Page 1

INSTRUCTION BOOK FOR

Multi-Mask Imager

Page 2

Important Safety

When using your video equipment, basic safety precautions should always be followed, including the following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled,

or contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating

at least equal to that of the appliance should be used. Cords

rated for less amperage than the appliance may overheat.

Save These Instructions

4. To reduce the risk of electric shock, do not disassemble this

appliance. Contact an authorized service dealer when repair

work is required. Incorrect reassembly can cause electric

shock when the appliance is used subsequently.

5. The use of an accessory attachment not recommended

by the manufacturer may cause a risk of ire, electric shock,

or injury to persons.

Mounting The Frame

Professional mounting techniques should be adhered to. Da-Lite Screen Company cannot be liable for substandard

or faulty installations.

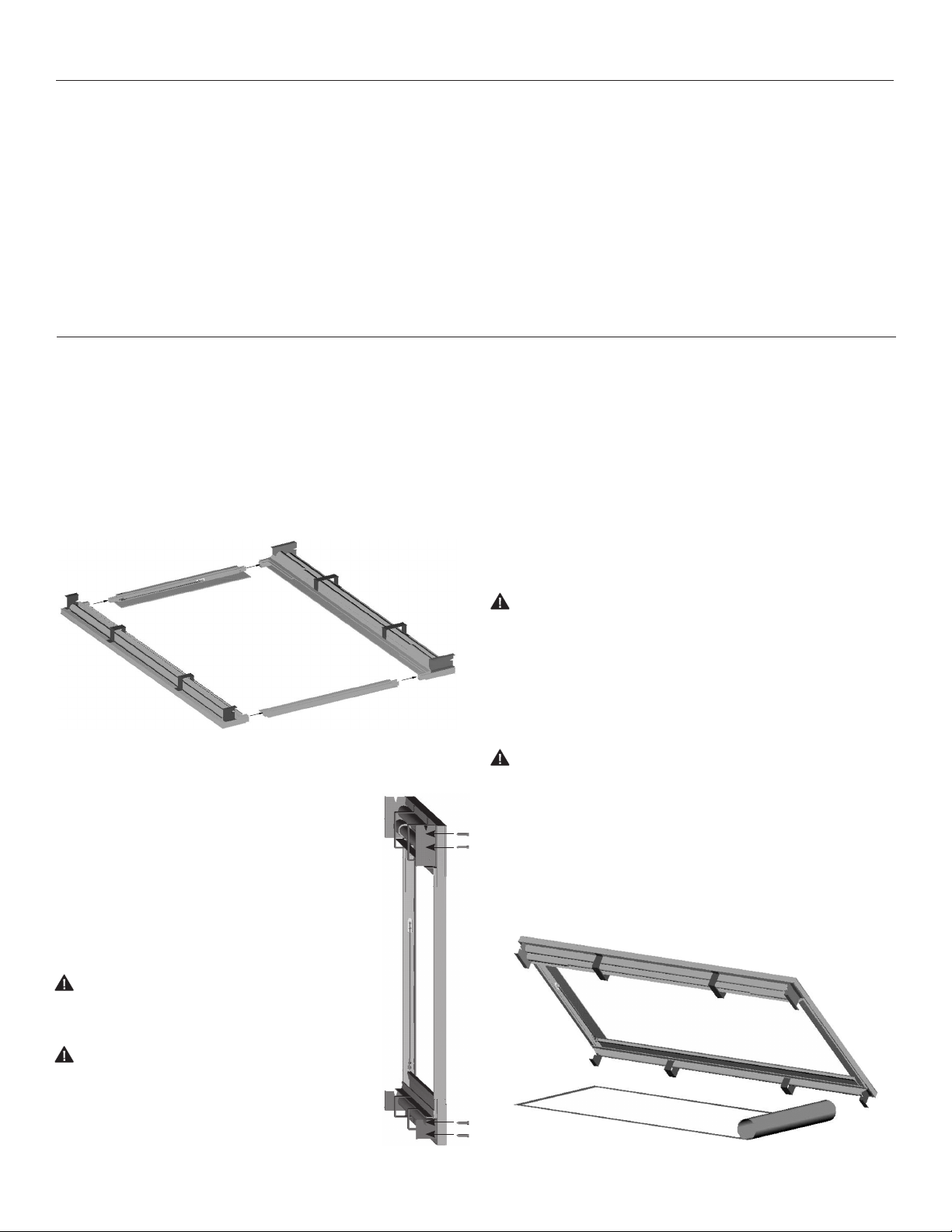

Frame Assembly

Assembly of the screen should be in a clean environment.

