Page 1

201 Daktronics Drive PO Box 5128 Brookings, SD 57006-5128

Tel: 1-800-DAKTRONICS (1-800-325-8766) Fax: 605-697-4700

Web: www.daktronics.com

Generation III Stackable

LED Scoreboards

Display Manual

ED-14091 Rev 5– 23 March 2012

Models

FB-2006

MS-2016

MS-2014

MS-2017

MS-2015

MS-2018

Page 2

Page 3

ED-14091

Please fill in the information below for your display; use it

for reference when calling Daktronics for assistance.

Display Serial No. _____________________________________________

Display Model No. _____________________________________________

Date Installed _________________________________________________

Product 1192

Rev 5 – 23 March 2012

DAKTRONICS, INC.

Copyright 2004-2012

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered

by the copyrights hereon may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

All Sport

NFPA International.

is a registered trademark of Daktronics, Inc. National Electric Code is a registered trademark of

Page 4

Page 5

Table of Contents

Section 1: Introduction ....................................................................................... 1

1.1 How to Use This Manual ...............................................................................1

1.2 Daktronics Nomenclature ..............................................................................2

1.3 Manual Overview ..........................................................................................3

1.4 Product Overview ..........................................................................................4

Scoreboard Options ................................................................................5

1.5 Model Identification ......................................................................................5

1.6 Product Safety Approval ...............................................................................6

Section 2: Specifications ................................................................................... 7

2.1 Model FB-2006-11/21 ...................................................................................9

2.2 Models MS-2014 and MS-2015 .................................................................. 10

2.3 Model MS-2016 ........................................................................................... 11

2.4 Model MS-2017 ........................................................................................... 12

2.5 Model MS-2018 ........................................................................................... 13

Section 3: Mechanical Installation .................................................................. 15

3.1 Installing Beams and Footings ..................................................................... 15

3.2 Installing Captions Modules ........................................................................ 15

3.3 Mounting Digit Modules ............................................................................. 16

Beam Mounting Digit Modules, Outdoor ............................................. 16

Section 4: Electrical Installation...................................................................... 19

4.1 Power ........................................................................................................... 19

Grounding ............................................................................................. 19

Power Installation ................................................................................. 20

4.2 Power and Signal Connection ...................................................................... 21

Connections Between Sections ............................................................. 22

Section 5: Maintenance and Troubleshooting ............................................... 25

5.1 Cabinet Specifications ................................................................................. 25

5.2 Component Location and Access ................................................................ 25

Replacing A Digit ................................................................................. 26

5.3 LED Drivers ................................................................................................ 26

Replacing a Driver ................................................................................ 27

5.4 Segmentation and Digit Designation ........................................................... 28

5.5 Lightening Protection .................................................................................. 28

5.6 Troubleshooting ........................................................................................... 28

5.7 Replacement Parts ....................................................................................... 29

5.8 Daktronics Exchange and Repair and Return Programs .............................. 30

Exchange Program................................................................................ 30

Repair & Return Program ..................................................................... 31

Daktronics Warranty and Limitation of Liability ................................. 32

Appendix A: Reference Drawings ....................................................................... 33

Appendix B: Scoreboard Options ....................................................................... 35

Appendix C: Daktronics Warranty and Limitation of Liability ......................... 37

Table of Contents i

Page 6

Page 7

Section 1: Introduction

Figure 1: Daktronics Drawing Label

This manual explains the installation and maintenance of the Stackable Outdoor Scoreboards.

If you have other questions regarding the safety, installation, operation, or service of these

systems, contact Daktronics. Customer Service Help Desk telephone numbers are listed on the

cover page of this manual.

1.1 How to Use This Manual

Important Safeguards:

Read and understand these instructions before installing the scoreboard.

Do not drop the control console or allow it to get wet.

Be sure the scoreboard is properly grounded with a ground electrode at the

scoreboard location.

Disconnect power to the scoreboard when it is not in use.

Disconnect power when servicing the scoreboard.

Do not modify the scoreboard structure or attach any panels or coverings to

the scoreboard without the written consent of Daktronics, Inc.

Figure 1 illustrates the Daktronics drawing numbering system. Daktronics identifies

individual engineering drawings by their drawing number (7087-P08A-69945 in the

example), which is located in the lower right corner of the drawing. This manual

refers to drawings by their last set of numbers and the letter preceding them. The

example would be Drawing A-69945.

Reference drawings in this manual are grouped and inserted in alphanumeric

order in Appendix A: Reference Drawings.

