Page 1

INSTRUCTION BOOK FOR

Large Dual Masking Electrol

Page 2

Important Safety Instructions

When using your video equipment, basic safety precautions

should always be followed, including the following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled,

or contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating

at least equal to that of the appliance should be used. Cords

rated for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this

appliance. Contact an authorized service dealer when repair

work is required. Incorrect reassembly can cause electric

shock when the appliance is used subsequently.

5. The use of an accessory attachment not recommended by

the manufacturer may cause a risk of ire, electric shock,

or injury to persons.

Save These Instructions

2

Page 3

Pre-Installation

1. Carefully unpack screen.

2. Make sure to recheck measurements of screen location

before installation.

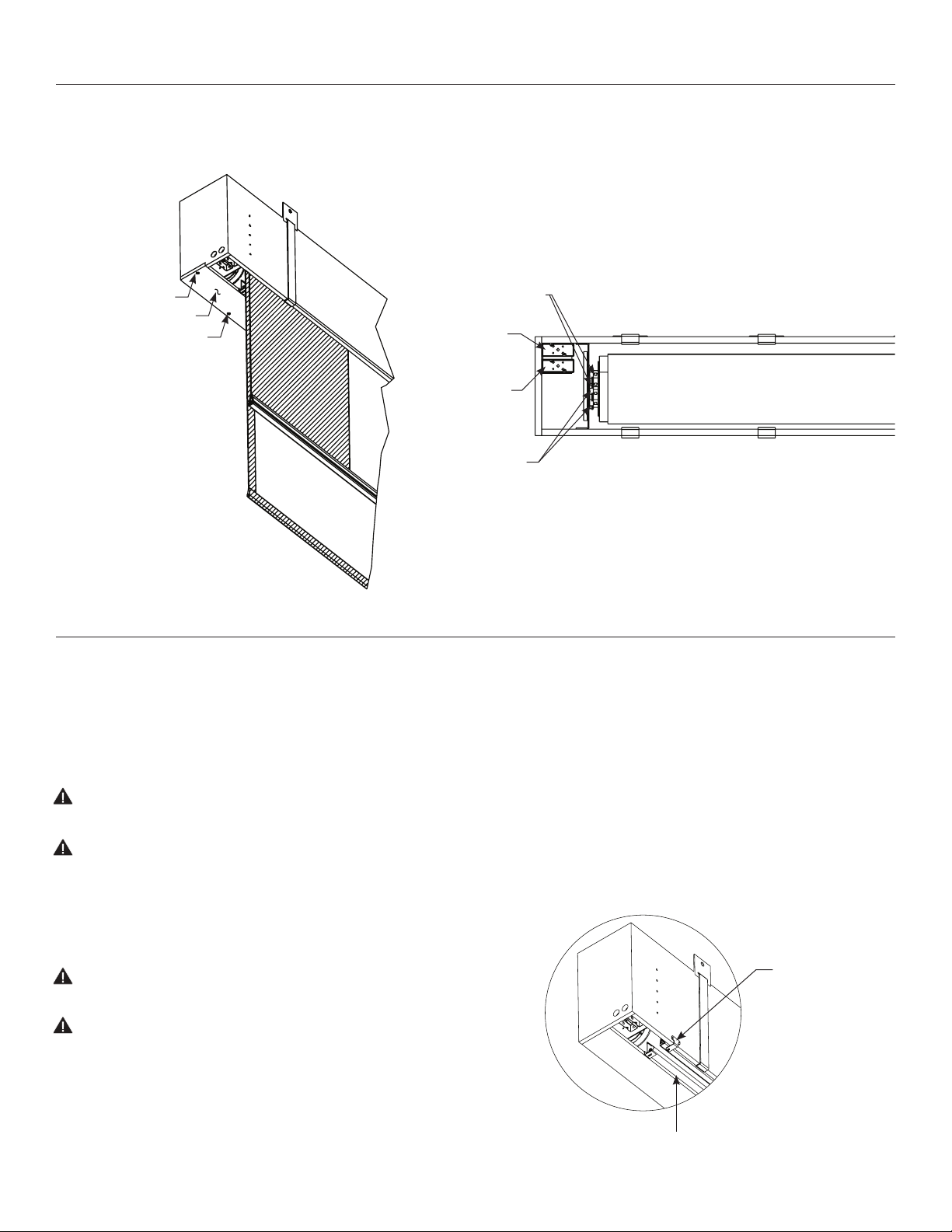

Drywall Screw

Access Panel

Machine Screw

Figure 1

3. Do not remove the wrapping paper or pull the orange string

Screens 14' wide and over use an ironing board to latten the

fabric. The ironing board is part of the access panel (Fig. 3).

