Page 1

The Da-Lite Difference.

Instruction Book for

COSMOPOLITAN® ELECTROL®

For Sizes Up To 9'x12'

DA-LITE SCREEN COMPANY, INC.

3100 North Detroit Street

Post Office Box 137

Warsaw, Indiana 46581-0137

Phone: 574-267-8101

800-622-3737

Fax: 574-267-7804

Toll Free Fax: 877-325-4832

www.da-lite.com

e-mail: info@da-lite.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using your video equipment, basic safety precautions should always be followed, including the

following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating at least equal to that of the appliance

should be used. Cords rated for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this appliance. Contact an authorized

service dealer when repair work is required. Incorrect reassembly can cause electric shock when

the appliance is used subsequently.

5. The use of an accessory attachment not recommended by the manufacturer may cause a risk of

fire, electric shock, or injury to persons.

SAVE THESE INSTRUCTIONS

PRE-INSTALLATION

1. Carefully unpack screen and remove outer wrapping from case.

2. Do not remove black tape or rubber bands from slat pocket.

3. Always handle screen in horizontal position.

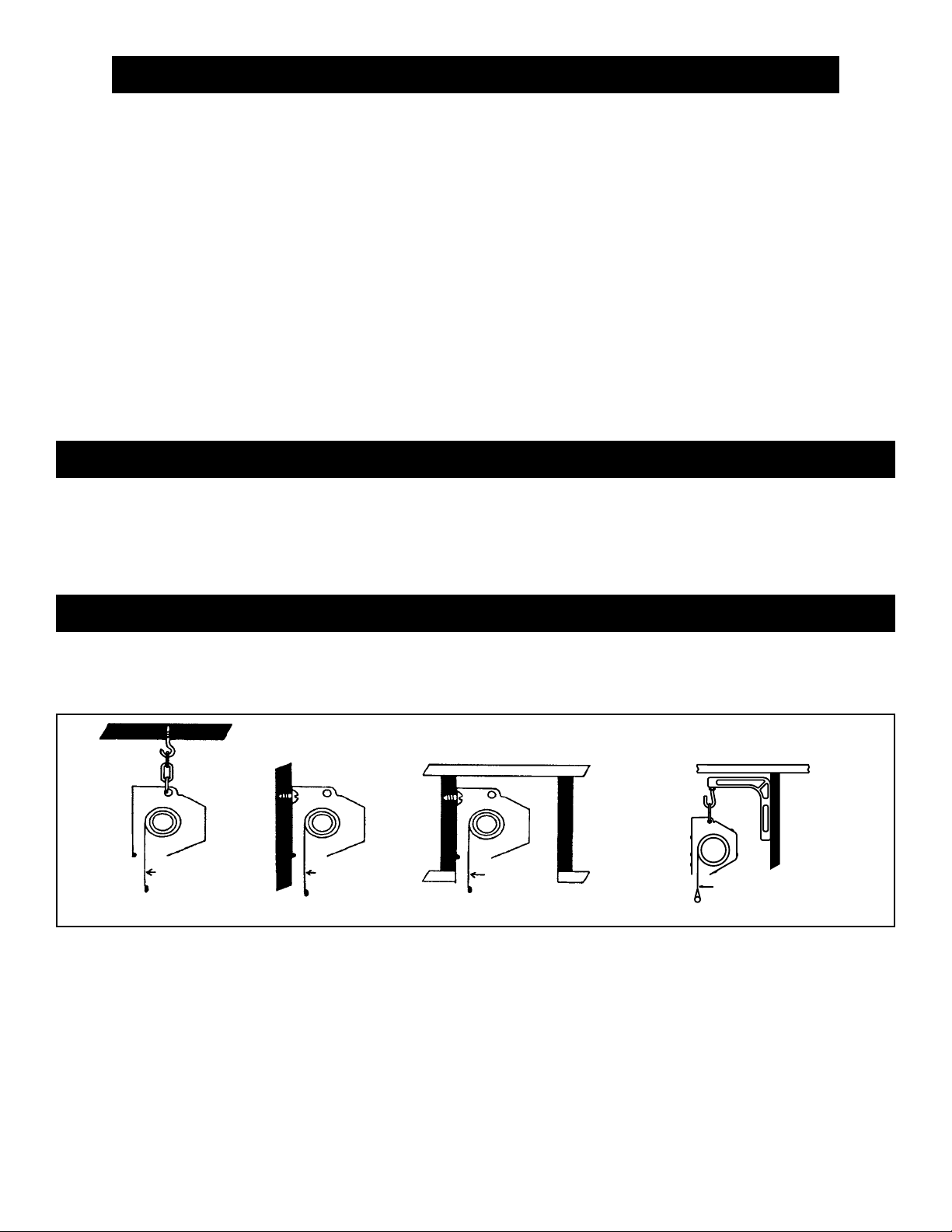

INSTALLATION

