INSTRUCTION BOOK FOR

Tensioned Large Advantage®

Deluxe Electrol

®

Important Safety Instructions

Pre-Installation

When using your video equipment, basic safety precautions

should always be followed, including the following:

1. Read and understand all instructions before using.

2. Close supervision is necessary when any appliance is used

by or near children. Do not leave appliance unattended while

in use.

3. Do not operate appliance with a damaged cord or if the

appliance has been dropped or damaged – until it has been

examined by a qualiied serviceman.

4. Position the cord so that it will not be tripped over, pulled, or

contact hot surfaces.

5. If an extension cord is necessary, a cord with a current rating

at least equal to that of the appliance should be used. Cords

rated for less amperage than the appliance may overheat.

6. To reduce the risk of electric shock, do not immerse this

appliance in water or other liquids.

7. To reduce the risk of electric shock, do not disassemble this

appliance. Contact an authorized service dealer when repair

work is required. Incorrect reassembly can cause electric

shock when the appliance is used subsequently.

8. The use of an accessory attachment not recommended by

the manufacturer may cause a risk of ire, electric shock, or

injury to persons.

1. Carefully unpack screen and remove outer wrapping

from case.

2. Make sure to recheck measurements of screen location

before installation.

PLEASE NOTE: Motor Operator Projection Screen Models

LADT, LADDT, LAD and LADD must be installed in accordance

with the requirements of the Local Building Codes, the

Canadian Electrical Code (CEC), CAN/CSA C22.1 and the

National Electric Code (NEC), NFPA 70. An appropriate

disconnect device shall be provided as part of the building

installation.

