Dallas Semiconductor DS1708R, DS1708, DS1707, DS1708T, DS1708S Datasheet

DS1707/DS1708

DS1707/DS1708

3.3 and 5.0 Volt MicroMonitor

FEATURES

• Holds microprocessor in check during power tran-

sients

• Automatically restarts microprocessor after power

failure

• Monitors pushbutton for external override

• Accurate 5%, 10% or 20% resets for 3.3 systems and

5% or 10% resets for 5.0 volt systems

• Eliminates the need for discrete components

• 20% tolerance compatible with 3.0 volt systems

• Pin compatible with the MAXIM MAX707/MAX708 in

8–pin DIP and 8–pin SOIC packages

• 8–pin DIP, 8–pin SOIC and 8–pin µ–SOP packages

available

• Industrial temperature range –40°C to +85°C

DESCRIPTION

The DS1707/DS1708 3.3 or 5.0 Volt MicroMonitor monitors three vital conditions for a microprocessor: power

supply, voltage sense, and external override. A precision temperature–compensated reference and

comparator circuit monitors the status of VCC at the

device and at an upstream point for maximum protection. When the sense input detects an out–of–tolerance

PIN ASSIGNMENT

PBRST

PBRST

1

2

V

CC

3

GND

4

IN

8–PIN DIP

(300 MIL)

V

CC

GND

IN

8–PIN SOIC

(150 MIL)

PBRST

V

CC

GND

IN

8–PIN µ–SOP

See Mech. Drawings

1

2

3

4

1

2

3

4

(118 MIL)

Section

DS1707 and DS1708_/R/S/T

RST

8

RST

7

6

NC

5

NMI

RST

8

7

RST

6

NC

5

NMI

8

RST

7

RST

6

NC

5

NMI

PIN DESCRIPTION

PBRST – Pushbutton Reset Input

V

CC

GND – Ground

IN – Input

NMI

NC – No Connect

RST – Active Low Reset Output

RST – Active High Reset Output

condition a non–maskable interrupt is generated. As

the voltage at the device degrades an internal power fail

signal is generated which forces the reset to an active

state. When VCC returns to an in–tolerance condition,

the reset signal is kept in the active state for a minimum

of 130 ms to allow the power supply and processor to

stabilize.

– Power Supply

– Non–maskable Interrupt

Copyright 1995 by Dallas Semiconductor Corporation.

All Rights Reserved. For important information regarding

patents and other intellectual property rights, please refer to

Dallas Semiconductor data books.

010996 1/9

DS1707/DS1708

The third function the DS1707/DS1708 performs is

pushbutton reset control. The DS1707/DS1708

debounces the pushbutton input and guarantees an

active reset pulse width of 130 ms minimum.

OPERATION

Power Monitor

The DS1707/DS1708 detects out–of–tolerance power

supply conditions and warns a processor–based system of impending power failure. When VCC falls below

the minimum V

RST and RST

tolerance, a comparator outputs the

CC

signals. RST and RST are excellent control signals for a microprocessor, as processing is

stopped at the last possible moment of valid V

CC

. On

power–up, RST and RST are kept active for a minimum

of 130 ms to allow the power supply and processor to

stabilize.

