Page 1

INSTRUCTION BOOK FOR

Series 200 And 300

Lace And Grommet Frame

Page 2

Installation

Frame Assembly

You will need a 9/16" wrench to assemble your Series 200/300 lace and grommet frame. If you have a split frame, you will also need a

3/16" allen wrench. Before beginning assembly make sure the work surface is clear of objects or debris that could scratch the frame or

puncture the viewing surface. Use the wrapping material to lay the frame sections on to keep from scratching the frame.

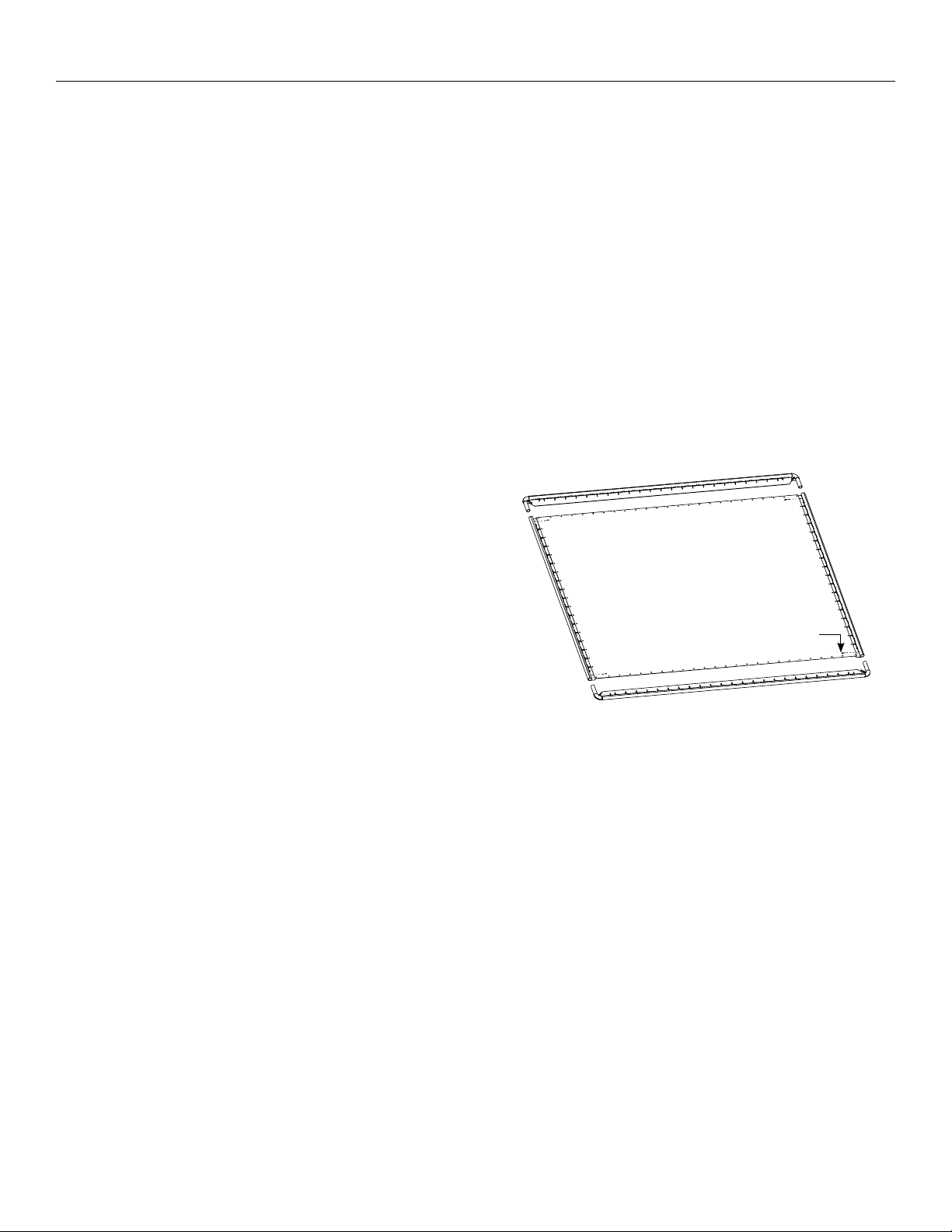

1. Unwrap the frame sections and orient them as shown in the

Figure below. Note that the ends are color coded. Make sure

the colors match at each corner. If your frame has the

optional Pro-Trim masked borders, lay the frame with the

borders facing down. Be sure to lay the frame on the

wrapping material to keep the Pro-Trim clean.

