Da-Lite 21816LI, 84403L User Manual

Tensioned Advantage® Electrol

®

Automatic Electric Projection Screen Model

SUGGESTED SPECIFICATIONS: projection screen(s),

(H) x (W), electrically operated 120 volt (60 Hz) not

more than 2.4 amp. with a quick connect male plug-in connector on the motor.

Shall have specially designed motor mounted inside the roller, to be three wire

with ground, quick reversal type, oiled for life, with automatic thermal overload

cutout, integral gears, capacitor and an electric brake to prevent coasting. To

have preset but adjustable limit switches to automatically stop picture surface

in the “up” and “down” positions. Junction box shall be externally integrated

into the housing making it possible to install the housing and wire to the

building’s electrical system during construction. The junction box shall contain

a quick connect connector that is mounted in the housing for easy plug-in

connection to the motorized fabric and roller assembly. The motorized fabric

and roller assembly to be installed in the case at the factory or at a later time

at the job site. The fabric roller to be of rigid steel. Screen to be designed for

left or right-hand motor installation. Screen fabric to be seamless and mildew

resistant with black masking borders standard. Each side of the fabric to have

tab guide cable system to maintain even lateral tension and hold surface lat.

Custom slat bar with added weight maintains vertical tension on the screen

surface. The ends of the slat to be protected by heavy duty plastic caps

enclosing a preset adjustable mechanism for screen tensioning. Top, front and

back of case to be made of extruded aluminum powder coated white. End

caps to be of heavy gauge steel powder coated white. Bottom of case to have

a removable access door. Door to be of extruded aluminum powder coated

white. Bottom of case to be self-trimming, with a built-in lange around the

bottom of the case. To be complete with integrated low voltage control unit

and three position control switch and cover plate. Suitable for use in

environmental air space in accordance with section 30022 (c) of the National

Electric Code, and sections 2 128, 12010 (3) and 12100 of the Canadian

Electrical Code, part 1, CSA C22.1. Screen to be

listed by Underwriters’ Laboratories.

