Page 1

INSTRUCTION BOOK FOR

Multi Format Imager

Page 2

Important Safety Instructions

When using your video equipment, basic safety precautions should always be followed, including the following:

1. Read and understand all instructions before using equipment.

2. Close supervision is necessary when any appliance is used by or

near children. Do not leave appliance unattended while in use.

3. Care must be taken as burns can occur from touching hot parts.

4. Do not operate appliance if it has been dropped or damaged

Save These Instructions

until it has been examined by a qualiied service technician.

5. To reduce the risk of electric shock, do not immerse this

appliance in water or other liquids.

6. The use of an accessory attachment not recommended by

the manufacturer may cause risk of ire, electric shock or

injury to persons.

Multi Format Imager Assembly

Preparation: Have ample space for this available on a lat clean surface such as a large table or loor. The work area should be larger

than the frame size. If the loor is used, clean papers should be spread to keep all dirt from the Pro-Trim surfaces.

Tools Required for Assembly: 1/8" Allen Wrench, 5/64" Allen Wrench, Carpenter's Level, Tape Measure, Electric Screw Gun, Utility Knife.

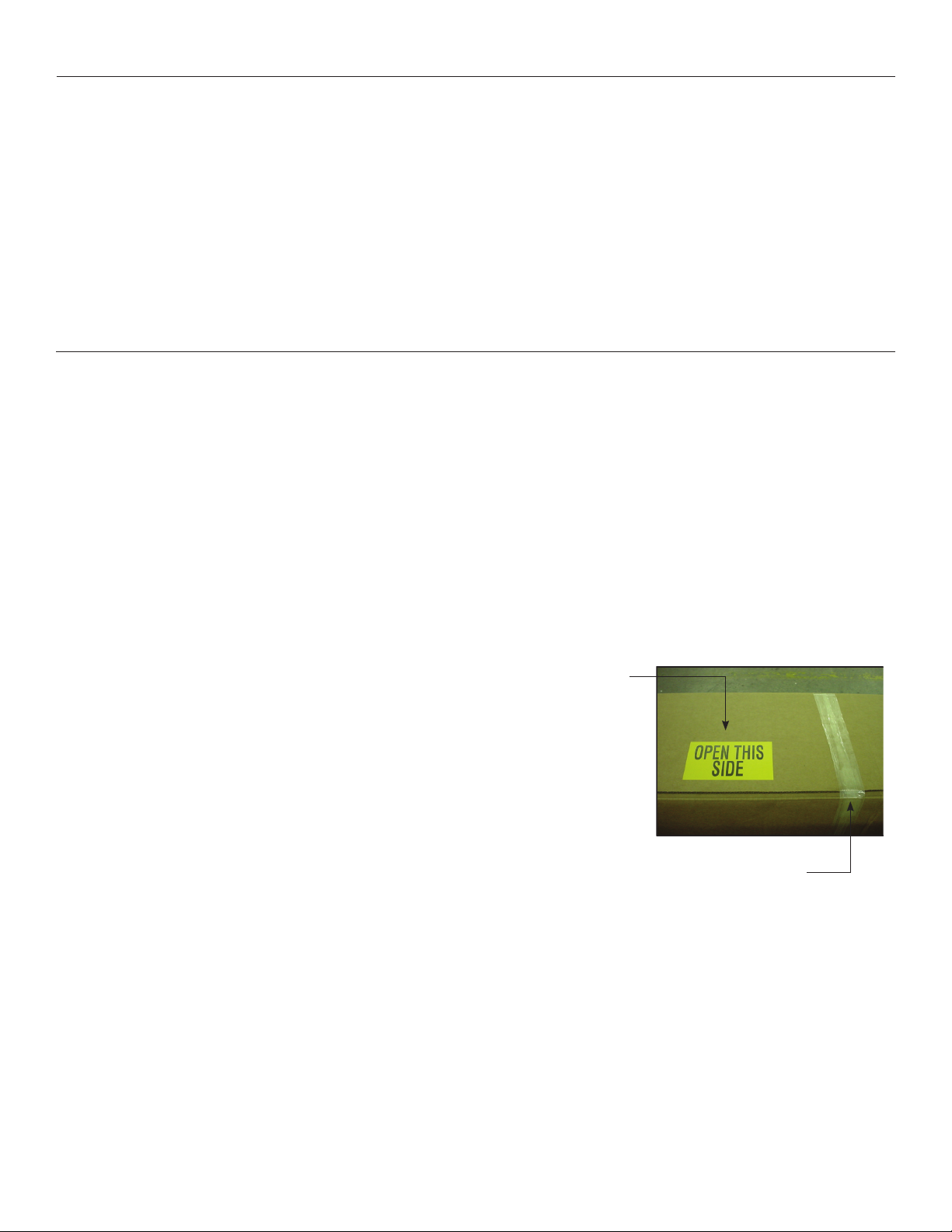

Unpackaging the Frame:

1. The frame will arrive in two separate cardboard boxes. One box

will be very long and will house the top and bottom pieces. The

smaller cardboard box will house the side frame pieces, hanger

hardware, assembly hardware and the wall switch.