2. If your frame has two-piece top and bottom frame sections,

match the color codes on the ends of the tubes. See split

frame assembly on page 4. When top and bottom sections

are assembled the corners should lay lat to assure that

the unit does not twist or bow.

3. Slide the side frame sections onto the top frame section.

Insert one 3/8" bolt at each corner and tighten (do not

over-tighten).

4. The next step is much easier with two people. With one

person at each end, slide the bottom frame section into the

side frame sections. Make sure each side slides evenly to

avoid binding. Insert one 3/8" bolt at each corner and tighten

(do not over-tighten).

5. Frame assembly is complete. Next, unwrap the viewing

surface (sold separately) and lay it face down inside

the frame assembly.

6. The viewing side of the surface is wrapped to the inside

of the roll so you will have to unroll the surface and then

turn it over. Be sure to lay the surface on the wrapping

material to keep it clean.

7. Start at one side of the frame and locate the center of the

viewing surface and frame. The center of the screen surface

can be identiied by a bright colored grommet on each of the

four sides. The center of the frame is marked by a piece of

colored tape. Starting at the center, begin attaching the hooks

on the frame into the grommets holes in the screen surface.

When you get to one end, the grommet in the corner of the

viewing surface should be attached to the s-hook in the

corner of the frame.

3/8" Bolt

4Pieces

Figure 1

2

Page 3

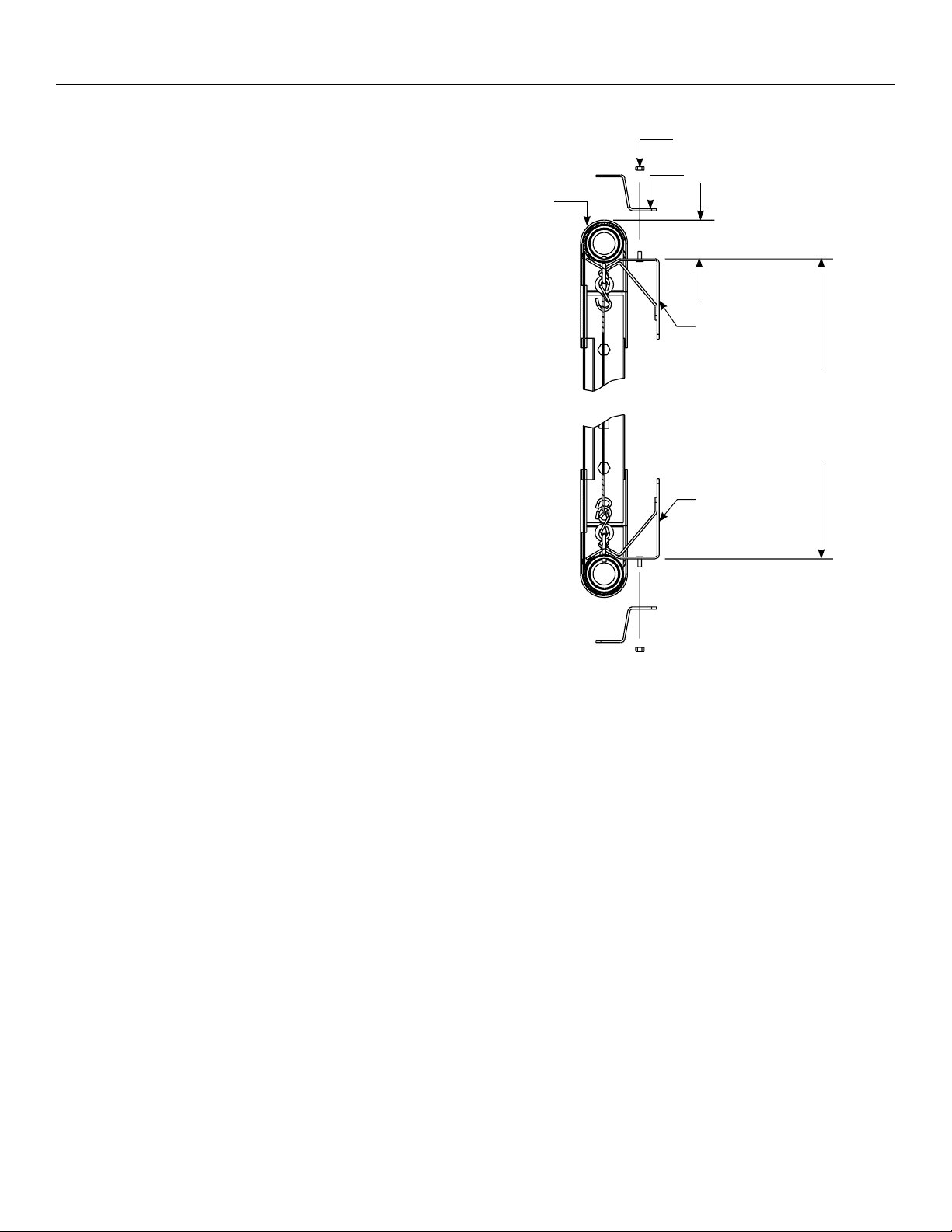

Series 200 Installation

The Series 200 frame is supplied with eyebolts for ceiling installations and hanger brackets for wall mount installations.

Ceiling Installation: The frame is predrilled for the attachment

of the eyebolts. There are 3 eyebolts for smaller frames with a

one-piece top frame rail. Larger frames with two-piece top frame

rails will have 4 eyebolts. Insert the eyebolts through the frame

and attach the hex nut to the eyebolt.

Wall Mount Installation: There are 6 hanger brackets for

