Dallas Semiconductor DS1710SN, DS1710S, DS1710N, DS1710EN, DS1710E Datasheet

...

1 of 14 111999

FEATURES

Converts CMOS RAMs into nonvolatile

memories

Automatically selects +3.0V or +5.0V

operation

SOIC version is pin-compatible with the

Dallas Semiconductor DS1210S and

DS1610S NV Controllers

Unconditionally write protects all of memory

when VCC is out of tolerance

Write protects selected blocks of memory

regardless of VCC status when programmed

Automatically switches to battery backup

supply when power-fail occurs

Provides for multiple batteries

Consumes less than 100 nA of battery current

Test battery on power-up by inhibiting the

second memory cycle

Optional 5% or 10% power-fail detection

16-pin DIP or 16-pin SOIC surface mount

package or 20-pin TSSOP package

Low forward voltage drop on the V

CC

switch

with currents of up to 150 mA

Optional industrial temperature range of

-40°C to +85°C

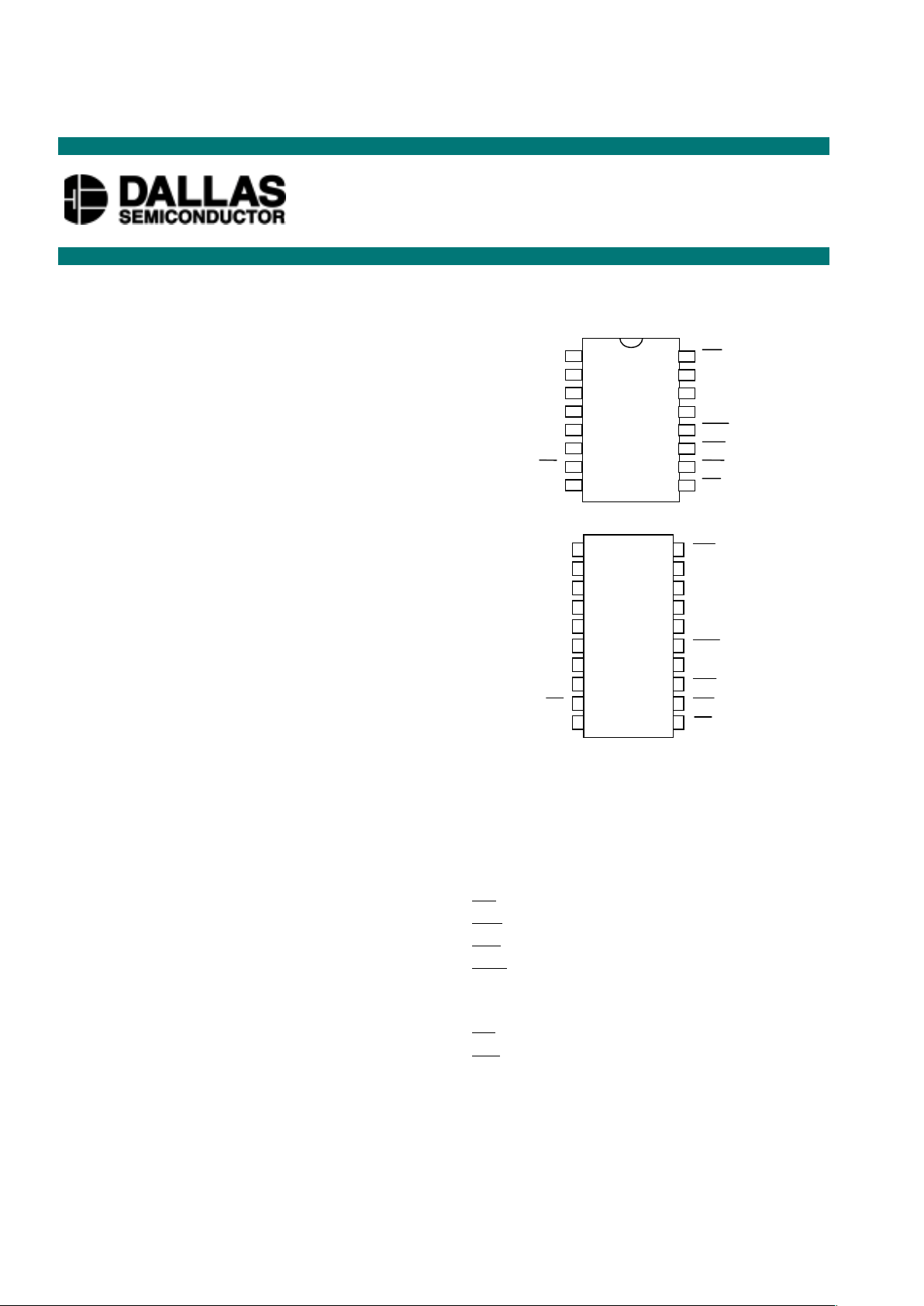

PIN ASSIGNMENT

PIN DESCRIPTION

V

CCI

- Input 2.7 to 5.5 Volt Supply

V

BAT1

- + Battery 1 Input

V

BAT2

- + Battery 2 Input

V

CCO

- RAM Power (VCC) Supply

GND - Ground

CEI - Chip Enable Input

CEO - Chip Enable Output

WEI - Write Enable Input

WEO - Write Enable Output

TOL - Power Supply Tolerance Select

A

W

- A

Z

- Address Inputs

DIS - Memory Partition Disable

PFO - Power-fail Output

NC - No Connect

DS1710

Partitioned NV Controlle

r

www.dalsemi.com

1

2

3

4

5

6

7

8

16

15

14

13

9

10

11

12

PFO

V

CCI

A

Z

V

BAT2

WEO

CEO

WEI

CEI

A

W

V

A

V

A

Y

TOL

DIS

GND

16-Pin DIP and 16-Pin SOIC

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

A

W

V

CCO

A

X

V

BAT1

A

Y

NC

TOL

NC

DIS

GND

PFO

V

CCI

A

Z

V

BAT2

NC

WEO

NC

CEO

WEI

CEI

20-Pin TSSOP

DS1710

2 of 14

DESCRIPTION

The DS1710 is a low-power CMOS circuit which solves the application problems of converting CMOS