2. To open the boxes, there is a side lap that is taped down the

length of the box. It will be labeled "Open This Side". Refer to

picture A. Carefully cut tape down the length of the box with a

utility knife and fold box open. You will have to pull hard as it is

stapled on the ends.

3. Inside each box the frame pieces will be individually paper

wrapped and taped. Remove all paper from pieces. Do not use

a utility knife to remove paper from pieces.

4. Remove all paper and styrofoam blocks from top frame

assembly after unwrapping.

Picture "A"

Open This Side

Cut Tape Here

2

Page 3

Multi Format Imager Assembly

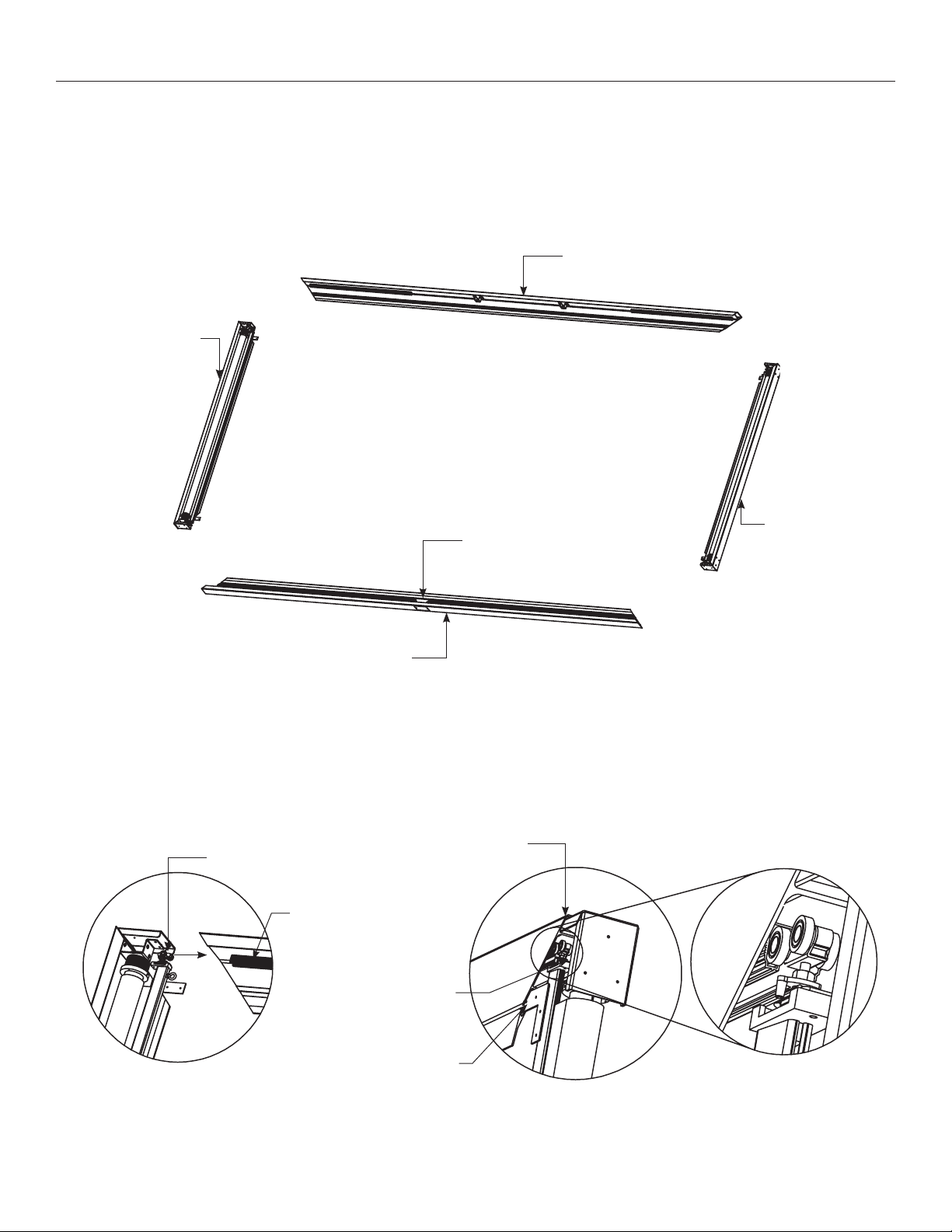

Frame Assembly:

1. In the hardware package, you will receive (12) #10 x .375" long button head screws and (8) #10 x .500" long button head screws

required for frame assembly.

2. Lay frame pieces out on loor or table as shown in Figure 1. The right and left side frame assemblies have the rollers and motors

attached to them. The bottom frame piece has (2) guide rails and the wiring junction box attached to it. The top frame piece will

have the (2) guide rails attached to it.