smaller frames with a one-piece top frame rail. 8 hanger brackets

are provided for larger frames with two-piece top frame rails.

Determine where the Series 200 frame will be mounted on the

wall. Consider the following before attaching the hanger

brackets to the wall.

• The hanger brackets must be anchored to a supported

section of the wall, such as a wall stud.

• The hanger brackets should be spaced on the wall

so they line up with the S-hooks on the frame. This

will prevent the lace cord from being pinched between

the frame and hanger.

• You will need at least 2" above the hanger bracket

to mount the Series 200 frame (see Figure 2).

• Frames with one-piece top frame rails should be

supported at the center of the frame and about

24 feet from each end of the frame.

• Frames with two-piece top frame rails should be

supported about 23 feet on each side of the center

joint and about 24 feet from each end of the frame.

Series

200

Frame

Hex Nut

Frame Clamp

2" Minimum

Upper Hanger

Bracket

Equals Outside Frame Height

• 3 ¾" With Pro-Trim Border

• 3 ½" Without Pro-Trim Border

(Pro-Trim Border Adds ¼"

To Frame Height

Lower Hanger

Bracket

Figure 2

1. Attach 3 or 4 hanger brackets (as required above) at the

same height along the wall. To determine the distance

between the upper and lower hanger brackets you must

measure the overall height of the frame. If your frame has the

Pro-Trim border subtract 33/4" from the overall height. If your

frame does not have the Pro-Trim border subtract 31/2" from

the overall height. Using this number, measure down from

each hanger bracket and mark the wall.

2. Line up the lower hanger bracket with the mark and secure

it to the wall. Refer to Figure 2.

3. Remove the frame clamp from the hanger brackets and

position the Series 200 frame on the hanger brackets as

shown in Figure 2.

4. Place the frame clamp onto the hanger bracket and

secure it with the supplied hex nut.

3

Page 4

Series 300 Installation

The Series 300 frame is supplied with eyebolts for ceiling installations and hanger brackets for wall mount installations.