RAMS into nonvolatile memories. In addition the device has the ability to unconditionally write protect

blocks of memory so that inadvertent write cycles do not corrupt program and special data space. The

incoming power supply voltage at the V

CCI

input pin is constantly monitored for an out-of-tolerance

condition. When such a condition is detected, both the chip enable and write enable outputs are inhibited

to protect stored data. The battery inputs are used to supply V

CCO

with power when V

CCI

is less than the

battery input voltages. Special circuitry uses a low leakage CMOS process which affords precise voltage

detection at extremely low current consumption. By combining the DS1710 Partitioned NV Controller

chip with a CMOS memory and batteries, nonvolatile RAM operation can be achieved.

The DS1710 Partitioned NV Controller incorporates all the functions of the DS1610 with the additional

feature of either +3.0V or +5.0V operation. The DS1710 functions like the Dallas Semiconductor DS1210

NV controller when the ( DIS) disable pin is grounded and also incorporates the power-up auto sensing.

An internal pulldown resistor to ground on the DIS pin of the DS1710S allows it to retrofit into DS1210S

applications. When the DIS pin is grounded the address inputs AW - AZ and the write enable input WEI

are ignored. Also the power-fail output PFO and the write enable output WEO are tristated.

POWER-UP AUTO SENSING

V

CCI

will accept either +3.0V or +5.0V input. Selection of 3V operation is automatically invoked when

VCC rises and remains between V

CCTP2

and V

CCTP1

for t

REC

. 5V operation is automatically selected if V

CC

rises and remains above both V

CCTP2

and V

CCTP1

for t

REC

. In either case, t

REC

is measured from the time

VCC first rises above V

CCTP2

. The DS1710 will not change modes until VCC falls below V

CCTP2

.

