Dallas Semiconductor DS1312S-2, DS1312S, DS1312E, DS1312 Datasheet

1 of 11 111999

FEATURES

Converts CMOS SRAM into nonvolatile

memory

Unconditionally write-protects SRAM when

VCC is out of tolerance

Automatically switches to battery backup

supply when VCC power failure occurs

Monitors voltage of a lithium cell and

provides advanced warning of impending

battery failure

Signals low-battery condition on active low

Battery Warning output signal

Optional -5% or -10% power-fail detection

Space-saving 8-pin DIP and SOIC packages

Optional 16-pin SOIC and 20-pin TSSOP

versions reset processor when power failure

occurs and hold processor in reset during

system power-up

Industrial temperature range of -40°C to

+85°C

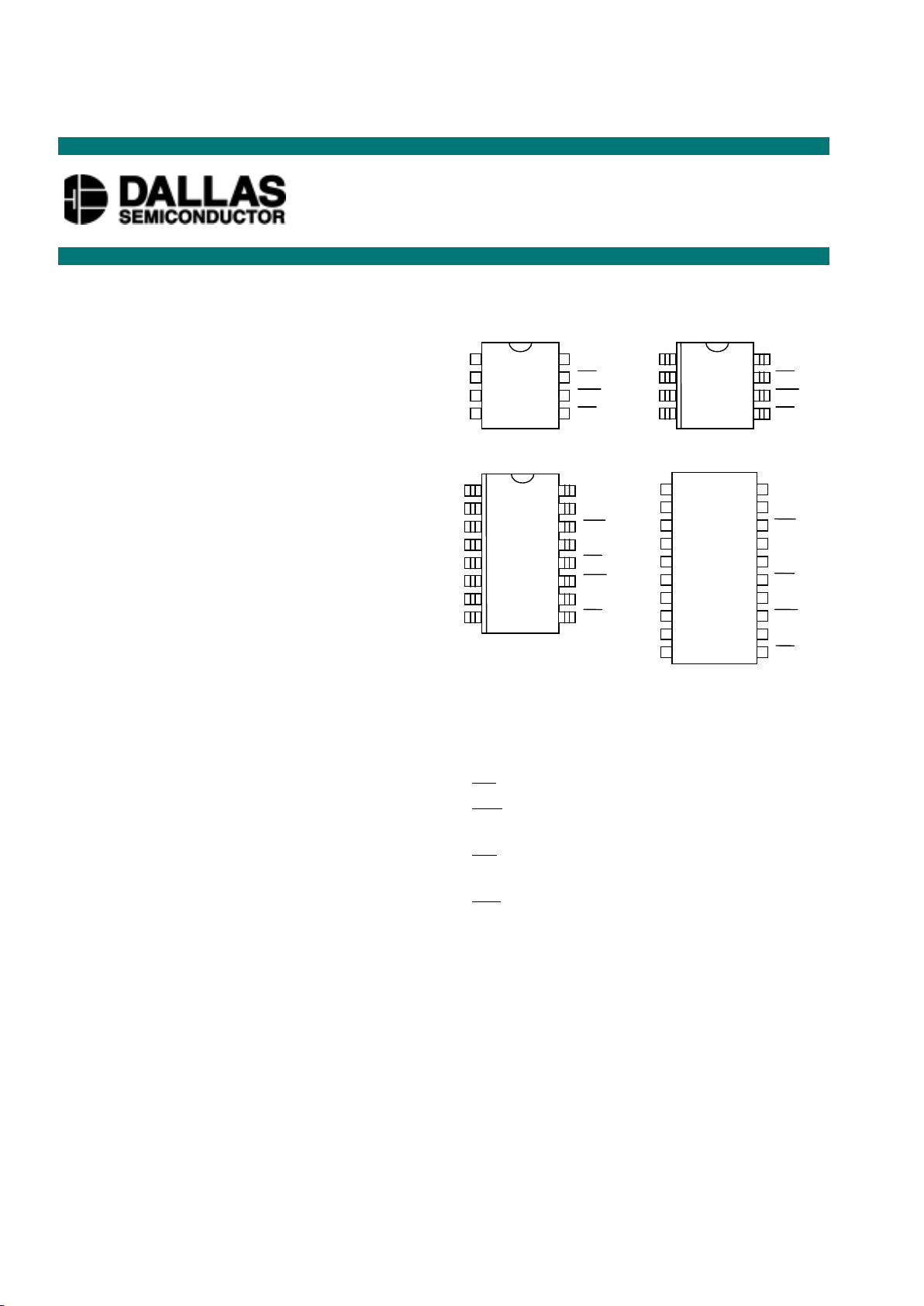

PIN ASSIGNMENT

PIN DESCRIPTION

V

CCI

- +5V Power Supply Input

V

CCO

- SRAM Power Supply Output

V

BAT

- Backup Battery Input

CEI - Chip Enable Input

CEO - Chip Enable Output

TOL - V

CC

Tolerance Select

BW - Battery Warning Output

(Open Drain)

RST - Reset Output (Open Drain)

GND - Ground

NC - No Connection

DESCRIPTION

The DS1312 Nonvolatile Controller with Battery Monitor is a CMOS circuit which solves the application

problem of converting CMOS RAM into nonvolatile memory. Incoming power is monitored for an outof-tolerance condition. When such a condition is detected, chip enable is inhibited to accomplish write

protection and the battery is switched on to supply the RAM with uninterrupted power. Special circuitry

uses a low-leakage CMOS process which affords precise voltage detection at extremely low battery

consumption.

DS1312

Nonvolatile Controller with Lithium

Battery Monitor

www.dalsemi.com

1

2

3

4

20

19

18

17

5

6

7

8

9

10 11

12

13

14

15

16

NC

V

CCI

RST

NC

NC

BW

NC

CEO

NC

CEI

NC

V

CCO

NC

V

BAT

NC

NC

TOL

NC

NC

GND

DS1312E 20-Pin TSSOP

1

2

3

4

8

7

6

5

GND

TOL

V

BAT

V

CCO

V

CCI

BW

CEO

CEI

DS1312S-2 8-Pin SOIC

(150-mil)

1

2

3

4

8

7

6

5

GND

TOL

V

BAT

V

CCO

V

CCI

BW

CEO

CEI

DS1312 8-Pin DIP

(300-mil)

1

2

3

4

16

15

14

13

5

6

7

89

10

11

12

NC

V

CCO

NC

V

BAT

NC

TOL

NC

GND

NC

V

CCI

RST

NC

BW

CEO

NC

CEI

DS1312S 16-Pin SOIC

(300-mil)

DS1312

2 of 11