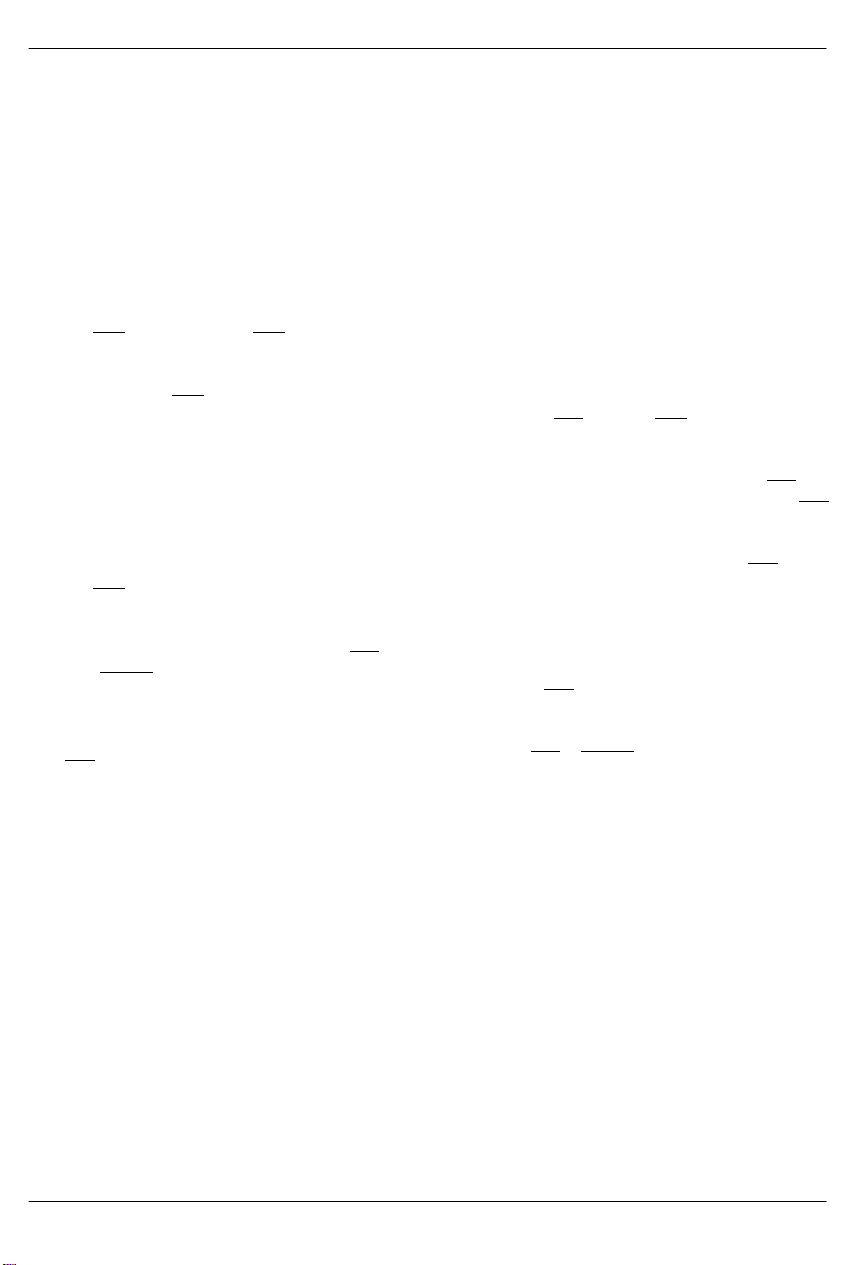

Pushbutton Reset

The DS1707/DS1708 provides an input pin for direct

connection to a pushbutton reset (see Figure 2). The

pushbutton reset input requires an active low signal.

Internally, this input is debounced and timed such that

RST and RST

signals of at least 130 ms minimum will be

generated. The 130 ms delay commences as the pushbutton reset input is released from the low level. The