There are three methods of mounting to include:

Flush against wall; Suspended from ceiling (use extension brackets); and Recessed above ceiling.

USE NO. 6 BRACKETS

CEILING HANGING

PICTURE SURFACE

NOTE: Under no circumstances should unit be completely sealed in recessed installation. Allow access for service. Picture surface

is centered in case. Case extends 4" beyond surface on either end. Do not attach anything to screen slat rod or bottom fabric pocket.

1. Make sure screen is level. Use a carpenter’s level and plumb level.

CAUTION! Do not cut wrapping paper or tape with knife or any sharp tool. Remove by hand.

s

!

2. Remove tape and rubber bands from slat pocket.

3. Install electrical hook up that applies to your unit. Make sure to review your Electrical Installation Checklists and

wiring diagrams (included) for either 120 volt switch, 220/240 volt switch, or low voltage control.

4. Test installation by running screen up and down a few times. Be prepared to stop screen. Standard Duty Cycle: 1

MIN. ON / 3 MIN. OFF.

NOTE: Must be installed in accordance with the requirements of the Local Building Codes, the Canadian Electrical Code (CEC), CAN/

CSA C22.1 and the National Electric Code (NEC), NFPA 70.

WALL MOUNTED

PICTURE SURFACE

CONCEALED (ALLOW ROOM FOR ACCESS)