OPERATION - DISABLE PIN CONNECTED TO V

CCO

The DS1710 performs five circuit functions required to battery-backup a RAM. First, a switch is provided

to direct power from the battery or the incoming power supply (V

CCI

) depending on which is greater. This

switch has a voltage drop of less than 0.2 volts. The second function provided by the DS1710 is powerfail detection. The incoming supply (V

CCI

) is constantly monitored. When the supply goes out of

tolerance a precision comparator detects power failure and inhibits both the chip enable output ( CEO ) and

the write enable output ( WEO ). A third function of write protection is accomplished by holding both the

chip enable output CEO and write enable output WEO to within 0.2 volts of V

CCO

when V

CCI

is out of

tolerance. If CEI is low at the time that power-fail detection occurs the CEO signal is kept low until CEI

is brought high again. However, CEO is forced high after 1.5 µs regardless of the state of CEI . Similarly,

if WEI is low at the time that power-fail detection occurs, the WEO signal will remain low until WEI is

brought high or 1.5 µs elapses. The delay of write protection until the current memory cycle is complete

prevents corrupted data. Power-fail detection occurs in the range of 4.75 to 4.5 volts with the tolerance

pin TOL grounded and in 5-volt mode. If the tolerance pin is connected to V

CCO

while in 5-volt mode,

then power-fail detection occurs in the range of 4.5 volts to 4.25 volts. If in 3-volt mode, the power-fail

detection will occur in the range of 2.7 to 2.5 volts. The PF0 signal is driven low and remains low until

V

CCI

returns to nominal conditions. During nominal supply conditions CEO will follow CEI and WEO

will follow WEI . The fourth function which the DS1710 performs is a battery status warning so that

potential data loss is avoided. Each time V

CCI

is applied to the device battery status is checked with a

precision comparator. If during battery backup, no switch occurred from one battery to the other, the

voltage of the battery supplying power when V

CCI

is applied is checked. If this voltage is less than 2.0

volts the second chip enable cycle after power is applied is inhibited. If any switch from one battery to

another did occur the voltage of both batteries is checked. If either voltage is less than 2.0 volts the

second chip enable cycle will be inhibited. Battery status can therefore be determined by performing a

DS1710

3 of 14

read cycle after power-up to any location in memory, verifying that memory location’s contents. A

subsequent write cycle can then be executed to the same memory location altering the data. If the next

read cycle fails to verify the written data then the data is in danger of being corrupted. The fifth function

of the DS1710 provides for battery redundancy. When data integrity is extremely important it is wise to

use two batteries to insure reliability. The DS1710 controller provides an internal isolation switch which

allows the connection of two batteries. When entering battery backup operation, the battery with the

highest voltage is selected for use. If one battery should fail, the other would then supply energy to the

connected load. The switch to a redundant battery is transparent to circuit operation and to the user. In

applications where battery redundancy is not a major concern a single battery should be connected to the

BAT1 pin. The BAT2 battery pin must be grounded. When batteries are first connected to one or both of

the V

BAT

pins V

CCO

will not show the battery potential until V

CCI

is applied and removed for the first time.

OPERATION - WRITE PROTECTION PROGRAMMING MODE

When the disable pin is connected to V

CCI

or V

CCO

, the DS1710 performs all of the functions described

earlier with the addition of a partition switch which selectively write protects blocks of memory. The state

of the DIS pin is strobed and latched as V

CCI

crosses the power-fail trip point so that the DS1710

maintains its configuration during power loss. If the strobed value of DIS is high, the internal pulldown

resistor on the DIS pin will be disconnected in the power-fail state to eliminate the possibility of battery

discharge. The register controlling the partition switch is selected by recognition of a specific binary

pattern which is sent on address lines AW - AZ. These address lines are normally the four upper order

address lines being sent to RAM. The pattern is sent by 20 consecutive read cycles with the exact pattern

as shown in Table 1. Pattern matching must be accomplished using read cycles; any write cycles will