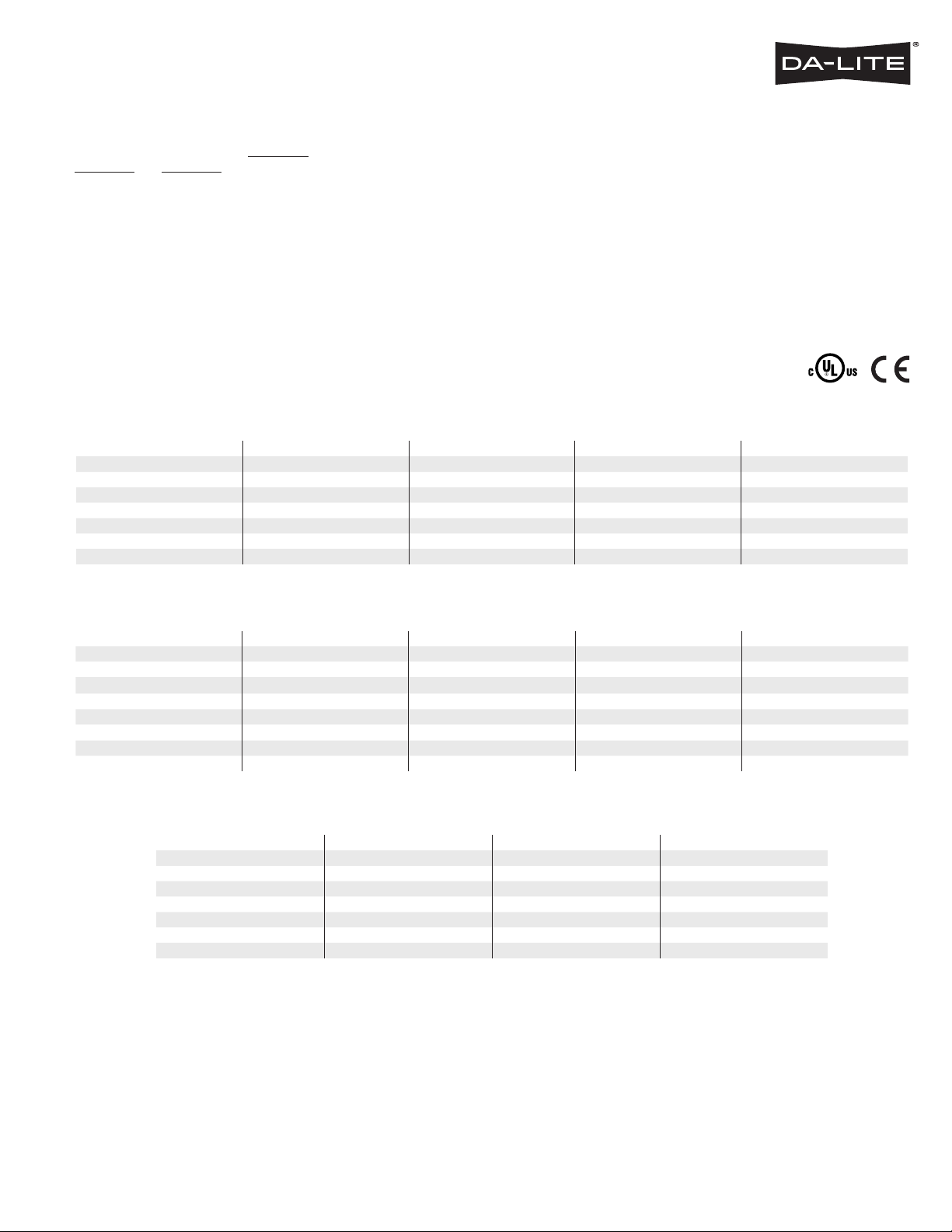

SPECIFICATION DATA

HDTV (16:9) Format Dimensions

Overall Length of Case*

Viewing Area (H x W) Nominal Diagonal

In. Cm In. Cm In. Cm In. Cm Lbs. Kg

45" x 80" 114 x 203 92" 234 96" 244 95" 241 92 41.7

52" x 92" 132 x 234 106" 269 108½" 276 107½" 273 99 44.9

54" x 96" 137 x 244 110" 279 113" 287 112" 284 104 47. 2

58" x 104" 147 x 264 119" 302 121½" 309 120½" 306 114 51.7

65" x 116" 165 x 295 133" 338 134½" 342 - - 135 61.2

78" x 139" 198 x 353 159" 404 159½" 405 - - 148 67.1

90" x 160" 229 x 406 184" 467 177½" 450 - - 169 76.8

For Vinyl Surfaces**

Overall Length of Case*

For Parallax Surface Approx. Ship. Wt.

Wide (16:10) Format Dimensions

Overall Length of Case*

Viewing Area (H x W) Nominal Diagonal

In. Cm In. Cm In. Cm In. Cm Lbs. Kg

50" x 80" 127 x 203 94" 239 96½" 245 95½" 243 92 41.7

57½" x 92" 146 x 234 109" 277 109½" 278 108" 274 111 50.3

60" x 96" 152 x 244 113" 287 114" 290 - - 104 47. 2

65" x 104" 165 x 264 123" 312 122½" 311 - - 114 51.7

69" x 110" 175 x 279 130" 330 129" 328 - - 125 56.7

72½" x 116" 184 x 295 137" 348 135½" 344 - - 135 61.2

87" x 139" 221 x 353 164" 417 156½" 398 - - 148 67.1

100" x 160 254 x 406 189" 480 178½" 453 - - 169 76.8

For Vinyl Surfaces**

Overall Length of Case*

For Parallax Surface Approx. Ship. Wt.

Video (NTSC 4:3) Format Dimensions

Overall Length of Case*

Viewing Area (H x W) Nominal Diagonal

In. Cm In. Cm In. Cm Lbs . Kg

43" x 57" 109 x 145 72" 183 72½" 184 77 34.9

50" x 67" 127 x 170 84" 213 83½" 212 86 39.0

60" x 80" 152 x 203 100" 254 97½" 24 8 98 44.5

69" x 92" 175 x 234 120" 305 111½" 283 111 5 0.3

87" x 116" 221 x 295 150" 381 138½" 3 52 135 61.2

108" x 144" 274 x 366 180" 457 163½" 415 151 68.5

120" x 160" 305 x 406 200" 508 180½" 458 169 76.7

*Case length does not include lange

**Vinyl surfaces include all HD Progressive, Da-Mat, Da-Tex and Dual Vision surfaces

PRODUCT NOTES

• All screens except Parallax standard with 12" black drop at the top. Screens with Parallax surface standard with 2" of black drop at the top.

