Page 1

INSTRUCTION BOOK FOR

Lace And Grommet

Theater-Type Screens

Page 2

Pre-Installation

Da-Lite Lace and Grommet screens are custom made to meet

the requirements for large surface installation of a relatively

permanent nature. Great care is taken in the production of these

screens to assure extreme serviceability and excellence of

picture reproduction. Maximum overall size is based on

fabric type.

The Lace and Grommet screen may be ordered in the fabrics

listed below – all of which are lame retardant and mildew

resistant. Trimmed with a strong 21/2" webbing and grommets

spaced uniformly every 6 inches. Lacing cord, included at a

slight extra charge, is laced through grommets and fastened to

hooks on frame. . . providing a completely wrinkle-free surface.

No frames are furnished, but suggestions for their construction

are provided on page 3.

Lace and Grommet style screens are not recommended unless

the stage has a ly loft for safe storage of the screen when

it is not in use.

Screens are priced per square foot on overall screen sizes, which

are 5" larger each way than picture area. When ordering Lace

and Grommet custom made screens, please give the following

dimensions:

1. Overall size, including black webbing.

2. Net picture area, excluding black webbing.

Approximate shipping weight, 1/2 lb. per square foot.

Large projection screens will have one or more vertical seams.

Choose from these famous surfaces:

Matte-White

High Contrast Matte White

Glass Beaded

Pearlescent

Da-Mat

High Contrast Da-Mat

Da-Tex (Rear)

High Power

Silver Vision

Cinema Vision

High Contrast Cinema Vision

High Contrast Cinema Perf

Dual Vision

Video Spectra® 1.5

Silver Matte

Audio Vision

High Contrast Audio Vision

Manufacturer's Precaution

Each Da-lite Screen is carefully inspected, wrapped and packed

in a manner that insures delivery to destination in irst class

condition. Careless handling of screens during installation can

Suggested Methods Of Installation

Conditions in theaters vary so greatly that no set of instructions

would be complete for each theater. The following suggestions,

regarding the installation, when supplemented with proper care

and good judgment in meeting local conditions will result in a

rapid and satisfactory installation.

Installing Screen to the frame: First, and most important, is to

handle the screen in a manner to prevent its being wrinkled

during installation.

Safest method is to lay the frame lat on a clean loor and unroll

the screen inside the frame. Tie it in at all four corners to ensure

centering in the frame. Then lacing should be installed around all

four sides. Do not attempt to draw lacing tight until after the

frame is raised to a vertical position.

result in screen surface being wrinkled, torn or damaged.

Da-Lite Screen Company does not assume responsibility

for such damage.

When necessary to install the screen to a frame already erected,

and one that cannot be taken down, it is necessary to stand the

rolled screen on end in front of the frame and tie it at frequent

intervals to the top of the frame as it is unrolled.

Before starting the actual lacing, we recommend tying the screen

to all four corners of the frame to insure its being spaced properly

inside the frame.

Things to Remember: Practically every installation will have its

own individual problem. For instance, you may ind in using your

old frame that it is not large enough to lace the screen on the

inside, in which case you would place the hooks on the front and

outer edge of the frame. For this purpose we recommend using

rooing nails every six inches, leaving one-fourth inch out of the

wood for the lacing cord.