PICTURE

SURFACE

FIGURE 1

TO HANG BEHIND

BEAM OR VALANCE

PICTURE

SURFACE

1

Page 3

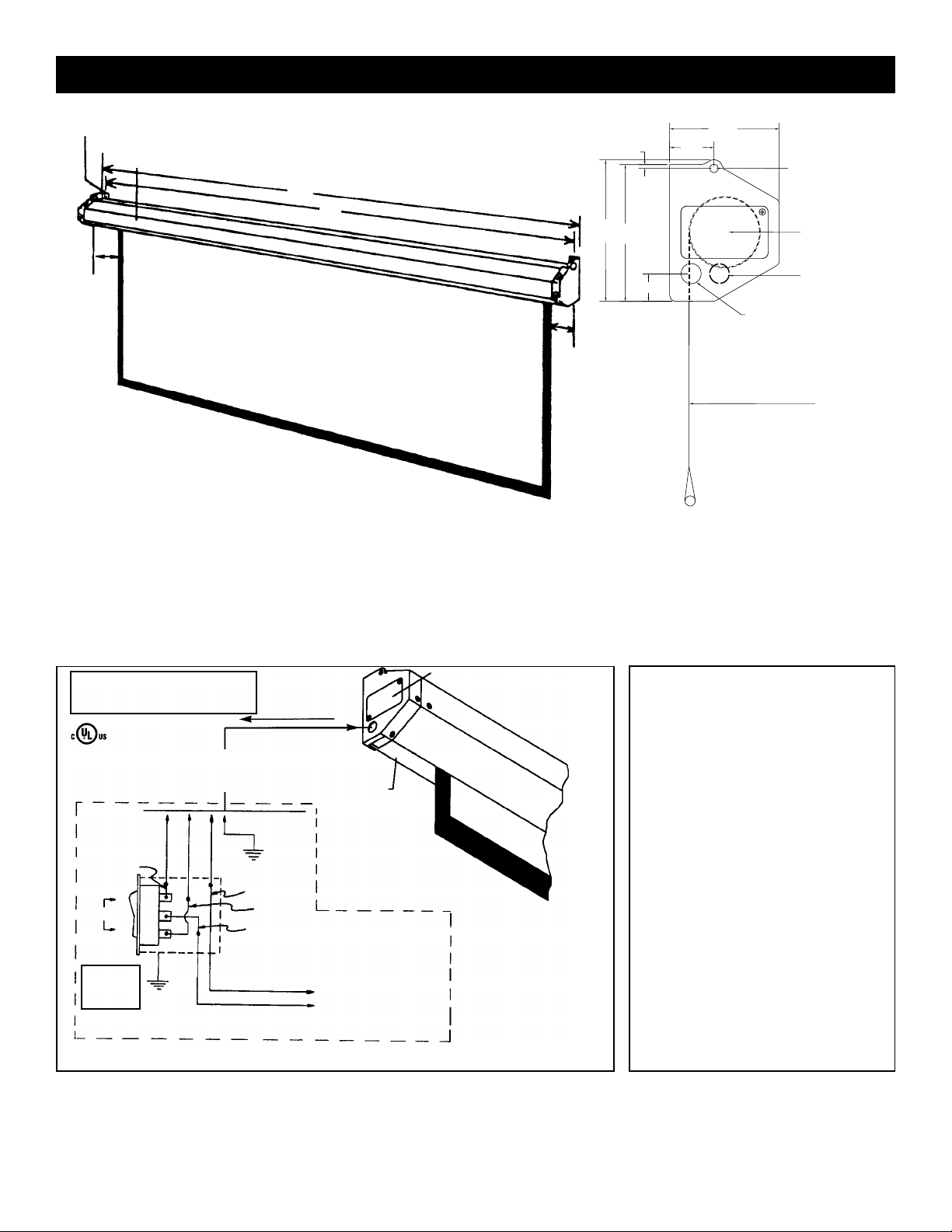

COSMOPOLITAN® ELECTROL® INSTALLATION

3/4" DIAMETER HOLE FOR

WALL INSTALLATION

MOTOR END

4"

Overall length A=fabric width + 8".

Length B is the distance between wall mounting holes

at back of end caps and is the fabric width + 6-1/2".

A

B

FABRIC HEIGHT x WIDTH AS ORDERED,

UP TO 12 FEET x 12 FEET.

FIGURE 2

23

4

⁄32"

5

⁄32"

129⁄32"

3

⁄8" DIAMETER FOR

CEILING

INSTALLATION

3

6

⁄32"

57⁄8"

13⁄16"

7

⁄8" DIAMETER OPENING

4"

FOR ELECTRICAL FITTINGS

ENCLOSURE COVER

7

⁄8" DIAMETER

KNOCK OUT

PICTURE

SURFACE

120V WIRING DIAGRAM

TO JUNCTION BOX, MOUNTED IN

SCREEN CASE, IN WHICH INTERNAL

WIRING TERMINATES IN WHITE,

BLACK AND RED LEADS

COMMON

WHITE

UP

RED

DOWN

BLACK

120 V. 60 HZ. 2.5 MAX. AMP

WHITE

RED

BLACK WITH

YELLOW

AC COMMON

AC HOT

OPERATING SWITCH AND

PLATE FURNISHED WITH

SCREEN. (SPDT WITH

CENTER OFF)

ROCKER

SWITCH

UP

OFF

DOWN

SIDE VIEW

OF SWITCH

AND BOX

BLACK

THIS SWITCH CANNOT BE USED WITH LVC.