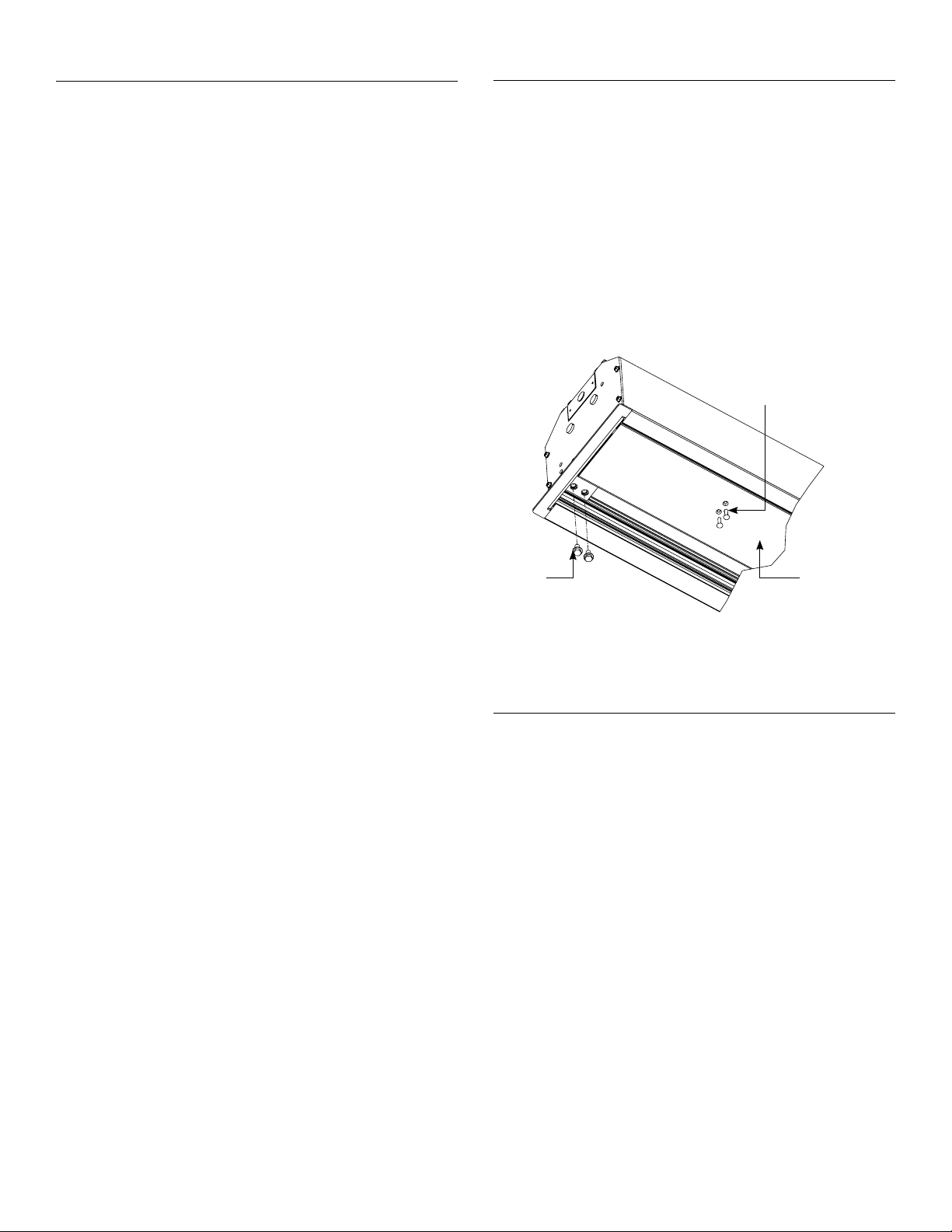

Door Support Screws

(Not All Sizes)

Bolts

Figure 1

Access

Door

Case Installation

1. The case provides multiple attachment points for bolts,

cables, or threaded rod. Page 5 shows threaded rod installed.

The variable position-mounting bracket may be located

anywhere along the length of the case. It is recommended to

keep the brackets spaced evenly enough to distribute the

weight of the screen. One mounting bracket is required for

every 4' of case length.

The case has a self-trimming lange around the bottom.

Ceiling tiles or drywall may be placed on top of this lange to

provide a inished appearance.

2. After securing the case in the ceiling check that the case is

level and plumb.

3. Use supplied 1/8" nex key to remove silver shipping brackets

attached to slat and screen case.

4. Install electrical connections that apply to your unit. Review

the wiring diagrams on page 4 for proper installation..

2

Screen And Roller Assembly Installation

If your screen was shipped with the motor and roller already installed proceed to step 7.

1. Remove four bolts from ends of door assembly (2 bolts on

each end) (Fig. 1). This will allow the door assembly to drop

open for access to case. For larger sizes, you will also need to

remove the door support screws.

2. Carefully unpack screen and roller assembly. Leave packing

paper on the roller.

3. Remove the square peg bracket from the motor end of the

roller assembly.

4. Remove the safety clip from the motor attachement bracket

located in the motor end of the screen housing.

5. Place the roller assembly into the case with the motor on the

left side. The limit switches should be facing down. Line up

the head of the motor with the motor attachment bracket.

6. Loosen four bolts that secure pin end mounting bracket into

housing. Lift pin end of roller into position and slide the

bracket into the roller pin. Tighten all four bolts.

7. Complete electrical hook-up by snapping motor 1/3 wire

connectors into case connectors.

8. Return to motor end and insert safety clip over casting

bracket to secure motor end.