Listed below are a number of drawing types commonly used by Daktronics, along

with the information that each is likely to provide.

System Riser Diagrams: overall system layout from control room to

display, power, and phase requirements.

Shop Drawings: fan locations, transformer locations, mounting

information, power and signal entrance points, and access method (front or

rear).

Schematics: power wiring, signal wiring, panelboard or power termination

panel assignments, signal termination panel assignments, and transformer

assignments.

Introduction 1

Page 8

Final Assembly: component locations, part numbers, display dimensions,

Figure 2: Scoreboard ID Label

and assembly/disassembly instructions.

All references to drawing numbers, appendices, figures, or other manuals are

presented in bold typeface, as in this example. ‘‘Refer to Drawing A-114667 for the

location of the driver enclosure.’’ Additionally, any drawings referenced within a

particular subsection are listed at the beginning of that subsection in the following

manner:

Reference Drawing:

Shop Drawing; 16 High 2 ½" Small Matrix ............ Drawing A-114667

Daktronics identifies manuals by their ED (engineering document) number, which is

located on the cover page of the manual. For example, this manual would be referred

to as ED-14091.

The serial and model numbers of a Daktronics scoreboard can be found on the ID

label on the display. The label will be similar to the one shown in Figure 2. When

calling Daktronics Customer Service, please have this information available to

ensure that your request is serviced as quickly as possible. For future reference, note

your scoreboard model number, serial number, and installation date on the front page

of this manual.

Daktronics displays are built for long life and require little maintenance. However,

from time to time, certain display components will have to be replaced. The

Replacement Parts List in Section 5 provides the names and part numbers of

components that may require replacement during the life of this display.

Following the Replacement Parts List is an explanation of Daktronics exchange and

replacement programs. Refer to these instructions if you must replace or repair any

display component.

1.2 Daktronics Nomenclature

To fully understand some Daktronics drawings, such as schematics, it is necessary to

know how various components are labeled in those drawings. You will find this

information useful when trying to communicate maintenance or troubleshooting

efforts.

2 Introduction

Page 9

The label ‘‘A’’ on a drawing item typically denotes an assembly. An assembly can

be a single circuit board or a collection of components that function together, usually

mounted on a single plate or in a single enclosure.

In addition, the following labeling formats might be found on various Daktronics

drawings:

‘‘TB _ _’’ denotes a termination block for power or signal cable.

‘‘F _ _’’ denotes a fuse.

‘‘E _ _’’ denotes a grounding point.

‘‘J _ _’’ denotes a power or signal jack.

‘‘P _ _’’ denotes a power or signal plug for the opposite jack.

Finally, Daktronics part numbers are commonly found on drawings. Those part

numbers can be used when requesting replacement parts from Daktronics Customer

Service. Take note of the following part number formats. (Not all possible formats

are listed here.)

‘‘0P- _ _ _ _- _ _ _ _’’ denotes an individual circuit board, such as a driver

board.

‘‘0A-_ _ _ _ - _ _ _ _’’ denotes an assembly, such as a circuit board and the

plate or bracket to which it is mounted. A collection of circuit boards

working as a single unit may also carry an assembly label.

‘‘W- _ _ _ _ ’’ denotes a wire or cable. Cables may also carry the assembly

numbering format in certain circumstances. This is especially true for

ribbon cables.

‘‘F- _ _ _ _ ’’ denotes a fuse.

‘‘T- _ _ _ _ ’’ denotes a transformer.

‘‘PR- _ _ _ _ _ - _’’ denotes a specially ordered part.

‘‘M- _ _ _ ’’ denotes a metal part, and ‘‘0M-_ _ _ _ _ _’’ typically denotes a

fabricated metal assembly.

1.3 Manual Overview

This manual details outdoor modular scoreboards with LED digits. It is divided into

the following sections:

Section 1 contains an overview of the product, product safety information, and

labeling and numbering descriptions.

Section 2 contains a table listing all of the mechanical specifications, circuit

specifications, and power requirements for each scoreboard module.

Section 3 contains general mechanical installation information.

Section 4 contains general electrical installation information.

Section 5 contains information needed to service the scoreboards and

troubleshoot problems.

Appendix A contains the engineering drawings referenced in this manual.

Appendix B contains drawings, descriptions, and installation instructions for

various scoreboard options.