NOTE: A single switch cannot be used to operate more than

one screen. Contact the factory for further information.

DOWN

WHITE LIMIT

SWITCH

ADJUSTMENT

WIRING ENCLOSURE COVER

IN MULTIPLE CONTROL

INSTALLATIONS THIS

SWITCH IS REPLACED BY

THE LOW VOLTAGE

CONTROL, OPERATED FROM

PUSH BUTTON STATIONS.

FIGURE 3

240 VOLT WIRING DIAGRAM FOR

STANDARD WALL SWITCH:

Da-Lite offers two styles of 240

volt wall switches for standard

operation. Please see wiring

diagram included in wall switch box

included with screen.

2

Page 4

SCREEN ADJUSTMENT FOR SCREENS WITHOUT A BUILT-IN LOW VOLTAGE CONTROL

Surface travel is stopped automatically in the fully opened and closed positions by limit switches that are properly

adjusted at DA-LITE. Should it be necessary to adjust for more or less picture drop (viewing area), proceed in the

following manner:

NOTE: Use a screwdriver or 5/32" Allen wrench to make adjustments.

SETTING THE DOWN LIMIT POSITION

TO REDUCE SCREEN DROP:

Turn the white limit switch screw (Figure 3) clockwise to decrease the amount of screen drop. Run the screen

down to test the stop position. If the screen drops too far, raise the screen about one foot and adjust the limit

switch again. Repeat until the desired position is set.

TO INCREASE SCREEN DROP:

Turn the white limit switch screw counterclockwise to increase the amount of screen drop. Run the screen down

to test the stop position. If the screen does not drop enough, raise the screen about one foot and adjust the limit

switch again. Repeat until the desired position is set. Do not adjust for more drop than what was ordered. At least

1-1/2 wraps of fabric must remain on the roller.

CAUTION: Do not adjust for more drop than what was ordered. At least 1-1/2 wraps of fabric must remain on the roller. This

!

s

screen comes standard with 0" or 2" black at the top. See the specification data sheet for details.

COSMOPOLITAN® ELECTROL® INSTALLATION

120V WIRING DIAGRAM WITH

OPTIONAL BUILT-IN VIDEO

PROJECTOR INTERFACE

CAUTION: THE PROJECTOR MUST BE TURNED OFF BEFORE CONNECTING THE

TRIGGER WIRES TO THE PROJECTOR. FAILURE TO DO SO MAY DAMAGE THE

CONTROLLER.

Use 2-conductor 20-24 gauge wire to extend the low voltage connection

from the projector’s 5 or 12-volt screen trigger output to the length

required to reach the VPI. When extending the low voltage connection

from the projector’s screen trigger output polarity does not matter. The

red and black wires from the VPI are interchangeable.

IMPORTANT NOTE:

The wall switch is REQUIRED to make any limit switch adjustments,

EVEN if a third party control system is used. Therefore, it is advised to

wire the switch or provide a 3-conductor connection that is accessible.

3-conductor 20-24 gauge wire can be used in place of the supplied RJ-14

cable to connect the wall switch. Connect the BUS terminals on the wall

switch to the corresponding BUS terminals on the splitter board.

UP

STOP

DOWN

FRONT OF

WALL SWITCH

LED

UP LIMIT

TACTILE

BUTTON

DOWN

TACTILE

BUTTON

BUS

LIMIT

BACK OF

WALL SWITCH

BLACK

RED

5/12 VOLT SCREEN

TRIGGER ON PROJECTOR

3

RJ-22 JACK

RJ-22

INPUTS

RJ-22

JACK

COM

5V

BUS

VPI TRIGGER

MODULE

RJ-22 OUTPUT

POWER

WIRE

BLACK (HOT)

WHITE (COMMON)

UP

DOWN

COMMON

BUS

5V

RJ-45

RECEPTACLE

RJ-45

JACK

DRY CONTACTS

BUS

DATA

CABLE

GREEN (GROUND)

