Page 1

INSTRUCTION BOOK FOR

Tensioned Executive Electrol

Page 2

Important Safety Instructions

Pre-Installation

When using your video equipment, basic safety precautions should

always be followed, including the following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled, or

contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating at

least equal to that of the appliance should be used. Cords rated

for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this

appliance. Contact an authorized service dealer when repair

work is required. Incorrect reassembly can cause electric shock

when the appliance is used subsequently.

5. The use of an accessory attachment not recommended by

the manufacturer may cause a risk of ire, electric shock, or

injury to persons.

Save These Instructions

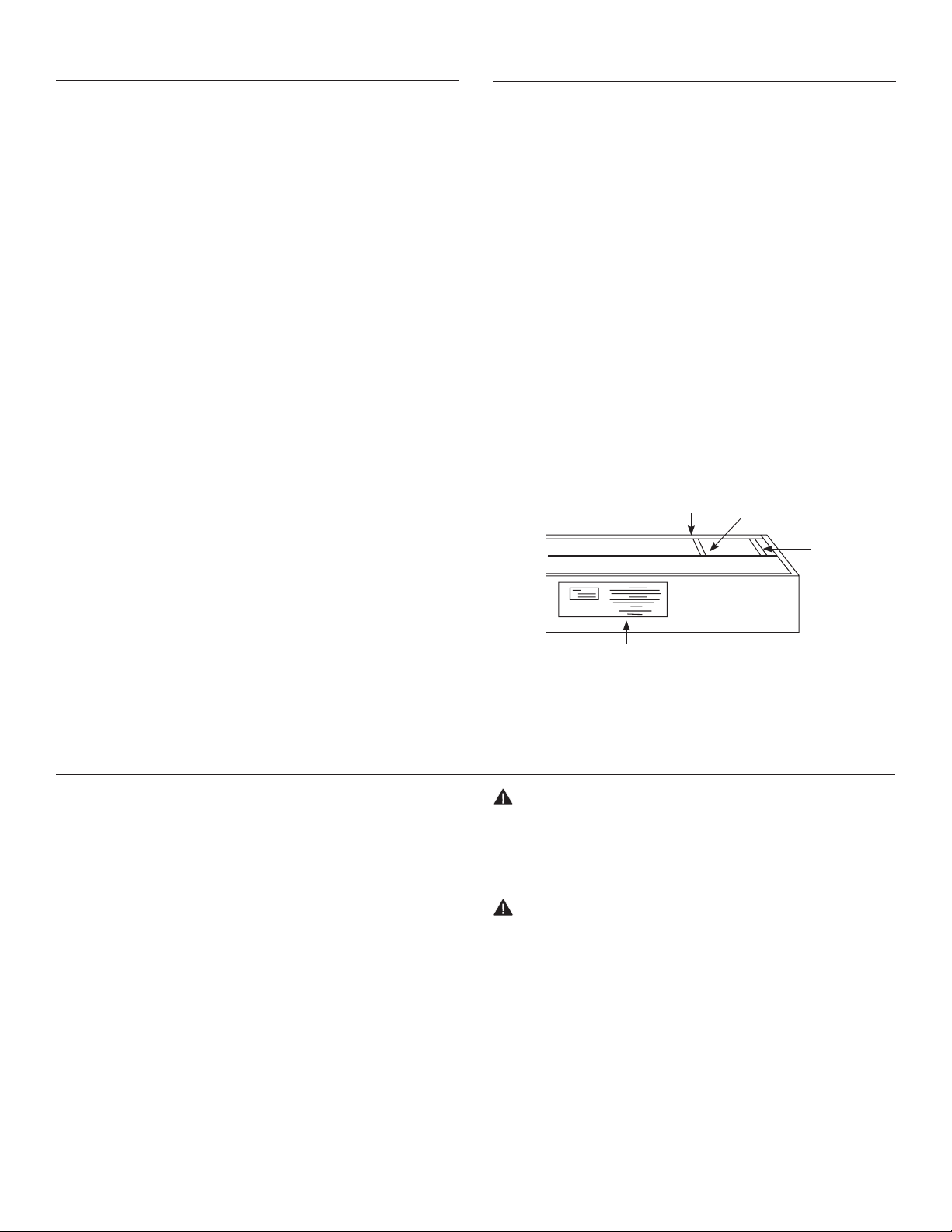

1. Carefully unpack screen and remove outer wrapping

from case.

