Page 1

The Da-Lite Difference.

Instruction Book for

TENSIONED EXECUTIVE ELECTROL®

DA-LITE SCREEN COMPANY, INC.

3100 North Detroit Street

Post Office Box 137

Warsaw, Indiana 46581-0137

Phone: 574-267-8101

800-622-3737

Fax: 574-267-7804

www.da-lite.com

e-mail: info@da-lite.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using your video equipment, basic safety precautions should always be followed, including the following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating at least equal to that of the

appliance should be used. Cords rated for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this appliance. Contact an authorized service dealer when repair work is required. Incorrect reassembly can cause electric

shock when the appliance is used subsequently.

5. The use of an accessory attachment not recommended by the manufacturer may cause a

risk of fire, electric shock, or injury to persons.

SAVE THESE INSTRUCTIONS

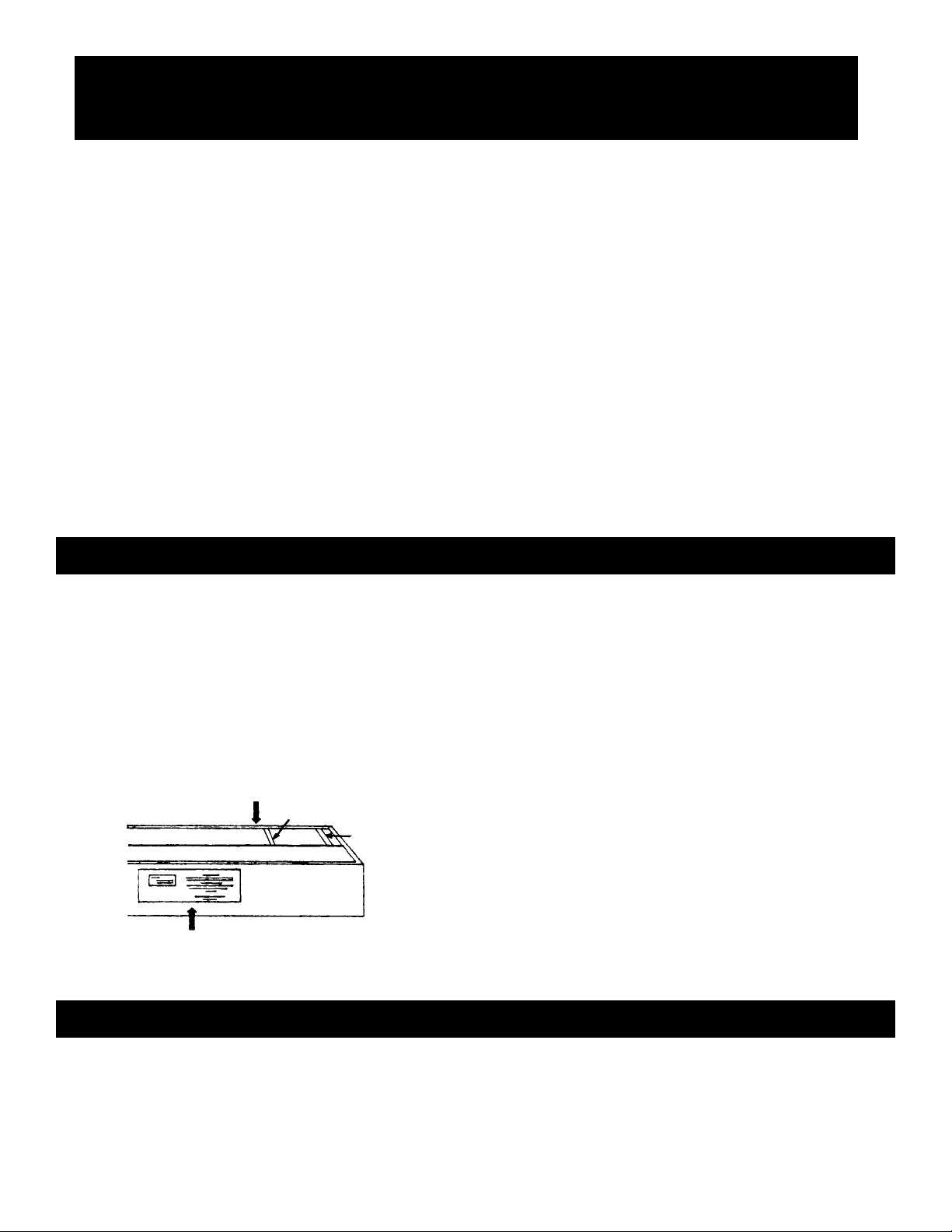

PRE-INSTALLATION

1. Carefully unpack screen and remove outer wrapping from case.

2. Remove instructions cover and please read instructions. (Fig. 1)

3. Remove fabric and cardboard strips from access door. (Fig. 1)

4. Remove access door by gently prying from edge of box toward the fabric door.

5. FOR TYPE 3 INSTALLATION ONLY. Remove wood strips along bottom of screen case.

NOTE: Screen surface is not centered in box. Screen surface is 25" from motor end.

6. Make sure to recheck measurements of screen location before installation.

7. Remove, reverse, and remount center support brackets.

CASE

FABRIC

STRIP

ACCESS DOOR

FABRIC DOOR

INSTRUCTION COVER

FIGURE 1

CARDBOARD

STRIP

INSTALLATION

1. Position screen under mounting location with the case opening down.

2. Install screen by raising unit into position between joists at one end only. Install one lag screw in each mounting

bracket. Secure opposite end. Support center of the screen using the brackets.

3. Level unit lengthwise with a carpenter’s level and a plum level.

CAUTION! Do not secure access door or seal in unit until screen has been secured in position and properly tested for satisfac-

!

tory operation. Do not fit unit so tightly that the screen surface drop door binds. Door drops by gravity only.

