Page 1

201 Daktronics Dr. PO Box 5128 Brookings SD 57006

www.daktronics.com

Fuelight™ FL-2109 Series

Petroleum Price Displays

Installation & Operation Manual

DD1398926 Rev 4—22 July 2011

Tel 888-DAK-SIGN (888-325-7446) Fax 605-697-4700

Page 2

Page 3

and/or Customer Service

DD1398926

Product 1478

Rev 4 – 22 July 2011

Complete the chart with specific information about this display so the details are readily available

when calling for service or replacement parts.

Information needed for technicians

Fill in the blanks

Location of the display:

Model number of this display:

Method of communication:

daktronics

Copyright 2008-2011

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher

assumes no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

taping, or information storage and retr iev al syste ms – without written permission of the publisher.

Fuelight™ and Fuelink™ are trademarks of Daktronics, Inc. Other trademarks used in this manual are the property of their respective

owners.

Page 4

Page 5

Table of Contents

Section 1: Introduction ................................................................................................................. 1

1.1 Display Overview ................................................................................................................... 1

1.2 Safety Precautions ................................................................................................................... 2

Section 2: Mechanical Installation .............................................................................................. 3

2.1 Support Structure Requirements .......................................................................................... 3

Pre-installation Checklist ................................................................................................ 3

2.2 Ventilation and Temperature Requirements ....................................................................... 3

2.3 Display Mounting ................................................................................................................... 4

General Mounting Procedure ......................................................................................... 4

Section 3: Power Installation ....................................................................................................... 5

3.1 Power Requirements .............................................................................................................. 5

3.2 Grounding ................................................................................................................................ 6

3.3 Power Installation ................................................................................................................... 7

Section 4: Signal Installation ....................................................................................................... 9

4.1 Signal Installation.................................................................................................................... 9

LED Driver ........................................................................................................................ 9

Signal Wiring .................................................................................................................... 9

Driver Rotary Switch Line and Face Settings ............................................................. 10

Section 5: Control Options ........................................................................................................ 11

5.1 FLR-100 Control Kit .............................................................................................................. 11

Editing the Display ........................................................................................................ 11

Increasing the Price ........................................................................................................ 11

Decreasing the Price ...................................................................................................... 11

Rapid Increase/Decrease .............................................................................................. 11

5.2 FLR-500 Control Kit .............................................................................................................. 12

Transmitter Use .............................................................................................................. 12

Petroleum Price Display Startup ................................................................................. 13

Petroleum Price Transmitter Operation ..................................................................... 13

Modifying Price Line Settings ...................................................................................... 14

Dimming ......................................................................................................................... 15

5.3 FLR-1500 and FLD-2000 (Outdoor/Indoor) Control Kits ............................................... 16

FLR-1500 Connection .................................................................................................... 16

FLD-2000 Connection to the Display (Outdoor and Indoor) ................................... 17

Table of Contents i

Page 6

DM-100 Insert and Code ............................................................................................... 18

Petroleum Price Display Startup .................................................................................. 18

DM-100 Controller Operation ...................................................................................... 19

Section 6: Maintenance and Troubleshooting ........................................................................ 23

6.1 Component Location and Access ........................................................................................ 23

Visual Structural Inspection ......................................................................................... 23

6.2 Display Diagnostics .............................................................................................................. 24

Driver Diagnostic LEDs ................................................................................................ 24

Power-up Self Test ......................................................................................................... 24

6.3 Troubleshooting .................................................................................................................... 25

Section 7: Replacement Parts ................................................................................................... 27

7.1 About Replacement Parts ..................................................................................................... 27

Section 8: Daktronics Exchange and Repair & Return Programs ......................................... 29

8.1 Exchange Program ................................................................................................................ 29

Before Contacting Daktronics ...................................................................................... 29

8.2 Repair & Return Program .................................................................................................... 30

Shipping Address .......................................................................................................... 30

Glossary ................................................................................................................................... 31

Appendix A: Reference Drawings................................................................................................. 33

Appendix B: Daktronics Warranty and Limitation of Liability ................................................... 35

ii Table of Contents

Page 7

FL-2109

HH

C

T#

Section 1: Introduction

This manual explains the installation, maintenance, and troubleshooting of Daktronics Fuelight™ FL2109 Outdoor LED Petroleum Price Displays and provides details for display maintenance.

1.1 Display Overview

The Fuelight™ model number is described as follows:

FL-2109-HH-C-T#-SF-CC

= Outdoor Fuelight™ digit display with backlit panel

= Digit height in inches

= Color: A=Amber, G=Green, R=Red

= T=Top Product Panel, #=Capt i on height in inches

SF

CC

Fuelight

™

FL-2109 displays are available

in both plain top-captioned cabinets and

cash/credit top-captioned cabinets and

feature standard petroleum price

formatting, employing a variable tenths

fraction. Figure 1 and Figure 2 provide

examples.

=

Single Face

=

Cash/Credit caption (optional)

FL-2109 series displays are designed for

installation as part of an outdoor display

system. Digit faceplates are black while

backlit panels vary. Displays are

mounted independently on a support

structure.

All Fuelight

™

displays are configured

with amber, green, or red LEDs.

Figure 1: Top Caption

Figure 2: Top Caption Cash/Credit

Introduction 1

Page 8

Fuelight™ outdoor LED displays have

been designed for use with FLR-100, FLR500, FLR-1500 and FLD-2000

communication kits.

In this manual, individual “displays”

combine to form whole “sign” structures.

Refer to Figure 3 for an example.

1.2 Safety Precautions

• Please read and understand

installation instructions before

installing.

• Do not drop control equipment or

allow it to get wet.

• Do not disassemble control

equipment or electronic components

of the display; this will make the

warranty null and void.

• Disconnect display power before

servicing power supplies to avoid

electrical shock.