Top Frame Assembly

Left Frame

Assembly

Junction Box

Assembly

Bottom Frame Assembly

Figure 1

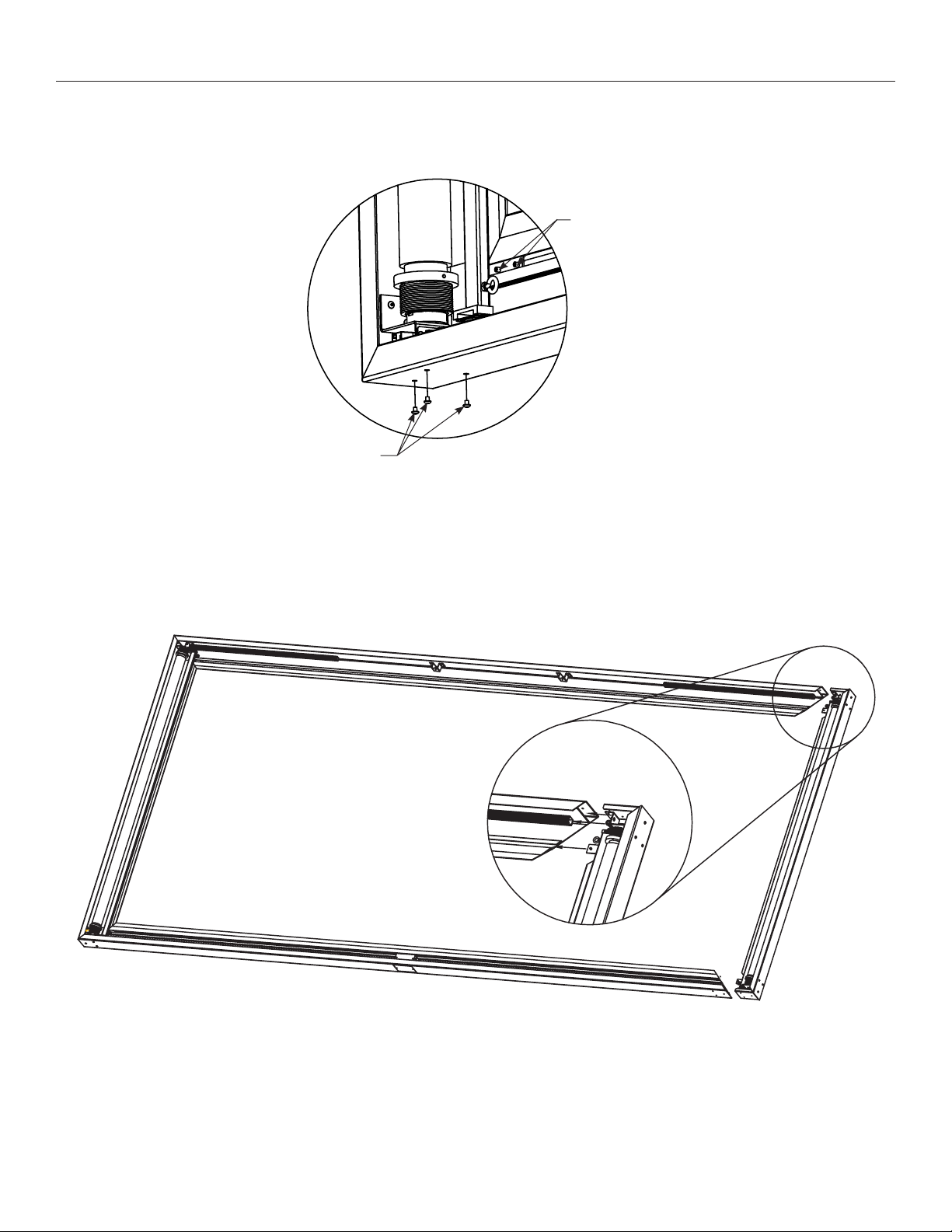

3. Assemble left side of frame to the top of frame. (NOTE: Figure 2 is looking from the back of the frame.) The large black metal L

bracket will slide into the aluminum extrusion while the small L bracket will slide into the aluminum channel. When sliding the

bracket into the top frame assembly, guide the slat roller carriage into the top aluminum guide channel as shown in Figure 3.