s

1

Page 3

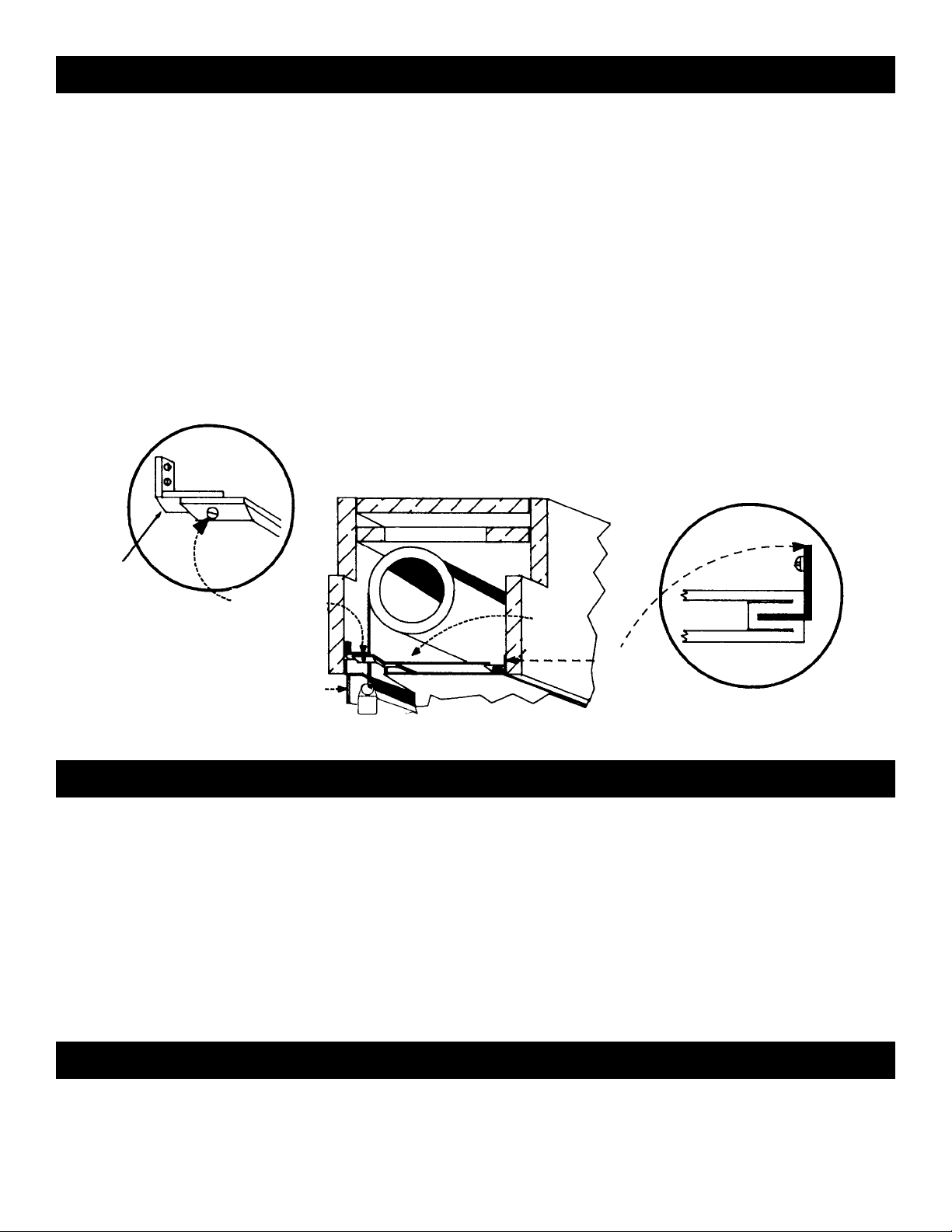

INSTALLATION

4. If you are going to cover screen door with paneling or other materials, allow access (suitable holes or a plug) to

screws for servicing.

5. Picture surface should hang freely. (Fig. 2) Remove any tape left hanging on back of fabric. Bottom edge should be

positioned between bottom edge of case and center of roller.

6. Install electrical hook up that applies to your unit. Unit should be wired by a qualified electrician.

7. Test installation by carefully running picture surface “up” and “down” several times. Be prepared to stop screen.

Fabric door must open freely to 90˚.

8. Make sure picture surface, when rolled down, has a full wrap around roller. No part of roller should be exposed.

Fabric door and picture surface will drop simultaneously when switch is pressed “down”. Door will close simultaneously with picture surface as picture surface rolls into case.

CROSS SECTION

FALSE TOP

BUMPER

BRACKET

ACCESS PANEL SCREW

(PAINTED)

FABRIC DOOR

ACCESS PANEL

PICTURE

SURFACE

ACCESS

PANEL CLIP

FIGURE 2

ACCESS DOOR INSTALLATION

1. Press switch “down” so that fabric door opens (Fig. 2).

2. Remove screws (2) located on each bumper bracket.

NOTE: The access door is slotted on one edge, permitting the slotted section to fit over the access panel clips on inside of case.