• Make certain that the display is properly grounded with an earth-ground electrode at the

display.

Figure 3: Displays in Sign Structure

2 Introduction

Page 9

Section 2: Mechanical Installation

Important Notes:

• Read and understand these instructions before installing the display.

• Properly ground the display with a ground rod at the display location.

• Disconnect power when servicing or not using the display.

• Do not modify the display structure or attach any panels or coverings.

2.1 Support Structure Requirements

The installer must ensure that the mounting structure and hardware can support the display,

and that the structure follows all local codes.

Support structure design depends on the mounting methods, display size, and weight.

Because every installation site is unique, no single procedure is approved by Daktronics for

mounting displays. The information contained in this section is general information only and

may not be appropriate for all installations.

Keep in mind the location of mounting clips. Display height and wind loading are also

critical factors to be considered. Consult the appropriate Shop Drawing for more

information.

Pre-installation Checklist

Verify the following before proceeding with installation:

• The display is in good condition after shipping and uncrating.

• A straight and square mounting frame is provided for the display.

Note: Height variation in any 4-foot horizontal section may not exceed

• Adequate support is provided for the display so that the structure will not yield at

any unsupported points after mounting.

• Clearance of 4”of unobstructed space above the top of the display is allowed to

remove the eyebolt.

Note: No clearance is required once the eyebolt is removed.

• Clearance around the entire front of the display is maintained to allow opening the

display for maintenance and proper ventilation.

• Be sure that any sprinkler systems near the display are pointed in a direction as to

not spray the front of the display.

2.2 Ventilation and Temperature Requirements

1

/4”.

Fuelight™ Petroleum Price digit displays are front ventilated. The display must NOT be fully

enclosed inside a support structure or sign or behind a sign face of plastic, glass, or other

material. The front of the display must be exposed to the air to allow for convection cooling.

Mechanical Installation 3

Page 10

Fuelight™ Petroleum digit displays are designed to operate in ambient temperatures ranging

from -40

o

F to +120oF. However, the overall sign structure should be designed and ventilated

in a way to keep the interior of the sign cabinet at a temperature not to exceed 140

Items to consider when designing a sign package to house LED price displays include:

• Solar gain from the black face of the price displays

• Solar gain from other sign cabinet surfaces

• Heat gain from electronics inside the displays

• Passive or active airflow with adequate intake and exhaust areas

Daktronics is not responsible for high-temperature failure due to inadequate ventilation.

2.3 Display Mounting

To maintain the structural integrity of the display cabinet, a 90-degree angle between the

cabinet and the lifting method must be maintained.

o

F.

If damage occurs because of improper lifting procedures, the warranty will be void.

General Mounting Procedure

1. Lift the display into position on the support structure using ALL eyebolts. Refer to

Figure 4 for an example.

Note: Do not attempt to permanently

support the display by the eyebolts.

2. Weld or use

stronger) bolts and hardware to

secure ALL of the clip angles to the

support structure as shown in the

appropriate Shop Drawing.

Note: Clip angles can be substituted

with alternative mounting methods

as long as ALL of the locations are

used.

3. After installation is complete,

carefully inspect the display for any

holes that may allow water to seep

into the display and seal any openings with silicone.

1

/2" grade-5 (or

Figure 4: Correct Lifting Procedures

If the eyebolts on the top of the display have been removed, plug the holes with bolts and the

rubber-sealing washer that was removed with the eyebolt unless an overhead structure

protects the area.

4 Mechanical Installation

Page 11

Section 3: Power Installation

Important Notes:

• Only a qualified individual should terminate power and signal cable at the display.

• All proposed changes must be approved by Daktronics' engineering staff, or the warranty

will be null and void.

Electrical installation consists of the following processes:

• Routing power and ground to the display driver/power enclosure

• Connecting the display ground to a grounding electrode at the display location.

Each Shop Drawing shows details on installation and access for electrical connections. Refer to the

notes on the appropriated Shop Drawing for the electrical requirements for that size of display.

Daktronics Fuelight

electronic components.

It is the responsibility of the electrical contractor to ensure that all electrical work meets or exceeds

local and national codes. Improper installation could result in serious damage to the equipment and

could be hazardous to personnel.

™

displays’ front panels are hinged to allow access to the digits, cabling, and other

3.1 Power Requirements

Do not connect displays to any voltage other than that listed on the display product label.

The dedicated 120 V circuit can be shared among all components of the sign structure

(including Fuelight

devices (such as air compressors or island lighting). A dedicated circuit is defined as one hot,

one neutral and one ground wire. Maximum amperage will vary with the number and type

of digit displays connected. All local and national electrical codes must be followed during

electrical installation.

Note: It is critical that the display circuit be fused at 15 A and that all conductors used must

be designed to pass a 15 A current in normal operation. Failure to meet wiring and overcurrent protection device requirements may violate local and national electrical codes and

will void the display warranty.

™

displays and fluorescent lighting), but not with other external electrical

Conductors of circuits delivering power to a Daktronics display shall be sized in accordance

with local and national electrical codes so that the power distribution systems is capable of

delivering full load power to the display while maintaining a voltage within 5 percent of the

utility nominal voltage.

Power Installation 5

Page 12

3.2 Grounding

Displays MUST be grounded according to

the provisions outlined in any applicable

local and national electrical codes and

according to the specifications in this

manual. Daktronics requires a resistance to

ground of 10 ohms or less.

The display system must be connected to an

earth-ground electrode installed at the

display, as shown in Figure 5. Proper

grounding is necessary for reliable

equipment operation and protects the

equipment from damaging electrical

disturbances and lightning. Refer to

Drawing B-329675 for more information on

grounding.

The display must be properly grounded, or

the warranty will be void.

Important points about grounding:

• Follow local and national codes: The material of an earth-ground electrode differs

from region to region and from conditions present at the site. Consult any local and

national electrical codes that may apply.

