Page 1

INSTRUCTION BOOK FOR

Motorized Scenic

Roller Screen

Page 2

Important Safety Instructions

When using your video equipment, basic safety precautions

should always be followed, including the following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled, or

contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating

at least equal to that of the appliance should be used. Cords

rated for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this

appliance. Contact an authorized service dealer when repair

work is required. Incorrect reassembly can cause electric

shock when the appliance is used subsequently.

5. The use of an accessory attachment not recommended by

the manufacturer may cause a risk of ire, electric shock, or

injury to persons.

WARNING: Before obtaining access to terminals, all

supply circuits must be disconnected.

ATTENTION! Avant d’accéder au bloc d’alimentation,

veuillez couper l’alimentation électrique.

6. An appropriate disconnect device shall be provided as part

of the building installation.

Save These Instructions

2

Page 3

Installation

Before proceeding with the installation please read the installation and operating instructions thoroughly. Make sure

to recheck measurements of screen and hanger locations before installation. Area must be clear for screen to operate.

With all lid sections removed from shipping container, remove the screws holding the frame to the shipping container

(2 per cross brace). The screen can now be carefully lifted out of the container.

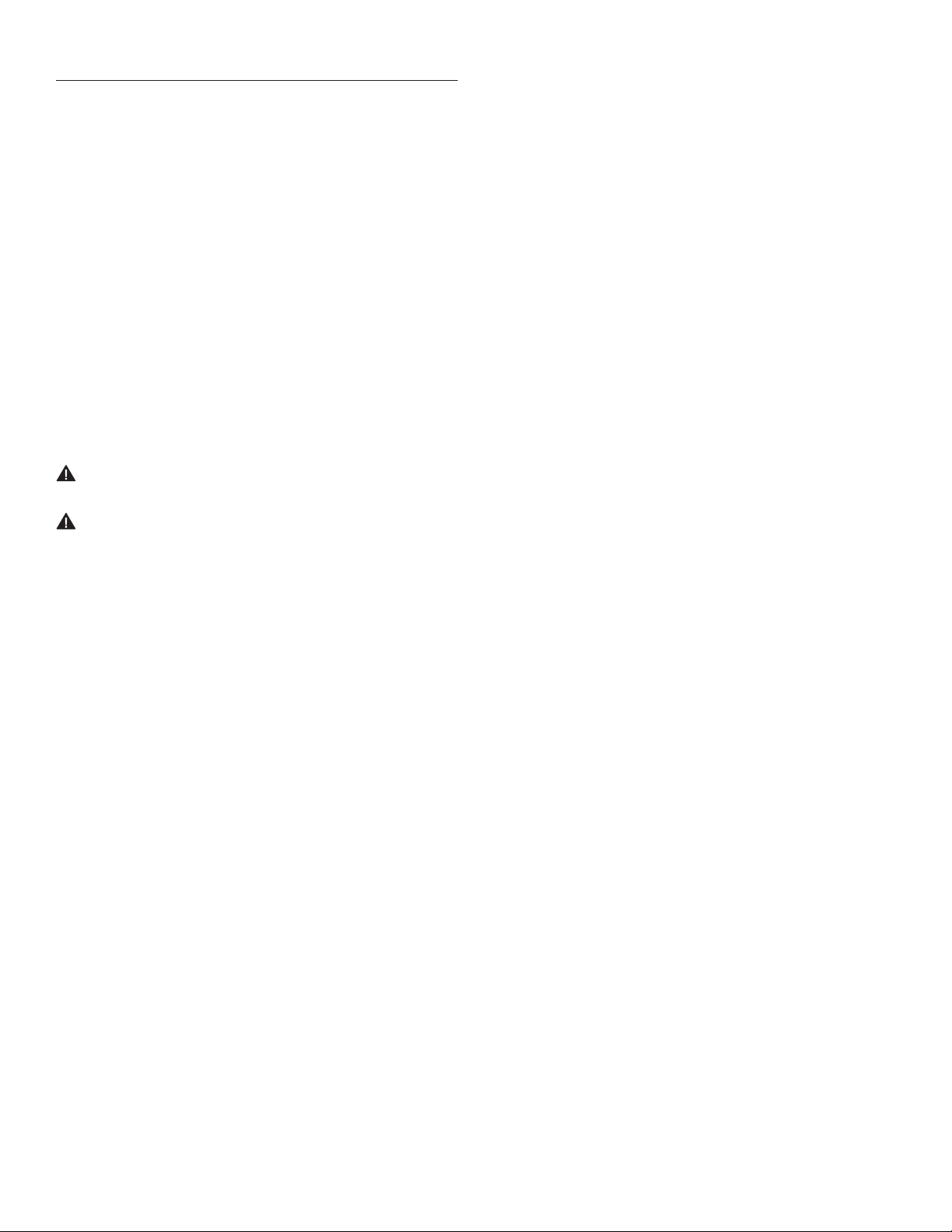

Method A

The frame can be mounted to ceiling with 5/16" diameter

threaded rods. Level frame from front to back and left to right.

Mount from all cross braces (Figure 1).

Suggested Method Of Installation

Method A – Secure To Ceiling

Ceiling

Secure To

Suit

Cross

Brace

Front

15"

Cable

Secure To Suit

⁄" Threaded Rod

(6 Cross Braces)

(Not Furnished)

