong

pullup by sending a Skip ROM protocol, then issuing the read power supply command. After this

command is issued, the master then issues read time slots. The DS18B20 will send back “0” on the

1-Wire bus if it is parasite powered; it will send back a “1” if it is powered from the V

pin. If the

DD

master receives a “0,” it knows that it must supply the strong pullup on the DQ line du ring temperature

conversions. See “Memory Command Functions” section for more detail on this command protocol.

STRONG PULLUP FOR SUPPLYING DS18B20 DURING TEMPERATURE

CONVERSION Figure 2

+3V - +5.5V

DS18B20

+3V - +5.5V

V

DD

µP

4.7k

GND

I/O

USING V

µP

TO SUPPLY TEMPERATURE CONVERSION CURRENT Figure 3

DD

TO OTHER

1-WIRE

EXTERNAL

+3V - +5.5V

+3V - +5.5V

4.7k

I/O

DS18B20

V

DD

4 of 27

DS18B20

OPERATION - MEASURING TEMPERATURE

The core functionality of the DS18B20 is its direct-to-digital temperature sensor. The resolution of the

DS18B20 is configurable (9, 10, 11, or 12 bits), with 12-bit readings the factory default state. This

equates to a temperature resolution of 0.5°C, 0.25°C, 0.125°C, or 0.0625°C. Following the issuan ce of

the Convert T [44h] command, a temperature conversion is performed and the thermal data is stored in

the scratchpad memory in a 16-bit, sign-extended two’s complement format. The temperature

information can be retrieved over the 1-Wire interface by issuing a Read Scratchpad [BEh] command

once the conversion has been performed. The data is transferred over the 1-Wire bus, LSB first. The

MSB of the temperature register contains the “sign” (S) bit, denoting whether the temperature is positive

or negative.

Table 2 describes the exact relationship of output data to measured temperature. The table assumes 12-bit

resolution. If the DS18B20 is configured for a lower resolution, insignificant bits will contain zeros. For

Fahrenheit usage, a lookup table or conversion routine must be used.

Temperature/Data Relationships Table 2

232221202-12-22-32-4LSB

MSb

SSSSS262524MSB

TEMPERATURE DIGITAL OUTPUT

+125°C 0000 0111 1101 0000 07D0h

+85°C 0000 0101 0101 0000 0550h*

+25.0625°C 0000 0001 1001 0001 0191h

+10.125°C 0000 0000 1010 0010 00A2h

+0.5°C 0000 0000 0000 1000 0008h

0°C 0000 0000 0000 0000 0000h

-0.5°C 1111 1111 1111 1000 FFF8h

-10.125°C 1111 1111 0101 1110 FF5Eh

-25.0625°C 1111 1110 0110 1111 FF6Fh

-55°C 1111 1100 1001 0000 FC90h

*The power on reset register value is +85°C.

(unit = °C)

(Binary)

LSb

DIGITAL

OUTPUT

(Hex)

OPERATION - ALARM SIGNALING

After the DS18B20 has performed a temperature conversion, the temper ature value is compared to the

trigger values stored in TH and TL. Since these registers are 8-bit only, bits 9-12 are ignored for

comparison. The most significant bit of TH or TL directly corresponds to the sign bit of the 16-bit

temperature register. If the result of a temperature measur ement is higher than TH or lower th an TL, an

alarm flag inside the device is set. This flag is updated with every temperature measurement. As long as

the alarm flag is set, the DS18B20 will respond to the alarm search command. This allows many

DS18B20s to be connected in parallel doing simultaneous temperature measurements. If somewhere the

temperature exceeds the limits, the alarming device(s) can be identified and read immediately without

having to read non-alarming devices.

5 of 27

DS18B20

64-BIT LASERED ROM

Each DS18B20 contains a unique ROM code that is 64-bits long. The first 8 bits are a 1-Wire family

code (DS18B20 code is 28h). The next 48 bits are a unique serial number. The last 8 bits are a CRC of

the first 56 bits. (See Figure 4.) The 64-bit ROM and ROM Function Control section allow the DS18B20

to operate as a 1-Wire device and follow the 1-Wire protocol detailed in the section “1-Wire Bus

System.” The functions required to control sections of the DS18B20 are not accessible until the ROM

function protocol has been satisfied. This protocol is described in the ROM function protocol flowchart

(Figure 5). The 1-Wire bus master must first provide one of five ROM function commands: 1) Read

ROM, 2) Match ROM, 3) Search ROM, 4) Skip ROM, or 5) Alarm Search. After a ROM function

sequence has been successfully executed, the functions specific to the DS18B20 are ac cessible and the

bus master may then provide one of the six memory and control function commands.