3. Place access panel so slot can be pushed over clips. Holes in access panel brackets should align with bumper

bracket holes.

4. Replace screws.

5. Make sure there is approximately 3⁄16" clearance around access door. Keep paint, plaster, tile or mastic out of hinge.

Fit access panel so it can be removed for maintenance.

SCREEN ADJUSTMENT

The picture surface drop, and the opening and closing of the fabric door, are controlled automatically by limit switches

which have been preset at Da-Lite. When the picture surface is moving upward, it is controlled by a limit switch that shuts

off when the door closes. The height for tensioned screens are adjusted at Da-Lite, changing the height of screen will

change the tension on fabric and cause the screen to hang improperly. Do not adjust.

2

Page 4

TENSIONED EXECUTIVE ELECTROL® INSTALLATION

SUGGESTED METHODS OF INSTALLATION

Offset mounting, recessed above ceiling, for plaster,

TYPE 1 & 2

dry wall or paneling. Door painted same finish as ceiling.

INCLUDING MOUNTING BRACKETS

7

9

⁄8"

1

⁄2"

9

8"

3"

FALSE TOP

12 1⁄16"

3

⁄4"

FILLER

BLOCK

3

⁄8" APPROX.

NOTE: Paint the same as doors

and ceiling or remove and

replace with ceiling tile.

CEILING

TILE

TYPE 1 & 2

Allow 1⁄8" min. clearance all around surface door.