Figure 2 Figure 3

Slat Roller

Carriage

Aluminum

Guide Channel

Large L

Bracket

Right Frame

Assembly

Make Sure Carriage

Rollers Are Seated

Properly in Aluminum

Channel

Small L

Bracket

3

Page 4

Multi Format Imager Assembly

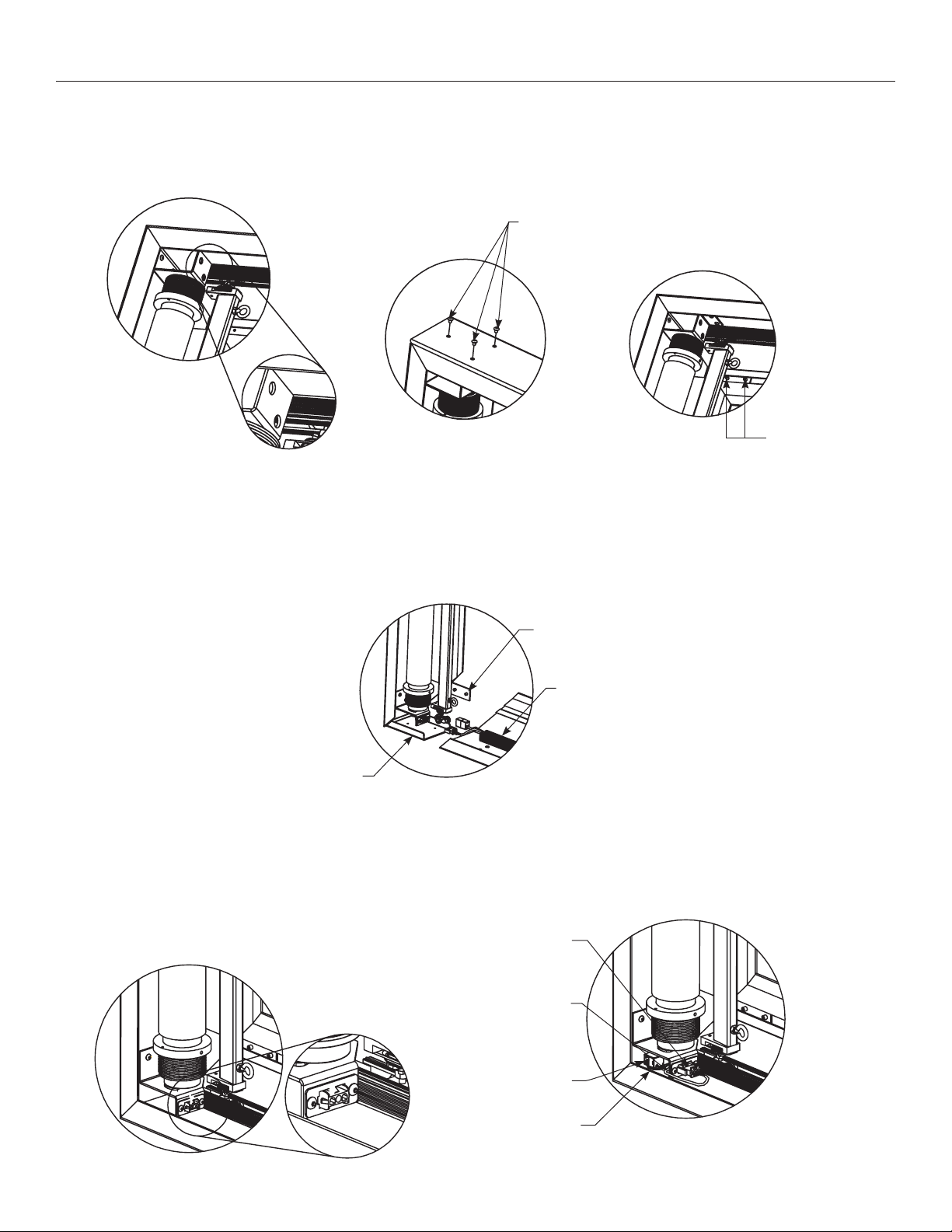

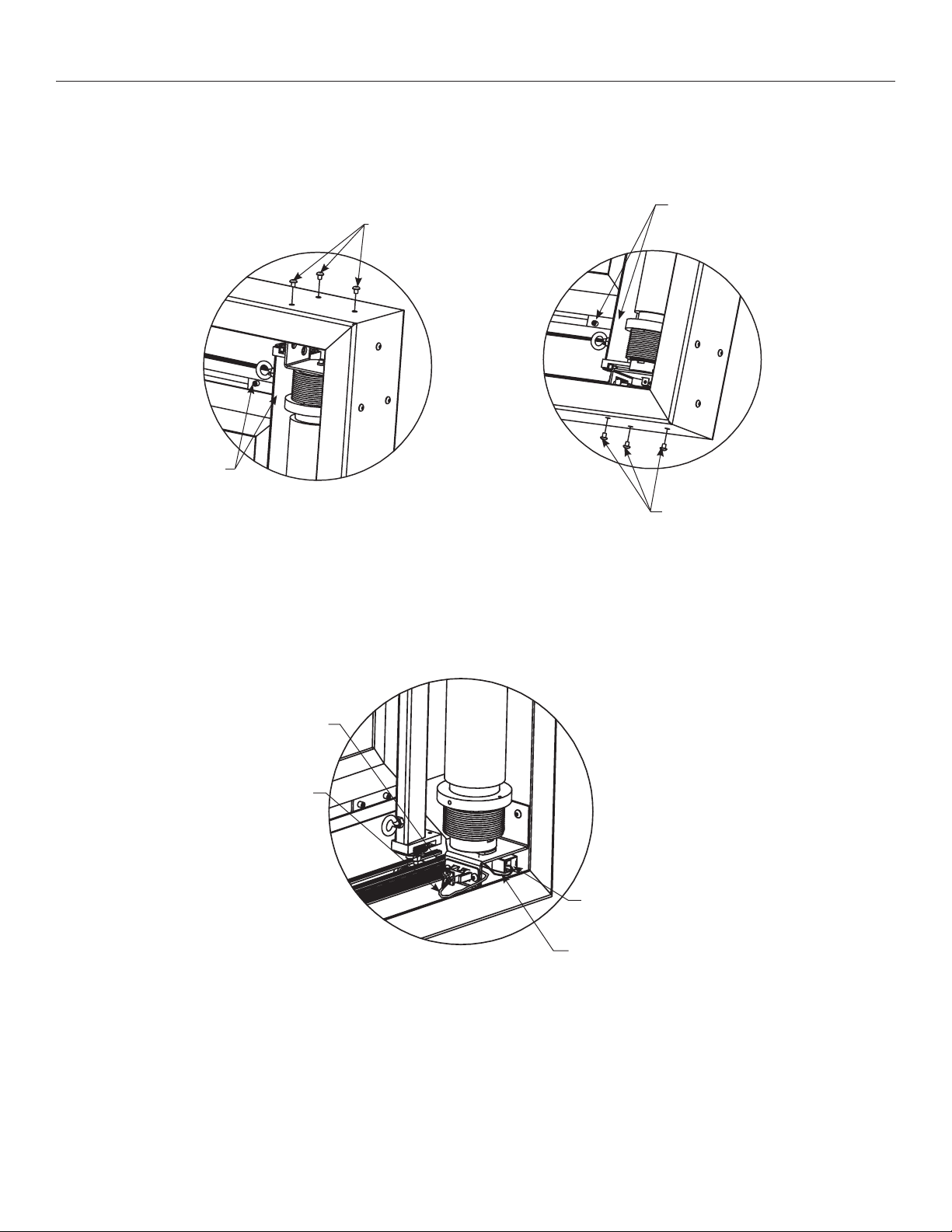

4. Fasten (3) #10 x .375" long button head screws through top of frame into the corner connector bracket. See Figure 5.

Tighten two set screws on lat "L" bracket to line up the front faces as shown in Figure 6.

Figure 4

Figure 5

5. Assemble bottom side of frame to left frame. The large metal L bracket will slide into the aluminum extrusion while the small

L bracket will slide into the aluminum channel. When sliding the bracket into the bottom frame assembly, guide the slat roller

carriage into the bottom aluminum guide channel. See Figure 7.

Fasten Screws

Through Top Frame

Assembly Into

Connecting Bracket

Figure 6

Tighten Set Screws

Until Front Surfaces

Are Flush

Figure 7

Large L

Bracket

6. Route the two cable assemblies around motor bracket and plug the 3 wire male connector into the 3 wire female connector

on the motor bracket. The motor will have a gray data cable with an RJ45 connector on the end coming out of the head of the

motor. Plug this end into the RJ45 coupler. Tuck the RJ45 coupler underneath motor bracket securely to prevent entanglement