Back

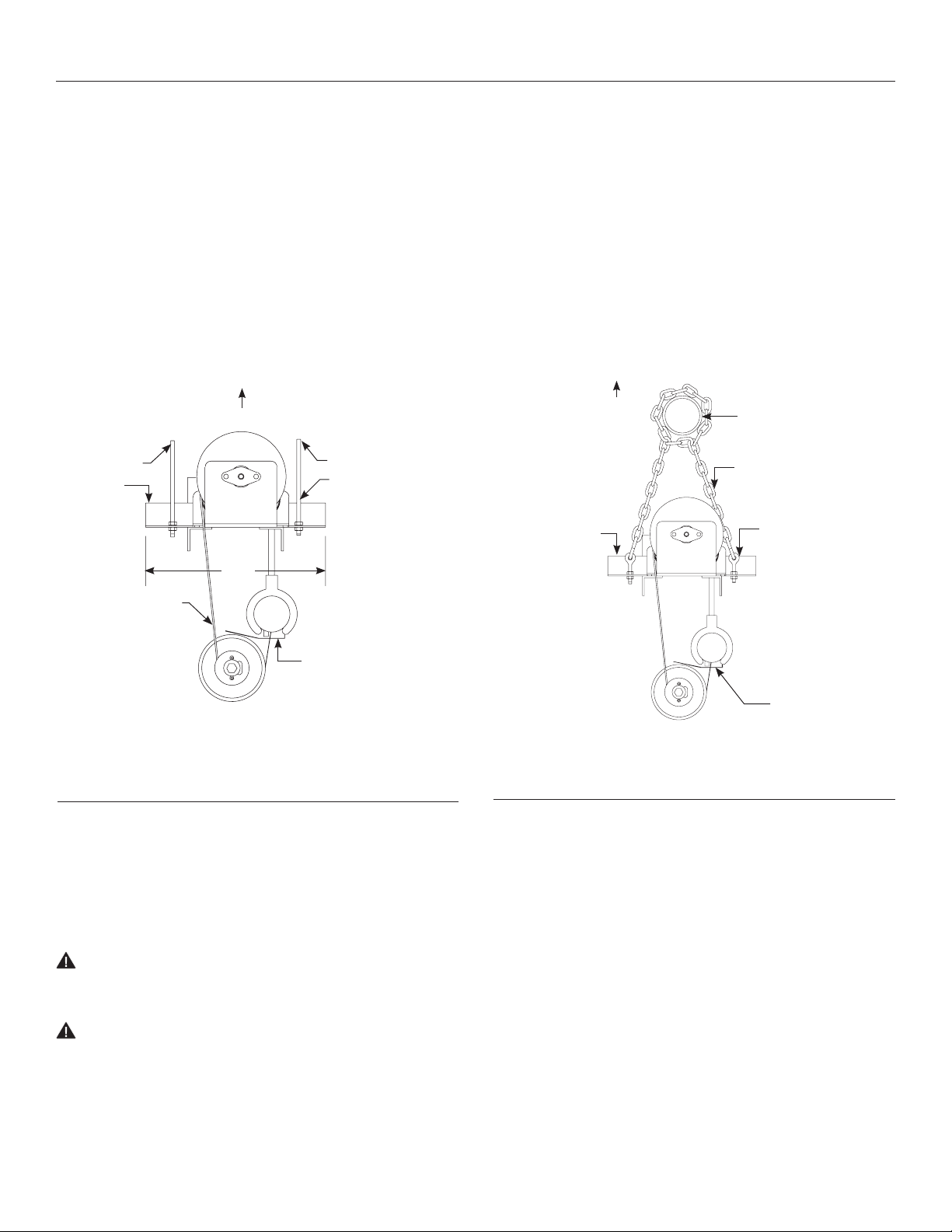

Method B

Hang from a pipe (ly the screen). Level frame from front to

back and left to right. Mount from all cross braces (Figure. 2).

NOTE: Motor pulley must clear pipe. Chains must clear

motor tubes.

Suggested Method Of Installation

Method B – “Flying Pipe”

Ceiling

Cross

Brace

Front

Pipe To Suit

Chain To Suit

(6 Cross Braces)

(Not Furnished)

Eye Bolts For Leveling

(Not Furnished)

Back

Safety Switch Trigger

Figure 1

Electrical Installation

Screen motors have been internally wired at Da-Lite. Wiring

designated “external” is completed by installer conforming to

local and national codes. Refer to wiring diagram on next page.

Check for satisfactory condition by operating the screen. Be

prepared to stop screen. Standard Duty Cycle:

1 MIN. 30 SEC. ON / 45 MIN. OFF.

CAUTION! Excessive continuous operation may cause

overheating and motors will shut of.

Let motors cool 10 to 15 minutes and continue test.

ATTENTION! Le fonctionnement continu et excessif peut

provoquer une surchaufe et l'arrêt du moteur. Laissez le

moteur refroidir pendant 10 à 15 minutes et poursuivez le

test.

Safety Switch

Trigger

Figure 2