• Do NOT use the support structure as an earth-ground electrode: The support

structure is generally embedded in concrete. If embedded in earth, the steel is either

primed, or it corrodes, making it a poor ground.

• Provide one grounding electrode for each sign structure: The grounding electrode is

typically at least one grounding rod for each sign structure. Other grounding

electrodes as described in any applicable local and national electrical codes may be

used.

• Confirm that resistance to ground is 10 ohms or less: This is required by Daktronics

for proper display performance. If the resistance to ground is higher than 10 ohms, it

will be necessary to install additional grounding electrodes to reduce the resistance.

The grounding electrode must be connected to the ground wire inside the display.

Figure 5: Correct Grounding

6 Power Installation

Page 13

3.3 Power Insta llation

The Daktronics Fuelight™ displays are installed using the provided ground and neutral

conductors. For this type of installation, the power circuit must contain an isolated earthground conductor. Do not connect neutral to ground at the disconnect or at the display, this

would violate electrical codes and void the warranty. Use a disconnect so that all

ungrounded conductors can be disconnected.

Figure 6: Power Harness

To connect power to the display:

1. Connect power to the power harness (“pigtail”) inside the display, refer to Figure 6

for an example.

The power harness has a 5-pin plug at one end and three wires: black, white, and

green/yellow. The plug is connected to the mating plug on the transformer and

allows for easy disconnection of the power harness.

2. Use wire nuts to connect power wires to the power harness.

Power Installation 7

Page 14

Page 15

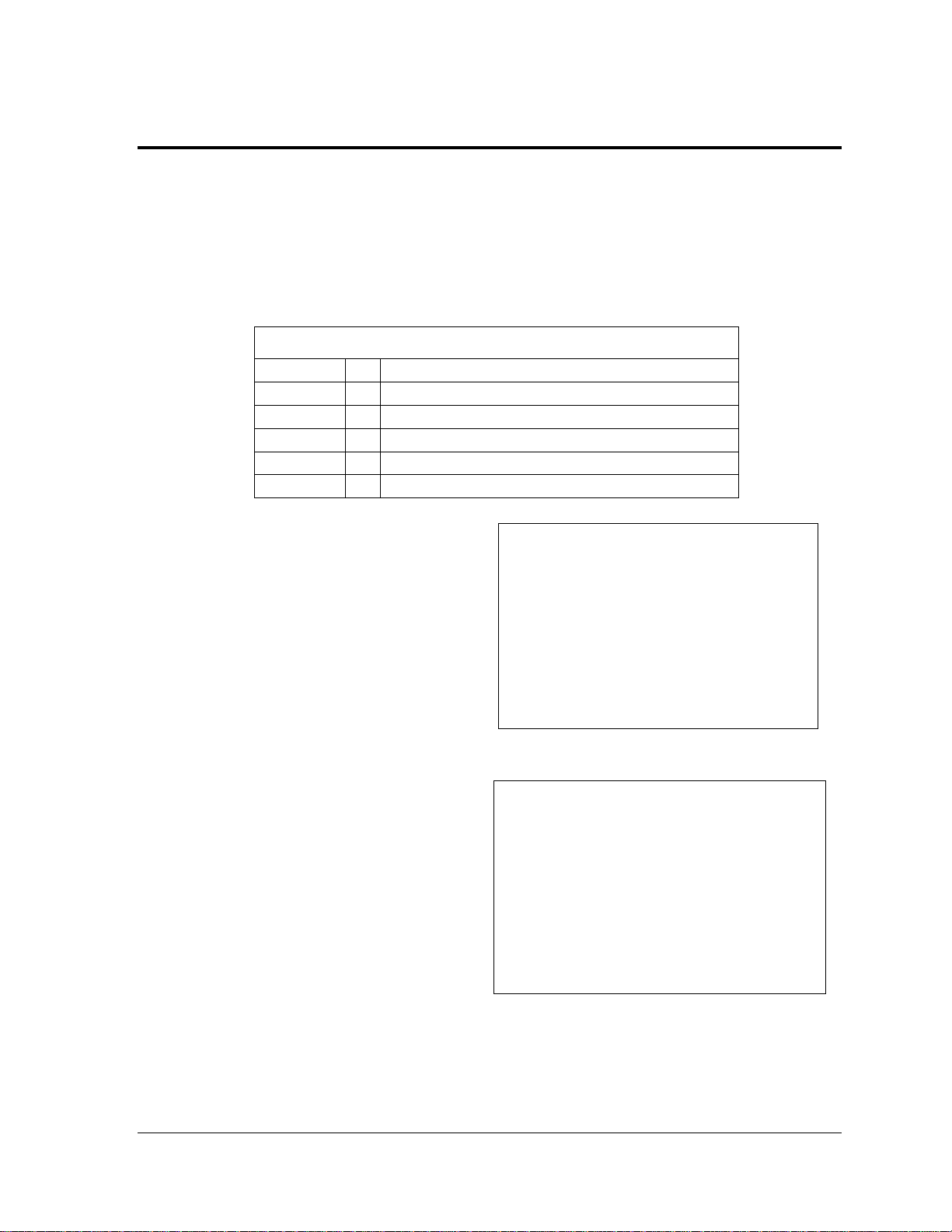

Driver Connectors

J1

Power Out to Digit 1

J2

Power Out to Digit 2

J3

Power Out to Digit 3

J4

Power Out to Digit 4

J5

AC Power Input

face)

1500)

another line)

J14

Host Driver Signal Input (for FLR-100)

Section 4: Signal Installation

4.1 Signal Installation

LED Driver

In the display, the LED driver performs the task of switching digits on and off. One driver at

each display installation is designated as the host driver (the driver with the antenna/signal

connection). This driver receives its signal directly from a control unit via the Signal In

connector (J12, J13, or J14). J12 is used with the FLR-500 and FLR-1500 control kits. J13 is used

with the FLD-2000 control kit on host drivers and for signal to client drivers. J14 is used with

the FLR-100 control kit.

