Page 1

Fiber Optic

Communication Manual

Installation, Maintenance,

& Troubleshooting

ED-14743 Rev 1 11 October 2004

331 32nd Ave PO Box 5128 Brookings SD 57006

Tel 605-697-4034 or 877-605-1113 Fax 605-697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

Page 2

ED-14743

Product 1321

Rev 1 – 11 October 2004

DAKTRONICS, INC.

Copyright © 2004

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered

by the copyrights hereon may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

®

Galaxy

is a registered trademark of Daktronics, Inc. All others are trademarks of their respective companies.

Page 3

i

Table of Contents

Introduction................................................................................................................................1

Network Concepts......................................................................................................................1

System/Cable Requirements........................................................................................... 1

Component Identification............................................................................................... 1

Installation..................................................................................................................................2

Signal Termination Between Displays.......................................................................................3

Primary - Mirror............................................................................................................. 3

Primary – Primary (RS422)............................................................................................ 4

Primary – Primary (Fiber).............................................................................................. 5

Replacement of the Fiber Optic Board.......................................................................................6

Alternate Location Installation...................................................................................................7

Troubleshooting .........................................................................................................................8

Signal Converter............................................................................................................. 8

Loop-Back test with Fiber.............................................................................................. 9

Conducting the Venus 1500 Software Test .................................................................... 9

Replacement Parts List.............................................................................................................11

Appendix A: Reference Drawings..................................................................... A-1

Table of Contents

Page 4

Page 5

Introduction

The typical system consists of a Windows based personal computer running Venus 1500

software and one or more displays. In addition, some means of signal connection must be

used to relay signal between the computer and the display

available: RS232, RS422, Modem, Fiber Optic, Radio, and Ethernet. Up to 240 displays can

exist on one network.

. There are six network systems

The purpose of this manual is to explain those items that are unique to a fiber communication

system, including the installation and possible servicing requirements. In addition, if there is

more than one display the manual will discuss the possible ways of connecting signal between

displays.

Network Concepts

System/Cable Requirements

A fiber optic network is a standard communication method transmitting light (signal)

through a glass fiber. A signal converter is needed to convert the computer’s RS232

signal to fiber optic signal; a minimum of two fibers is required.

The cable is usually a 4-fiber cable (Daktronics part number W-1376). Two fibers

are used for display communications and the other two are saved for spares. The

cable may be either direct burial or routed in conduit, but it should not be subjected

to mechanical flexing. The maximum length of a fiber optic cable is 2,000 feet

(611.6 meters) from the signal converter to the fiber signal termination enclosure at

the display.

One advantage of using fiber over copper wire is that the signal and power lines can

be routed through the same conduit.

Component Identification

RS232: RS232 is a standard PC

communication type with a maximum cable

length of 25 feet (7.62 meters).