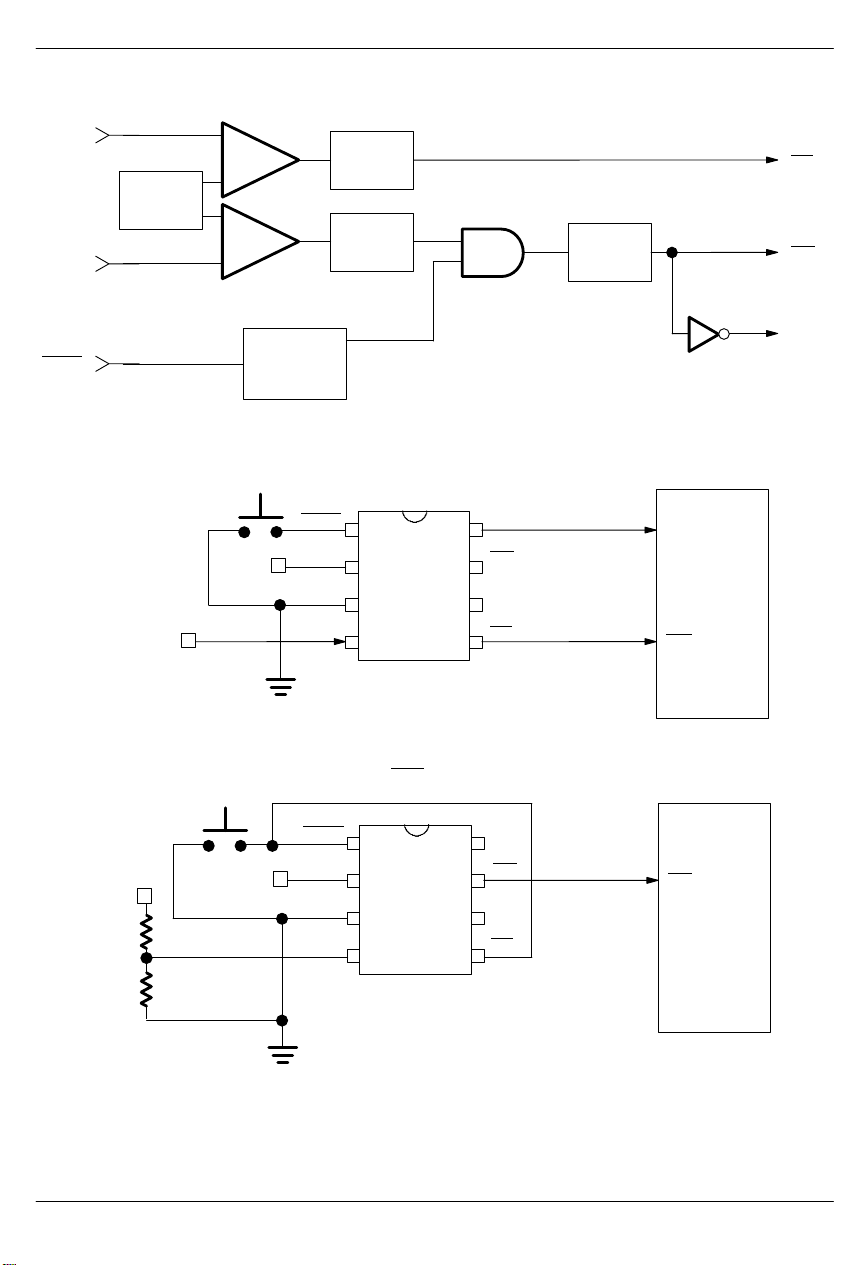

pushbutton can be initiated by connecting the NMI

out-

put to the PBRST input as shown in Figure 3.

Non–Maskable Interrupt

The DS1707/DS1708 generates a non–maskable interrupt (NMI) for early warning of a power failure. A precision comparator monitors the voltage level at the IN pin

relative to an on–chip reference generated by an internal band gap. The IN pin is a high impedance input

allowing for a user–defined sense point. An external

resistor voltage divider network (Figure 5) is used to

interface with high voltage signals. This sense point

may be derived from a regulated supply or from a higher

DC voltage level closer to the main system power input.

Since the IN trip point V

is 1.25 volts, the proper val-

TP

ues for R1 and R2 can be determined by the equation as

shown in Figure 5. Proper operation of the

DS1707/DS1708 requires that the voltage at the IN pin

be limited to V

voltage at the supply being monitored (V

. Therefore, the maximum allowable

CC

MAX

) can also

be derived as shown in Figure 5. A simple approach to

solving the equation is to select a value for R2 high

enough to keep power consumption low, and solve for

R1. The flexibility of the IN input pin allows for detection

of power loss at the earliest point in a power supply system, maximizing the amount of time for system shut–

down between NMI

and RST/RST.

When the supply being monitored decays to the voltage

sense point, the DS1707/DS1708 pulses the NMI

output to the active state for a minimum 200 µs. The NMI

power fail detection circuitry also has built–in hysteresis

of 100 µV . The supply must be below the voltage sense

point for approximately 5 µs before a low NMI

will be

generated. In this way , power supply noise is removed

from the monitoring function, preventing false interrupts. During a power–up, any detected IN pin levels

below VTP by the comparator are disabled from generating an interrupt until VCC rises to V

any potential NMI

reaches V

Connecting NMI

pulse will not be initiated until V

.

CCTP

to PBRST would allow the non–mask-

. As a result,

CCTP

CC

able interrupt to generate an automatic reset when an

out–of–tolerance condition occurred in a monitored

supply. An example is shown in Figure 3.