1. Connect the four frame pieces by matching the colored

tapes on the ends of the frame pieces. See Figure 1.

2. Secure with the supplied 5/16" setscrews.

Unpacking and Unrolling the Screen

The viewing side of the screen surface is rolled to the inside.

The screen surface is rolled lengthwise.

1. Remove screen from packaging.

2. On a clean loor, unroll the screen surface viewing side up.

3. Allow the paper to unroll between backside of the screen

surface and loor. See Figure 3.

Figure 1

Positioning the Frame on the Wall

1. Without the screen fabric attached, position the

frame on the wall at the location you desired.

2. Make sure the unit is level and plumb. (You may

need to use shims between the brackets and the

wall to achieve vertical plumb.)

3. Mark the position of the bracket holes on the

wall. See Figure 2.

CAUTION: If the screen is not mounted so that

it is level and plumb, horizontal masking may

jam on retraction.

CAUTION:

• Be careful not to touch or scratch the viewing side

of the surface with ingernails and any sharp tools.

• Do not use any tools to fasten the screen surface

to the frame.

• Do not fold or crease the screen.

ATTENTION:

• Prenez soin de ne pas toucher ou rayer la face de

projection de l'écran avec les ongles ou tout autre objet

pointu.

• N'utilisez aucun outil pour attacher la surface de l'écran

au cadre.

• Ne pliez pas ou ne froissez pas l'écran

ATTENTION: Si l'écran n'est pas installé de

sorte qu'il soit droit et plat, le masquage

horizontal risque de se coincer lors de

l'enroulement.

2

Figure 2

Figure 3

Page 3

Mounting The Frame

Electrical Wiring

Attaching the Screen Surface to Frame

1. Place the frame over the screen surface.

2. While lifting the frame with one hand, snap the screen surface

onto the frame. Gently allow the screen to stretch onto snaps.

See Figure 4. Attach the snaps on the top corners and top

horizontal irst, lift the frame to a vertical position to inish

attaching the rest of the snaps.

Figure 4

Tensioning the Bottom Masking Panel

Electrical wiring is required for each mask roller motor. The

vertical masking systems have one motor at the frame top.

Horizontal masking systems have one motor at the frame top

and one at the bottom.

A motor requires standard 120V/220V input. All connections are

made to the electrical box on the audience left side of the unit.

Horizontal

Mask

Connection

Vertical Mask

Connection

Horizontal

Mask

Connection

1. Carefully remove all tape strips securing surfaces around

rollers. Slats should move freely. See Figure 5.

2. Locate the spring tension cables on either side of the unit.

3. Connect the eye snap to the eyelet on the bottom masking

panel bar. See Figure 5. You will need to pull the cable slightly.

4. Repeat for the other side.

Surface

Tape Strip

Eye

Snap

Slat

Spring Tension Cable

Eyelet

Figure 6

Figure 5

Slat

3

Page 4

Multi-Mask Imager Installation

Installing the High Voltage Switch Control (Standard)

Three standard 3-position wall switches are supplied. The high-voltage control is connected to the electrical source.

It alternates directions of mask motion by means of a hot lead, using the 3-position switches.

120V Wiring Diagram

To Motor

Rocker

Switch

Up

Of

Down

Side View

Of Switch

And Box

220 / 240V

Wiring Diagram

Red

Down Red

Up Black

Common

White

White

Black

Black With

Yellow

AC Common

AC Hot

120V. 60HZ 2.5 Max. Amp

This Switch Cannot Be Used With LVC.

NOTE: A single switch cannot be used to operate more than

one screen. Contact the factory for further information.

To Motor

Operating Switch,

Switch Box, And

Plate Furnished

With Screen

(SPDT With

Center Of)

In Multiple Control

Installations This Switch

Is Replaced By The Low

Voltage Control,

Operated From Push

Button Stations.

In Multiple Control

Installations This Switch Is

Black (Down)

Brown (Up)

Up

Of

Rocker

Switch

Down

Rear View Of DPDT,

With Center Of

NOTE: A single switch cannot be used to operate more than

one screen. Contact the factory for further information.