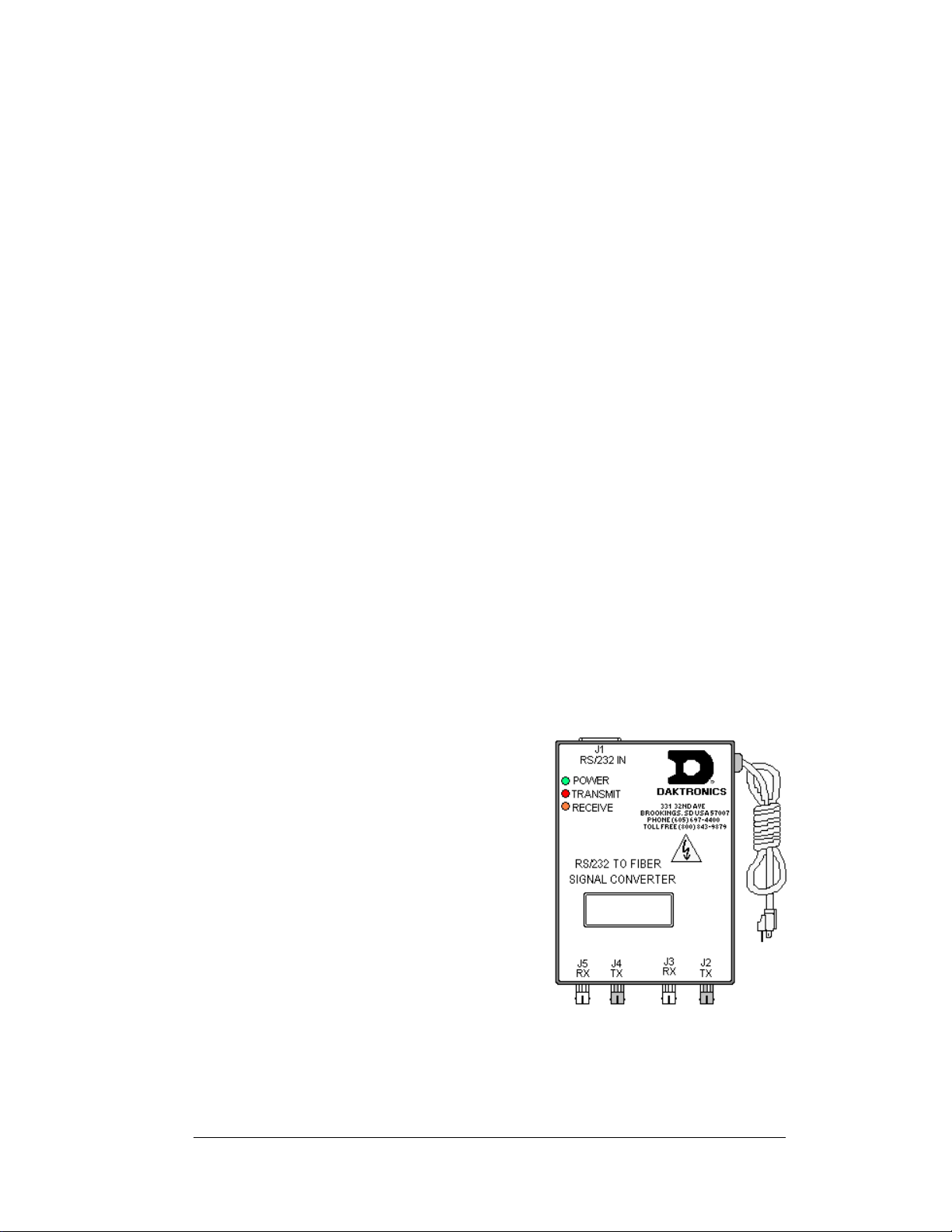

Signal Converter: The signal converter,

shown in Figure 1, is a Daktronics supplied

unit that converts the data from RS232 to

fiber optic signal. The signal converter is

connected to the control PC via a straight

through serial cable.

Serial Port: An actual serial port is required

for direct connections from the computer to

the signal converter.

Note: Certain USB adapters create an

“actual” serial port and others create

“virtual” ports. The Venus 1500

software will not recognize a virtual

port. Therefore, the use of a USB

adaptor is not supported by Daktronics.

Fiber Optic Communication Manual 1

Figure 1: RS232 to Fiber Signal Converter

Page 6

Venus 1500: Daktronics designed, Windows

messages on the display. Refer to the Venus 1500 Software manual, ED-13530, for

software operation.

®

based software used to create and edit

Installation

Reference Drawings:

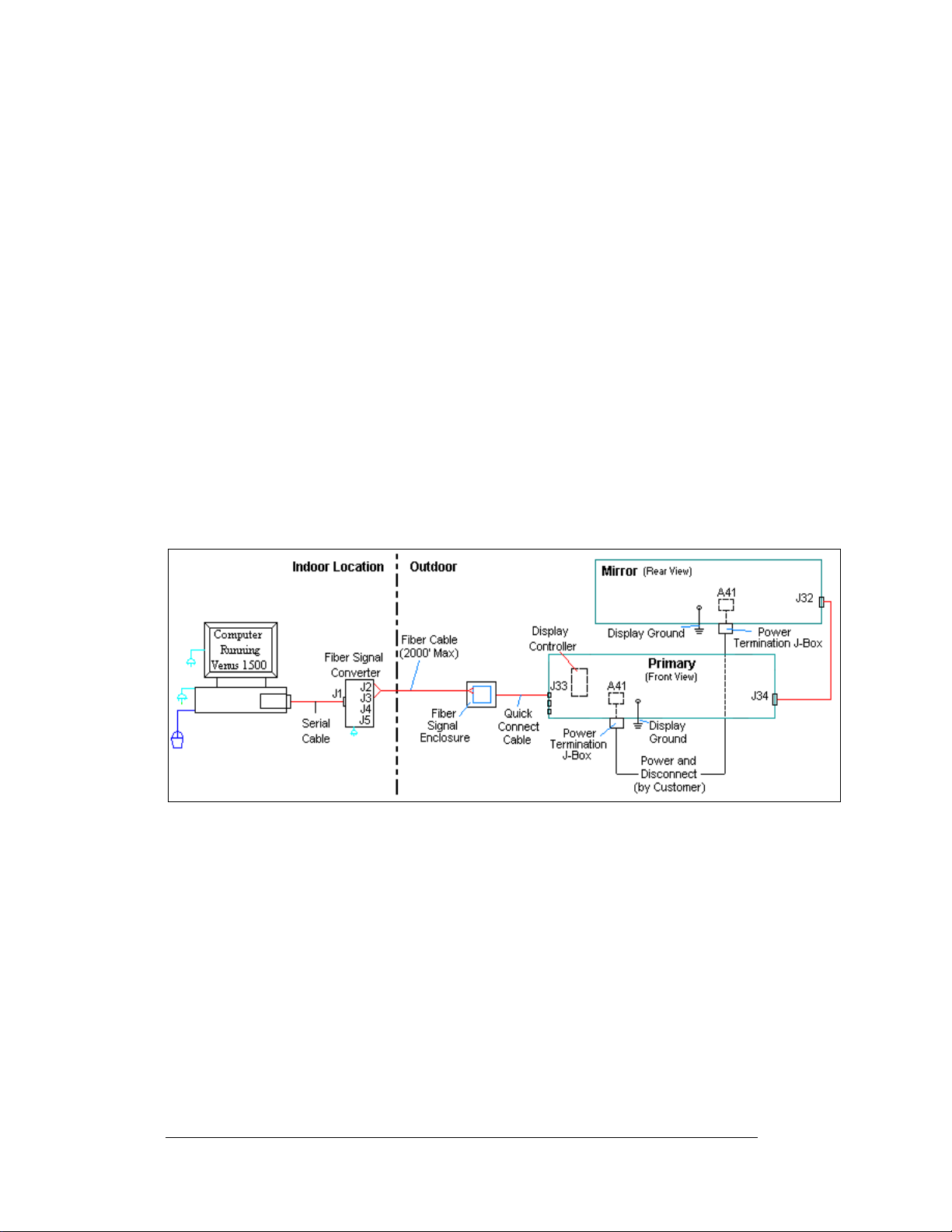

System Riser Diagram, Comm Box, Fiber, QC........................ Drawing A-211735

A fiber-controlled display requires the following connections:

1. The control computer connects to the signal converter (Daktronics part number 0A-

1127-0256) through a DB9 to DB25 serial cable (W-1249).

2. From the signal converter, fiber cable (Daktronics part number W-1376) is run to the

fiber optic board in the weather resistant enclosure at the display. (In certain cases,

the display may be ordered with the fiber optic board mounted in the display. In

those cases, the terminations will be the same.)

3. When connecting fiber cables, always connect transmit (TX) to receive (RX) and

receive (RX) to transmit (TX). Refer to Figure 2 and Drawing A-211735 for the

system layout.

4. In the case of fiber only, signal and display power can be run through the same

conduit.

Figure 2: Fiber Optic Display Controller

Note: The cable from the signal termination enclosure to the display can be routed though

conduit, through the display pole or should be secured to protect it from weathe r or

vandalism.