Introduction 3

Page 10

1.4 Product Overview

Reference Drawings:

Layout View; MS-2015-11-21, G3 ............................... Drawing A-189437

Layout View; MS-2014-11-21, G3 ............................... Drawing A-189446

Layout View; MS-2018-11-21, G3 ............................... Drawing A-189492

Layout View, MS-2016-11-21, G3 ............................... Drawing A-202065

Layout View, MS-2017-11-21, G3 ............................... Drawing A-213041

Layout View, FB-2006-11-21, G3 ................................ Drawing A-221063

The scoreboards detailed in this manual are part of a family of outdoor scoring and

timing displays designed to offer simple installation and easy reliability.

Microprocessor control assures consistent operation and accuracy. The scoreboards

are illustrated in the Reference Drawings listed above.

Because this scoreboard series is based on a modular design, there can be any

number of module and caption combinations. Some displays may utilize a single

module, while others may consist of multiple modules arranged vertically.

The heavy-gauge aluminum cabinets for the displays have a 2'-4" display face and

they are 7" deep by 9'-0" long. Caption sections are also 9'-0" long, but they measure

only 7" high. Refer to Section 2 for a complete list of weights, dimensions, and

power specifications.

The four basic displays described in this manual are configured as follows:

Models MS-2014 and MS-2018 consist of two powered sections with digits

indicating clock/score and player/penalty, as well as an unpowered caption

panel. MS-2018 also features an unpowered panel that shows shots on goal.

Model MS-2015 is a single powered section with digits indicating

clock/score only.

Model MS-2016 is a three-section display with game time digits as well as

digits indicating home score, period, and guest score.

Model MS-2017 is a three-section display with game time digits as well as

digits indication home & guest score, period, foul information, player foul

information, possession and bonus..

Model FB-2006 is a three-section display with powered clock/score and

statistics sections as well as an unpowered caption panel.

Each scoreboard on this series begins with a one- or two-line section, which means

the section either has a single row or two rows of 10" numeric digits. The boards use

either red or amber LEDs (light emitting diode) to illuminate the display. LEDs are

tiny, solid-state components that use a semiconductor chip to transform electrical

current into light. They are high intensity, low energy lighting units. Because of their

LED technology, the modular scoreboards consume little power, some barely more

4 Introduction

Page 11

than a household lamp. Power usage for the stackable sections in this series ranges

from 150 W to a maximum of 450 W.

Caption sections are unpowered units that attach to the top or bottom of a digit

section. The caption sections in models MS-2014 and MS-2018 indicate PLAYER

and PENALTY for both teams and use permanent, 5" vinyl captions for the digit

mounted directly below it. The caption section in model FB-2006 indicates DOWN,

yards TO GO, BALL ON and QTR (quarter) for the digit section mounted directly

below it as well. Stackable scoreboard installations may also contain optional ad

panels, attachments which can be used to display sponsor names or other advertising

messages.

The stackable scoreboards have been designed for use with the Daktronics All

Sport 5010 Control Console. The controllers use All Sport 5000 Series sport inserts

(keyboard overlays), and the boards operate without modification on All Sport 5000

signal protocol.

Scoreboard Options

The stackable scoreboards have been designed with several standard options. Popular

add-on features include a 12 V DC horn and changeable captions. Guides for the

changeable caption panels are already installed on the MS-2014 and MS-2018

scoring and caption sections; optional panels can be customized to display team

names or for virtually any other purpose.

Each of the scoreboard options is illustrated and described in Appendix B.

1.5 Model Identification

Reference Drawings:

Layout View; MS-2015-11-21, G3................................ Drawing A-189437

Layout View; MS-2014-11-21, G3................................ Drawing A-189446

Layout View; MS-2018-11-21, G3................................ Drawing A-189492

Layout View, MS-2016-11-21, G3................................ Drawing A-202065

Layout View, MS-2017-11-21, G3................................ Drawing A-214362

Layout View, FB-2006-11-21, G3 ................................ Drawing A-221063

Daktronics scoreboards are differentiated by their model numbers: For all

scoreboards included in this manual, the two-letter prefix, MS-, identifies the model

as a multisport display. The next four numbers identify the specific model.

Most Daktronics scoreboards also carry a two-number suffix that refers to indooroutdoor status and power supply: -11 and -21 are outdoor, 120 V AC displays,

respectively. The LED scoreboards in this manual are currently configured as -11 or

-21 displays.

Reference drawings are found at the end of this manual in Appendix A: Reference

Drawings.

Introduction 5

Page 12

1.6 Product Safety Approval

Daktronics stackable scoreboards are ETL-listed and tested to CSA standards.

Contact Daktronics with any questions regarding the testing procedures.