2. Remove instructions cover and please read

instructions. (Fig. 1)

3. Remove fabric and cardboard strips from access

door. (Fig. 1)

4. Remove access door by gently prying from edge of box

toward the fabric door.

5. FOR TYPE 3 INSTALLATION ONLY. Remove wood strips along

bottom of screen case.

NOTE: Screen surface is not centered in box. Screen surface

is 25" from motor end.

6. Make sure to recheck measurements of screen location

before installation.

7. Remove, reverse, and remount center support brackets.

Case

Access Door

Fabric Door

Fabric

Strip

Cardboard

Strip

Installation

1. Position screen under mounting location with the case

opening down.

2. Install screen by raising unit into position between joists at

one end only. Install one lag screw in each mounting bracket.

Secure opposite end. Support center of the screen using the

brackets.

3. Level unit lengthwise with a carpenter’s level and

a plum level.

Instruction Cover

Figure 1

CAUTION! Do not secure access door or seal in unit

until screen has been secured in position and properly

tested for satisfactory operation. Do not it unit so tightly

that the screen surface drop door binds. Door drops by

gravity only.

ATTENTION! Ne ixez pas la trappe d'accès ou ne scellez

pas l'unité jusqu'à ce qu'il ait été correctement mis en

place et qu'il fonctionne convenablement. Ne serrez pas

l'unité au point que la surface de la trappe d'accès de

l'écran soit bloquée. La trappe tombe uniquement à cause

de la gravité.

2

Page 3

Installation (Continued)

4. If you are going to cover screen door with paneling or other

materials, allow access (suitable holes or a plug) to screws

for servicing.

5. Use supplied 1/8” nex key and a 7/16” wrench to remove silver

shipping brackets attached to slat and screen case.