Ceiling Installation: The frame is predrilled for the attachment

of the eyebolts. There are 3 eyebolts for smaller frames with a

one-piece top frame rail. Larger frames with two-piece top frame

rails will have 4 eyebolts. Insert the eyebolts through the frame

and attach the hex nut to the eyebolt.

Wall Mount Installation: There are 6 hanger brackets for

smaller frames with a one-piece top frame rail. 8 hanger brackets

are provided for larger frames with two-piece top frame rails.

Determine where the Series 300 frame will be mounted on the

wall. Consider the following before attaching the hanger brackets

to the wall.

• The hanger brackets must be anchored to a supported

section of the wall, such as a wall stud.

• The hanger brackets should be spaced on the wall so

they line up with the S-hooks on the frame. This will

prevent the lace cord from being pinched between the

frame and hanger.

• You will need at least 3" above the hanger bracket to

mount the Series 300 frame (see Figure 3).

• Frames with one-piece top frame rails should be

supported at the center of the frame and about 24 feet

from each end of the frame.

• Frames with two-piece top frame rails should be

supported about 23 feet on each side of the center joint

and about 24 feet from each end of the frame.

Series

300

Frame

Hex Nut

Frame Clamp

3" Minimum

Upper Hanger

Bracket

Equals Outside Frame Height

• 4 ¾" With Pro-Trim Border

• 4 ½" Without Pro-Trim Border

(Pro-Trim Border Adds ¼"

To Frame Height

Lower Hanger

Bracket

Figure 3

1. Attach 3 or 4 hanger brackets (as required above) at the

same height along the wall. To determine the distance

between the upper and lower hanger brackets you must

measure the overall height of the frame. If your frame has the

Pro-Trim border subtract 43/4" from the overall height. If your

frame does not have the Pro-Trim border subtract 41/2" from

the overall height. Using this number, measure down from

each hanger bracket and mark the wall.

2. Line up the lower hanger bracket with the mark and secure it

to the wall. Refer to Figure 3.

3. Remove the frame clamp from the hanger brackets and

position the Series 300 frame on the hanger brackets as

shown in Figure 3.

4. Place the frame clamp onto the hanger bracket and secure it

with the supplied hex nut.

4

Page 5

Split Frame Assembly

1. Loosely tighten set screw so that pieces will still move

freely. See Figure 4.

2. Slide tube over connector and line up hole. See Figure 5.

3. Insert second set screw and tighten all the way until tube

is secure. See Figure 6.

Figure 4

Figure 6

4. Tighten irst set screw the rest of the way. See Figure 6.

5. Finished joint should look like Figure 7.

Figure 5

Figure 7

Page 6

Page 7

Page 8

LIMITED ONE YEAR WARRANTY ON DA-LITE PRESENTATION PRODUCTS

Milestone AV Technologies LLC warrants certain Da-Lite branded products to the original purchaser only, to be free from defects in

materials and workmanship for a period of one (1) year from the date of purchase by the original purchaser; provided they are properly

operated according to Da-Lite's instructions and are not damaged due to improper handling or treatment after shipment from the

factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental damage, or which has been tampered

with or repaired by a person other than authorized Da-Lite personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option) the defective part of the merchandise.

Returns for service should be made to your Da-Lite dealer. If it is necessary for the dealer to return the screen or part to Da-Lite,

transportation expenses to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in shipment.

To protect yourself against damage or loss in transit, insure the product and prepay all transportation expenses.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANTABILITY. Any implied warranties of itness for use,

or merchantability, that may be mandated by statute or rule of law are limited to the one (1) year warranty period. This warranty gives

you speciic legal rights, and you may also have other rights, which vary from state-to-state. TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, NO LIABILITY IS ASSUMED FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION

OF EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may contact our Sales Partners at PO Box 137,

Warsaw, IN 465810137, (574) 2678101, (800) 6223737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DA-LITE BRANDED PRODUCTS SHALL NOT BE BOUND BY THIS

WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH THE DA-LITE WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

A Milestone AV Technologies Brand

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.da-lite.com

DL–0286 01.14

© 2013 Milestone AV Technologies LLC. Printed in U.S.A.

94696

Loading...

Loading...