as shown in Figure 9.

Figure 8

Plug Motor Power In

Route Power

Cable Behind

Motor Bracket

Tuck Excess Wire

Underneath Motor

Tuck RJ45 Coupler

Motor Bracket

From Motor Head

Small L

Bracket

Aluminum Guide

Channel

Figure 9

Bracket

Underneath

Data Cable

4

Page 5

Multi Format Imager Assembly

7. Finish assembling corner assembly by inserting (3) #10 x .375" long button head screws through bottom of frame into the corner

L connector bracket. Tighten two set screws on lat "L" bracket to line up the front faces as shown in Figure 10.

Figure 10

Fasten Screws

Through Bottom Frame

Assembly Into

Connecting Bracket

8. Assemble right side of frame to top and bottom frame assemblies. The two large black metal L brackets will slide into top and

bottom aluminum extrusion while the two small metal L brackets will slide into the aluminum channel. When sliding the right side

assembly into the aluminum extrusion, guide the slat roller carriage into the top and bottom guide channels as shown in Figure 11.

Tighten Set Screws

Until Front Surfaces

Are Flush

Figure 11

5

Page 6

Multi Format Imager Assembly

9. Assemble top right and bottom right corner assembly by inserting (3) #10 x .375" long button head screws through bottom of frame

into the corner L connector bracket. Tighten two set screws on lat "L" bracket to line up the front faces as shown in Figure 12.