4

Blue (Common)

Brown/Yellow

Brown AC Hot

Blue AC Common

220/240V. AC 50HZ

2 Amp. Max

Blue Jumper Wire

Operating Switch,

Switch Box, And

Plate Furnished

With Screen.

Junction

Box

Replaced By The Low

Voltage Control, Operated

From Push Button Stations.

NOTE:

Must Be Wired To Conform To

Local Wiring Code. This Switch

Cannot Be Used With L.V.C.

Page 5

Hanging The Screen On The Wall

1. Attach the wall brackets to the wall using appropriate

fasteners at previously marked locations.

Side

Side

Cover

2. Attach the Side Covers to the frame by sliding the Bolts on

the Side Cover tube into the openings on the top and bottom

brackets. See Figure 7.

Opening

Figure 7

Operating The Mask Adjusting The Mask Extension

When you lower or retract a mask, it will stop at its present limit.

If an obstacle (such as a person or furniture) gets in the path of a

mask as it is lowered, you should use the switch control to stop

the mask's motion; it will not automatically stop if it hits an

obstacle.

NOTE: The horizontal masking panels move more slowly than

the vertical masking panels. The slower motion allows you to

adjust the image area with greater precision.

When a mask is not in use, you should store it in the fully

retracted position.

CAUTION: Do not operate the motor when any of the

following occurs:

• The unit emits any smoke, heat, abnormal noise

or unusual odor.

• The unit is damaged in some way, such as damage from a

water leak.

• If any of these situations occur, call a qualiied

service person.

ATTENTION: Ne mettez pas le moteur en marche lorsque :

• L'unité émet de la fumée, un bruit anormal, de la chaleur

ou une odeur inhabituelle.

• L'unité est endommagée d'une quelconque façon (ex.

dommage dû à une fuite d'eau).

• Si l'une de ces situations se produisait, appelez un

technicien qualiié.

CAUTION: Improper adjustment of the limit switches

can cause irreparable damage to a mask itself, resulting

in voiding the factory warranty.

ATTENTION: Un réglage inapproprié des interrupteurs de

in de course peut endommager de manière irréversible le

masque et entraîner l'annulation de la garantie.

The extension and retraction limit switches have been preset

at the factory. In general, we advise you to avoid readjusting

these switches.

In some cases, to enable proper alignment of the displayed

image on the screen, you may need to adjust the extension

of a mask. If adjustment to the extension is necessary, carefully

follow these instructions.

WARNING! A mask is fully retracted when the batten

is lush with the bottom of the case. Do not attempt

adjustments with a retraction (UP) limit switch that will

further retract a mask. Incorrect adjustment of that

switch will cause severe mask damage. Please consult the

factory if you have any questions.

AVERTISSEMENT! Un masque est complètement rétracté

lorsque la latte est alignée avec le bas du caisson.

N'essayez pas d'efectuer des réglages avec un

interrupteur de in de course d'enroulement (VERS LE

HAUT) qui causera une rétraction additionnelle d'un

masque. Un réglage incorrect de cet interrupteur peut

endommager sérieusement le masque. Veuillez contacter

l'usine si vous avez des questions.

5

Page 6

Adjusting The Mask Extension (Continued)

Modifying the Extension of the Mask

1. You can increase the extension of a mask up to 3" past the

factory preset stop, or you can decrease the extension by

approximately 46" from the factory preset stop. Do not

attempt to modify a mask extension beyond these

recommended amounts.

2. The limit switches are accessed through openings located on

the left side of the frame as shown in Figure 8.

3. Horizontal mask units have limit switches at the top and

bottom of the screens, a set for each roller tube.

WARNING! The up limit switch(es) retract the batten

further into the unit. Adjusting it is not advised. Refer to 1,

3 or 5 as appropriated in Figure 8.

AVERTISSEMENT! Le(s) interrupteur(s) de in de course

supérieur(s) rétracte(nt) la latte à l'intérieur de l'unité. Le

réglage n'est pas recommandé. Référez-vous au points 1,

3 ou 5 tel qu'indiqué dans la igure 8.