2

Page 3

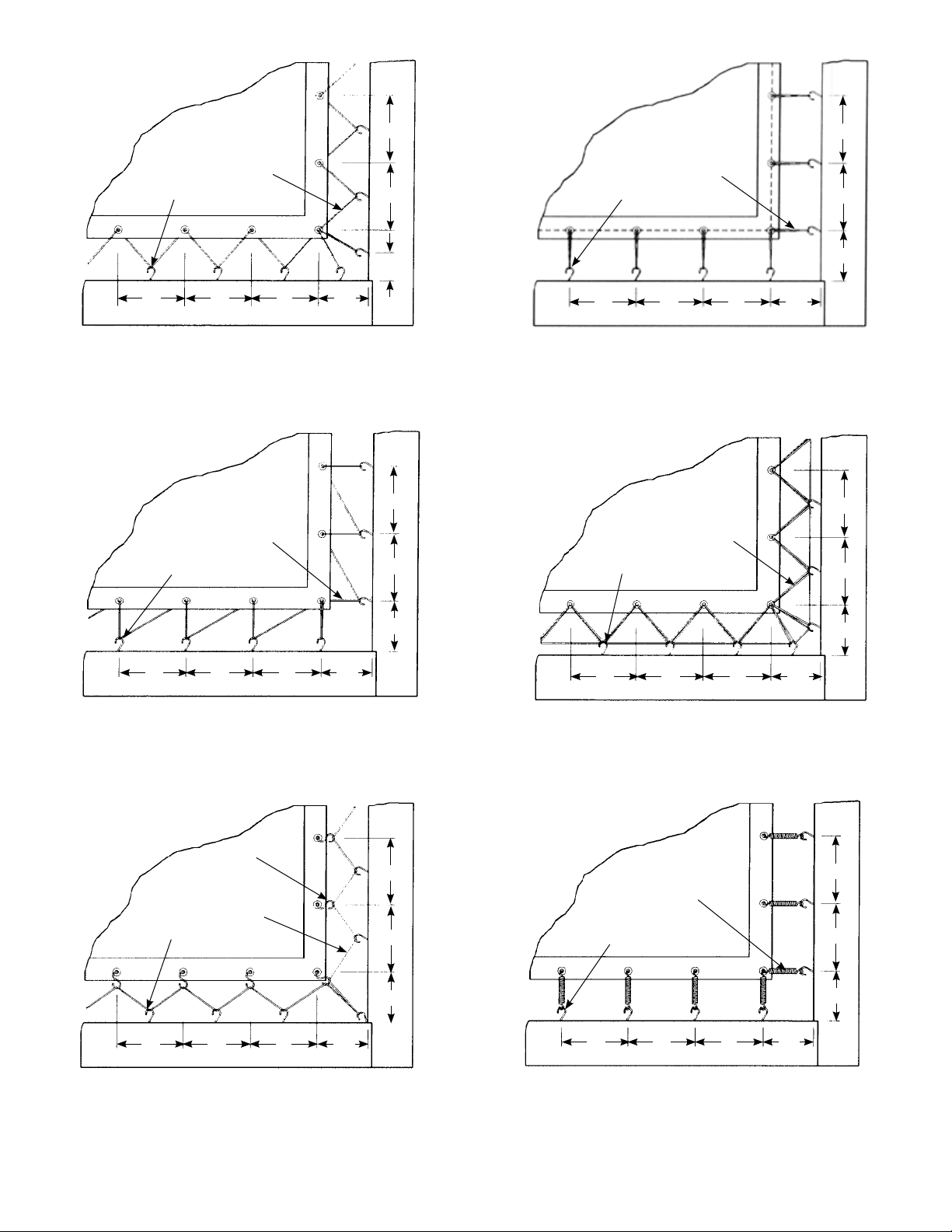

No. 10

Screw

Hooks

Lacing

Cord

6"

No. 10

Screw

6"

Hooks

Lacing

Cord

6"

6"

2.5"

6"

6"

6"

4.5"

Wood Frame

Zig Zag Lacing

Zig Zag Lacing of lacing cord alternately through grommets

and under hooks is a method that will produce good results.

Use this method where it is necessary to lace a screen to a pipe

frame without hooks.

6"

No. 10

Screw

Hooks

Lacing

Cord

6"

4.5"

6"

6"

6"

4.5"

Wood Frame

Diagonal Lacing

Diagonal Lacing provides a desirable tension on the fabric.

It facilitates putting the correct tension in the correct direction

regardless of the grommet and hook relationship.

4.5"

6"

6"

6"

4.5"

Wood Frame

Single Loop Lacing

Single Loop Lacing is fast since each loop is merely doubled,

pushed through the grommet and down over the screw hook.

Alignment between grommet and screw hook must be straight

to avoid puckering of picture surface.

6"

No. 10

Screw

Hooks

Lacing

Cord

6"

2.5"

6"

6"

6"

4.5"

Wood Frame

Double Loop Lacing

Double Loop Lacing tends to eliminate any tendency of the

picture surface to creep at the edges or unnecessary puckering.

This is overcome by pulling each loop over two hooks.

“S“ Hooks

6"

No. 10

Screw

Hooks

Shock

Cord

6"

4.5"

6"

6"

6"

4.5"

Wood Frame

Shock Cord (Elastic) Lacing

Shock Cord Lacing calls for elastic lacing cord (approx. 3/16" dia.)

and “S“ hooks (approx. 11/2") which are inserted in grommet

holes. This is the fastest method and usually considered

adequate. (Shock cord not supplied by Da-Lite.)

6"

Springs

No. 10

Screw

Hooks

6"

4.5"

6"

6"

6"

4.5"

Wood Frame

Spring Lacing

Spring Mounting is a more expensive method, usually reserved

for rear screens used out of doors. Here grommet holes must

be in perfect alignment with the screw hooks. (Springs not

supplied by Da-Lite.)

3

Page 4

Suggested Screen Frame Building Instructions

NOTE: Inside width and height of screen frame should be

12" greater than picture size or 7" greater than over-all size

(including the webbing).

Lumber – Redwood, Spruce, Pine, White Fir. Use 2" x 4" stock

for frames to hold screens 11' x 14' or under. Use 2" x 6" stock

for screens of larger sizes.

Cutting Lumber – 2" x 4" stock-Cut sides or vertical pieces

1' 8" longer than over-all vertical measurements of screen.

Notching

2" x 4" stock. Notch 2 vertical

(shortest) pieces as shown.

2" x 6" stock is notched

longer and deeper.

Cut top and bottom or horizontal pieces 1' 3" longer than

over-all horizontal width of screen. 2" x 6" stock-Cut vertical

pieces 2' longer than over-all vertical measurements of screen.

Cut top and bottom of horizontal pieces 1' 6" longer than

over-all horizontal width of screen.

Bolting Frames

Drill 7/16" hole through notched

pieces. Drill 1/4" hole into ends of

horizontal pieces. Use 3/8" lag bolt

with washer on 2" x 4" frames at

corners. Use same lag bolts and

washers for 2" x 6" stock.

Lacing Hooks

Place #8 screw hooks 41/2" from

inside of corners. Space all others

6" apart. Measurements are same

for frames of 2" x 4" and 2" x 6" stock.

Bracing

Bolt 2" x 4" corner braces to

back of frame at all corners

or gusset plates as illustrated.

On 2" x 6" stock frames, up to

20' width, uses braces 8' long.

10' braces for 20' to 24' widths

and 12' braces for widths

over 24'.

Lacing With Roofing Nails

Use large head rooing nails on face

of frame. Frame is now ready for

lacing screen into position.

4

Page 5

567

Page 6

Page 7

Page 8

LIMITED ONE YEAR WARRANTY ON DA-LITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DA-LITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DA-LITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL–0270 01.14

© 2013 Milestone AV Technologies LLC. Printed in U.S.A.

79160

Loading...

Loading...