Adjustment

Knob “Down”

Mask Motor

Wiring Box

Screen Motor

Wiring Box

Adjustment

Knob “Up”

until the screen is installed.

Figure 2

Installation

NOTE: Unit is not to be installed in air handling space.

Hangers (If required)

1. Make sure hangers are placed to it into the

pre-determined notches.

2. Level unit lengthwise with a carpenter’s plum level.

CAUTION! Do not completely seal in unit. Access room must

be allowed for motor repair or fabric replacement.

ATTENTION! Ne ixez pas complètement l'unité. Un espace doit

être laissé pour pouvoir réparer le moteur ou remplacer la

toile.

3. Remove the slat retainer brackets from the front of the case (Fig. 3).

4. Remove wrapping paper and tape strips.

CAUTION! Do not cut wrapping paper or tape with knife

or any sharp tool. Remove by hand.

ATTENTION! Ne coupez pas le papier d'emballage ou le ruban

adhésif avec un couteau ou un outil tranchant. Retirez à la

main.

NOTE: Must be installed in accordance with the requirements of

the Local Building Codes, the Canadian Electrical Code (CEC), CAN/

CSA C22.1 and the National Electric Code (NEC), NFPA 70. An

appropriate disconnect device shall be provided as part of the

building installation.

6. Test installation by carefully running surface up and down several

times. Be prepared to stop screen. Standard Duty Cycle: 1 MIN. ON /

10 MIN. OFF.

NOTE: The picture surface, when rolled down, should have at least

a full wrap and a half around the roller. Do not allow any part of the

roller to become exposed.

Slat Retainer

Brackets

(3 Screws)

5. Install electrical hook up that applies to your unit. Make sure to

review your Electrical Installation Checklists and wiring diagrams

(included) for either 110 volt switch, 220/240 volt switch, or DRC

low voltage control.

Figure 3

Ironing Board

(Screens 14' Wide And Over)

3

Page 4

Screen Adjustment For 120V Screens

CAUTION! The mask should not be ield adjusted for more or less drop.

ATTENTION! Le masque ne doit pas être ajusté sur place pour régler la chute.

Surface travel is stopped automatically in the fully opened and closed positions by limit switches that are properly adjusted at Da-Lite.

Should it be necessary to adjust for more or less drop of picture, proceed in the following manner:

NOTE: Use a screw driver or allen wrench to make adjustments.

More screen drop

1. Remove access panel (Fig. 1).

2. Place operating switch in “down” position.

3. When the screen stops, turn the “down” limit knob (Fig. 2)

one-quarter turn counterclockwise. Test by raising picture

surface approximately two feet, then lower again. Repeat until

desired picture surface position is attained.

NOTE: Must leave 11/2 wraps of fabric on roller!

4. Replace access panel.

Large Dual Masking Electrol® Instructions

Junction Box

Located in

Screen Housing

120V Wiring Diagram

Down

Common

Ground

Up

Black

Red

White

Green

Less screen drop

1. Remove access panel. (Fig. 1).

2. Raise picture surface approximately two feet

above desired level.

3. Place operating switch in “of” position.

4. Turn the “down” limit knob (Fig. 2) one-quarter turn

clockwise. Test by raising picture surface approximately

two feet, then lower again. Repeat until desired picture

surface position is attained.

5. Replace access panel.

Junction Box

Located in

Screen Housing

Black

Red

White

Green

Up

Down

Common

Ground

Mask Motor

IMPORTANT NOTE:

Switch junction box must be connected to

ground using the procective earthing screw.

4

4 – Wire

Mask Motor

Double Gang JBox

Provided By Da-Lite

Of

Down

Up

Mask

Screen

4 – Wire

Screen Motor

Up

Of

Down

Black (Hot)

White (Common)

Ground Wire

Screen Motor

Protective Earthing

Stud Inside Junction Box

115 V. AC 60 Hz

Input

Page 5

Screen Adjustment For 220V/240V Screens

CAUTION! The mask should not be ield adjusted for more or less drop.

ATTENTION! Le masque ne doit pas être ajusté sur place pour régler la chute.

Surface travel is stopped automatically in the fully opened and closed positions by limit switches that are properly adjusted at Da-Lite.