010996 2/9

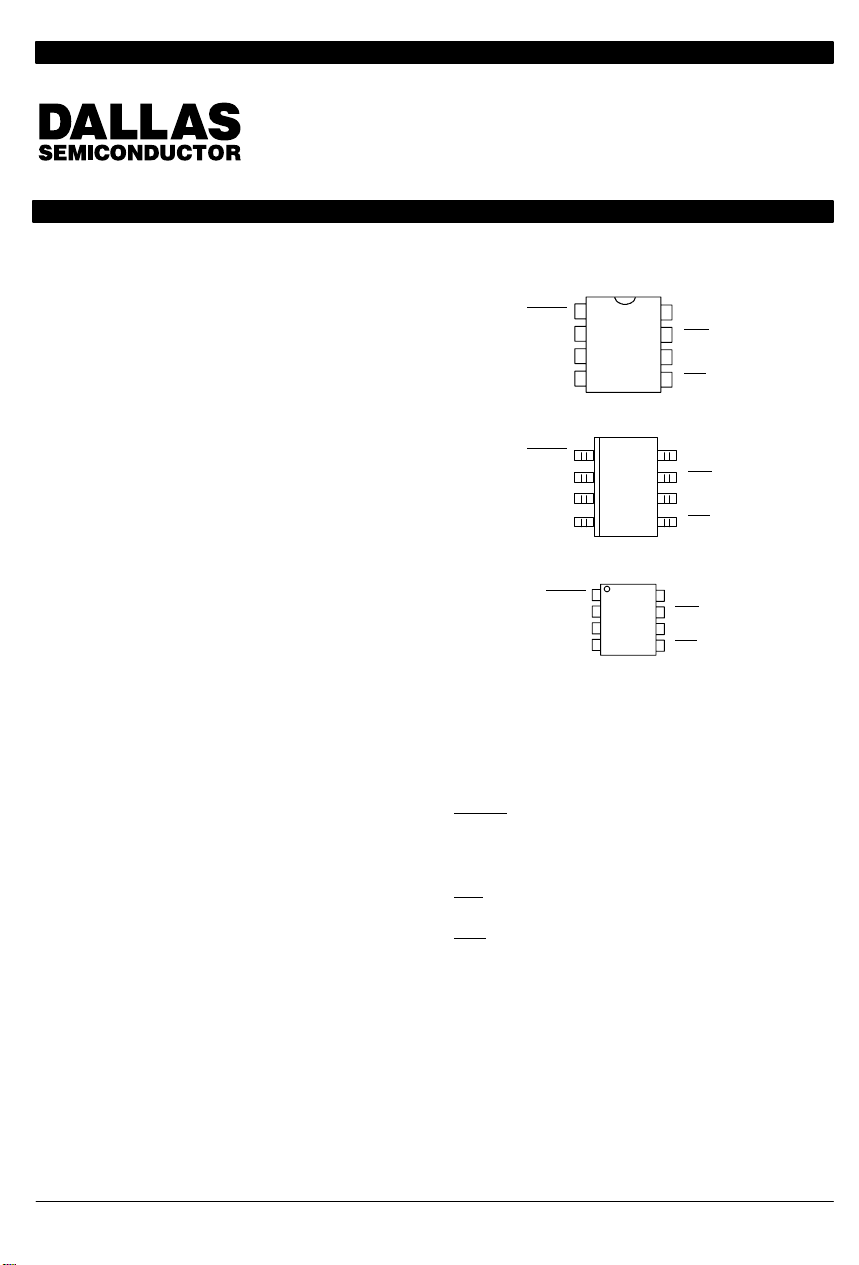

MICROMONITOR BLOCK DIAGRAM Figure 1

DS1707/DS1708

IN

–

+

T.C.

V

PBRST

REFERENCE

CC

–

+

LEVEL SENSE

DEBOUNCE

AND

PUSHBUTTON RESET Figure 2

5V

UPSTREAM

SUPPLY

VOLTAGE

DIGITAL

SAMPLER

DIGITAL

SAMPLER DIGITAL

PBRST

V

GND

CC

DS1708

IN

RST

RST

NC

NMI

DELAY

RST

INT0

8051

µP

NMI

RST

RST

PUSHBUTTON RESET CONTROLLED BY NMI Figure 3

PBRST

V

UPSTREAM

SUPPLY

VOLTAGE

5V

CC

DS1707

GND

IN

RST

RST

NC

NMI

µP

RST

010996 3/9

Loading...

Loading...