6 Introduction

Page 13

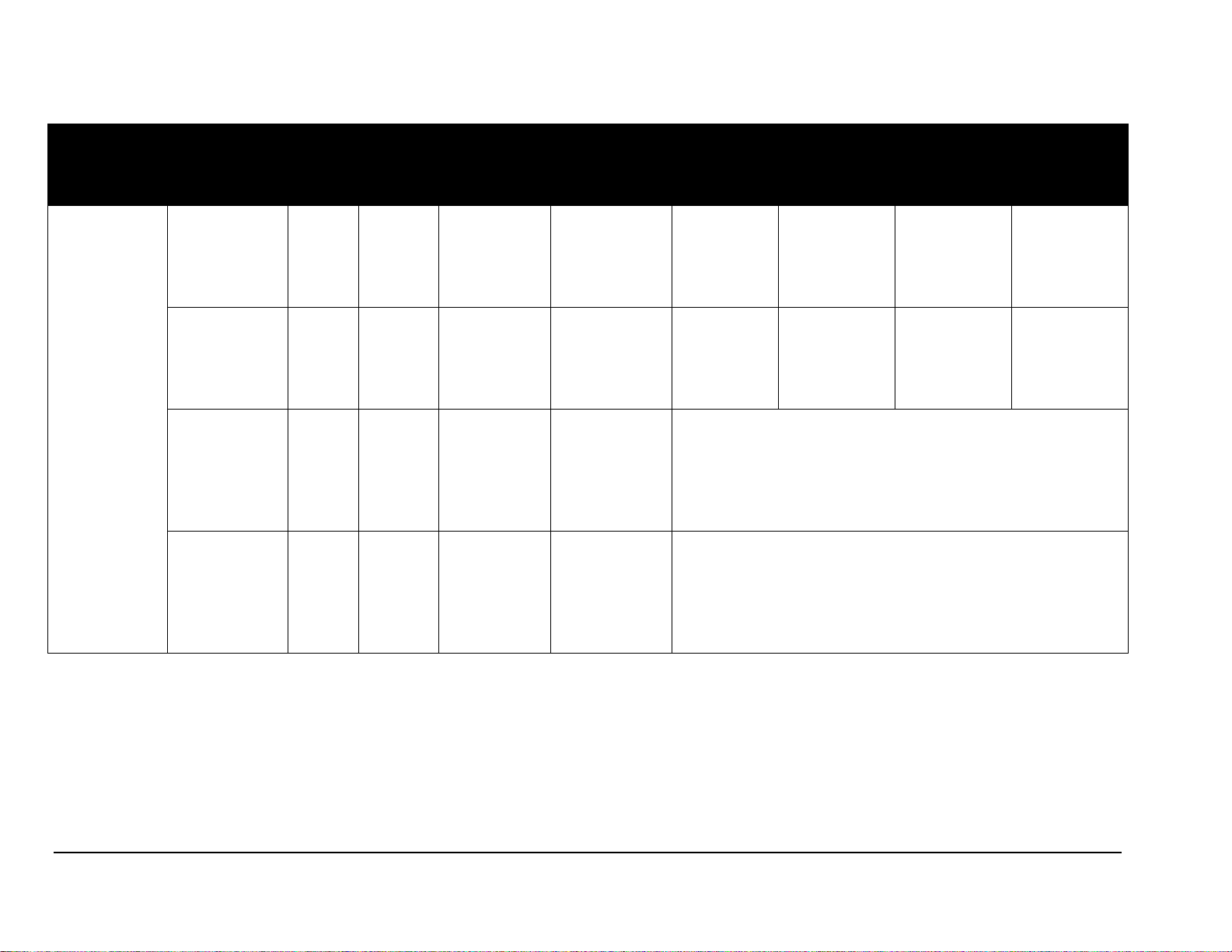

Section 2: Specifications

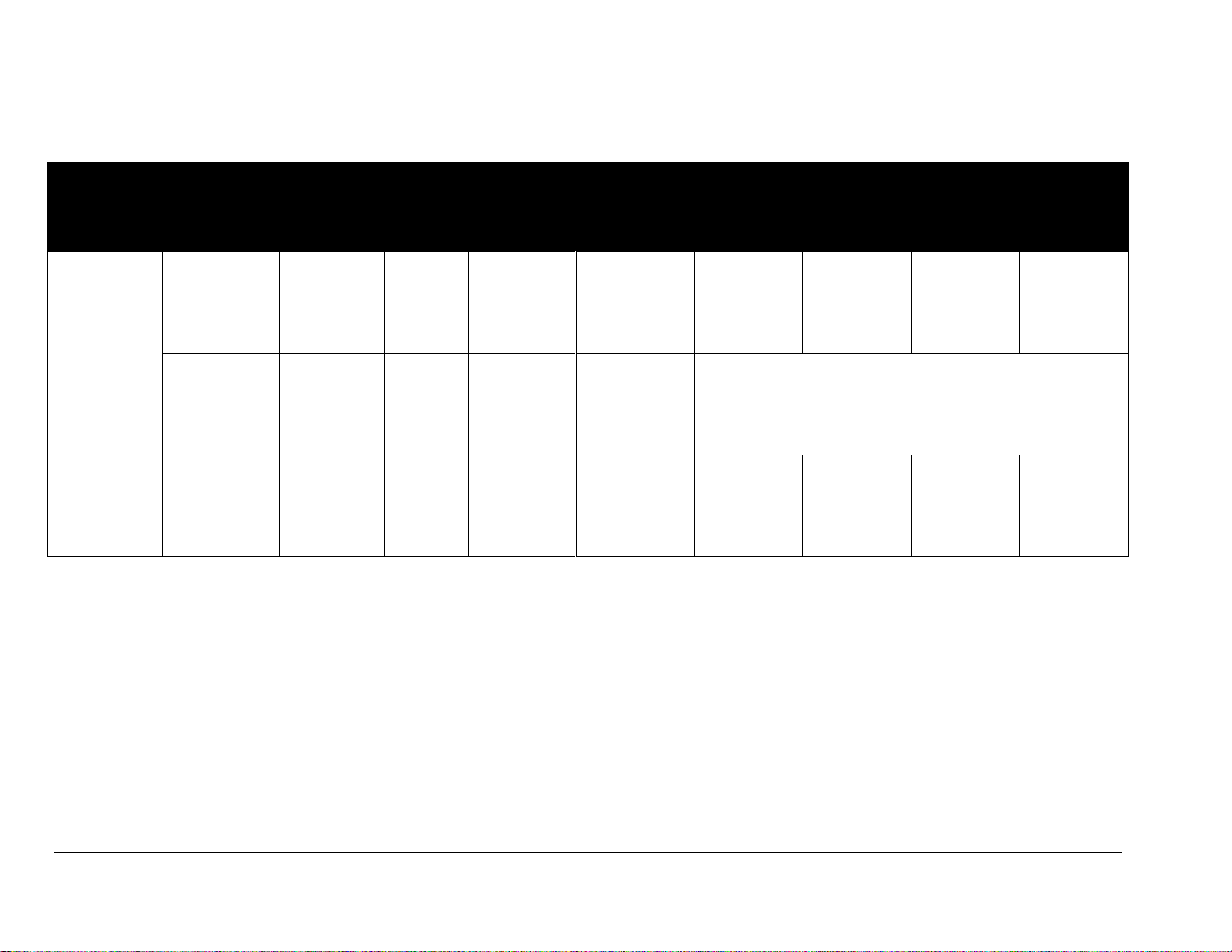

The following table lists all of the mechanical and electrical specifications, as well as power

requirements for each model listed in this manual. Models are listed in alphanumeric order.

Specifications 7

Page 14

Page 15

2.1 Model FB-2006-11/21

Model

Section

Dimensions

(Height, Width, Depth)

Weight

Uncrated

(Crated)

Digit Size

Digit Color

Maximum

Wattage

Power

Amps per

Line

(Single

Phase)

Driver

Number

and

Address

FB-2006

Clock/Score

H2'-4"

W9'-0"

D7"

711 mm

2743 mm

178 mm

60 lb 27 kg

(114 lb 52 kg)

10"

-11 red

-21 amber

300 W

120 V AC

2.5 A

A1 12

Captions

H7"

W9'-0"

D7"

178 mm

2743 mm

178 mm

25 lb 11 kg

(47 lb 21 kg)

None

Unpowered

Statistics

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

178 mm

42 lb 19 kg

(86 lb 39 kg)

10"