Flush mounting, recessed above ceiling. For use

1

⁄4" max. paneling or installation in existing ceil-

with

ing using molding around door.

3

⁄4"

FALSE TOP

1

12

⁄16"

PICTURE

SURFACE

1

⁄4"

1

2

⁄2"

“L” BRACKET

DRYWALL SCREW

4

3

⁄4"

1

⁄4" MAX.

1

⁄8"

3 1⁄2"

ELECTRICAL

OUTLET

MOUNTING

BRACKETS

3

⁄16" THICK

TYPE 3

Allow 1⁄4" min. clearance all around surface door.

Extended mounting, recessed above ceiling. For

use with acoustical or other ceiling tile 3⁄4" thick laid

over door.

LENGTH OF FABRIC WIDTH

22"

+ 28

3

⁄4", ALL SIZES

“L” BRACKET

FALSE TOP

9

11

SURFACE DOOR

ACCESS DOOR

3

⁄16"

2

1

⁄16"

12

1

⁄2"

1

FALSE TOP

5

⁄16"

⁄4" x 1" SCREW

& NUT INSERT

MOUNTING

BRACKETS

SHIM

3

1

⁄4" x 2"

⁄4"

LAG SCREW

1

4

⁄2"

3

Page 5

TENSIONED EXECUTIVE ELECTROL® INSTALLATION

120V WIRING DIAGRAM

INTERNAL

WIRING

EXTERNAL WIRING

TO BE COMPLETED

BY INSTALLER

CAPACITOR

BLACK

BLACK

UP

OFF

DOWN

BLACK (DOWN)

BLACK

BLACK

SIDE VIEW OF

SWITCH & BOX

BLACK

BLUE

RED (UP)

WHITE

BLACK

(DOWN)

RED

WHITE (COMMON)

WHITE

GREEN

RED (UP)

(GROUND)

RED

BLACK WITH YELLOW

AC COMMON

AC HOT

120VAC 60HZ.

1 AMP. MAX

OPERATING SWITCH, SWITCH BOX,

AND PLATE FURNISHED WITH

SCREEN. (SPDT) WITH CENTER OFF)

THIS SWITCH CANNOT BE USED WITH L.V.C.

DOWN LIMIT SWITCH

DOOR SOLENOID LIMIT SWITCH

MOTOR: 120V.60 CYCLES

DOWN

ADJ.

BLUE

WHITE

JUNCTION BOX, MOUNTED IN

SCREEN CASE, IN WHICH INTERNAL

WIRING TERMINATES IN WHITE,

BLACK AND RED LEADS

1/10 HP INTERMITTENT DUTY WITH

AUTO-RESET THERMAL PROTECTOR

SOLENOID

UP LIMIT SWITCH

(OPERATED BY DOOR)

IN MULTIPLE CONTROL INSTALLATIONS THIS

SWITCH IS REPLACED BY THE LOW-VOLTAGE

CONTROL, OPERATED FROM PUSH-BUTTON

STATIONS.

240 VOLT WIRING DIAGRAM

FOR STANDARD WALL SWITCH:

Da-Lite offers two styles of 240 volt wall

switches for standard operation. Please

see wiring diagram included in wall

switch box included with screen.

4

Page 6

TROUBLESHOOTING

SYMPTOM

1. Screen will not operate or will not

go “down”.

Motor does not hum.

CAUSE

(a) Blown fuse.

(b) Tripped circuit breaker.

(c) Improper wiring to operating

switch.

(d) Improper wiring to junction box in

screen.

NOTE: Use low voltage control (LVC)

electrical checklist for either 1- or 3 button control.

Defective wall switch.

Defective LVC unit.

(e) Thermal overload tripped (exces-

sive overheating).

(f) Burned out motor winding.

(g) Defective limit switch.

SOLUTION

(a) Replace fuse.

(b) Reset circuit breaker.

(c) Tighten all loose wire connec-

tions. Correct any improper connections. Check for power.

“Down” Position

Check for power across black and

white leads.

“Up” Position

Check for power across red and

white leads.

(d) “Down” Position

Check for power at black and

white leads.

“Up” Position

Check for power at red and

white leads.

Shut power “off” at breaker.