J11

J12

J13

Signal Output (to client driver in next line of the

Host Driver Signal Input (for FLR-500 and FLR-

Host Driver Signal Input (for FLD-2000) and

Client Driver Signal Input (from driver of

Signal Wiring

Signal termination varies depending upon the type of

control kit included with the display. Signal from the

control transmitter/controller communicates with the

host driver. Signal then travels from J11 (output) on the

host driver to J13 (input) on the driver of the next face or

line.

1. Route cable to J12 (for FLR-500 or FLR-1500), J13

(for FLD-2000) or J14 (for FLR-100) on the host

driver within the host display; refer to Figure 7

for details.

2. Route the RJ14 cable from J11 OUT on the host driver to the next client display,

connecting at J13 IN.

3. Follow step 2 for all displays in the network.

Figure 7: Driver

Refer to the quick guides provided with the display for more information on signal

installation.

Signal Installation 9

Page 16

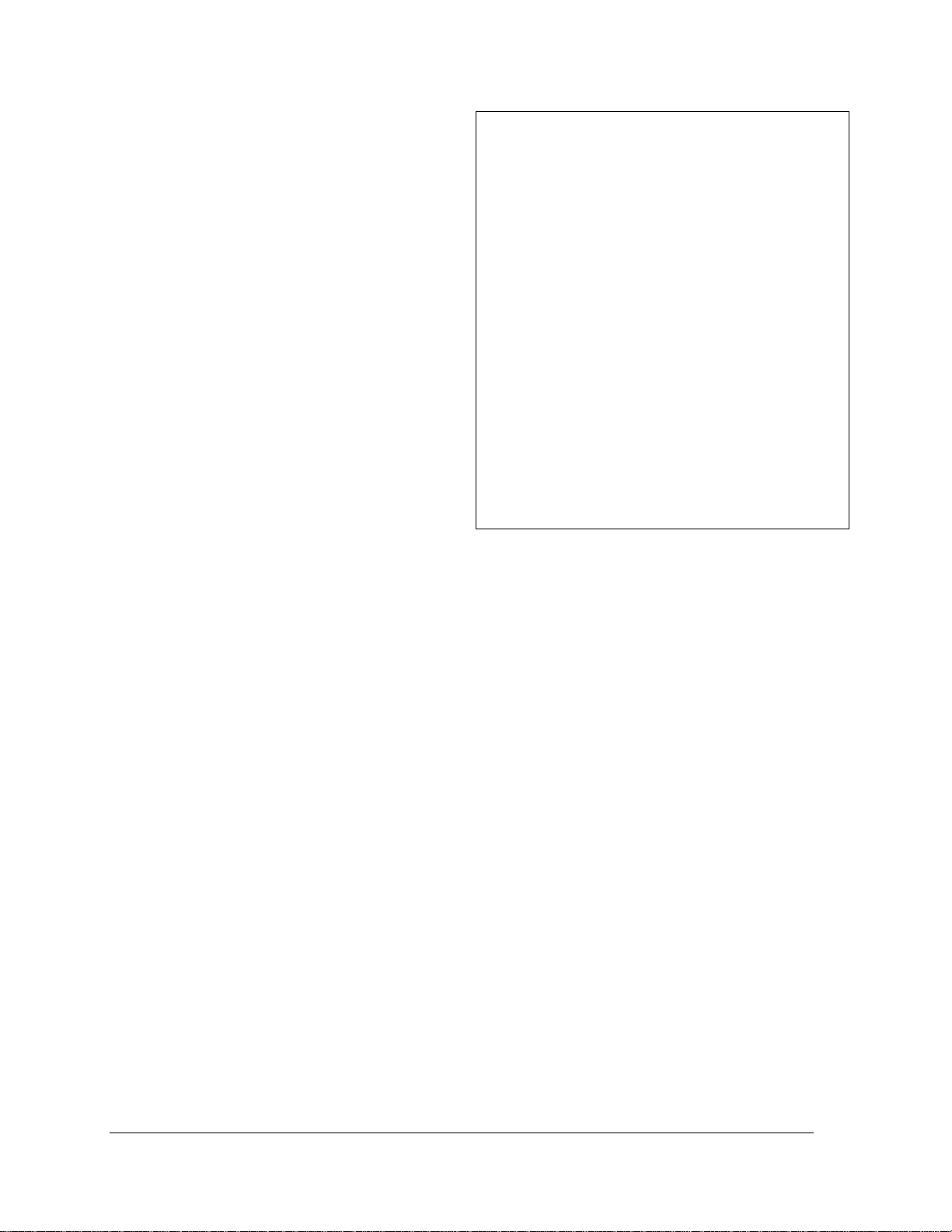

Driver Rotary Switch Line and Face Settings

The first driver at each display installation is designated as a host driver –

the driver with the antenna/signal connection. The host driver sends the

line information out to the client drivers.

Every driver must have a unique line and face setting (or “address”) that

identifies the face and line of the display.

The line and face numbers are set by turning the rotary switches located

on the driver at S1 and S2, refer to Figure 8 for locations. Set the line

number using S1 and the face number using S2.

All displays with the same line number will show the same price. For

example, two displays, one with a driver set to Line 1, Face 1 and one with

a driver set to Line 1 Face 2, will display the same price. Refer to Figure 8

for an example.

Figure 8: Rotary

Switches

10 Signal Installation

Page 17

Section 5: Control Options

The FLR-100, FLR-500, FLR-1500, and FLD-2000 (indoor or outdoor) control kits can be used to

change petroleum prices displayed on the LED Fuelight

provided in this section discuss the functions the operator uses to control the Petroleum Price display

with each control type.