-11 red

-21 amber

300 W

120 V AC

2.5 A

A1

12

Specifications 9

Page 16

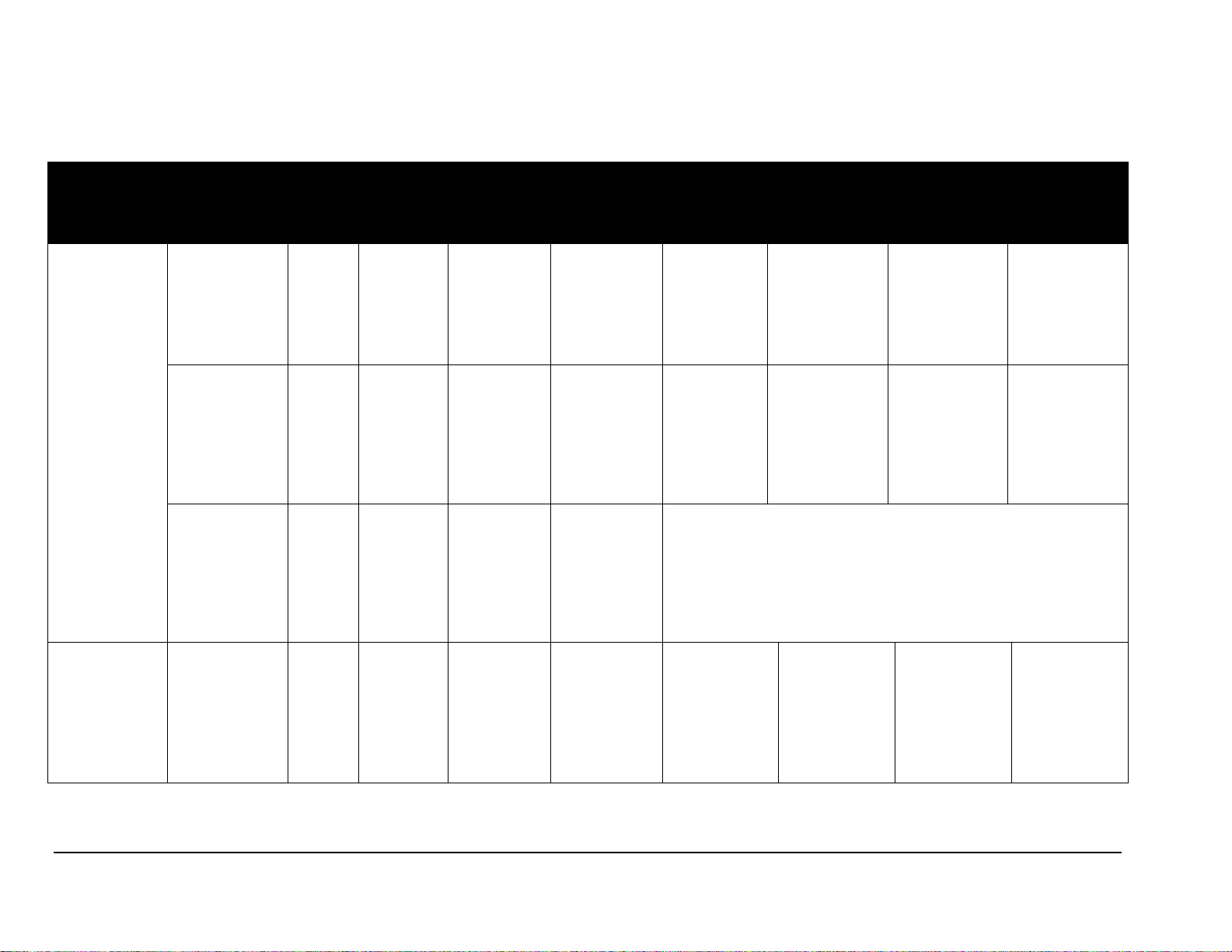

2.2 Models MS-2014 and MS-2015

Model

Section

Dimensions

(Height, Width,

Depth)

Weight

Uncrated

(Crated)

Digit Size

Digit Color

Maximum

Wattage

Power

Amps per

Line

(Single

Phase)

Driver

Number and

Address

MS-2014

Clock/Score

H2'-4"

W9'-0"

D7"

914 mm

2743 mm

177 mm

75 lb 34 kg

(142 lb 64 kg)

10"

-11 red

-21 amber

300 W

120 V AC

2.5 A

A1

71

Player/Penalty

H2'-4"

W9'-0"

D7"

914 mm

2743 mm

177 mm

85 lb 39 kg

(161 lb 73 kg)

10"

-11 red

-21 amber

600 W

120 V AC

5.0 A

A2

72

A3

73

Captions

H7"

W9'-0"

D7"

177 mm

2743 mm

177 mm

25 lb 11 kg

(47 lb 21 kg)

N/A

Unpowered

MS-2015

Clock/Score

H2'-4"

W9'-0"

D7"

914 mm

2743 mm

177 mm

60 lb 27 kg

(114 lb 51 kg)

10"

-11 red

-21 amber

300 W

300 V AC

2.5 A

A1

71

Note: Signal wires must be a minimum of 22 AWG with shield.