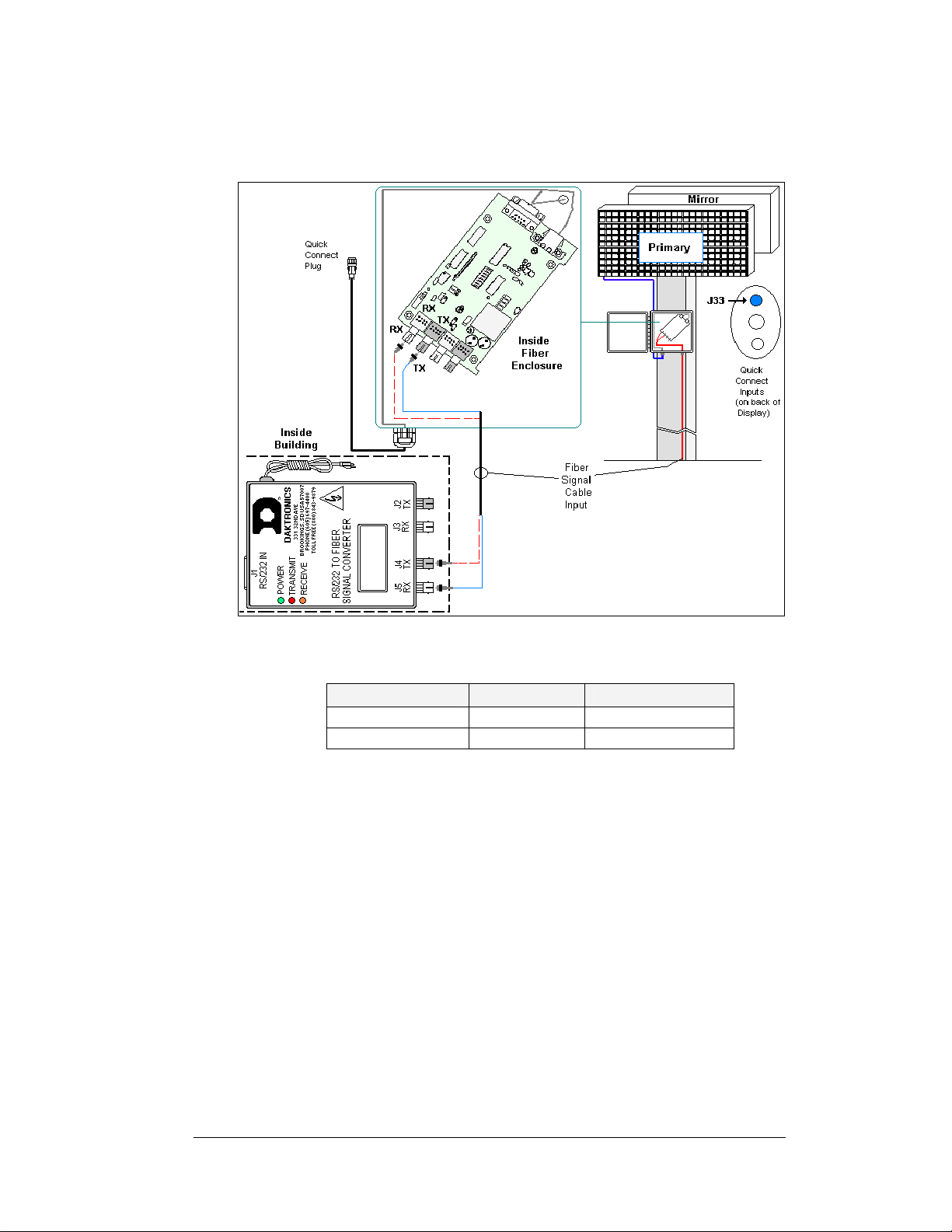

Complete the following steps to connect the signal termination enclosure:

1. Mount the signal termination enclosure within 25 feet of the display.

2. Route fiber optic cable to the enclosure. Two fibers are required.

3. Connect transmit (J4/J2) at the signal converter to receive (J5) in the enclosure and

receive (J5/J3) to transmit (J4). Refer to

termination locations.

4. Connect the quick connect cable from the enclosure to the primary display. Connect

the cable to the red jack, J33, top, labeled RS 232/RADIO.