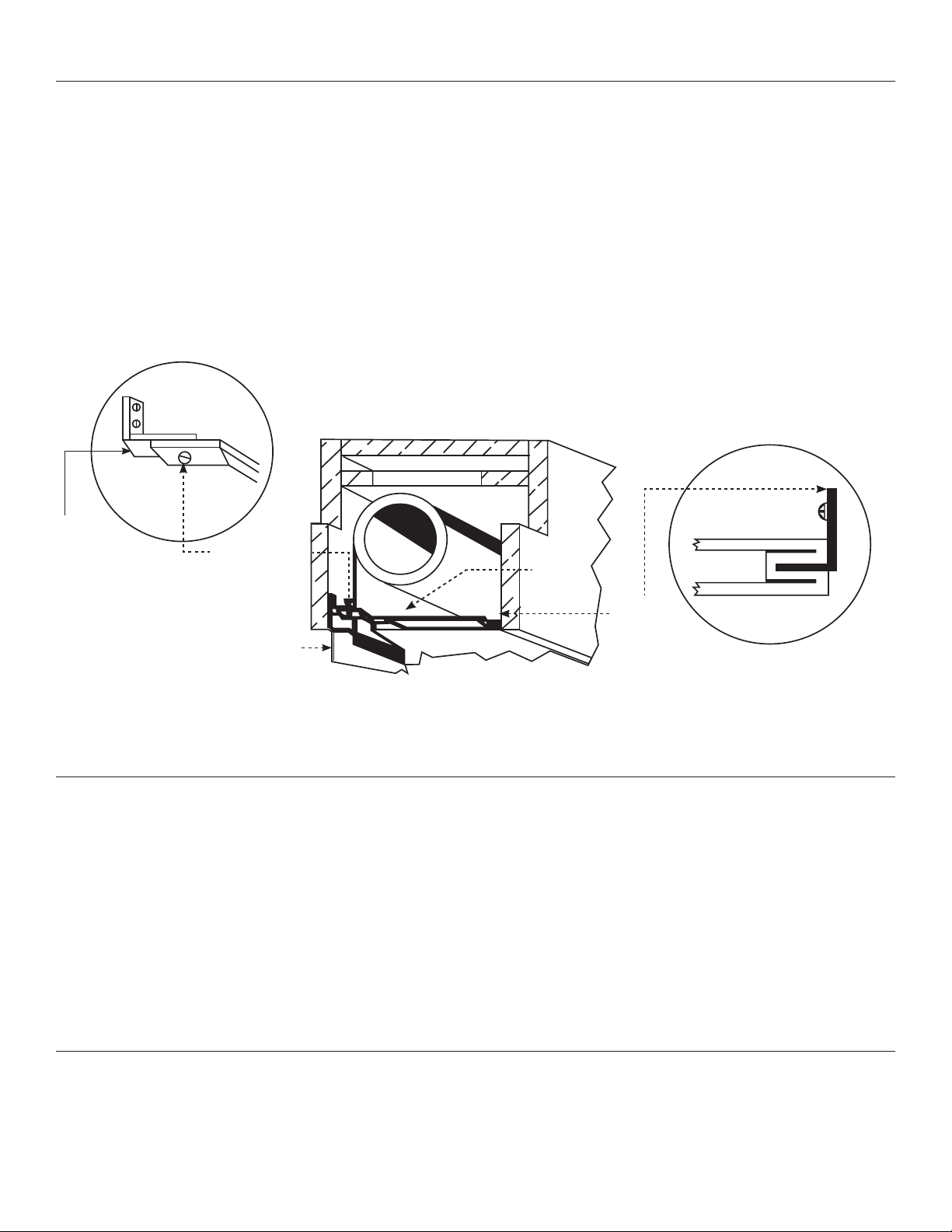

6. Picture surface should hang freely. (Fig. 2) Remove any tape

left hanging on back of fabric. Bottom edge should be

positioned between bottom edge of case and center of roller.

7. Install electrical hook up that applies to your unit. Unit should

be installed by a qualiied electrician.

False Top

Bumper

Bracket

Access Panel

Screw (Painted)

Fabric Door

Access Panel

NOTE: Must be installed in accordance with the requirements

of the Local Building Codes, the Canadian Electrical Code

(CEC), CAN/CSA C22.1 and the National Electric Code (NEC),

NFPA 70.

8. Test installation by carefully running picture surface “up” and

“down” several times. Be prepared to stop screen. Fabric door

must open freely to 90˚.

9. Make sure picture surface, when rolled down, has a full wrap

around roller. No part of roller should be exposed. Fabric door

and picture surface will drop simultaneously when switch is

pressed “down”. Door will close simultaneously with picture

surface as picture surface rolls into case.

Cross Section

Picture

Surface

Access

Panel Clip

Figure 2

Access Door Installation

1. Press switch “down” so that fabric door opens (Fig. 2).

2. Remove screws (2) located on each bumper bracket.

NOTE: The access door is slotted on one edge, permitting the

slotted section to it over the access panel clips on inside of

case.

3. Place access panel so slot can be pushed over clips.

Holes in access panel brackets should align with bumper

bracket holes.

4. Replace screws.

5. Make sure there is approximately 3⁄16" clearance around

access door. Keep paint, plaster, tile or mastic out of hinge.

Fit access panel so it can be removed for maintenance.