10 Specifications

Page 17

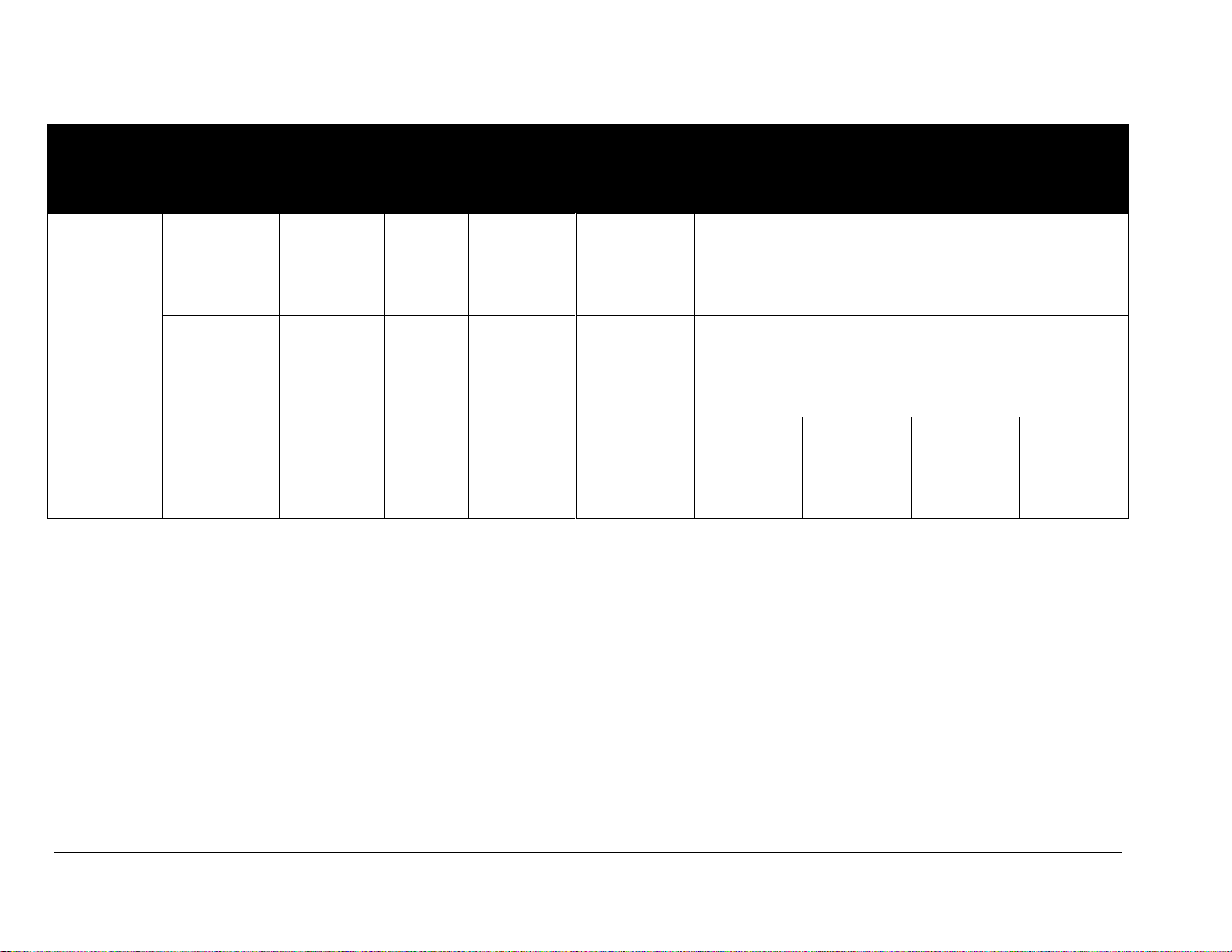

2.3 Model MS-2016

Model

Section

Dimensions

(Height, Width, Depth)

Weight

Uncrated

(Crated)

Digit Size

Digit Color

Maximum

Wattage

Power

Amps per

Line

(Single

Phase)

Driver

Number

and

Address

MS-2016

Clock

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

177 mm

45 lb 20 kg

(86 lb 39 kg)

10"

-11 red

-21 amber

Unpowered

Captions

H7"

W9'-0"

D7"

177 mm

2743 mm

177 mm

25 lb 11 kg

(47 lb 21 kg)