Remove wall switch and check

for broken or loose connection.

Replace if defective.

Check LVC electrical checklist.

(e) Let motor cool down for 15 min-

utes. Try again.

(f) Disconnect motor leads and

check for continuity between

black and white wires for “down”

position. Check for continuity between red and white wires for

“up” position. Replace gear motor

if either combination shows an

open circuit.

(g) Disconnect “down” limit switch

from circuit. Check for continuity.

Switches are normally closed and

open on contact. Replace if defective.

2. Motor hums.

(a) Temporary fabric binding.

(b) Shipping bracket not removed.

(c) Defective capacitor.

5

(a) With power “off,” turn roller by

hand to free binding.

(b) Remove shipping bracket and

wooden wedge.

(c) Replace capacitor

Page 7

TROUBLESHOOTING

SYMPTOM

3. Screen will not move “up.”

Motor does not hum.

Motor hums.

4. Screen starts upward and door

closes immediately shutting off

motor.

CAUSE

(a) No power between red and white

leads in junction box.

Check LVC. See above.

(b) Thermal overload tripped (acts as

a breaker).

(c) Burned out motor winding.

(d) Temporary fabric binding.

(e) Burned out capacitor.

(f) Broken wire or loose connection

in “up” position (red and white

leads).

(a) Defective solenoid limit switch.

Solenoid pin not retracting.

(b) Defective solenoid.

SOLUTION

(a) Check fuse. Reset circuit breaker.

Correct improper wiring.

(b) Let motor cool for 15 minutes. Try

again.

(c) Check for power between red

and white motor leads. Replace

motor if there is power.

(d) With power “off,” turn roller by

hand to free binding.

(e) Replace capacitor.

(f) Secure connection or replace

wire.

(a) Manually retract pin a few times.

(b) Check for power to the solenoid

terminals. If there is power, replace solenoid.

Check blue wire between sole-

noid switch and solenoid. It is

either crimped or broken. Repair

or replace.

5. Fabric door does not fully open.

Screen runs.

NOTE: Remember, door must open by

gravity.

6. Clicking noise in each downward

revolution.

7. Loud buzzing noise. (a) Solenoid not fully retracting. (a) Check for foreign object caught in

8. Door closes on fabric, leaving 15"

to 20" left hanging out.

(a) Door binding. Plaster, paint or ad-

hesive can cause the hinge to

stick.

(b) Case may be put into a bind dur-

ing installation.

(c) Inadequate clearance around the

fabric door on new installations.

(a) Non-energized solenoid.

NOTE: There should be three clicks.

(a) Lost roller wrap. (a) See installation instructions.

(a) Clean hinge and apply oil.

(b) Tighten or loosen lag screws

located on back of case.

(c) Provide adequate clearance.

(a) Check for power to solenoid.

(b) Replace solenoid.

solenoid. Remove object. Tighten

4 mounting screws.

Check for pin binding.

6

Page 8

TROUBLESHOOTING

SYMPTOM

9. Screen jammed. Will not operate,

motor hums, door open, closing

mechanism detached from door.

CAUSE

(a) Closing mechanism detached

from door, allowing it to jam into

box.

10. Scraping or grinding noise. (a) If metal shipping bracket is left at-

tached to screen, it may be rubbing on motor end of roller.

11. Gear noise. (a) Gear may need light weight

grease.

12. Incorrect down limit switch

setting.

13. Door closes and screen contin-

(a) Lost roller wrap.

(b) Limit switch out of adjustment.

(a) Door limit out of adjustment.

ues to run upward.

(b) Door limit switch is shorted.

SOLUTION

(a) After securing fabric to roller,

loosen set screws on motor gear

and manually rotate solenoid

assembly back over top of roller

into position, then reattach door.

Match flats on motor drive shaft

to gear set screws and tighten.

(a) Remove shipping brace.

(a) Apply light weight grease.

(a) See installation instructions.

(b) See door closure and timing

instructions.

(a) Loosen nut holding limit switch.

Rotate adjusting position, then

secure.

(b) Repair short or replace limit

switch.

Printed in U.S.A. 76359 Rev. 9/09

7

Loading...

Loading...