Should it be necessary to adjust for more or less drop of picture, proceed in the following manner:

NOTE: Use a screw driver or allen wrench to make adjustments.

More screen drop

1. Remove access panel (Fig. 1).

2. Place operating switch in “down” position.

3. When the screen stops, turn the “down” limit knob (Fig. 2)

one-quarter turn counterclockwise. Test by raising picture

surface approximately two feet, then lower again. Repeat until

desired picture surface position is attained.

NOTE: Must leave 11/2 wraps of fabric on roller!

4. Replace access panel.

Large Dual Masking Electrol® Instructions

Junction Box

Located in

Screen Housing

240V Wiring Diagram

Down

Common

Ground

Up

Brown

Black

Blue

Green/Yellow

Less screen drop

1. Remove access panel. (Fig. 1).

2. Raise picture surface approximately two feet

above desired level.

3. Place operating switch in “of” position.

4. Turn the “down” limit knob (Fig. 2) one-quarter turn

clockwise. Test by raising picture surface approximately

two feet, then lower again. Repeat until desired picture

surface position is attained.

5. Replace access panel.

Junction Box

Located in

Screen Housing

Brown

Black

Blue

Green/Yellow

Up

Down

Common

Ground

Mask Motor

IMPORTANT NOTE:

Switch junction box must be connected to

ground using the procective earthing screw.

4 – Wire

Mask Motor

Double Gang JBox

Provided By Da-Lite

Of

Down

Up

Mask

Screen

4 – Wire

Screen Motor

Up

Of

Down

Brown (Hot)

Blue (Common)

Ground Wire

Screen Motor

Protective Earthing

Stud Inside Junction Box

220 V. AC 50 Hz

Input

5

Page 6

Large Dual Masking Electrol® Instructions

Length = Fabric Width + 19", All Sizes

11 1⁄2"

19 1⁄2"

Mounting Bracket

(3 Provided)

Electrical

Outlets

Motor End

9 1⁄2"

9 1⁄2"

Suggested Methods Of Installation

NOTE: Unit is not to be installed in air handling space.

Ceiling Type Hanger

Picture

Surface

Wall Or Ceiling Mount With Hangers

Wall type hangers and ceiling type hangers are standard

equipment. One set is supplied with each screen. Useful

for recessed installations.

For Exposed Installation

If the screen is to be mounted in an exposed position, it may be covered

with inished plywood, veneer, paneling, plastic wall covering or a valance.

Wall Type Hanger

Picture

Surface

Rafters

Picture

Surface

Recessed Above Ceiling

Other methods of installation will suggest

themselves in new buildings where it would

be an easy matter to provide a recess for

the screen to conceal it when not in use.

Do not seal in—allow access.

6

Page 7

Troubleshooting

Symptom Cause Solution

Screen will not operate

and motor does not hum.

Incorrect line voltage.

Branch circuit fuse blown. Replace fuse.

Tripped branch circuit breaker. Reset circuit breaker.

No power to operating switch or junction.

Power at junction box

Thermal overload tripped.

Broken wire in the “down” or “up” position. Check for continuity. Cut o old splice and reconnect.

Defective motor, limit switch or capacitor. Replace motor assembly. NOTE: Motor is a sealed assembly.

Verify 115125V (or 220240V). If insuicient voltage, rewire

incoming electric line..

Check above. Tighten all loose wire connections.

Correct any improper connections.

“Down” Position

Check for power across black and white leads.

“Up” Position

Check for power across red and white leads.

Let motor cool down for 15 minutes. Try again.

Motor capacitor burned out.. Replace motor assembly.

Incorrect stopping position in

downward direction.

Incorrect stopping position in

upward direction.

Noise.

NOTE: Screen will operate

with a low pitched hum.

Coasting. Defective brake. Replace motor assembly.

Lost roller wrap. See instructions below..

“Down” limit switch out of adjustment See installation instructions.

Lost roller wrap. See instructions below..

“Up” limit switch out of adjustment Adjust “up” limit switch. See installation instructions

Gear Noise. Replace motor assembly.

Restoring Lost Roller Wrap

1. Tape a strap to the bottom of the screen surface.

2. Push strap over back of roller.

3. Feed fabric as you pull strap to draw fabric over top of roller.

4. Remove tape and strap.

7

Page 8

LIMITED ONE YEAR WARRANTY ON DALITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DALITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DALITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL0246 (Rev. 2) 09.14

© 2014 Milestone AV Technologies LLC. Printed in U.S.A.

22624

Loading...

Loading...