In addition to battery-backup support, the DS1312 performs the important function of monitoring the

remaining capacity of the lithium battery and providing a warning before the battery reaches end-of-life.

Because the open-circuit voltage of a lithium backup battery remains relatively constant over the majority

of its life, accurate battery monitoring requires loaded-battery voltage measurement. The DS1312

performs such measurement by periodically comparing the voltage of the battery as it supports an internal

resistive load with a carefully selected reference voltage. If the battery voltage falls below the reference

voltage under such conditions, the battery will soon reach end-of-life. As a result, the Battery Warning

pin is activated to signal the need for battery replacement.

MEMORY BACKUP

The DS1312 performs all the circuit functions required to provide battery-backup for an SRAM. First, the

device provides a switch to direct power from the battery or the system power supply (V

CCI

). Whenever

V

CCI

is less than the switch point VSW and V

CCI

is less than the battery voltage V

BAT

, the battery is

switched in to provide backup power to the SRAM. This switch has voltage drop of less than 0.2 volts.

Second, the DS1312 handles power failure detection and SRAM write-protection. V

CCI

is constantly

monitored, and when the supply goes out of tolerance, a precision comparator detects power failure and

inhibits chip enable output ( CEO ) in order to write-protect the SRAM. This is accomplished by holding

CEO to within 0.2 volts of V

CCO

when V

CCI

is out of tolerance. If CEI is (active) low at the time that

power failure is detected, the CEO signal is kept low until CEI is brought high again. Once CEI is

brought high, CEO is taken high and held high until after V

CCI

has returned to its nominal voltage level. If

CEI is not brought high by 1.5 µs after power failure is detected, CEO is forced high at that time. This

specific scheme for delaying write protection for up to 1.5 µs guarantees that any memory access in

progress when power failure occurs will complete properly. Power failure detection occurs in the range

of 4.75 to 4.5 volts (5% tolerance) when the TOL pin is wired to GND or in the range of 4.5 to 4.25 volts

(10% tolerance) when TOL is connected to V

CCO

.