Figure 12

Fasten Screws

Through Top Frame

Assembly Into

Connecting Bracket

Tighten Set Screws

Until Front Surfaces

Are Flush

10. Route the two cable assemblies around motor bracket and plug the 3 wire male connector into the 3 wire female connector

on the motor bracket. The motor will have a gray data cable with an RJ45 connector on the end coming out of the head of the

motor. Plug this end into the RJ45 coupler. Tuck the RJ45 coupler underneath motor bracket securely to prevent entanglement

as shown in Figure 13.

Tighten Set Screws

Until Front Surfaces

Are Flush

Fasten Screws

Through Bottom Frame

Assembly Into

Connecting Bracket

Plug Motor

Power In

Route Power

Cable Behind

Motor Bracket

Tuck Excess

Wire Underneath

Motor Bracket

Figure 13

Tuck RJ45 Coupler

Underneath Motor

Bracket

Data Cable

From Motor Head

6

Page 7

Multi Format Imager Assembly

11. Untape black steel wire tension cable from bottom left side assembly. Un-wire tie the cable assembly. Run black steel wire tension

cable down around pulley at end and bring back towards the end. You may have to pull slightly hard and clip the tension cable to

the eyebolt secured in the slat bar as shown in Figure 14. Be careful not to pinch your ingers in the spring. Repeat this step for

bottom right corner of screen.

Clip Wire Tension

Cable To Eyebolt

Wrap Wire

Tension Cable

Around Pulley

Pinch Guard

Figure 14

7

Page 8

Multi Format Imager Assembly

12. Assemble pinch guard bracket using (2) #10 x .375" long button head screws to opposite side of pulley bracket as shown in Figure 15.

Repeat this step for bottom right corner of screen.

Fasten Screws Through

Pinch Guard

Bracket

Figure 15

Pinch Guard Bracket

Into Pulley Bracket

13. Untape black steel wire tension cable from top left side assembly. Un-wire tie the cable assembly. This cable assembly will have an

extra safety wire ran through the spring. Run black steel wire tension cable down around pulley at end and bring back towards the

end. You may have to pull slightly hard and clip the tension cable to the eyebolt secured in the slat bar as shown in Figure 16.

Be careful not to pinch your ingers in the spring. Repeat this step for top right corner of screen.

Figure 16

Wrap Wire

Tension Cable

Around Pulley

Pinch Guard

8

Page 9

Multi Format Imager Assembly

14. Assemble pinch guard bracket using (2) #10 X .375" long button head screws to opposite side of pulley bracket as shown in Figure 17.

Repeat this step for top right corner of screen.

Figure 17

Fasten Screws Through

Pinch Guard Bracket

Into Pulley Bracket

Pinch Guard

Bracket

15. Attach irst side of safety cable to eyebolt in middle of screen. Attach other side of safety cable to the eyebolt in side of frame

in front of wind up pulley. Repeat this step for top right corner of screen.

Figure 18

Safety Cable

Passes Through

Middle Of Spring

Clip Safety Cable

To Middle Eyebolt

9

Page 10

Multi Format Imager Installation

Wall Mounting Assembly:

1. Depending on size of screen it will be shipped with either

2 wall brackets that are 48" long or 2 wall brackets that are

64" long. Two small "L" brackets included will be used to hold

frame securely to wall at bottom.

2. To install the Multi-Format Imager over a Da-Lite Perm-Wall

screen you will need to place the supplied wooden spacers

between the screen and the wall.

Da-Snap, Imager and Cinema Contour frame do not require

any spacers.

3. Refer to Figure 16 for hanger bracket location. Dimension "A"

will vary depending on the type of screen you have.

Dimension "A" is measured from the top of the screen

frame to the top of the hanger bracket.

Screen Type: Dimension "A"

Cinema Contour 33/4"

Perm-Wall 43/4"

Imager 43/4"

Da-Snap 51/4"

4. Both wall brackets must be mounted into at least two wall

studs. Two mounting points must be spaced at least 24" away

from each other. Wall studs must be 2 x 4 construction.

Check to make sure both brackets are vertically level with

each other.

5. Drill hole for mounting bracket in to wall. Dimension for hole

is shown from the top bracket to center hole position. It is

recommended to use a 1/4" x 11/2" Lag Screw (not supplied)

to fasten bracket to wall.

Mount Locations Must

Be Spaced At Least Three

Holes From One Another.

Figure 20

"A"

1 ½"

Figure 19

10

Page 11

Multi Format Imager Installation

6. Wall hanging brackets must be evenly spaced across top of frame. Measure the frame width and divide by three then make two

marks from the end. The center of each wall bracket shall be located on those marks.

Figure 21

Frame Width / 3

Frame Width / 3

11

Page 12

Multi Format Imager Installation

7. Hang the frame assembly on the hanger brackets as shown in Figure 22. Be careful as bracket is to slide in front of the aluminum

guide channel. There is a lip on the back of the frame that wedges itself in to the hanger bracket once fully installed on bracket.

This is a two person installation. Do not attempt to do this without two people.

