Page 1

INSTRUCTION BOOK FOR

Dual Format Imager

Page 2

Important Safety Instructions

Pre-Installation

When using your video equipment, basic safety

precautions should always be followed, including the

following:

1. Read and understand all instructions before using.

2. Close supervision is necessary when any appliance is

used by or near children. Do not leave appliance

unattended while in use.

3. Care must be taken as burns can occur from touching

hot parts.

4. Do not operate appliance with a damaged cord or if the

appliance has been dropped or damaged - until it has

been examined by a qualiied serviceman.

5. To reduce the risk of electric shock, do not immerse this

appliance in water or other liquids.

6. The use of an accessory attachment not recommended

by the manufacturer may cause a risk of ire, electric

shock, or injury to persons.

Save These Instructions

Have space for this unit available on a lat clean surface such as

a large table or loor. The work area should be larger than the

frame size. If the loor is used, clean papers should be spread to

keep all dirt from the Pro-Trim surfaces.

Tools Required for Installation

1/8" and 5/64"

Allen Wrenchs

Carpenter's Level

Tape Measure

Electric Screw Gun Utility Knife

2

Page 3

Unpackaging the Frame:

1. The frame will arrive in two separate cardboard boxes. One

box will be very long and will house the top & bottom pieces.

The smaller cardboard box will house the side frame pieces,

hanger hardware, hardware required to put frame together

and the wall switch.

2. To open the boxes there is a side lap that is taped down the

length of the box. It will be labeled OPEN THIS SIDE (Figure 1).

Carefully cut tape down the length of the box with a utility

knife and fold box open. You will have to tear hard on the

ends as it is stapled on the ends.

Frame Assembly

3. Inside each box the frame pieces will be individually paper

wrapped and taped. Remove all paper from pieces.

CAUTION: DO NOT USE A UTILITY KNIFE TO REMOVE

PAPER FROM PIECES

ATTENTION: N'UTILISEZ PAS DE COUTEAU UTILITAIRE

POUR RETIRER LE PAPIER DES PIÈCES.

4. Remove all paper and styrofoam blocks from top frame

assembly after unwrapping.

1. In the hardware bag, you will receive (12) #10 x .375" long hex

button head screws and (4) #10 x .500" long hex button head

screws required for frame assembly.