BATTERY VOLTAGE MONITORING

The DS1312 automatically performs periodic battery voltage monitoring at a factory-programmed time

interval of 24 hours. Such monitoring begins within t

REC

after V

CCI

rises above V

CCTP

, and is suspended

when power failure occurs.

After each 24-hour period (t

BTCN

) has elapsed, the DS1312 connects V

BAT

to an internal 1.2 MΩ=test

resistor (R

INT

) for one second (t

BTPW

). During this one second, if V

BAT

falls below the factory-

programmed battery voltage trip point (V

BTP

), the battery warning output BW is asserted. While BW is

active battery testing will be performed with period t

BTCW

to detect battery removal and replacement.

Once asserted, BW remains active until the battery is physically removed and replaced by a fresh cell.

The battery is still retested after each V

CC

power-up, however, even if BW was active on power-down. If

the battery is found to be higher than V

BTP

during such testing, BW is deasserted and regular 24-hour

testing resumes.

BW has an open-drain output driver.

Battery replacement following BW activation is normally done with V

CCI

nominal so that SRAM data is

not lost. During battery replacement, the minimum time duration between old battery detachment and

new battery attachment (t

BDBA

) must be met or BW will not deactivate following attachment of the new

battery. Should BW not deactivate for this reason, the new battery can be detached for t

BDBA

and then re-

attached to clear

BW .

DS1312

3 of 11

NOTE: The DS1312 cannot constantly monitor an attached battery because such monitoring would

drastically reduce the life of the battery. As a result, the DS1312 only tests the battery for one second out

of every 24 hours and does not monitor the battery in any way between tests. If a good battery (one that

has not been previously flagged with BW ) is removed between battery tests, the DS1312 may not

immediately sense the removal and may not activate BW until the next scheduled battery test. If a battery

is then reattached to the DS1312, the battery may not be tested until the next scheduled test.

NOTE: Battery monitoring is only a useful technique when testing can be done regularly over the entire

life of a lithium battery. Because the DS1312 only performs battery monitoring when VCC is nominal,

systems which are powered-down for excessively long periods can completely drain their lithium cells

without receiving any advanced warning. To prevent such an occurrence, systems using the DS1312

battery monitoring feature should be powered–up periodically (at least once every few months) in order

to perform battery testing. Furthermore, anytime BW is activated on the first battery test after a power-up,

data integrity should be checked via checksum or other technique.

POWER MONITORING

DS1312S and DS1312E varieties have an additional reset pin. These varieties detect out-of-tolerance

power supply conditions and warn a processor-based system of impending power failure. When V

CCI

falls

below the trip point level defined by the TOL pin (V

CCTP

), the V

CCI

comparator activates the reset signal

RST . Reset occurs in the range of 4.75 to 4.5 volts (5% tolerance) when the TOL pin is connected to

GND or in the range of 4.5 to 4.25 volts (10% tolerance) when TOL is connected to V

CCO

.

RST also serves as a power-on reset during power-up. After V

CCI

exceeds V

CCTP

, RST will be held active

for 200 ms nominal (t

RPU

). This reset period is sufficiently long to prevent system operation during

power-on transients and to allow t

REC

to expire. RST has an open-drain output driver.

FRESHNESS SEAL MODE

When the battery is first attached to the DS1312 without V

CC

power applied, the device does not

immediately provide battery-backup power on V

CCO

. Only after V

CCI

exceeds V

CCTP

and later falls below

both VSW and V

BAT

will the DS1312 leave Freshness Seal Mode and provide battery-backup power. This

mode allows a battery to be attached during manufacturing but not used until after the system has been

activated for the first time. As a result, no battery energy is drained during storage and shipping.