™

Petroleum Price displays. The instructions

5.1 FLR-100 Control Kit

The FLR-100 control kit can control four unique prices on multiple faces using an RC-50

transmitter and has a maximum range of 100 feet. The instructions provided in this section

discuss the functions the operator uses to control the displays.

Editing the Display

To edit the price on the display, press and hold any button for five seconds. When the display

is in Edit mode, the decimal LEDs blink.

On the transmitter, each pair of buttons corresponds to a price line on the display. Each line

is numbered to indicate the line it corresponds to.

Increasing the Price

To increase the price, press [+] for the

corresponding line.

Note: Make sure the display is in Edit

mode.

Decreasing the Price

To decrease the price, press [-] for the

corresponding line.

Note: Make sure the display is in Edit

mode.

Rapid Increase/Decrease

To rapidly increase or decrease a price,

press and hold the button for the

corresponding line.

Note: If no button is pressed for more

than 10 seconds, the display exits the

Edit mode. The prices are saved, and

the display returns to its normal state.

Control Options 11

Figure 9: Transmitter

Page 18

5.2 FLR-500 Control Kit

The FLR-500 control kit includes a radio transmitting

device, a radio receiving device, and all hardware and

instructions.

The FLR-500 control kit programs petroleum prices

displayed on the LED Fuelight

and has a maximum range of 500 feet.

Note: Although multiple wireless hand-held transmitters

may be connected to a single wireless base station server,

the rate display application allows for only one hand-held

device to be connected at a time.

™

Petroleum Price display

Transmitter Use

The RC-100 transmitter can be configured to program

petroleum price displays. Refer to the control quick guide,

which came with the control kit, for information on the

correct setup of the FLR-500 Control Kit.

The RC-100 transmitter is charged by a wall pack

transformer. Plug the wall pack transformer into a 120

VAC power pack, and connect it to the transmitter. Once

charged, the RC-100’s operation time will vary depending upon how often it is used.

Figure 10: Transmitter

12 Control Options

Page 19

new code

↑↓

<ENTER>.

GAS PRICE ↓↑

1 ↓ $1.23 9/10

1 ↓ $1.23 9/10

the line settings.

Petroleum Price Display Startup

To operate the Fuelight™ Petroleum Price displays, the transmitter must first be programmed

to the gas price function. Use the <SET FUNCTION>key on startup. Use the following table

as a guide to startup procedure.

LCD Screen Action

Press Ent to select a

SELECT FUNCTION

Press <ALT>, and then <NEW CODE> to select

a new price display function. Press <CLEAR> to

resume a new function. Use the <

keys to select the new price function; then press

Press the arrow up or down keys <↑↓> until the

gas price option is shown. Press the <ENTER>

key to accept.

> arrow

The hand-held transmitter should now be ready for use. The transmitter will “remember” the

last function setting, so this step should only need to be done with a new transmitter or one

that is configured for different displays.

Petroleum Price Transmitter Operation

The transmitter LCD display will default to showing the current display settings on power

up. The following text will be shown on the LCD.

LCD Screen Action

LINE PRICE

<EDIT> TO MODIFY

The display will toggle between these two

screens.

Press the up or down arrow k eys <↑↓> to scroll

through the current setting for any of the lines

on the display.

Press the <ENTER/EDIT> key to modify any of

Control Options 13

Page 20

$D.CC T/10 ↓

↓

incorrect.

Modifying Price Line Settings

The petroleum price can be modified either by pressing the <EDIT> key during operation or

using the <MENU> key. Refer to the following key to identify the item to be edited.

L = Current line number to be edited

D.CC = Current dollars and cents value to edit

T = Current tenths of cent value to edit

LCD Screen Action

EDIT LINE L

Press any of the number keys to edit the price

value for this line. Press the down arrow key <

to modify the value of the 1/10-cent data for this

line (see note below).

Press <ENTER> to accept the new value or

press <CLEAR> to abort the changes.

Note: The flashing asterisk on the LCD shows

the current data being edited.

Many displays do not have a changeable 1/10cent digit. Changing the tenths-cent value from 9

on these digits will make the digit appear

>

14 Control Options

Page 21

AUTOMATIC ↓

section for details.

MAX INTENSITY ?

dimming maximum setting

ENTER TO SET

is the maximum intensity level.

Dimming

The dimming level of the display can be adjusted in two ways. A light sensor mounted in the

display driver can detect the level of ambient light at the display location and dim the

display’s LEDs accordingly. This function is known as automatic dimming.

When the manual dimming function is selected, the LEDs remain at the same level of

brightness regardless of the level of light detected at the display. To select either of these

functions, press <DIMMING>. The current setting is shown on the bottom line of the LCD.

LCD Screen Action

DIMMING

SET AUTO DIMMING

INTENSITY XX↓↑

XX – Current intensity (1-16)

Max Intensity - 16

Press the down arrow key <↓> to toggle

through dim settings:

Automatic – The display automatically dims

based on the light detected at the display

Manual – The display dimming level is set

manually. Once set, this value remains

regardless of the level of light detected at the

display.

Blank Sign – The display can be blanked out

without powering down. Refer to the blank sign

Press the <ENTER/EDIT> key to edit the auto

dimming max intensity. This is the maximum

intensity that the display will use in full-bright

modes (during daylight hours.)

Press <CLEAR> to keep the current auto

Press the up or down arrow k ey <↑ ↓> to

modify the current intensity of the display

(Note: The RC-100 must be communicating

with the display)

Press <ENTER> to accept this intensity. If

manual dimming mode is selected, this will be

the new intensity for the display. If the

automatic dimming mode is selected, the

display will illuminate in full-bright mode, which

Control Options 15

Page 22

BLANK SIGN ↓

<CLR> NO

the sign.

DIMMING

BLANK THE SIGN?

<ENT> YES

Press <ENTER> to accept this option.