Extra drop may alter case dimensions. Contact Da-Lite for details.

• Overall case length dimensions +/- ¼" (6mm).

• Electrical junction box extends 2⅛" (5.4 cm) past case length on left end of case, 1⅛" (2.9 cm) past ceiling lange.

• Internal junction box available. Will add 3½" (8.9 cm) to overall case length and must be speciied at time of order, recommended for drywall

installations.

• Junction box on top of case available. Will add 3½" (8.9 cm) to overall case length and 1⅞" (4.8 cm) to height at left end of case; must be speciied at

time of order.

For Vinyl Surfaces** Approx. Ship. Wt.

PRODUCT NOTES (continued)

• Detail dimensional drawings, wiring diagrams and

installation instructions available upon request.

• Speciications subject to change without notice.

• Custom formats and sizes available upon request.

• All screens come standard with the Silent Drive

System.

SURFACE INFORMATION

• All viewing surfaces are standard with black backing

except Da-Tex® and Dual Vision.

• Parallax available in sizes up to 58" x 104" in HDTV

format and 57½" x 92" in Wide format.

• HD Progressive 1.1 Perf and HD Progressive 1.1 Contrast

Perf available in sizes up to 87" x 116" in Video format

and 78" x 139" in HDTV format.

• All surfaces will be seamless in the image area.

• All HD Progressive, Da-Mat, Da-Tex and Dual Vision

surfaces are ire retardant.

WHEN ORDERING, MARK APPROPRIATE SELECTIONS

1. Select Size from Charts.

2. Select viewing surface (All Da-Lite surfaces are GREENGUARD GOLD Certiied.):

Parallax 0.8

HD Progressive 0.6

HD Progressive 0.9

HD Progressive 1.1

HD Progressive 1.1 Perf

HD Progressive 1.1 Contrast

HD Progressive 1.1 Contrast Perf

HD Progressive 1.3

Da-Mat

High Contrast Da-Mat

®

®

Da-Tex®(Rear)

Dual Vision

3. Options:

Internal Junction Box (see product notes)

Junction Box on Top of Case

(see product notes)

220 Volt (50 Hz) Motor.

Video Projector Interface Control – built-in

(Adds 10" to case length on 220V

motor only).

SCB100 RS232 Serial Control Board –

built-in (adds 10" to overall length of case).

NET100 Ethernet-Serial Adapter

SCB200 RS232 Serial Control Board –

built-in (adds 10" to overall length of case).

WC200 Wall Controller

IR200 Infrared Remote`

4. Optional Accessories:

Wireless Remote Control for LVC.

Key Locking Cover Plate for LVC Switch.

Radio Frequency Remote.

Radio Frequency Range

Extender

Infrared Remote.