reset the pattern matching circuitry. If this pattern is matched perfectly, then the 21st through 24th read

cycle will load the partition switch. Since there are 16 possible write protected partitions, the size of each

partition is determined by the size of the memory. For example, a 128k X 8 memory would be divided

into 16 partitions of 128k/16 or 8k X 8. Each partition is represented by one of the 16 bits contained in

the 21st through 24th read cycle as defined by AW through AZ and shown in Table 2. A logical 1 in a bit

location sets that partition to write protect. A logical 0 in a bit location disables write protection. For

example, if during the pattern match sequence bit 22 on address pin A

X

were a 1, this would cause the

partition register location for partition 5 to be set to a 1. This in turn would cause the DS1710 to inhibit

WEO from going low as WEI goes low whenever A

ZAYAXAW

=0101. Note that while setting the partition

register, data which is being accessed from the RAM should be ignored as the purpose of the 24 read

cycles is to set the partition switch and not for the purpose of accessing data from RAM. Also note that

on initial battery attach the partition register can power-up in any state.

DS1710

4 of 14

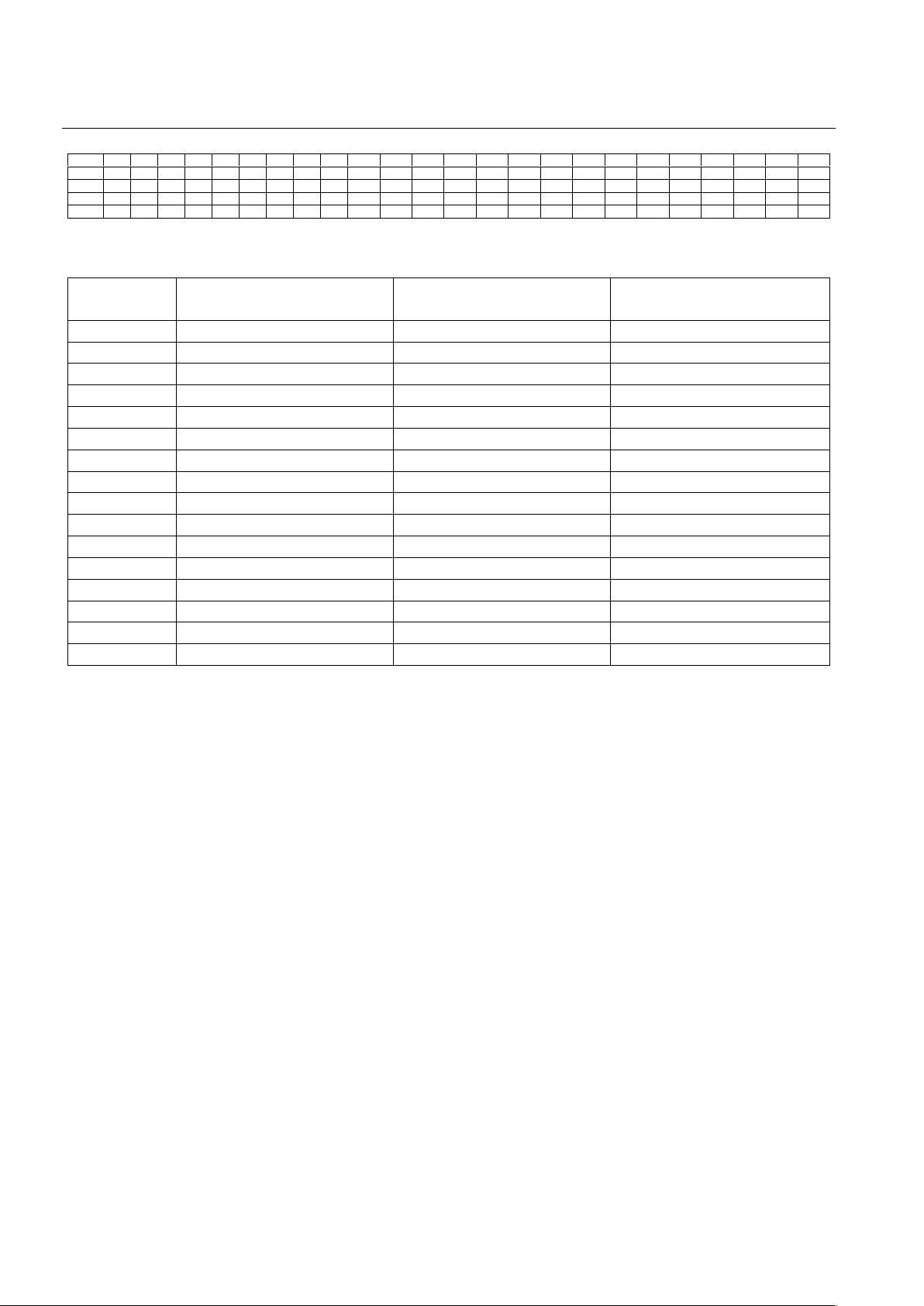

PATTERN MATCH TO WRITE PARTITION REGISTER Table 1

123456789101112131415161718192021222324

AW1011110011 1 0 0 0 0 0 1 1 0 1 X X X X

AX1111100111 0 0 1 0 1 1 0 0 0 0 X X X X

AY1111001110 0 1 0 1 0 1 0 0 0 1 X X X X

AZ1100011100 1 0 0 0 1 0 1 0 0 0 X X X X

PARTITION REGISTER MAPPING Table 2

Address

Pin

Bit number in pattern

Match sequence

Partition Number Address State Affected

(AZ AY AX AW)