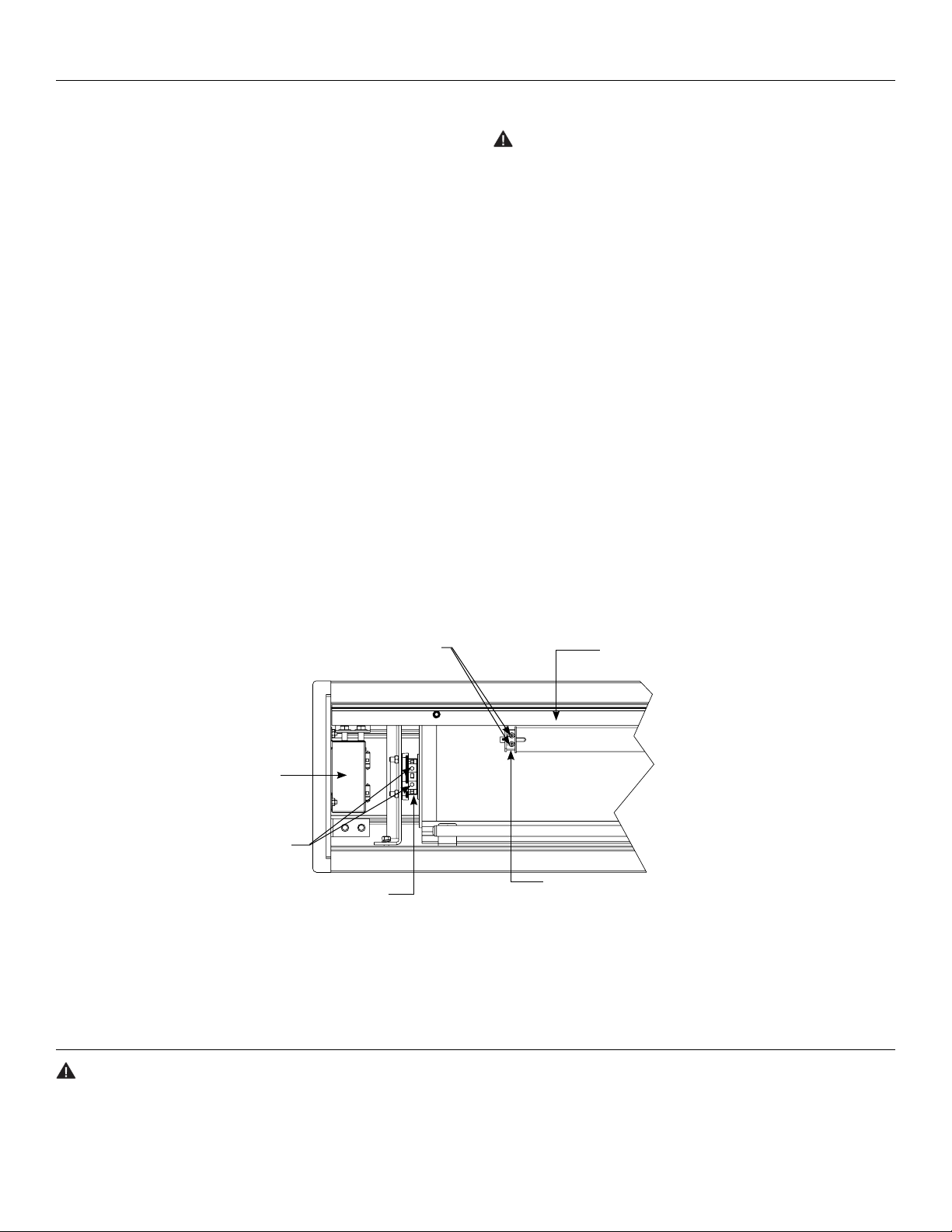

CAUTION! Do not cut tape on fabric with a knife or any

sharp tool. Remove by hand.

9. Carefully remove tape strips securing picture surface around

roller. Slat should move freely (Fig. 2). (Only if the roller

assembly is pre installed.)

10. Test installation by operating the screen several times. Be

prepared to stop the screen. The door assembly will not

close until the wall switch is placed in the up position and

when the screen motor stops at its limit switch in the up

direction.

NOTE: Unit duty cycle is 1 minute on, 3 minutes of.

NOTE: Excessive continuous operation may cause the motor

to overheat. If this happens the motor will shut of until it

cools to a normal operating temperature.

11. Close door assembly and replace four bolts at ends of door (2

bolts on each end) (Fig. 1).

Dual Motor LVC

Control Box

Screen Motor

Limit Switches

Door Motor

Limit Switches

Screen Motor

Door Motor

Figure 2

Access Door

Assembly

Screen Adjustment

Contact Da-Lite at 8006223737 or 5742678101 if screen or door motor needs adjustment.

3

Loading...

Loading...