Slide Frame Over

Figure 22

Hanger Brackets

Bracket

Back Lip Of Frame

Will Wedge Down

Between Wall

Bracket And Wall

Figure 24

Figure 23

12

Page 13

Multi Format Imager Wiring Diagram

1. To connect power to unit locate junction box cover on bottom frame assembly. There will be two black screws holding the wiring

box cover on as shown in Figure 25.

Figure 25

Remove Two

Screws Holding

Junction Box

Cover

2. Install electrical connections. Make sure to review the wiring diagram for proper hook up as shown in Figure 26.

NOTE: Must be installed in accordance with the requirements of the

Local Building Codes, the Canadian Electrical Code (CEC), CAN/CSA C22.1

and the National Electric Code (NEC), NFPA 70. An appropriate disconnect

device shall be provided as part of the building installation.

6P6C

RJ22 Cable

From QAUX

Three Conductor

Power Wire

To QEYE

RJ45

Coupler

Manual 2

+12V

Bus (RP Data)

RQ Data

+5V

Ground

RQ Clock

Manual 1

RJ45

Brown

Blue

Yellow

Green

Red

Black

Orange

Purple

8P8C

RJ45 Cable

Left Motor

Quick Connect

Motor Plug

(Ground)

Green

White

(Common)

Input

120V / 60Hz

Figure 26

Black

(Hot)

RJ45

Coupler

Quick Connect

Motor Plug

Right Motor

13

Page 14

Multi Format Imager Wiring Diagram

Green

3. Connect IR eye to splitter for screen operation. IR eye shall be plugged into a QEYE port on the primary

splitter as shown in Figure 27.

IR EYE

QEYE Inputs

6P6C

RJ22 Cable

From QAUX

To QEYE

6P4C

RJ14 Cable

Figure 27

Primary Splitter

Secondary Splitter

RJ22

+12V

Bus (RP Data)

RQ Data

+5V

Ground

RQ Clock

Blue

Yellow

Red

Black

White

RJ14

Bus (RP Data)

RQ Data

+5V

Ground

White

Green

Red

Black

NOTES:

1. 6P6C = 6 Pins 6 Conductor Wire

2. 6P4C = 6 Pins 4 Conductor Wire

Multi Format Imager Operation

The Multi-Format imager has been preset to four diferent

formats. The screen can be set to any format by simply pressing

the corresponding button on the remote. Below is a list of each

button function.

IMPORTANT! When operating the switch, press and release the

buttons. Do not hold the button for more than ive (5) seconds

or the button will be reprogrammed to the current screen

position.

3 – Sets format to NTSC (1.33:1) format.

2 – Sets format to HDTV (1.78:1) format.

1 – Sets format to Letterbox (1.85:1) format.

OPEN – Sets format to Anamorphic (2.35:1) format.

STOP – Stops the masks at any position when pressed.

< > – Individual Control of left and right mask.

Test installation by carefully running mask surfaces in and out

23 times. Be prepared to stop screen.

Standard Duty Cycle: 1 Min. On. / 3 Min. Of.

CAUTION! Excessive continuous operation may cause

overheating. If motor overheats do not press on remote

and allow motor to cool for 30 minutes.

ATTENTION! Le fonctionnement continu et excessif peut

provoquer une surchaufe. Si le moteur surchaufe,

n'utilisez pas la télécommande et laissez le moteur

refroidir pendant 30 minutes.

Figure 28

14

Page 15

Multi Format Imager Intermediate Stop Adjustment

1. To adjust intermediate stopping positions make sure both

masks are completely retracted into the frame. Press the left

mask ">" button. The mask will start to move outward. Press

the stop button at the position you want it set to. If you go

too far outward press the left mask "<" button and the mask

will retract back into the case.

2. Press the right mask "<" button. The mask will start to move

outward. Press the stop button at the position you want it set

to. If you go too far outward press the right mask ">" button

and the mask will retract back into the case.

Multi Format Imager Limit Travel Adjustment

1. To make limit travel adjustments you will need the 3-button

low voltage wall switch that was shipped with your masking

screen.

2. Locate the junction box cover on bottom frame assembly.

Remove two screws holding junction box cover on the

bottom of frame.

3. Unplug the 6P6C cable that goes from QEYE of primary

splitter to QAUX of secondary splitter as shown in Figure 29.

3. Once both masks are at the desired stopping position. Press

and hold Preset 1, Preset 2 or Preset 3 button on remote for

10 seconds.

4. Repeat steps 1 thru 3 for other Preset locations.

4. Unplug the IR eye end of the 6P4C cable that goes from the

QEYE of primary splitter to the IR eye.

5. To adjust travel of left mask. Plug the 6P4C cable into the

back of wall switch as shown in Figure 30. The wall switch

LED will blink green twice when the 6P4C cable is plugged in.

T6 From

QAUX To QEYE

Figure 29

Primary Splitter

Secondary Splitter

Switch

LED

"Up" Limit

Button

"Down" Limit

Button

Figure 30

RJ22

Jack

15

Page 16

Multi Format Imager Limit Travel Adjustment

6. Locate the two tactile buttons on the back of the switch.

They are square silver with black round buttons as shown

in Figure 30.