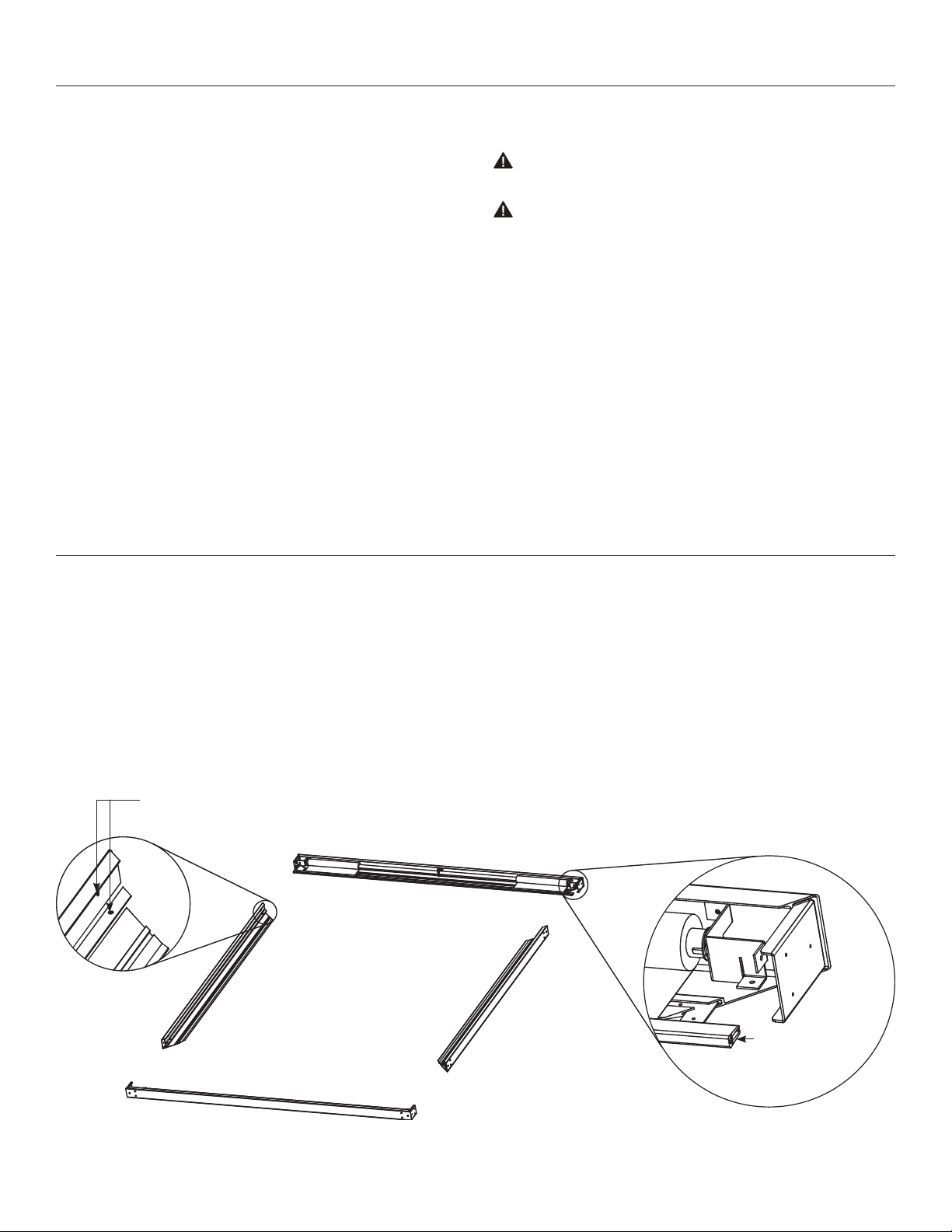

2. Lay frame pieces out on loor or table as shown in Figure 1.

The top frame assembly has the roller and motor assembly

attached to it. The side frames are the two shorter pieces.

Watch side piece to make sure oriented properly. The sides

have two riv nuts used for roller mounting brackets that

should face toward the top frame piece.

Rivnut

Top of Frame

Left of

Frame

Right of

Frame

Bottom of Frame

Make sure slat is

guided in to the

channel

Figure 1

3

Page 4

Frame Assembly (continued)