Screen Adjustment

1. With screen in complete unrolled position, examine the

screen surface carefully. If fabric does not hang lat, loosen

the nuts on the eyebolts of the black clamps. Adjust the

wingnuts to pull or relax the fabric as needed. Several clamp

heights may be adjusted depending on the severity of the

hang. After adjustment, tighten the nuts against the

underside of the frame. Caution stage hands and others to

check area before lowering screen. Do not bump screen with

ladders, scenery, etc.

Check the cables to make sure they are winding on the motor

and roller pulleys properly.

3

Page 4

Motorized Scenic Roller Installation

120V Wiring Diagram

Power Input

120VAC / 60HZ

Safety Switch

White - (Common)

Black - (Hot)

Green - (Ground)

White - (Common)

Red - (Up)

Black - (Down)

Green - (Ground)

Brown - Out Of

White

BLACK

Controller

Red - Out Of

Controller

White - (Common)

Red - (Up)

Black - (Down)

Red - Out Of Controller

Brown - Out Of Controller

White - (Common)

Red - (Up)

Black - (Down)

Green - (Ground)

240V Wiring Diagram

NOTES:

1. FUSE RATED 15A 250VAC

Safety Switch

Power Input

240VAC / 50HZ

3.6 AMPS

Blue - (Common)

Brown - (Hot)