The next LCD dialog will ask whether to blank

the sign or not. The LCD toggles between Yes

and No. Pressing <CLEAR> resumes normal

operation; pressing <ENTER> actually blanks

5.3 FLR-1500 and FLD-2000 (Outdoor/Indoor) Control Kits

The Fuelight

Figure 11, is a hand-held controller designed

to operate Daktronics LED Fuelight

displays. It can connect to the display as a

part of one of the following two control kits:

1. FLR-1500 control kit: Uses two

2. FLD-2000 control kit: Connects

™

DM- 100 controller, shown in

™

fixed-mount radios and has a

maximum range of 1,500 feet

between radios.

directly to a J box at the base of the

display or at an indoor location and

has a maximum range of 2,000 feet.

The console’s liquid crystal display (LCD)

guides the user through the operation of the

system.

Refer to the control quick guide, which came

in the control kit, for information on

connection procedures and petroleum price

controller startup.

Figure 11: DM-100 Controller

FLR-1500 Connection

The Fuelight™ FLR-1500 control kit is designed to operate Daktronics LED Fuelight™

displays. Connection to the display uses two fixed-mount radios.

16 Control Options

Page 23

FLD-2000 Connection to the Display (Outdoor and Indoor)

The Fuelight™ displays may be controlled from a location inside a building or from the base

of the displays. The following subsections provide more detail on both installation types.

Outdoor Installation

This control option permits operation of the sign

from the base of the display, refer to Figure 12

for an example. The DM-100 controller is

connected to an outdoor junction box (J box)

mounted on the display pole, which routes the

signal to the sign through a 2-pair cable (in

conduit, where required).

This control option does not require the

controller to be connected to a power outlet. In

this configuration, the DM-100 controller uses

the sign as a power source.

To operate the display using this setup:

• Connect the 9-pin to 9-pin cable from the

DM-100 controller to the J box mounted

on the display pole.

Indoor Installation

This control option permits operation of

the sign from an indoor control location;

refer to Figure 13 for an example. The

hand-held controller is connected to an

indoor J box, which routes the signal to

the display through a 2-pair cable (in

conduit, where required).

To operate the display using this setup:

1. Connect the 9-pin to 9-pin cable

from the DM-100 controller to

the 9-pin J box.

2. Plug the controller’s wall pack

transformer in to a 120 VAC

outlet.

Figure 12: FLD-2000 Outdoor Connection

Figure 13: FLD-2000 Indoor Connection

Control Options 17

Page 24

GAS PRICE

This display appears briefly.

PRESS SET FUNCT

the second LCD prompt is displayed.

GAS PRICE ↓↑

.

DM-100 Insert and Code

The DM-100 uses a keypad insert to

program price information for Daktronics

LED Fuelight

™

Displays. The DM-100 insert

illustrated in Figure 14 is used to control the

displays.

If an insert is lost or damaged, make a copy

of the insert from Drawing A-167856

located in Appendix A. Cut this to size and

slide it into the DM-100 pocket. Use this as a

reference until a replacement is received.

To start the controller and use the insert to

program information into the display

driver, follow the instructions in control

quick guide, which came with the control

kit.

Figure 14: DM-100 Insert

Petroleum Price Display Startup

To operate the petroleum price displays, the DM-100 must first be programmed to the gas

price function. Use the <SET FUNCTION> key on startup. Use the following table as a guide

to startup procedures.

LCD Screen Action

CURRENT

FUNCTION

CHANGE

FUNCTION?

SELECT FUNCTION

For indoor installation only: Plug the wall pack

transformer into a 120 VAC power outlet, and

connect it to the DM-100.

This message appears next on the screen.

If “GAS PRICE” was shown on the bottom line

of the LCD during startup, do nothing. The

controller will automatically default to previous

Gas Price settings.

If a function other than “GAS PRICE” was

shown on the bottom line of the LCD during

startup, press the <SET FUNCTION> key while

Press the arrow up or down k eys <↑↓> until the

gas price option is shown. Press the <ENTER>

key to accept

The DM-100 controller should now be ready for use. The controller will “remember” the last

function setting, so this step should only need to be done with a new controller or one that is

configured for different displays.

18 Control Options

Page 25

1 ↓ $1.23 9/10

1 ↓ $1.23 9/10

the line settings.

$D.CC T/10 ↓

↓

incorrect.

DM-100 Controller Operation

The Petroleum Price Controller LCD display will default to showing the current display

settings on power up. The following text will be shown on the LCD.

LCD Screen Action

LINE PRICE

<EDIT> TO MODIFY

The display will toggle between these two

screens.

Press the up or down arrow k eys <↑↓> to scroll

through the current setting for any of the lines

on the display.

Press the <ENTER/EDIT> key to modify any of

To modify Price Line Settings:

1. Press either the <EDIT> key during operation or the <MENU> key. (Refer to the

following Menu Items chart.)

2. The following keys identify editable items:

• L = Current line number to be edited

• D.CC = Current dollars and cents value to edit

• T = Current tenths of cent value to edit

LCD Screen Action

EDIT LINE L

Press any of the number keys to edit the price

value for this line. Press the down arrow key <

to modify the value of the 1/10-cent data for this

line (read Note following).

Press <ENTER> to accept the new value or

press <CLEAR> to abort the changes.

Note: The flashing asterisk on the LCD shows

the current data being edited.

Many displays do not have a changeable 1/10cent digit. Changing the tenths-cent value fr om 9

on these digits will make the digit appear

>

Control Options 19

Page 26

Settings

Get status?

version x.x

To access Menu Items:

Menu Items

1. Press the <MENU> key.

2. Press the number of the desired menu item.

• Use Menu Items 1-5 to edit the price on each line of the

display. Lines are typically numbered top to bottom

with 1 being the top of the display.

• Use Menu Item 6 to run an LED test.