7. To adjust how far the mask travels outward towards the

middle of masking screen, press and hold the down tactile

button until the LED on back of switch turns solid red. This

will put the motor in limit set mode. Turn the wall switch over

and use the down button on front of switch. Press and hold

until the desired travel position is reached. If you travel to far

outward you can press the up to move mask inward. If you

press and let go of either up or down button the motor will

do a small jog in that direction for iner adjustment of mask.

Once desired position is reached turn switch over press and

hold the down tactile button until the LED on back of switch

blinks red twice. The outward travel limit is now set.

8. To adjust how far the mask travels inwards away from the

middle of making screen, press and hold the up tactile button

until the LED on back of switch turns solid green. This will put

the motor in limit set mode. Turn the wall switch over and use

the up button on front of switch. Press and hold until the

desired travel position is reached. If you travel to far inward

you can press the down to move the mask outward. If you

press and let go of either up or down button the motor will

do a small jog in that direction for iner adjustment of mask.

Once desired position is reached turn switch over press and

hold up tactile button until the LED on back of switch blinks

green twice. The inward travel limit is now set.

9. To test limit switch setting, press and release the up or

down button on the wall switch to operate the mask.

10. To adjust travel of right mask. Unplug the 6P4C cable from

the QEYE of primary splitter and plug into the QEYE of

secondary splitter.

11. Locate the two tactile buttons on the back of the switch.

They are square silver with black round buttons as shown

in Figure 30.

12. To adjust how far the mask travels outward towards the

middle of masking screen, press and hold the up tactile

button until the LED on back of switch turns solid green. This

will put the motor in limit set mode. Turn the wall switch over

and use the up button on front of switch. Press and hold until

the desired travel position is reached. If you travel to far

outward you can press the down to move mask inward. If you

press and let go of either up or down button the motor will

do a small jog in that direction for iner adjustment of mask.

Once desired position is reached turn switch over press and

hold the up tactile button until the LED on back of switch

blinks green twice. The outward travel limit is now set.

13. To adjust how far the mask travels inwards away from the

middle of making screen, press and hold the down tactile

button until the LED on back of switch turns solid red. This

will put the motor in limit set mode. Turn the wall switch over

and use the down button on front of switch. Press and hold

until the desired travel position is reached. If you travel to far

inward you can press the up to move the mask outward. If

you press and let go of either up or down button the motor

will do a small jog in that direction for iner adjustment of

mask. Once desired position is reached turn switch over

press and hold down tactile button until the LED on back of

switch blinks red twice. The inward travel limit is now set.

14. Replace the 6P6C cable that goes from QEYE of primary

splitter to QAUX of secondary splitter as shown in Figure 29.

15. Unplug the 6P4C cable from the QEYE of secondary splitter

and plug back into the QEYE of primary splitter.

16. Unplug the 6P4C cable from the back of wall switch and plug

back into IR Eye.

17. Replace junction box cover.

18. Reset intermediate stopping positions. (See Intermediate

Stop Adjustment).

16

Page 17

Troubleshooting

Visit www.da-lite.com to ind installation and troubleshooting

videos and tutorials. You will also ind a link to Live Chat for

interactive support and you can contact us by email at

info@da-lite.com or by phone at (800) 6223737 or (574) 2678101

with any troubleshooting questions.

Symptom Cause Solution

Masking System will not operate.

Motor does not hum.

Masking System does not stop at

correct position.

Incorrect line voltage.

Blown fuse. Replace fuse.

Tripped circuit breaker. Reset circuit breaker.

No power to junction.

Power at junction box

Thermal overload tripped.

Defective motor, limit switch or capacitor.

Capacitor burned out. Replace motor assembly.

Limit switch is out of adjustment. See Limit Travel Adjustment section.

Squeaking, rubber end plug rubbing on motor. Center roller in case.

Verify 115125V (or 220240V). If insuicient voltage,

rewire incoming electric line.

Check above. Tighten all loose wire connections.

Correct any improper connections.

Check for power across black and white leads.

Let motor cool down for 30 minutes. Try again.

Replace motor assembly.

NOTE: Motor is a sealed assembly.

Noise.

NOTE: Masking Systems will operate

with a low-pitched hum.

Coasting. Defective Brake. Replace motor assembly.

Fabric hangs crooked.

Grinding. Foreign object in screen rubbing on

roller or fabric.

Gear noise. Replace motor assembly.

Masking System not installed properly. Check for level and plumb.

Mask is damaged. Replace mask.

Remove.

17

Page 18

18

Page 19

19

Page 20

LIMITED ONE YEAR WARRANTY ON DALITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DALITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DALITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL–0249 (Rev. 2) 10.14

© 2013 Milestone AV Technologies LLC. Printed in U.S.A.

39500

Loading...

Loading...