Screen Adjustment

The picture surface drop, and the opening and closing of the fabric door, are controlled automatically by limit switches which have been

preset at Da-Lite. When the picture surface is moving upward, it is controlled by a limit switch that shuts of when the door closes. The height

for tensioned screens are adjusted at Da-Lite, changing the height of screen will change the tension on fabric and cause the screen to hang

improperly. Do not adjust.

3

Page 4

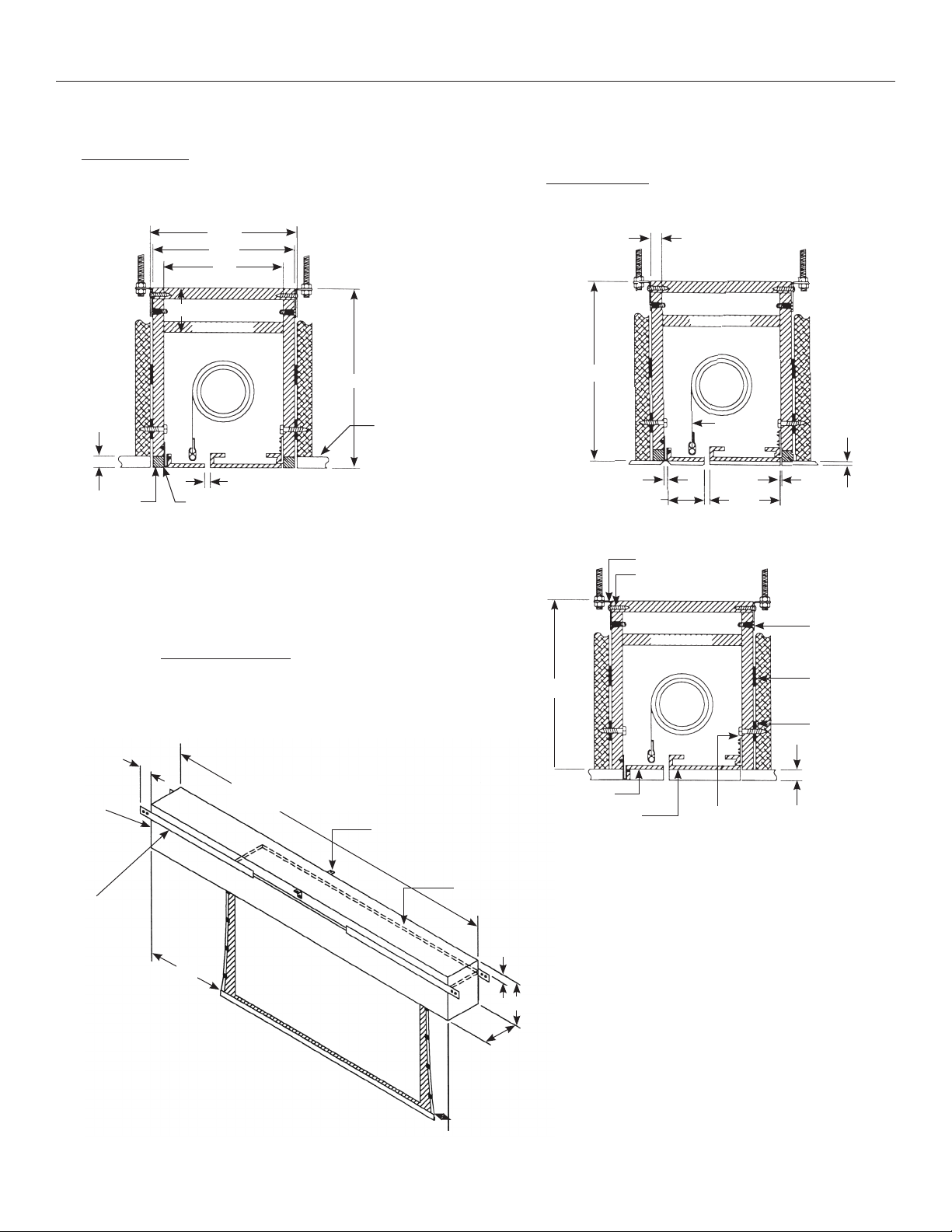

Tensioned Executive Electrol® Installation

Suggested Methods of Installation

Type 1 & 2

Ofset mounting, recessed above ceiling, for plaster,

dry wall or paneling. Door painted same inish as ceiling.