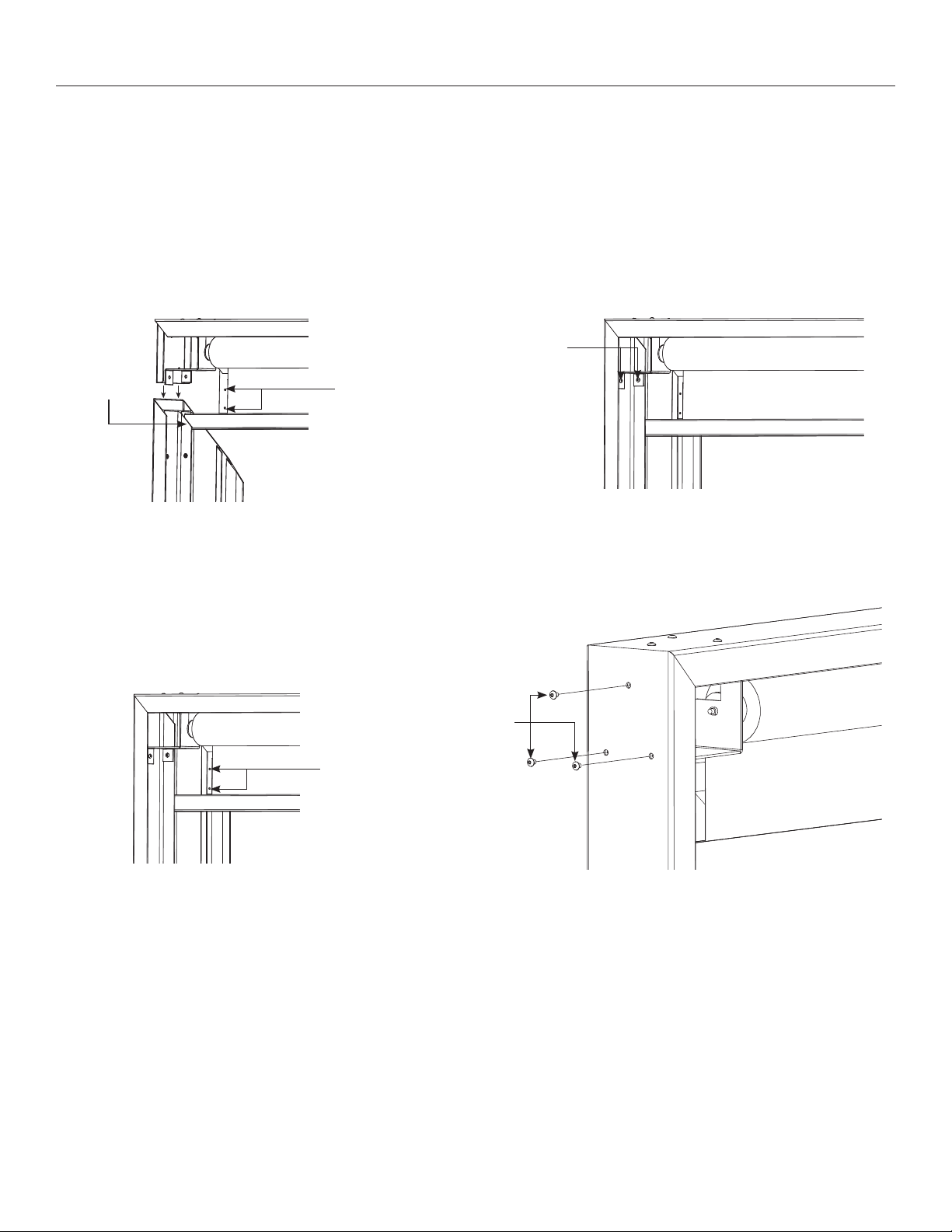

3. Assemble left side of frame to the top of frame. The large

black metal L bracket will slide into the aluminum extrusion

while the small L bracket will slide into the aluminum channel.

The pin end bracket needs to be on the outer surface to bolt

into the rivnuts of the left side piece. The slat will need to be

guided in between the standing in and the front of the frame.

Guide slat in

front of in

Figure 2 – Back of Frame

Loosen set

screws for

clearence

before

inserting

side pieces.

4. Using a 5/64" allen wrench, tighten set screws in frame

straightner bracket. Adjust set screw so that the front surfaces

evenly match at the corner (Figure 4).

5. Using a 1/8" allen wrench, insert (3) #10 x .375" long button head

screws in frame corner connector bracket. Tighten down snug to

frame surface (Figure 5).

Fasten pin

end bracket

(2) #10 x .500"

Figure 3 – Back of Frame

Figure 4 – Back of Frame

Button

Head

Screws

Set Screws

Figure 5

4

Page 5

Frame Assembly (continued)

6. Assemble right side of frame to the top of frame. This is done

exactly the same way as the left side. When assembling the

unit, route the motor wire behind bracket as shown and

attach ield wiring box to side of frame (Figure 6 and 7).

7. Assemble bottom of frame to the right and left sections of

frame. This is done by sliding the large black metal L brackets

into the aluminum extrusion while the small L brackets will

slide in the aluminum channels. Then repeat steps 8 and 9 on

each side (Figure 8).

Route motor

wire behind

bracket

Motor

Ground

Screw

(2) 1/420 x .375"

screws atiach box

to frame

Installation Hole

For 1/2" Conduit

Figure 6 – Back of Frame Figure 7 – Back of Frame

Incoming Wire

Grounding Lug

Figure 8

5

Page 6

Wall Mounting Assembly

1. Depending on size of screen it will be shipped with either 2

wall brackets that are 48" long or 2 wall brackets that are 64"

long. Two small L brackets included will be used to hold

frame securley to wall at bottom.

2. To install the Dual Format lmager over a Da-Lite Perm-Wall

screen you will need to place the supplied wooden spacers

between the screen and the wall.

NOTE: Da-Snap, lmager and Cinema Contour frames do not

require any spacers.

3. Refer to Figure 9 hanger bracket location. Dimension A will

vary depending on the type of screen you have. Dimension A

is measured from the top of the screen frame to the top of

the hanger bracket.

Screen Type Dimension A

Cinema Contour 33/4"

Perm-Wall 43/4"

lmager 43/4"

Da-Snap 51/4"

A

Figure 9

4. Both wall brackets must be mounted into at least two wall

studs. Check to make sure both brackets are vertically level

with each other.

5. Drill holes and attach mounting brackets into wall. You will

need at least 4" clearance above the drilled holes to hang the

screen. Dimension for hole is shown from the top bracket to

center hole position. It is recommended to use a ¼" x 1 ½" lag

screw (not supplied) to fasten bracket to wall.