A

W

BIT 21 PARTITION 0 0000

A

X

BIT 21 PARTITION 1 0001

A

Y

BIT 21 PARTITION 2 0010

A

Z

BIT 21 PARTITION 3 0011

A

W

BIT 22 PARTITION 4 0100

A

X

BIT 22 PARTITION 5 0101

A

Y

BIT 22 PARTITION 6 0110

A

Z

BIT 22 PARTITION 7 0111

A

W

BIT 23 PARTITION 8 1000

A

X

BIT 23 PARTITION 9 1001

A

Y

BIT 23 PARTITION 10 1010

A

Z

BIT 23 PARTITION 11 1011

A

W

BIT 24 PARTITION 12 1100

A

X

BIT 24 PARTITION 13 1101

A

Y

BIT 24 PARTITION 14 1110

A

Z

BIT 24 PARTITION 15 1111

DS1710

5 of 14

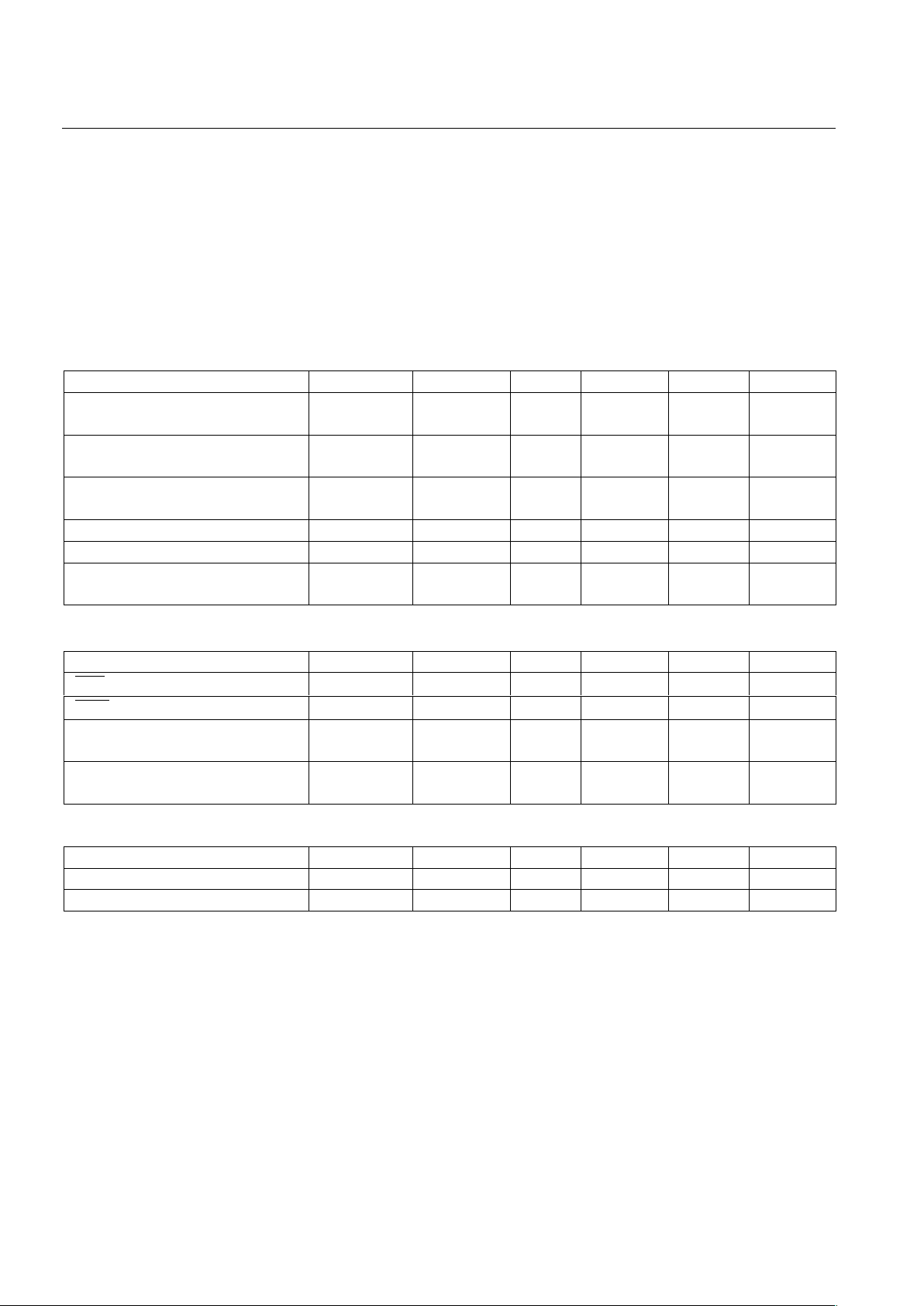

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground -0.5V to +7.0V

Operating Temperature 0°C to 70°C

Storage Temperature -55°C to +125°C

Soldering Temperature 260°C for 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions

above those indicated in the operation sections of this specification is not implied. Exposure to

absolute maximum rating conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (0°C to 70°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Pin 6 = GND Supply Voltage

(5V Operation)

V

CCI

4.75 5.0 5.5 V 1

Pin 6 = V

CCO

Supply Voltage

(5V Operation)

V

CCI

4.5 5.0 5.5 V 1

Pin 6 = GND Supply Voltage

(3V Operation)

V

CCI

2.7 3.0 4.0 V 1

Logic 1 Input V

IH

2.0 VCC+0.3 V 1

Logic 0 Input V

IL

-0.3 +0.8 V 1

Battery Input V

BAT1

,

V

BAT2

2.0 4.0 V 1, 2

DC ELECTRICAL CHARACTERISTICS (0°C to 70°C; V

CCI<VBAT

, V

CCI<VCCTP2

)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

CEO Output

V

OHL

V

BAT

-0.2 V

WEO Output

V

OHL

V

BAT

-0.2 V

V

BAT1

or V

BAT1

Battery Current

I

BAT

100 nA 2, 3

Battery Backup Current @

V

CCO

= V

BAT

-0.2V

I

CCO2

150 µA 6, 8

CAPACITANCE (TA = 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

IN

5pF

Output Capacitance C

OUT

7pF

Loading...

Loading...