2

Figure 3 and the provided table for fiber

Fiber Optic Communication Manual

Page 7

5. For displays with an internal fiber optic board only: Route the fiber cable into

the back of the display, being careful not to damage any interior components. Make

the connections to the fiber optic board as normal.

Figure 3: Signal Converter to Fiber Optic Enclosure

Signal Converter to Display Fiber Optic Board

Signal Converter Field Cabling Fiber Optic Board

J2 Transmit (TX1) (Color varies) J5 Receive (RX2)

J3 Receive (RX1) (Color varies) J4 Transmit (TX2)

Signal Termination Between Displays

Reference Drawings:

Controller II, Galaxy, 8-conn, J1087 .........................................Drawing B-204771

Primary - Mirror

Most displays are shipped as either a single Primary display or two displays in a 2V,

Primary – Mirror configuration.

The Primary – Mirror (2V) quick connect cable (W-1503) is used to terminate signal

between two displays. The six-foot cable goes from the Signal OUT (J34) on the

primary display to the Signal IN (J32) on the mirror display.

Fiber Optic Communication Manual 3

Page 8

Figure 4: Quick Connect Boards

Figure 5: Display Interconnect

Primary – Primary (RS422)

If your location requires two displays that cannot be mounted back-to-back, two

primary displays will need to be installed. Those displays can be connected using an

RS422 signal cable or by fiber. In the case of RS422, the following connections will

need to be made:

1. Open the display, as explained in Section 4.4 of your display manual, and

locate the controller panel for these displays.

2. Route the cable through conduit from the back of the first primary display

to the back of the second primary display. Use one of the knockouts for

access, being careful not to damage any internal components

3. Use either a 4-pair signal cable or two 4-condutor, shielded cables to

connect both the signal and the temperature sensor information between

displays.

4. The signal cable will connect from TB3 out on the first primary display to

either:

• A surge board at TB1 in a second primary display

• (or) To TB2 on the controller in the second primary display.

• Note: In either case the connections are flipped. See the table and

Drawing B-204771 for connections on both displays.

• Signal connections between two controllers are shown in Figure 6.

Figure 6: Interconnection from Primary to Primary

4

Fiber Optic Communication Manual

Page 9

5. See the instructions for the Optional Temperature Sensor in the appendix of

Primary – Primary (Fiber)

If your location requires two displays that cannot be mounted back-to-back, two

primary displays will need to be installed. Those displays can be connected using an

RS422 signal cable or by fiber. In the case of fiber, the following connections will

need to be made:

1. Locate the signal enclosures or open the display, as explained in Section 4.4

2. Route the cable through conduit between the enclosures or from the back of

3. Use the fiber cable to connect from transmit and receive of the output jacks

4. See the instructions for the Optional Temperature Sensor in the appendix of

the display manual for connections that need to be made for the temperature

sensor termination.

Primary – Primary Interconnect Cable

Face A – RS422

OUT (TB3)

Pin 1 (GND) Shield Pin 6 (GND)

Pin 2 (D2OUT-N) Red Pin 5 (D1IN-N)

Pin 3 (D2OUT-P) Black Pin 4 (D1IN-P)

Pin 4 (D2IN-N) Green Pin 3 (D1OUT-N)

Pin 5 (D2IN-P) White Pin 2 (D1OUT-P)

Pin 6 (Shield) Pin 1 (Shield)

Field

Cabling

Face B – RS422

IN (TB2)

of your display manual, to locate the controller panel for these displays.

the first primary display to the back of the second primary display. In the

case of internally mounted fiber optic boards, use one of the knockouts for

access, being careful not to damage any internal components

(J2 and J3) to transmit and receive of the input jacks (J4 and J5) on the fiber

optic board. Always connect transmit to receive and receive to transmit as

shown in shown in

Figure 7 and the table.

the display manual for connections that need to be made for the temperature

Figure 7: Fiber Optic Interconnect

Fiber Optic Communication Manual 5

Page 10

sensor termination.