GROUND–MUST BE CONNECTED

TO BUILDING GROUND

POWER INPUT 120VAC / 60HZ

FIGURE 4

Page 5

COSMOPOLITAN® ELECTROL® INSTALLATION

120V WIRING DIAGRAM

WITH OPTIONAL BUILT-IN

LOW VOLTAGE CONTROL

LED

RJ-22

UP LIMIT

TACTILE

UP

STOP

DOWN

FRONT OF

WALL SWITCH

BUTTON

DOWN LIMIT

TACTILE

BUTTON

BUS

COM

5V

BACK OF

WALL SWITCH

BUS

RJ-22

JACK

3-conductor 20-24 gauge wire can be used in place of

the supplied RJ-14 cable to connect the wall switch.

Connect the BUS terminals on the wall switch to the

corresponding BUS terminals on the splitter board.

IMPORTANT NOTE:

The wall switch is REQUIRED to make any limit switch

adjustments, EVEN if a third party control system is

used. Therefore, it is advised to wire the switch or

provide a 3-conductor connection that is accessible.

INPUTS

RJ-22

JACK

POWER WIRE

WHITE (COMMON)

RJ-14 PIN-OUTS

(TAB IS FACING UP)

RJ-22

OUTPUT

BLACK (HOT)

BUS (RP DATA)

RQ DATA

GND

UP

DOWN

COMMON

BUS

5V

RJ-45

RECEPTACLE

+5V

DRY CONTACTS

BUS

RJ-45 JACK

WHITE

GREEN

RED

BLACK

GREEN (GROUND)

POWER INPUT 120VAC / 60HZ

Standard RJ-22 can be used in place of RJ-14Supplied RJ-14 cable

DATA

CABLE

GROUND–MUST BE

CONNECTED TO

BUILDING GROUND

RJ-22 PIN-OUTS

(TAB IS FACING UP)

BLUE

+12V

GND

+12V

GND

YELLOW

GREEN

RED

+5V

BLACK

WHITE

BROWN

BLUE

YELLOW

GREEN

RED

+5V

BLACK

ORANGE

PURPLE

BUS (RP DATA)

RQ DATA

RQ CLOCK

RJ-45 PIN-OUTS

(TAB IS FACING UP)

MANUAL 2

BUS (RP DATA)

RQ DATA

RQ CLOCK

MANUAL 1

FIGURE 5

SCREEN ADJUSTMENT FOR 120V SCREENS WITH A BUILT-IN LOW VOLTAGE CONTROL OR VPI

1. Locate the wall switch and remove the cover plate from the 3-button wall switch and remove the switch from the

junction box.

2. Locate the two tactile buttons on the back of the switch. They are square silver with black round buttons. See

Figure 4 (VPI) or Figure 5 (LVC) for diagram.

3. To adjust the down limit switch, press and hold the down tactile button until the LED on back of switch turns solid

red. This will put the motor in limit set mode. Turn the wall switch over and use the down button on front of

switch. Press and hold until the desired travel position is reached. If you travel to far down you can press the up to

move the screen upward. If you press and let go of either up or down button the motor will do a small jog in that

direction for finer adjustment of screen. Once desired position is reached turn switch over press and hold down

tactile button until the LED on back of switch blinks red twice. The down limit is now set.

4. To adjust the up limit switch, press and hold the up tactile button until the LED on back of switch turns solid green.

This will put the motor in limit set mode. Turn the wall switch over and use the up button on front of switch. Press

and hold until the desired travel position is reached. If you travel to far up you can press the down to move the

screen downward. If you press and let go of either up or down button the motor will do a small jog in that direction

for finer adjustment of screen. Once desired position is reached turn switch over press and hold up tactile button

until the LED on back of switch blinks green twice. The up limit is now set.

5. To test limit switch setting, press and release the up or down button on the wall switch to operate the screen.

6. Replace switch and cover plate on the wall.

NOTE: If the screen is in limit set mode and no buttons are pushed for 20 seconds, the LED on the back of the wall switch

will turn off, the motor will return to run mode and no changes will be saved. If this occurs, return to step 3 for

down limit adjustment or step 4 for up limit adjustment.