Including Mounting Brackets

9 ⅞"

9 ½"

8"

3"

False Top

12 ⁄"

¾"

Ceiling

Tile

Filler

Block

⅜" Approx.

NOTE: Paint the same as doors

and ceiling or remove and

replace with ceiling tile.

Type 1 & 2

Allow ⅛" min. clearance all around surface door.

Flush mounting, recessed above ceiling. For use

with ¼" max. paneling or installation in existing ceiling

using molding around door.

¾"

False Top

12 ⁄"

¼"

2 ½"

Picture

Surface

4 ¾"

¼" Max.

⅛"

“L” Bracket

Drywall Screw

Electrical

Outlet

Mounting

Brackets

⁄" Thick

3 ½"

Type 3

Allow ¼" min. clearance all around surface door.

Extended mounting, recessed above ceiling. For

use with acoustical or other ceiling tile ¾" thick laid

over door.

Length Of Fabric Width

+ 28 ¾", All Sizes

“L” Bracket

False Top

22"

9 ½"

2 ⁄"

12 ⁄"

11 ⁄"

Surface Door

Access Door

False Top

Lag Screw

¼" x 2"

¼" x 1" Screw

& Nut Insert

Mounting

Brackets

SHIM

3

⁄4"

4 ½"

4

Page 5

Tensioned Executive Electrol® Installation

120V Wiring Diagram

Black

Down Limit Switch

Capacitor

Black

Black

Internal

Wiring

External Wiring

to Be Completed

By Installer

Black

Up

Of

Down

Side View Of

Switch & Box

Black (Down)

White (Common)

White

Black

Blue

Red (Up)

White

Black

(Down)

Red

Green

Red (Up)

(Ground)

Red

Black With Yellow

AC Common

AC Hot

120VAC 60Hz.

1 Amp. Max

Door Solenoid Limit Switch

Down

Adj.

Blue

White

Up Limit Switch

(Operated By Door)

Junction Box Mounted In

Screen Case, In Which Internal

Wiring Terminates In

White, Black And Red Leads

In Multiple Control Installations This Switch

Operating Switch,

Switch Box, And

Plate Furnished

With Screen. (SPDT)

With Center Of

Is Replaced By The Low Voltage Control,

Operated From Push-Button Stations.

Motor: 120V.60 Cycles 1/10 HP Intermittent

Duty With Auto-Reset Thermal Protector

Solenoid

This Switch Cannot Be Used With L.V.C.

240 Volt Wiring Diagram

For Standard Wall Switch:

Da-Lite ofers two styles of 240 volt wall

switches for standard operation. Please see

wiring diagram included in wall switch box

included with screen.

5

Page 6

Troubleshooting

Visit www.da-lite.com to ind installation

and troubleshooting tutorials. You will also ind a link to

Live Chat for interactive support and you can contact us

by email at info@da-lite.com or by phone at (800) 6223737 or

(574) 2678101 with any troubleshooting questions.

Symptom Cause Solution

Blown fuse. Replace fuse.

Tripped circuit breaker. Reset circuit breaker.

Tighten all loose wire connections. Correct any improper

connections. Check for power.

“Down” Position

Screen will not operate or will

not go “down”.

Motor does not hum.

Improper wiring to operating switch.

Improper wiring to junction box in screen.

NOTE: Use low voltage control (LVC) electrical

checklist for either 1- or 3- button control.

Defective wall switch.

Defective LVC unit.

Check for power across black and white leads.

“Up” Position

Check for power across red and white leads.

“Down” Position

Check for power at black and white leads.