Fiber Optic Board (Primary 1) to Fiber Optic Board (Primary 2)

Fiber Optic Board Field Cabling Fiber Optic Board

J3 Receive (RX2) (Color varies) J4 Transmit (TX1)

J2 Transmit (TX2) (Color varies) J5 Receive (RX1)

Replacement of the Fiber Optic Board

The following directions are to replace a fiber optic board in the signal termination enclosure

mounted at the display. (In certain cases, the display may have been ordered with the fiber

optic board mounted in the display. The following directions are also true for those

installations.)

1. To replace a fiber optic board, first disconnect the power and signal connections

(refer to

2. The fiber optic board is held in place with four

nuts. Carefully remove them using a 5/16” nut

driver.

3. Install the new fiber optic board, replace the nuts

and reconnect power and signal cables.

The fiber optic board has three LEDs.

1. The green power LED (DS1) should remain lit

while power is applied to the fiberboard.

2. The amber receive LED (DS2) will flash when

the display fiber optic board is accepting signal

from the signal converter.

3. The red transmit LED (DS3) will flash when the

fiber optic board is sending to the signal

converter.

In addition, the fiber optic board has several input and

output jacks:

1. J4 and J5 are the two fiber connectors, to which

the fiber signal converter connects. (They can also be used for connecting to another

fiber optic board in a previous primary display if necessary.)

2. J6 is for the AC power coming from the display.

3. J1, a DB9 connector, that will transfer the signal to the display through the quick

connect cable.

4. J2 and J3 are used only if connected to a second fiberboard in another Primary

display. J7 is not used in the enclosure application.

Figure 8 for connector locations).

Figure 8: Fiber Optic Board in Enclosure

6

Fiber Optic Communication Manual

Page 11

Alternate Location Installation

Reference Drawings:

Schem; Primary Signal, Internal, with QC ................................Drawing B-206146

Note: If the display was ordered with the fiber optic board internally installed, these

connections have already been completed.

If necessary, the fiber optic board can be moved from the signal termination enclosure and

located in the display. The fiber optic board will be mounted on the standoffs next to the

controller board or in the left end of the display. The following connections will need to be

made for the fiber optic board to operate in the display:

1. Route the fiber through conduit to the back of the display. Use one of the knockouts

for access, being careful not to damage any internal components.

2. Connect two fiber lines of the fiber cable (Daktronics part number W-1376) from the

signal converter to the fiber optic board. Always connect receive on the signal

converter to transmit (J5) on the fiberboard and transmit at the signal converter to

receive (J4) on the fiber optic board.

3. Signal connects from the J7 output on the fiber optic board to J3 on the controller.

Use a straight 8-conductor, RJ45 cable (Daktronics part number 0A-1229-0054) to

make the connection.

4. Using the pre-terminated power cable, provided in the display, connect power from

the transformer (10 VAC) into J6 on the fiberboard.

5. See

Figure 9 and Drawing B-206146 for fiber connections in the display.

Figure 9: Relocating the Fiber Board in the Display

Fiber Optic Communication Manual 7

Page 12

Troubleshooting

Signal Converter

The following table gives the typical state of the signal converter when the LEDs are

either on or off. Refer to

locations of the various components.

LED

Indicators

Power

On Steady

TX

OFF Steady

Brief Flicker SC is transmitting data

ON Steady

RX

OFF Steady Normal state, SC is not re ceiving data

Brief Flicker SC is receiving data

TX/RX

ON Steady

Fiber Signal Converter (0A-1127-0256)

The following tables give the jack pin-outs for a fiber signal

converter.

JACK OPERATION

J2 TX1 (out)

J3 RX1 (in)

J4 TX2 (out)

J5 RX2 (in)