IMPORTANT NOTE: The wall switch is REQUIRED to make any limit switch adjustments, EVEN if a third party control

system is used. Therefore, it is advised to wire the switch or provide a 3-conductor connection that is

accessible.

4

Page 6

COSMOPOLITAN® ELECTROL® INSTALLATION

240V WIRING DIAGRAM

WITH OPTIONAL BUILT-IN

LOW VOLTAGE CONTROL

BLUE (COMMON)

240VAC 50HZ

GROUND–MUST BE

CONNECTED TO

BUILDING GROUND

BROWN (HOT)

GREEN

GREEN

GROUND TO CASE

MOTOR

OPTIONAL IR AND RF

REMOTE CONTROL

RJ9

UP

+5V

COM

DN

SPLITTER

DRY CONTACTS

CONNECT SUPPLIED

RJ9 CABLE TO

SPLITTER AND

SWITCH, OR USE 4

CABLE CONDUCTOR

TO CONNECT TO

SCREW TERMINALS.

RJ9

LOW-VOLTAGE WALL SWITCH

UP DN

3-POSITION

SWITCH

GND +5V

UP

STOP

DOWN

FRONT BACK

RJ9

ILT RJ9 PIN-OUTS

(TAB IS FACING UP)

IR or UP BLACK

GND COMMON RED

+5V GREEN

DN or DATA WHITE

IMPORTANT NOTE: The wall switch is REQUIRED to make any limit

switch adjustments, EVEN if a third party control

system is used. Therefore, it is advised to wire the

switch or provide a 4-conductor connection that is

accessible.

FIGURE 6

SCREEN ADJUSTMENT FOR 220V/240V SCREENS WITH A BUILT-IN LOW VOLTAGE CONTROL

1. Remove the cover plate from the 3-button wall switch and remove the switch from the junction box.

2. Locate small 3-position switch on back of wall switch. (See Figure 6)

3. To adjust the down limit switch, slide the 3-position switch to the down position. Press and hold the down button

to run the screen down to the desired stop position. Release the button to stop the screen. DO NOT PUSH THE

STOP BUTTON.

4. When the screen is in the desired down position, slide the 3-position switch to the off (center) position. The down

limit switch is now set.

5. To adjust the up limit switch, slide the 3-position switch to the up position. Press and hold the up button to run the

screen up to the desired stop position. Release the button to stop the screen. DO NOT PUSH THE STOP BUTTON.

6. When the screen is in the desired up position, slide the 3-position switch to the off (center) position. The up limit

switch is now set.

7. To test limit switch setting, make sure the 3-position switch is in the off (center) position. Press and release the up

or down button on the wall switch to operate the screen.

8. Replace switch and cover plate on the wall.

NOTE: If stop button is pressed, the wall switch will reverse direction. To correct this, press the stop button again. This

will reset the switch. You will have to re-set both the up and the down settings.

IMPORTANT NOTE: The wall switch is REQUIRED to make any limit switch adjustments, EVEN if a third party control

system is used. Therefore, it is advised to wire the switch or provide a 4-conductor connection that is

accessible.

5

Page 7

TROUBLESHOOTING

Visit www.da -lite.com/products/tutorials.php to find installation and troubleshooting tutorials. You will also

find a link to Live Chat for interactive support and you can contact us by email at info@da-lite.com or by phone

at (800) 622-3737 or (574) 267-8101 with any troubleshooting questions.

SYMPTOM

1. Screen will not operate.

Motor does not hum.

Motor hums.

CAUSE

(a) Incorrect line voltage.

(b) Blown fuse.

(c) Tripped circuit breaker.

(d) No power to operating switch or

junction.

Power at junction box

(e) Thermal overload tripped.

(f) Broken wire in the “up” or ”down”

position.