“Up” Position

Check for power at red and white leads.

Shut power “o” at breaker. Remove wall switch and

check for broken or loose connection. Replace if

defective.

Check LVC electrical checklist.

Motor hums.

Thermal overload tripped (excessive

overheating).

Burned out motor winding.

Defective limit switch.

Temporary fabric binding. With power “o,” turn roller by hand to free binding.

Shipping bracket not removed. Remove shipping bracket and wooden wedge.

Defective capacitor. Replace capacitor.

Let motor cool down for 15 minutes. Try again.

Disconnect motor leads and check for continuity

between black and white wires for “down” position.

Check for continuity between red and white wires for

“up” position. Replace gear motor if either combination

shows an open circuit.

Disconnect “down” limit switch from circuit. Check for

continuity. Switches are normally closed and open on

contact. Replace if defective.

6

Page 7

Troubleshooting

Symptom Cause Solution

Screen will not move “up.”

Motor does not hum.

Motor hums.

Screen starts upward and door closes

immediately shutting o motor.

No power between red and white leads in

junction box.

Check LVC. See above.

Thermal overload tripped (acts as a breaker). Let motor cool for 15 minutes. Try again.

Burned out motor winding.

Temporary fabric binding. With power “o,” turn roller by hand to free binding.

Burned out capacitor. Replace capacitor.

Broken wire or loose connection in “up”

position (red and white leads).

Defective solenoid limit switch.

Solenoid pin not retracting.

Defective solenoid.

Check fuse. Reset circuit breaker.

Correct improper wiring.

Check for power between red and white motor leads.

Replace motor if there is power.

Secure connection or replace wire.

Manually retract pin a few times.

Check for power to the solenoid terminals. If there is

power, replace solenoid.

Check blue wire between solenoid switch and solenoid.

It is either crimped or broken. Repair or replace.

Door binding. Plaster, paint or adhesive can

Fabric door does not fully open.

Screen runs.

NOTE: Remember, door must

open by gravity.

Clicking noise in each downward

revolution.

Loud buzzing noise. Solenoid not fully retracting.

Door closes on fabric, leaving 15" to

20" left hanging out.

cause the hinge to stick.

Case may be put into a bind during installation. Tighten or loosen lag screws located on back of case.

Inadequate clearance around the fabric door

on new installations.

Non-energized solenoid.

NOTE: There should be three clicks.

Lost roller wrap. See installation instructions.

Clean hinge and apply oil.

Provide adequate clearance.

Check for power to solenoid.

Replace solenoid.

Check for foreign object caught in solenoid. Remove

object. Tighten 4 mounting screws.

Check for pin binding.

7

Page 8

Troubleshooting

Symptom Cause Solution

Screen jammed. Will not operate,

motor hums, door open, closing

mechanism detached from door.

Scraping or grinding noise.

Gear noise. Gear may need light weight grease. Apply light weight grease.

Incorrect down limit switch setting.

Door closes and screen

continues to run upward.

Closing mechanism detached from door,

allowing it to jam into box.

If metal shipping bracket is left attached

to screen, it may be rubbing on motor

end of roller.

Lost roller wrap. See installation instructions.

Limit switch out of adjustment. See door closure and timing instructions.

Door limit out of adjustment.

Door limit switch is shorted. Repair short or replace limit switch.

After securing fabric to roller, loosen set screws on

motor gear and manually rotate solenoid assembly back

over top of roller into position, then reattach door. Match

lats on motor drive shaft to gear set screws and tighten.

Remove shipping brace.

Loosen nut holding limit switch.

Rotate adjusting position, then secure.

8

Page 9

91011

Page 10

Page 11

Page 12

LIMITED ONE YEAR WARRANTY ON DALITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DALITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DALITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL–0266 (Rev. 2) 10.14

© 2014 Milestone AV Technologies LLC. Printed in U.S.A.

76359

Loading...

Loading...