To Increase a Mask's Fully Extended (Mask Down)

Stop Position:

1. Lower the mask to its current stop position.

2. Locate the down limit switch(es) located on the left side of

the frame. Refer to 2, 4 or 6 as appropriate in Figure 8. Use an

Allen wrench to turn the switch in a counterclockwise

direction. If the power is on, the mask will drop incrementally

as the switch is turned. NOTE: One complete turn of the

switch will make approximately a 1/2" change in the mask's

stop position.

1

2

3

4

5

6

Horizontal Mask

Vertical Mask

Screen

Horizontal Mask

Figure 8

Screen Care And Cleaning

With reasonable care, you expect many years of trouble-free use

of your Da-Lite projection screen.

To Decrease the Screen Extension:

1. Lower the mask until it is extended about halfway down.

2. Locate the down limit switch(es) located on the left side of

the frame. Refer to 2, 4 or 6 as appropriate in Figure 8. Use

an Allen wrench to turn the switch in a clockwise direction.

NOTE: One complete turn of the switch will make

approximately a 1/2" change in the mask's stop position.

3. Activate the mask in the down direction until it reaches

the newly reduced stop position. Repeat this procedure

until the desired stop position is reached.

Once you have made the adjustment, whenever you lower

the mask, it will automatically stop at the new position.

6

We encourage you to keep your screen clean. Avoid getting any

foreign material on the screen. It may not be possible to remove

scratches, paint, ink, etc.

General Maintenance

The screen surface on your Multi-Mask Imager is delicate.

Special attention to these instructions should be followed

when cleaning.

• A draftsman-style brush may be used to lightly whisk away

any loose dirt or dust particles. (This type of brush is usually

available at oice supply stores.)

• For tougher spots, use a mild solution detergent, water and a

soft cloth. Rub lightly. Blot with a damp sponge to absorb

excess water.

Do not use any other cleaning materials on the screen.

Replacement Parts and Service

No user-serviceable parts are contained within the unit.

Contact your dealer or the factory if you require part

replacement or service.

Page 7

Troubleshooting

Refer to the following guidelines if you encounter a diiculty in the operation of your Da-Lite Multi-Mask Imager screen.

Problems related to electrical or motor function may require a qualiied service person or electrician.

Should you have a problem that is not addressed here, call Da-Lite customer service.

Symptom Cause Solution

Mask won't operate.

Mask won't roll up or down

(even though power is

available).

Mask roller chatters when

power is activated.

Unit hums in up mode (Mask

has already retracted).

Mask drops when up direction

is activated (grinding noise

occurs).

No 120V/220V power available.

Outboard switching problem.

Bad connection at switch.

Can be caused by voltage drop, bad connections

or a defective switch.

The mask batten is retracting too far into the case.

Failure to correct can damage motor. Do not use

the unit until this problem is resolved.

Drop in voltage.

Check to see if the circuit breaker has switched o.

Reset if needed.

Check outboard switching apparatus. Check voltage

availability. Contact and Electrician..

Have an electrician or qualiied service person check

the connection as follows:

• If you have a high voltage control switch,

check switch line connections.

• If you have a low voltage control unit,

check switch line connections.

Have an electrician or qualiied service person

check all hook-ups including all outboard wiring.

Have a qualiied service person adjust the UP limit switch.

Turn the adjusting screw clockwise.

Mask motor requires full voltage. Have an electrician or

qualiied service person check the available voltage.

Mask continues past bottom

stop position.

Batten retracts too far into

frame.

Dirt, ingerprints, marks, etc. on

screen surface.

Indentations appear on screen

surface.

Horizontal mask jams upon

retraction.

White limit switch is out of adjustment. Re-adjust the Down limit switch. See pp. 67 of this manual.

Yellow limit switch out of adjustment. Failure to

correct can damage motor. Do not use the unit

until this problem is resolved.

Improper handling of screen.

Debris or particles adhering to screen

due to static cling.

The unit was not level and plumb when mounted. Remount the unit making sure that it is level and plumb.

Have a qualiied service person adjust the

UP limit switch. See pp. 67 of this manual.

Brush o or use a mild detergent solution

with clean rag or cotton swab.

Check back of screen: gently brush debris away by hand.

7

Page 8

LIMITED ONE YEAR WARRANTY ON DALITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DALITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DALITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL0287 (Rev. 2) 10.14

© 2014 Milestone AV Technologies LLC. Printed in U.S.A.

94727

Loading...

Loading...