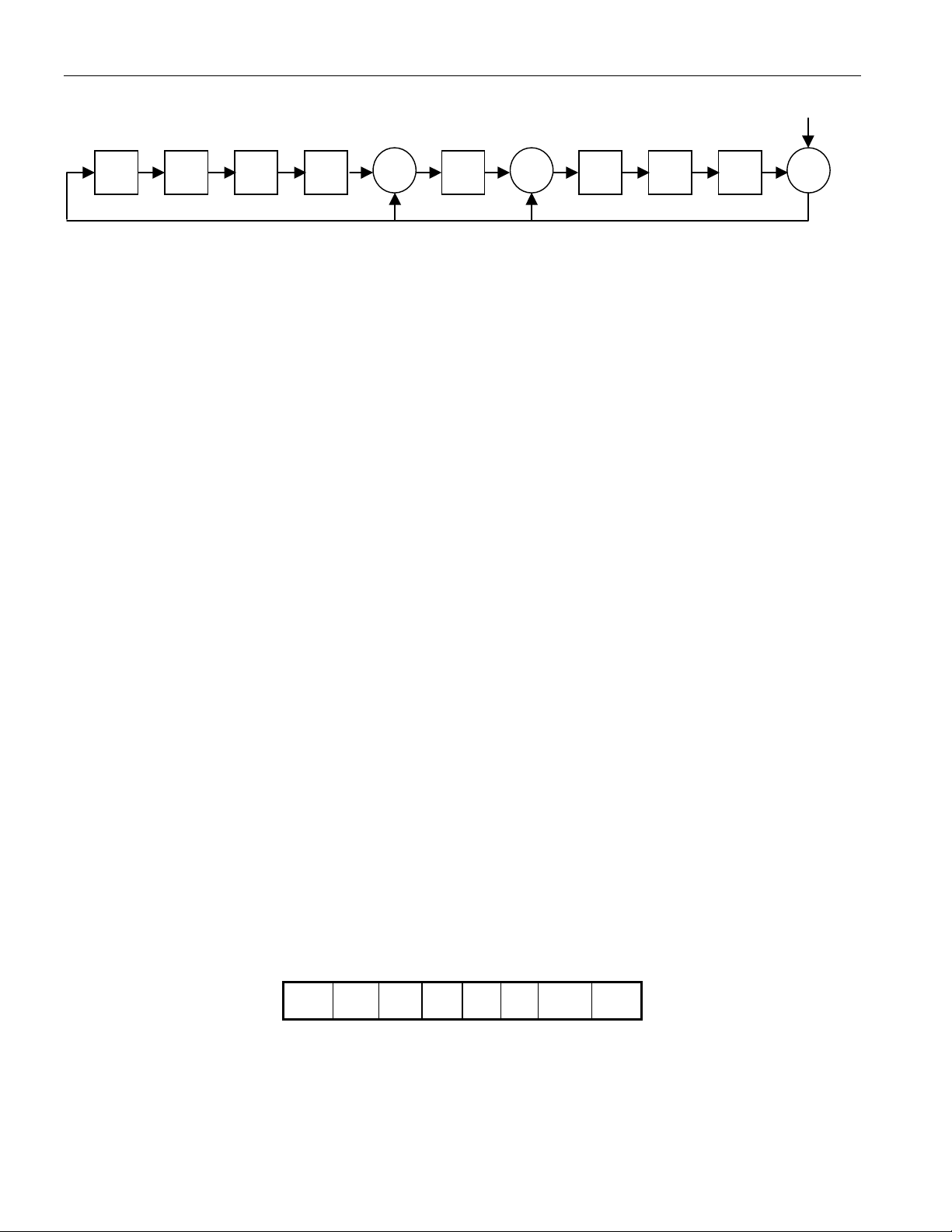

CRC GENERATION

The DS18B20 has an 8-bit CRC stored in the most significant byte of the 64-bit ROM. The bus master

can compute a CRC value from the first 56-bits of the 64-bit ROM and compare it to the value stored

within the DS18B20 to determine if the ROM data has been received error-fre e by the bus master. The

equivalent polynomial function of this CRC is:

CRC = X8 + X5 + X4 + 1

The DS18B20 also generates an 8-bit CRC value using the same polynomial function shown above and

provides this value to the bus master to validate the transfer of data bytes. In each case where a CRC is

used for data transfer validation, the bus master must calculate a CRC value using the polynomial

function given above and compare the calculated value to either the 8-bit CRC value stored in the 64-bit

ROM portion of the DS18B20 (for ROM reads) or the 8-bit CRC value computed within the DS18B20

(which is read as a ninth byte when the scratchpad is read). The comparison of CRC values and decision

to continue with an operation are determined entirely by the bus master. There is no circuitry inside the

DS18B20 that prevents a command sequence from proceeding if the CRC stored in or calculated by the

DS18B20 does not match the value generated by the bus master.

The 1-Wire CRC can be generated using a polynomial generator consisting of a shift register and XOR

gates as shown in Figure 6. Additional information about the Dallas 1-Wire Cyclic Redundanc y Check is

available in Application Note 27 entitled “Understanding and Using Cyclic Redundancy Checks with

Dallas Semiconductor Touch Memory Products.”

The shift register bits are initialized to 0. Then starting with the least significant bit of the family code,

1 bit at a time is shifted in. After the 8th bit of the family code has been entered, then the serial number is

entered. After the 48th bit of the serial number has been entered, the shift register contains the CRC

value. Shifting in the 8 bits of CRC should return the shift register to all 0s.

64-BIT LASERED ROM Figure 4

8-BIT CRC CODE 48-BIT SERIAL NUMBER

MSB LSB MSB LSB MSB LSB

6 of 27

8-BIT FAMILY CODE

(28h)

ROM FUNCTIONS FLOW CHART Figure 5

DS18B20

7 of 27

1-WIRE CRC CODE Figure 6

(

)

(

)

