Page 1

HD Progressive

Spec Sheet

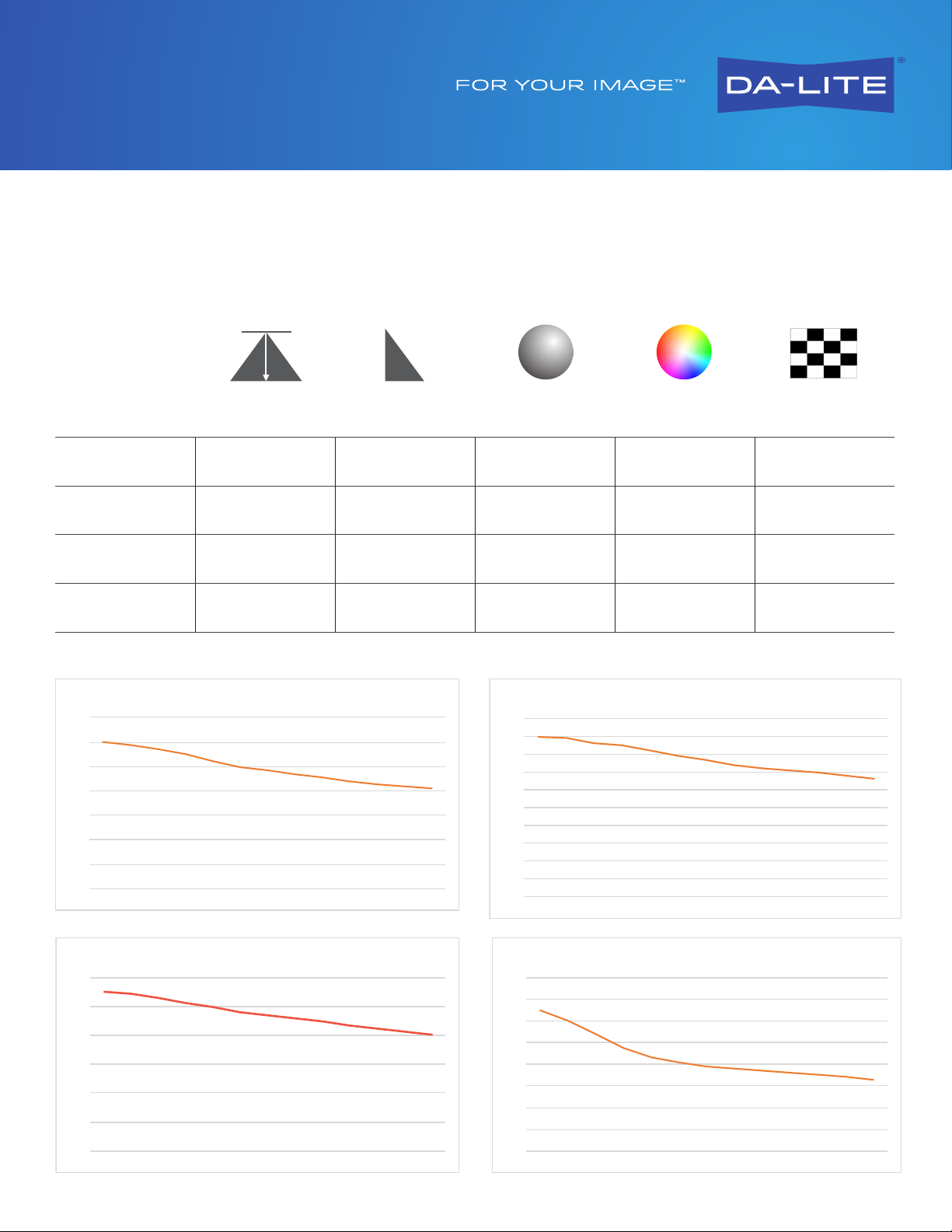

SURFACE GAIN

HALF

ANGLE

GLOSS

(AT 75°)

COLOR SHIFT

(CCT AT 60°)

HD 0.6 0.60 85° 18 1% 55:1

HD 0.9 0.90 85° 21 1.5% 50:1

HD 1.1 1.10 85° 24 3% 48:1

HD 1.3 1.30 75° 27 3% 48:1

HD Progressive 0.6

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0° 5° 10° 15 ° 20° 25° 30° 35 ° 40° 45° 50° 55° 60°

HD Progressive 0.9

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0° 5° 10° 15° 20 ° 25 ° 30° 35 ° 40° 45° 50° 55° 60°

CONTRAST

RATIO

HD Progressive 1.1

1.20

1.00

0.80

0.60

0.40

0.20

0.00

0° 5° 10° 15° 2 0° 25° 30° 3 5° 40° 45° 50° 55 ° 60°

HD Progressive 1.3

1.60

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

0° 5° 10° 15° 20° 25° 30° 35° 40° 45° 50° 55° 60°

Page 2

Contrast

Based on ANSI/INFOCOMM 3M2011 issued 6/30/2011, a 1 degree spot luminance meter - Minolta Luminance Meter LS100

was used to measure the light passing through each sample when a computer graphic generated 4 x 4 checkerboard

image was projected from a 1080P Epson ProLite Pro Cinema projector. Each rectangle had an aspect ratio of

approximately 1.33:1 (width:height). The total image size was 800 pixels by 600 pixels; 8” wide and 6” tall when projected

on the sample. The projector, displayed image and light meter were axially aligned with the sample midway between

and 28” from both the image source and the luminance meter. The projector was warmed up at least 30 minutes before

readings were taken. Measurements were made in a darkened room with ambient lux < 1. The projector’s full white output

was measured between 2000 and 2500 lux and full black image was between 3 and 5 lux. Readings were taken from the

center of each rectangle by pivoting and rotating the meter at a ixed stationary point. Contrast ratio was computed as: CR

= White Average / Black Average, where White Average = / 8, and Black Average = / 8

Gloss

Surface gloss is the relection measured using a BYK Microgloss 75° gloss meter.

Color Shift

A front projection sample was illuminated with a 6500K full white image which was 3600 – 4000 Lux incident brightness

at the center. Proper axial alignment between the projector, sample, and meter was assumed. The center point of the

sample was measured using a spectrophotometer from 18” away to determine the color temperature (CCT, K) of the coating

both on-axis and o-axis at 60°. A ratio of the two readings represents the percent shift in color temperature.

Color Shift = 1CCT60°/CCT0°

Gain /Half Angle

Gain was determined by comparing the luminance of a front-projected sample to the luminance of a white lambertian

relectance standard (ie. Magnesium Carbonate). Minimal ambient lighting and proper axial alignment between the diuse

light source, sample (or standard), and luminance meter were assumed. The distance between the meter and sample and

between the light source and sample should be held constant for optimal accuracy. Half Angle is the o-axis viewing angle

at which the measured brightness of the sample’s center point is 50% of the peak on-axis reading.

Milestone AV Technologies

3100 North Detroit Street

Warsaw, Indiana 46582

P: 574.267.8101 or 800.622.3737

F: 574.267.7804 or 877.325.4832

E: info@da-lite.com

www.milestone.com

DL-0639 02.16

©2016 Milestone AV Technologies LLC.

Loading...

Loading...