Green/Yellow (Ground)

Blue - (Common)

Black - (Up)

Brown - (Down)

Green/Yellow - (Ground)

Brown - Out

Of Controller

Red - Out Of

White Black

Black

Controller

Blue - (Common)

Black - (Up)

Brown - (Down)

Blue - (Common)

Black - (Up)

Brown - (Down)

Green/Yellow (Ground)

Red - Out Of Controller

Brown - Out Of Controller

4

Page 5

Motorized Scenic Roller Installation

120V / 240V Wall Switch

Wiring Diagram

Front

Of

Wall

Switch

UP

STOP

DOWN

Back

Of

Wall

Switch

Red - (Up)

Black - (Down)

White - (Common)

Optional RF Remote

Connection

Not Used

NOTE: 2024AWG wire recommended for

connecting wall switch to sychronization

controller.

IMPORTANT! The wall switch terminal block can be connected inside the wiring compartment. The controller does not need to be

removed from the junction box unless an RF remote is being connected. Use caution when removing the controller from the box as it

is easily damaged.

5

Page 6

Limit Switch Adjustment

The stop positions of the screen are preset at the factory. If adjustments are necessary, the limit switch screws located at the end

of each motor can adjust the stop positions. Use a 5/32" hex key or a lat screwdriver. Adjustments should be made in small increments

by turning the adjustment screws a half turn at a time. Refer to igure 3.

Setting The "Down" Limit Position.

Screen Drops Too Far:

Left motor (as viewed from audience side): Turn the white limit

switch screw clockwise to decrease the amount of fabric drop.

Right motor (as viewed from audience side): Turn the yellow limit

switch screw clockwise to decrease the amount of fabric drop.

After adjusting the limit screws on both motors, run the screen

down to test the stop position. Repeat until the desired position

is set.

Screen Does Not Drop Enough:

Left motor (as viewed from audience side): Turn the white

limit switch screw counterclockwise to increase the amount

of fabric drop.

Right motor (as viewed from audience side): Turn the yellow

limit switch screw counterclockwise to increase the amount

of fabric drop.

After adjusting the limit screws on both motors, run the screen

down to test the stop position. Repeat until the desired position

is set. Do not adjust for more drop than what was ordered. At

least 11/2 wraps of fabric must remain on the roller.

Setting The "Up" Limit Position.

Screen Travels Up Too Far:

Left motor (as viewed from audience side): Turn the yellow limit

switch screw clockwise to decrease the amount of travel.

Right motor (as viewed from audience side): Turn the white limit

switch screw clockwise to decrease the amount of travel.

After adjusting the limit screws on both motors, run the screen

up to test the stop position. If the screen travels up too far, the

safety stop switch will be activated and all power to the motors

will be shut of. You will have to deactivate the switch by hand. To

do this, push down on the switch trigger (see Figure 1) to release

the switch and have someone run the screen down. This safety

switch is to prevent the screen from traveling too far and binding

the motors should the motor limit switches fail.

Screen Does Not Travel Up Far Enough:

Left motor (as viewed from audience side): Turn the yellow limit

switch screw counterclockwise to increase the amount of travel.

Right motor (as viewed from audience side): Turn the white limit

switch screw counterclockwise to increase the amount of travel.

After adjusting the limit screws on both motors, run the

screen up to test the stop position. Repeat until the desired

position is set.

6

Page 7

Limit Switch Adjustment

Motor 1 Motor 2

Yellow - Up Limit

Clockwise = Less Up Travel

Counterclockwise = More Up Travel

White - Down Limit

Clockwise = Less Down Travel

Counterclockwise = More Down Travel

Top View - Audience Side

Figure 3

7

Page 8

LIMITED ONE YEAR WARRANTY ON DALITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DALITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DALITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL–0278 (Rev. 3) 02.15

© 2015 Milestone AV Technologies LLC. Printed in U.S.A.

84222

Loading...

Loading...