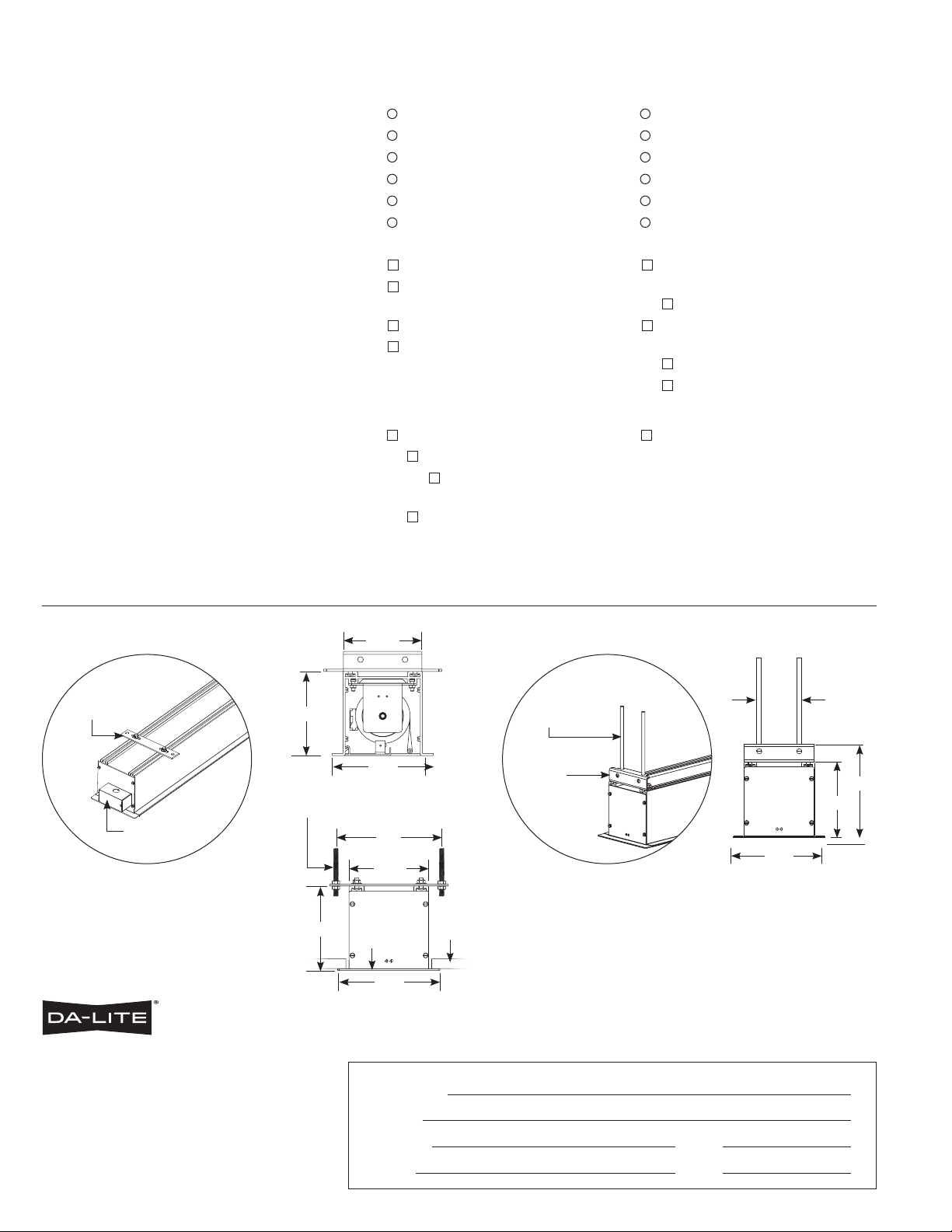

SUGGESTED METHODS OF INSTALLATION:

Variable Position

Mounting Bracket

Motor

End

Electrical

Junction Box

Audience

Side

Method One Method Two

6 ⁄"

6 ⁄"

7 ¾"

3/8" Threaded Rod (Not Included)

Attached to Mounting Bracket

9 ¼"

6 ⁄"

6 ⁄"

Self-Trimming

Flange

7 ¾"

Finished

Ceiling

⅜" Threaded Rod

(Not Supplied)

Hanger

Bracket

3 ⁄"

7 ⁄"

6 ⁄"

7¾"

FOR YOUR IMAGE | legrandav.com

USA P 866.977.3901 E info@da-lite.com

CANADA P 877.345.4329 E canadainfo@milestone.com

EMEA P +31 495 580 840 E emea.sales@milestone.com

APAC P +852 2145 4099 E asia.da-lite@milestone.com

In British Columbia, Milestone AV Technologies ULC carries on business as MAVT

Milestone AV Technologies ULC.

©2018 Milestone AV Technologies. DL0147 (Rev. 11) 8/18 Da-Lite is a registered

trademark of Milestone AV Technologies. All other brand names or marks are

used for identiication purposes and are trademarks of their respective owners.

All patents are protected under existing designations. Other patents pending.

Project Name:

Architect:

Contractor: Phone:

Reseller: Phone:

Loading...

Loading...