(g) Defective motor, limit switch or

capacitor.

(h) Capacitor burned out.

SOLUTION

(a) Verify 115-125V (or 220-240V). If

insufficient voltage, rewire

incoming electric line.

(b) Replace fuse.

(c) Reset circuit breaker.

(d) Check above. Tighten all loose

wire connections. Correct any

improper connections.

“Down” Position

Check for power across black

and white leads.

“Up” Position

Check for power across red

and white leads.

(e) Let motor cool down for 15

minutes. Try again.

(f) Check for continuity. Cut off old

splice and reconnect.

(g) Replace motor assembly.

NOTE: Motor is a sealed assembly.

(h) Replace motor assembly.

2. Incorrect stopping position in

downward direction.

3. Incorrect stopping position in

upward direction.

4. Noise.

NOTE: Screen will operate with a

low pitched hum.

5. Coasting.

6. Roller displaced from mounting

bracket.

RESTORING LOST ROLLER WRAP

1. Push strap over back of roller.

2. Tape end of strap to pocket.

(a) Lost roller wrap.

(b) “Down” limit switch out of

adjustment

(a) Lost roller wrap.

(b) “Up” limit switch out of

adjustment

(a) Gear noise.

(a) Defective brake.

(a) Pin end slipped out of nylon

bearing.

3. Feed fabric as you pull strap to draw fabric over top.

4. Remove tape and strap.

(a) See instructions below.

(b) See installation instructions.

(a) See instructions below.

(b) Adjust “up” limit switch. Call

factory for instructions

(a) Replace motor assembly.

(a) Replace motor assembly.

(a) Realign pin end bracket.

6

Page 8

LIMITED ONE YEAR WARRANTY

ON DA-LITE PRESENTATION PRODUCTS

Da-Lite Screen Company, Inc. warrants its products to the original purchaser only, to be free from

defects in materials and workmanship for a period of one (1) year from the date of purchase by

the original purchaser provided they are properly operated according to Da-Lite’s instructions and

are not damaged due to improper handling or treatment after shipment from the factory.

This warranty does not apply to equipment showing evidence of misuse, abuse or accidental

damage, or which has been tampered with or repaired by a person other than authorized Da-Lite

personnel.

Da-Lite’s sole obligation under this warranty shall be to repair or to replace (at Da-Lite’s option)

the defective part of the merchandise. Returns for service should be made to your Da-Lite dealer.

If it is necessary for the dealer to return the screen or part to Da-Lite, transportation expenses

to and from Da-Lite are payable by the purchaser and Da-Lite is not responsible for damage in

shipment. To protect yourself against damage or loss in transit, insure the product and prepay all

transportation expenses.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES AS TO FITNESS FOR USE AND MERCHANT ABILITY. Any implied

warranties of fitness for use, or merchantability, that may be mandated by statute or rule of law

are limited to the one (1) year warranty period. This warranty gives you specific legal rights, and

you may also have other rights, which vary from state-to-state. NO LIABILITY IS ASSUMED

FOR EXPENSES OR DAMAGES RESULTING FROM INTERRUPTION IN OPERATION OF

EQUIPMENT, OR FOR INCIDENTAL, DIRECT, OR CONSEQUENTIAL DAMAGES OF ANY

NATURE.

In the event that there is a defect in materials or workmanship of a Da-Lite product, you may

contact our Sales Partners at PO Box 137, Warsaw, IN 46581-0137, (574) 267-8101, (800) 622-3737.

IMPORTANT: THIS WARRANTY SHALL NOT BE VALID AND DA-LITE SHALL NOT BE

BOUND BY THIS WARRANTY IF THE PRODUCT IS NOT OPERATED IN ACCORDANCE WITH

DA-LITE’S WRITTEN INSTRUCTIONS.

Keep your sales receipt to prove the date of purchase and your original ownership.

7Printed in U.S.A. 46832 Rev. 9/11

Loading...

Loading...