1 ½"

Figure 10

6

Page 7

Wall Mounting Assembly (continued)

6. Hang the frame assembly on the hanger brackets as shown

in image. Carefully slide bracket between the top of the frame

extrusion and the roller assembly. There is a lip on the back

of the frame that wedges itself into the hanger bracket once

fully installed on bracket. This is a two person installation. Do

not attempt to do this without two people.

The top of the frame assembly will be approximately 1 ¾" above

the hanger brackets when mounted.

Slide frame

over brackets

Bracket

Figure 11

Figure 12

Back lip of frame will

wedge down between

wall bracket and wall

Figure 13

7

Page 8

120V Wiring Diagram for Standard Wall Switch

NOTE: Junction box located on left upper side of frame

Note: A single switch cannot be used to operate more than one

screen. Contact Da-Lite for further information.

White

Black

Red

Green

Motor

UP

OFF

DOWN

White

Black (Up)

Red (Down)

AC Common

Red

AC Hot 120VAC 60Hz 1 Amp

Black

SPOT Switch

with Center Of

CAUTION: This switch

can not be used with LVC.

ATTENTION: Ce commutateur ne peut être

utilisé avec le tableau de contrôle basse

tension.

Black/Yellow

8

Page 9

Post Installation Procedures Travel Adjustments:

1. Test installation by carefully running mask surface up and

down 23 times. Be prepared to stop screen. Standard Duty

Cycle: 1 MIN. ON I 3 MIN. OFF.

CAUTION! Excessive countinous operation may cause

overheating. If motor overheats put switch in center-of

position and allow motor to cool for 30 minutes.

ATTENTION! Le fonctionnement continu et excessif peut

provoquer une surchaufe. Si le moteur surchaufe, mettez

le commutateur au centre sur la position Of et laissez le

moteur refroidir pendant 30 minutes.

Masking travel is stopped automatically in the up and down

positions by limit switches that are properly adjusted at the

factory. Should it be necessary to adjust the stop positions,

proceed in the following manner:

NOTE: Use a screw driver or 5/32" Allen wrench to make

adjustments.

MORE SCREEN DROP

1 . Place operating switch in "down" position.

2. When the mask stops, turn the "down" limit knob (WHITE) one

turn counterclockwise. Test by raising the mask

approximately two feet, then lower again. Repeat until desired

picture surface position is attained.

LESS SCREEN DROP

1. Raise picture surface approximately two feet above

desired level.

2. Place operating switch in "of" position.

3. Turn the "down" limit knob (WHITE) one turn clockwise. Test

by raising the mask approximately two feet, then lower again.

Repeat until desired picture surface position in attained.

9

Page 10

Troubleshooting

Symptom Cause Solution

Masking System will not

operate. Motor does not hum.

Screen will not operate

and motor does not hum.

Power at junction box.

Incorrect line voltage.

Blown fuse. Replace fuse.

Tripped circuit breaker. Reset circuit breaker.

No power to operating switch

or junction.

Thermal overload tripped. Let motor cool down for 15 minutes. Try again.

Broken wire in the “down” or “up” position. Check for continuity. Cut o old splice and reconnect.

Defective motor, limit switch or capacitor. Replace motor assembly. NOTE: Motor is a sealed assembly.

Capacitor burned out. Replace motor assembly.

Verify 115125V (or 220240V). If insuicient voltage, rewire

incoming electric line.

Check above. Tighten all loose wire connections. Correct any

improper connections.

Down Position

Check for power across black and white leads.

Up Position

Check for power across red and white leads.

Masking System does not stop

at correct position.

Noise.

NOTE: Masking System will

operate with a low-pitched

hum.

Coasting. Defective brake. Replace motor assembly.

Mask hangs crooked.

Limit switch is out of adjustment. See Mask Travel Adjustment section on page 9.

Squeaking, rubber end plug rubbing on motor. Center roller in case.

Grinding. Foreign object in screen rubbing on roller

or fabric.

Gear noise. Replace motor assembly.

Masking System not installed properly. Check for level and plumb.

Mask has backed up inside case.

Mask is damaged. Replace mask.

Remove.

Adjust "down" limit switch slowly until roller is exposed and

wrinkle comes out, then readjust for proper drop.

10

Page 11

11

Page 12

LIMITED ONE YEAR WARRANTY ON DALITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DALITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DALITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL–0293 (Rev. 2) 09.14

© 2014 Milestone AV Technologies LLC. Printed in U.S.A.

37865

Loading...

Loading...