• Use Menu Item 7 allows the user access to change the

display options.

• Menu Item 8 will not be necessary for displays

operating without a modem.

• Menu Item 9 can be used with a bi-directional display

setup to get display status back from the driver. The

controller will cycle through various LCD message

screens, illustrated in the following table, that show

display status. Press <CLEAR> at any time to exit the

Display Status submenu.

• Menu Item 10 can be used to set the display time. Refer to the following table to

set the time and date. If the time and date are already correct, enter through and

press <ENTER> to send the date and time to the display.

Key Setting

1 Price Line 1

2 Price Line 2

3 Price Line 3

4 Price Line 4

5 Price Line 5

6 LED Test?

7 Display Option

8

Modem

9 Display Status

10 Set Time 12HR

LCD Screen Action

Display status

Driver Firmware

Press <ENTER> to get the status of the display that is

connected to the DM-100.

The LCD will scroll through the status sent back from the

display. Following is a list of responses:

Firmware Version

This is the firmware version programmed on t he hos t

MASC driver in the display.

To adjust the Dimming Level:

1. Press <DIMMING> on the keypad. The current setting is shown on the bottom line

of the LCD.

Note: The dimming level of the display can be adjusted in two ways. A light sensor, located

on each driver, can detect the level of ambient light at the display location and dims the

sign’s LEDs accordingly. This function is known as Automatic Dimming. When the Manual

Dimming function is selected, the LEDs remain at the same level of brightness regardless of

the level of light detected at the display.

2. Refer to the following tables to set the dimming level:

20 Control Options

Page 27

MAX INTENSITY ?

dimming maximum setting.

ENTER TO SET

is the maximum intensity level.

AUTOMATIC ↓

display.

LCD Screen Action

DIMMING

Press the down arrow key <↓> to toggle

through dim settings:

Automatic – The display automatically dims

based on the light detected at the display

Manual – The display dimming level is set

manually. Once set, this value remains

regardless of the level of light detected at the

If AUTOMATIC dimming is selected, the following LCD prompt will appear:

LCD Screen Action

SET AUTO DIMMING

Press the <ENTER/EDIT> key to edit the auto

dimming max intensity. This is the maximum

intensity that the display will use in full-bright

modes (during daylight hours).

Press <CLEAR> to keep the current auto

The following LCD prompt is shown for both MANUAL and AUTOMATIC dimming

selections:

LCD Screen Action

INTENSITY XX↓↑

XX – Current intensity (1-16)

Max Intensity - 16

Press the up or down arrow k ey <↑ ↓> to

modify the current intensity of the display

(Note: The DM-100 must be connected to the

display)

Press <ENTER> to accept this intensity. If the

manual-dimming mode is selected, this will be

the new intensity for the display. If the

automatic dimming mode is selected, the

display will illuminate in full-bright mode, which

To Update the Display:

1. After connecting to the display with the DM-100 controller, press <UPDATE

DISPLAY> to display the new sequence on the display.

2. This button will also allow for a preview of the new sequence on the LCD.

Control Options 21

Page 28

Page 29

Section 6: Maintenance and Troubleshooting

Important Notes:

• Disconnect power before any repair or maintenance is done on the display.

• Qualified service personnel must make any access to internal display electronics.

• Disconnect power when the display is not in use.

6.1 Component Location and Access

All internal electronic components and digits can be reached by opening the hinged access

doors on the front of the display. Figure 15 demonstrates the internal display component

layouts. Component placement varies slightly with each Fuelight

™

model.

Figure 15: Typical Front View with Face Panel Open

Visual Structural Inspection

At least once a year, check the display to ensure the structure and components are in good

condition. Inspect the paint and cabinet for corrosion. Make sure fasteners are tight. Tighten

or replace as required.

Note: Disconnect power before servicing the display. Also disconnect power when the

display is not in use. Prolonged power-on may shorten the life of some electronic

components.

Maintenance and Troubleshooting 23

Page 30

working.

receiving data.

receiving data.

Information Shown on Display

Meaning of Information

rNN

Revision Number of the Software

XLY

X = Sign #, L is Constant, Y = Line #

123 9/10

Digit Layout, if connected properly

6.2 Display Diagnostics

Driver Diagnostic LEDs

The driver has five LEDs that indicate whether it is

functioning properly. Refer to Figure 16 for their locations.

These LEDs can help pinpoint problems with the driver

set-up or operation.

LED Name Function Label Indication

DS1 Power POWER

DS2 Status STATUS

DS3 Transmit TX

DS4 Receive RX

DS5

RC-50

Receive

RC-50

RX

On constantly when

operating correctly.

Blinking when driver

is operating

correctly.

On when

microcontroller is not

working.

Off when

microcontroller is not

Flickers when

transmitting data.

Flickers when

Flickers when

receiving data from

the RC-50

transmitter (FLR-100

control kit).

Off when not

Figure 16: Driver Diagnostic LEDs

Power-up Self Test

A useful troubleshooting tool is the power on self-test performed by the host driver every

time the display powers up. The display should show the information listed in the left

column. Sign (X) and Line (Y) numbers refer to the rotary switch settings for the specific

display.

24 Maintenance and Troubleshooting

Page 31

appears on the wrong line.

to Section 4.1).

correct digits.

different driver output.

display.

6.3 Troubleshooting

This chart lists some symptoms that may be encountered with the displays. For each

symptom, possible causes and corrective actions are indicated. This list does not include

every possible problem but does represent some of the more common situations that may

occur.

Symptom/Condition Possible Cause Possible Solution

Check the power LED on the

No display in the face/sign will

light.

Power incorrectly installed.

host driver. If not lit, connect

power as described in Section

3.

Multiple-line sign with all lines

showing the same prices, or data

Garbled display.

Digit will not light.

Segment or several LEDs will not

light.

Line and face numbers not set

correctly.