DS1312

4 of 11

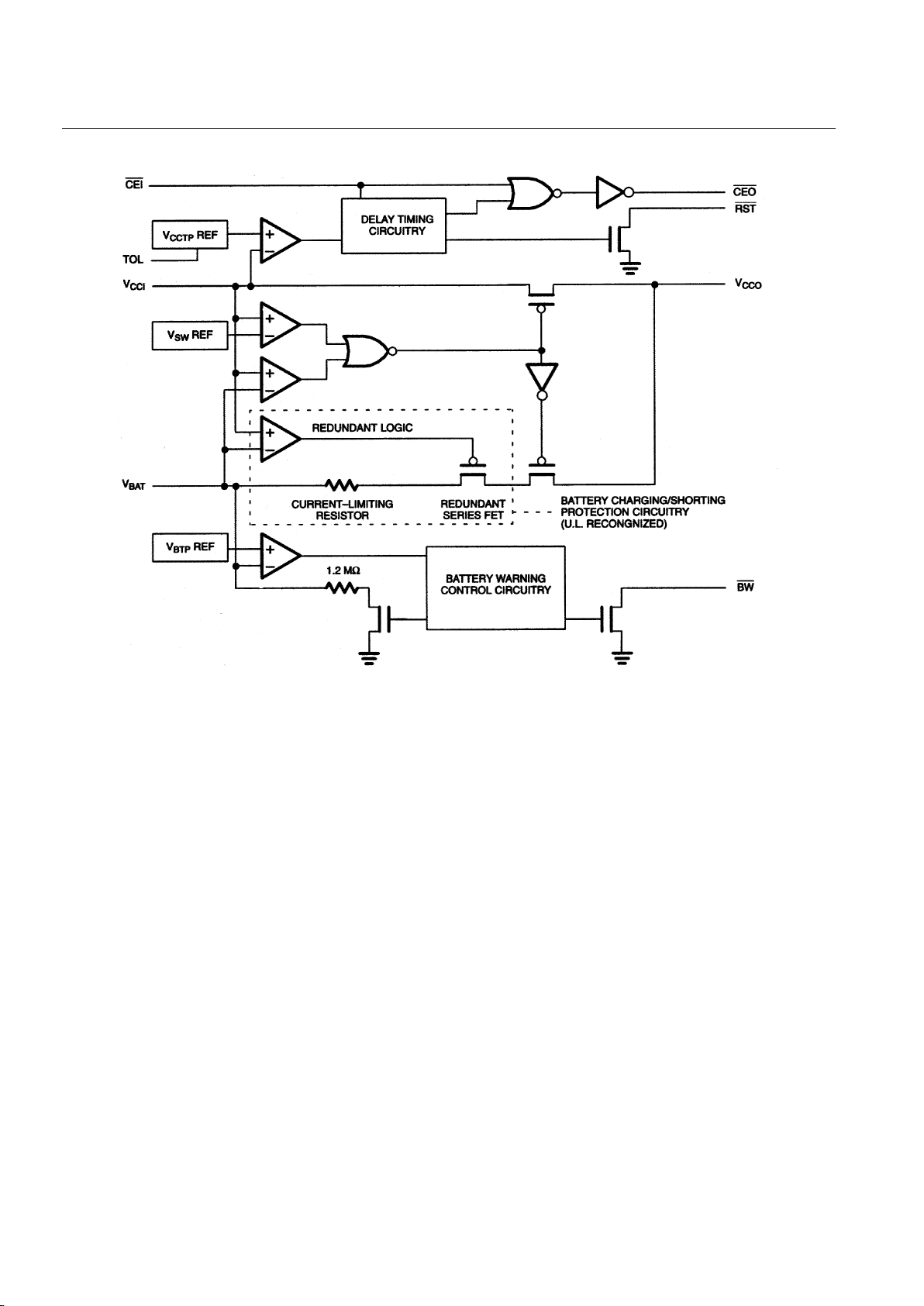

FUNCTIONAL BLOCK DIAGRAM Figure 1

Loading...

Loading...