DS18B20

INPUT

MSB

LSB

MEMORY

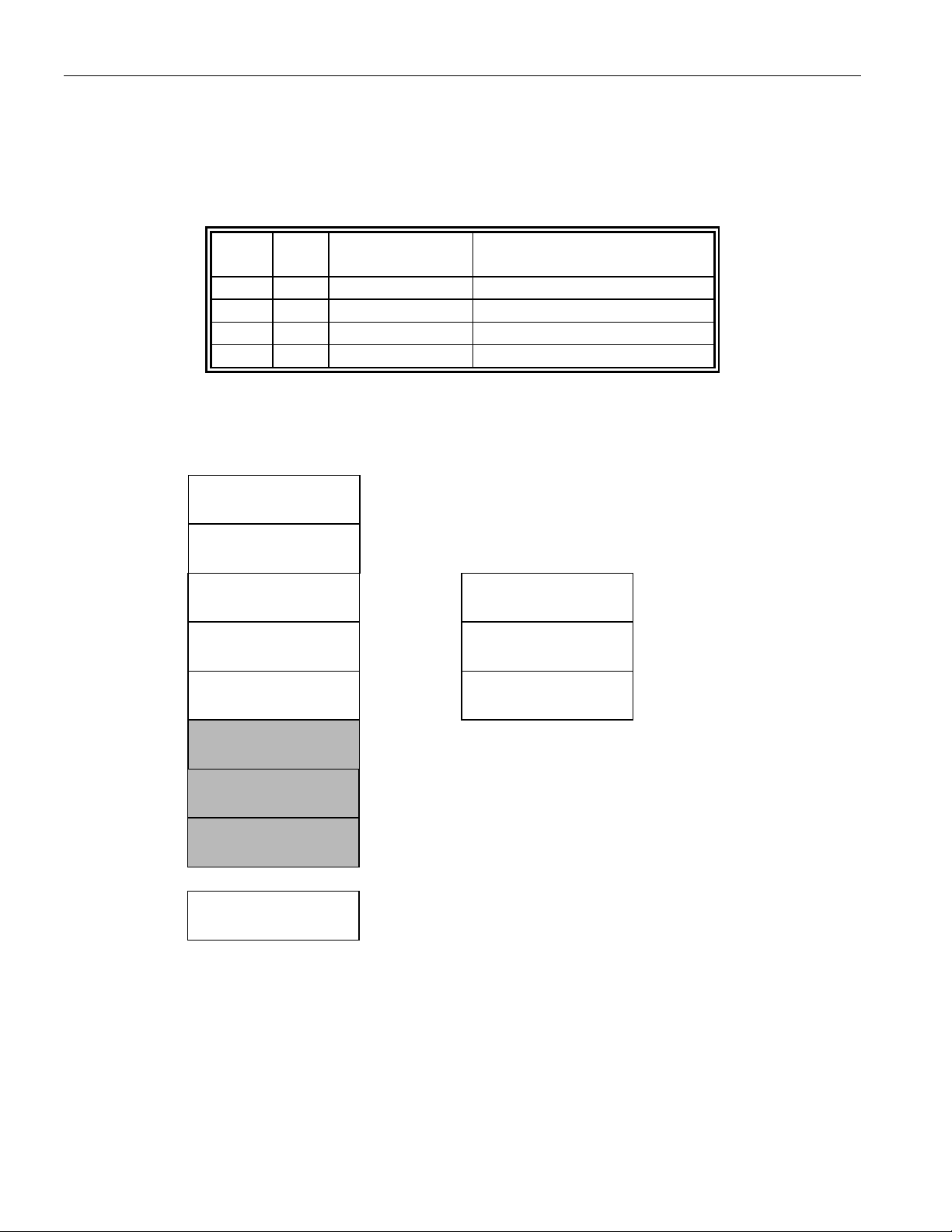

The DS18B20’s memory is organized as shown in Figure 8. The memory consists of a scratchpad RAM

and a nonvolatile, electrically erasable (E2) RAM, which stores the high and low temperature triggers TH

and TL, and the configuration register. The scratchpad helps insure data integrity when communicating

over the 1-Wire bus. Data is first written to the scratchpad using the Write Scratchpad [4Eh] command.

It can then be verified by using the Read Scratchpad [BEh] command. After the dat a has been verifi ed, a

Copy Scratchpad [48h] command will transfer the data to the nonvolatile (E2) RAM. This process insures

data integrity when modifying memory. The DS18B20 EEPROM is rated for a minimum of 50,000

writes and 10 years data retention at T = +55°C.

The scratchpad is organized as eight bytes of memory. The first 2 bytes contain the LSB and the MSB of

the measured temperature information, respectively. The third and fourth bytes are volatile copies of T H

and TL and are refreshed with every power-on reset. The fifth byte is a volatile copy of the configuration

register and is refreshed with every power-on reset. The configuration register will be explained in more

detail later in this section of the datasheet. The sixth, seventh, and eighth bytes are used for internal

computations, and thus will not read out any predictable pattern.

It is imperative that one writes TH, TL, and config in succession; i.e. a write is not valid if one writes

only to TH and TL, for example, and then issues a reset. If any of these bytes must be written, all three

must be written before a reset is issued.

There is a ninth byte which may be read with a Read Scratchpad [BEh] command. This b yte contains a

cyclic redundancy check (CRC) byte which is the CRC over all of the eight previous bytes. This CRC is

implemented in the fashion described in the section titled “CRC Generation”.

Configuration Register

The fifth byte of the scratchpad memory is the configuration register.

It contains information which will be used by the device to determine the resolution of the temperature to

digital conversion. The bits are organized as shown in Figure 7.

DS18B20 CONFIGURATION REGISTER Figure 7

0R1R0111 1 1

MSb LSb

Bits 0-4 are don’t cares on a write but will always read out “1”.

Bit 7 is a don’t care on a write but will always read out “0”.

8 of 27

DS18B20

R0, R1: Thermometer resolution bits. Table 3 below defines the resolution of the digital thermometer,

based on the settings of these 2 bits. There is a direct tradeoff between resolution and conversion time, as

depicted in the AC Electrical C haracteristics. The factory default of these EEPROM bits is R0=1 and

R1=1 (12-bit conversions).

Thermometer Resolution Configuration Table 3

R1 R0 Thermometer

Resolution

0 0 9 bit 93.75 ms (t

0 1 10 bit 187.5 ms (t

1 0 11 bit 375 ms (t

1 1 12 bit 750 ms (t

DS18B20 MEMORY MAP Figure 8

SCRATCHPAD

BYTE

TEMPERATURE LSB

TEMPERATURE MSB

TH/USER BYTE 1

TL/USER BYTE 2

CONFIG

0

1

2

3

4

Max Conversion

Time

2

E

RAM

TH/USER BYTE 1

TL/USER BYTE 2

CONFIG

conv

conv

conv

conv

/8)

/4)

/2)

)

RESERVED

RESERVED

RESERVED

CRC

5

6

7

8

9 of 27

Loading...

Loading...