ON

OFF

Figure 10 for an illustration of the signal converters and the

Typical States Troubleshooting

Signal Converter (SC) is receiving

Power

SC is not receiving power

Internal 1 AMP fuse is bad Replace SC

SC is not connected to a serial port Connect to open computer COM

1. Serial port or serial cable is bad

2. Computer COM port in sleep mode

Normal state, SC is not transmitting

data

1. Field Cabling between SC and

display is bad

2. Connected to display output jack or

terminated incorrectly

3. Bad COM port on display controller

(If serial cable is connected) Bad SC Replace SC

J1 - 25 Pin DB-F

PIN OPERATION

2 TX-P (out)

3 RX-P (in)

7 GND

port

1. Try another port or replace

serial cable

2. Communicate to display

1. Eliminate cabling by

disconnecting wire/cable from

SC to display controller

2. Check connections and

terminations

3. Eliminate by disconnecting

wire/cable to display controller

Figure 10: RS232/Fiber Signal

Converter

8

Fiber Optic Communication Manual

Page 13

Loop-Back test with Fiber

1. Locate the fiber optic board in the signal termination

enclosure.

2. Label the fiber ends connected to the board and carefully

remove them as shown in

3. Connect the ends into the fiber splice (Daktronics part# P-

1197), as shown in

4. When the fibers are connected, perform the loop-back test

using the Venus 1500 software as described in

Conducting the Venus 1500 Software Test

Figure 11.

Figure 12.

Figure 12: Connecting TX and RX Fibers with Fiber Splice

Figure 11: Fiber Optic Board

Conducting the Venus 1500 Software Test

1. Open Venus 1500 Administrator.

2. Click on Network Configuration and open the direct network by clicking on the

[+] in front of Direct Network.

Fiber Optic Communication Manual 9

Page 14

3. Right click on the network you want to Test.

4. Click on [Test].

5. If the Transmit LED on the signal converter flickers the signal is getting to the

signal converter. That means that the right Com port is being used, however if it

does not flicker there is either a software or hardware problem with the

computer.

6. If you get the same message in the “Received” box as in the “Sent” box, the

loop-back test was successful, implying that the cable is good to that point.

7. If “No Response” appears in the “Received” box the test failed due to one of the

following problems:

10

Fiber Optic Communication Manual

Page 15

a. The correct computer COM port is not being used or USB port is not

configured as a “serial” port. (If the Transmit LED flickered this was not

the problem.)

b. Communication problem:

• The fiber or the ends on the fiber are bad.

c. There was a problem conducting the test:

• The serial cable to the signal converter is bad or not plugged in.

• The signal converter is not plugged in.

8. If the words “It appears as if this port has a modem attached”, the modem will

need to be moved or you need to use a different COM port.

After the test is complete:

1. Remove the fiber splice, and reconnect fiber to fiberboard.

2. Run the test again, without the splice, and the test should fail.

3. Use Venus 1500 Display Manager to get status to ensure communication now

works correctly.

Replacement Parts List

The following table contains some of the items that may need to be replaced over a period of

time. Many of the parts also have their part numbers on labels affixed to them.

To prevent theft, Daktronics recommends purchas ing a lockable cabinet to store manuals and

replacement/spare parts.

Signal Converter, Fiber 0A-1127-0256

Fiber Signal Termination Enclosure (Comm. Box) 0A-1229-0107

Signal Board, RS232 to Fiber, 12V 0P-1127-0024

6-pin M to cable end, 25 ft, Fiber W-1484

Serial Cable, DB9-F to DB25-M, 6 ft. W-1249

Four Fiber cable, 62.5/125 grade W-1376

RJ45, M-M 18” cable, 8-conductor 0A-1229-0054

Plug; 1 pin F, Fiber optic, Splicer P-1197

Interconnect Cable; 31-pin male to 31-pin male, 6’,

QC

Quick Connect Interface, Input, w/Ethernet 0P-1229-2004

31-pin, Quick Connect Input/Output Board 0P-1229-2005

Part Description Part Number

W-1503

Fiber Optic Communication Manual 11

Page 16

Page 17

Appendix A: Reference Drawings

The following drawings are listed in numerical order by size (A, B, etc.). Those drawings are

listed according to size.

System Riser Diagram, Comm Box, Fiber, QC...............................Drawing A-211735

Controller II, Galaxy, 8-conn, J1087................................................Drawing B-204771

Schem; Primary Signal, Internal, with QC.......................................Drawing B-206146

Appendix A: Reference Drawings A-1

Page 18

Page 19

Page 20

Page 21

Loading...

Loading...