Driver malfunction.

Digit malfunction. Digit the control.

Cable to the digit broken or

disconnected.

Poor contact at driver connection. Clean the contacts.

Driver malfunction. Replace the driver.

Poor contact at driver connection.

Broken or disconnected cable between

driver and digit.

Set a different line number for

each display on each face (refer

Check driver to make sure

signal cables are routed to the

Cycle power to the display.

Replace the driver.

Check cable by switching it to a

Replace the cable.

Clean the contact or replace the

harness.

Replace the cable.

Display shows “E4.”

Maintenance and Troubleshooting 25

Broken LEDs. Replace the segment or digit.

No Message Error: This code is shown

when a price has not been set on the

Use the control method to set

the price on the display.

Page 32

Page 33

Section 7: Replacement Parts

Important Notes:

• Disconnect power before any repair or maintenance is done on the display.

• Only qualified service personnel should make any access to internal display electronics.

• Disconnect power when the display is not in use.

7.1 About Replacement Parts

Most components within the display carry a label that lists the

part number. A typical label is shown in Figure 17 with the part

number in bold. Use the part number on the label to easily

order replacement parts from Customer Service.

Refer to Section 8 for instructions on obtaining parts from

Daktronics.

Figure 17: Typical Part Label

Replacement Parts 27

Page 34

Page 35

Section 8: Daktronics Exchange and Repair &

Return Programs

8.1 Exchange Program

The Daktronics Exchange Program is a quick, economical service for replacing key

components in need of repair. If a component fails, Daktronics sends a replacement part to

the customer who, in turn, returns the failed component to Daktronics. This not only saves

money but also decreases equipment downtime. Customers who follow the program

guidelines explained below will receive this service.

Before Contacting Daktronics

Fill in these numbers before calling Customer Service:

Display Serial Number:________________________________________

Display Model Number:_______________________________________

Date Installed:________________________________________________

Location of Sign:______________________________________________

Daktronics Customer ID Number:_______________________________

To participate in the Exchange Program, follow these steps.

1. Call Daktronics Customer Service: 888-DAK-SIGN (888-325-7446) to order the

exchange part.

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the failed part within 3 weeks of

the ship date.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. A charge will be made for the replacement part immediately, unless a qualifying

service agreement is in place.

In most circumstances, the replacement part will be invoiced at the time it is shipped.

If the failed part or replacement part is not returned to Daktronics within 3 weeks of

the ship date, it is assumed that the customer is purchasing the replacement part and

will be invoiced for the value of the new sale part.

If the part or parts are returned within 2 weeks of the second invoice date, Daktronics

will credit the customer for the amount of the second invoice. If after 2 weeks

Daktronics has still not received the parts back, the customer must pay the second

invoice and will not be credited for the return of the failed part.

Daktronics reserves the right to refuse parts that have been damaged due to acts of

nature or causes other than normal wear and tear.

Exchange and Repair Program 29

Page 36

8.2 Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Phone: 888-DAK-SIGN (888-325-7446) Fax: 605-697-4000

2. Receive a Return Materials Authorization (RMA) number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing. Daktronics does not recommend using packing peanuts

when shipping.

4. Enclose:

• Your name

• Address

• Phone number

• The RMA number

• A clear description of symptoms

Shipping Address

Daktronics Inc.

Customer Service Receiving

PO Box 5128

201 Daktronics Drive

Brookings, SD 57006

Attn: RMA#____________

30 Exchange and Repair Program

Page 37

Glossary

Cabinet: The metal body of a display.

Client Driver: All drivers not designated as the host driver. The host receiver sends the line

information out to the clients. Each client should use specific line and face numbers (“address”).

Digit Circuit Board: The circuit board on which the LEDs for the entire digit are mounted.

Digit Panel: Metal panel on which the digit circuit boards or digit segments are mounted. The digit

panel must be opened to access the display’s internal components.

Digit Segment: A group of LEDs in a digit that function as a single circuit. On 24” and larger digits,

each segment is an individual circuit board.

DM-100 Controller: A component used to transmit price data to displays operating with FLR-1500

and FLD-2000 Control Kits.

Driver: The circuit in a display that receives signal from the controller in order to operate the digits,

causing the correct numbers to be shown.

Host Driver: The driver that receives signal from the controller, and transmits it to the other drivers

in the sign. On radio-controlled displays, the host driver is connected to the radio receiver. On directwired displays, the host driver is wired to the control J box.

Light Emitting Diode (LED): A low energy, high intensity lighting unit used in Fuelight

RC-50 Transmitter: A component used to transmit price data to displays operating with FLR-100

Control Kits.

RC-100 Transmitter: A component used to transmit price data to displays operating with FLR-500

Control Kits.

Signal Surge Suppression Card: An electrical device used to protect equipment from high-voltage

surges in the signal line.

Transformer: A device that takes in 120 VAC and steps in down to 20 VAC for use by the driver.

™

displays.

Glossary 31

Page 38

Page 39

Appendix A: Reference Drawings

This manual refers to drawings by listing the last set

of digits and the letter preceding them. Figure 18

illustrates a Daktronics drawing label, located in the

lower-right corner of a drawing. In the example, the

drawing number would be referred to as Drawing A-

397727.

Insert; LL-2551 DM-100 Price/T&T Display ............................................................... Drawing A-167856

Riser Diagram, DM-100 Wired Control ...................................................................... Drawing A-267491

Grounding Detail, Gas Price Displays ....................................................................... Drawing B-329675

To obtain copies of shop drawings or other reference drawings specific to your display, contact

Daktronics Customer Service.

Figure 18: Drawing Label

Phone: 888-DAK-SIGN (888-325-7446)

Reference Drawings 33

Page 40

Page 41

Appendix B: Daktronics Warranty and Limitation

of Liability

Warranty and Limitation of Liability 35

Loading...

Loading...