None

Unpowered

Score/Period

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

177 mm

45 lb 20 kg

(86 lb 39 kg)

10"

-11 red

-21 amber

300 W

120 V AC

2.5 A

A1

13

Specifications 11

Page 18

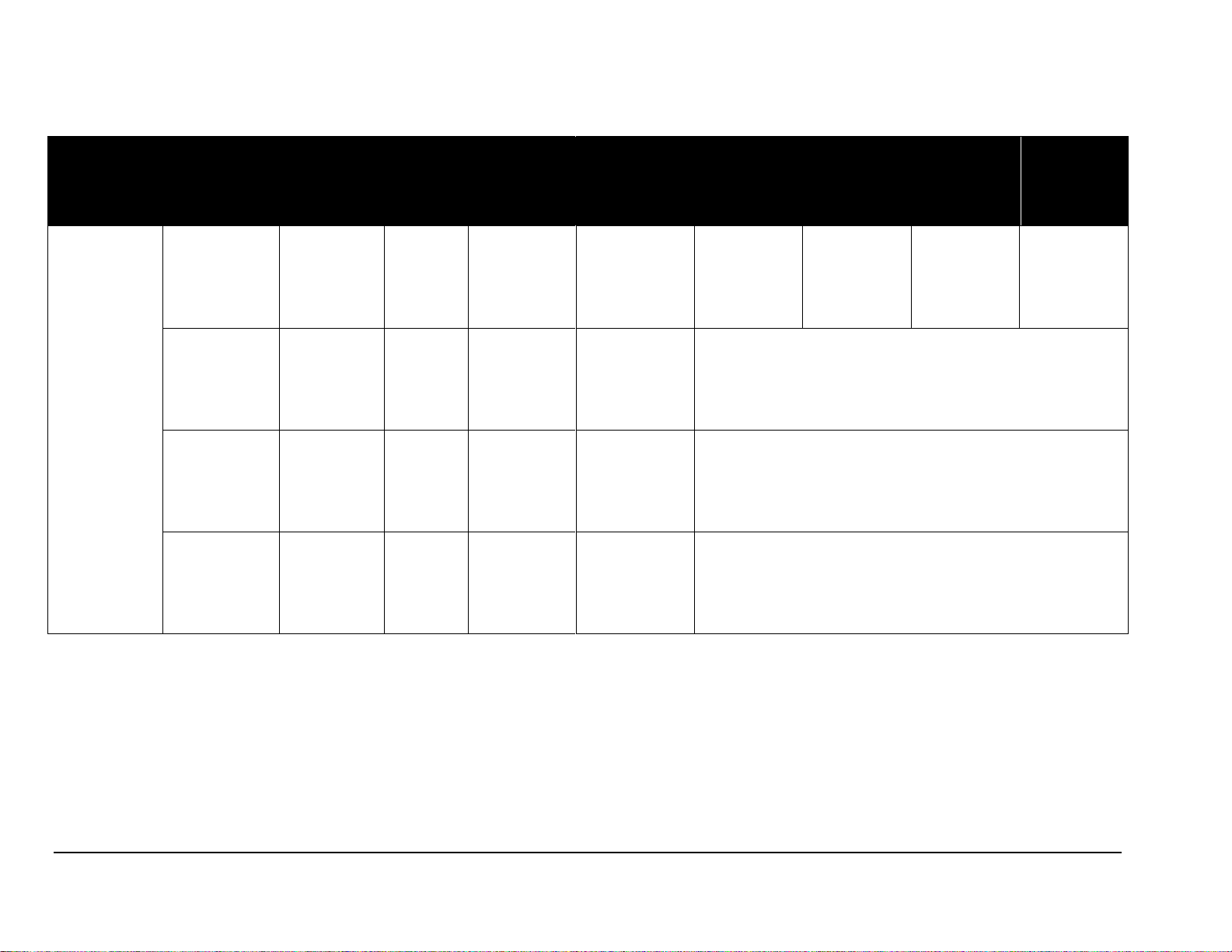

2.4 Model MS-2017

Model

Section

Dimensions

(Height, Width, Depth)

Weight

Uncrated

(Crated)

Digit Size

Digit Color

Maximum

Wattage

Power

Amps per

Line

(Single

Phase)

Driver

Number

and

Address

MS-2017

Score/Period

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

177 mm

75 lb 34 kg

(142 lb 64 kg)

10"

-11 red

-21 amber

300 W

120 V AC

2.5 A

A1 17

Clock

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

177 mm

75 lb 34 kg

(142 lb 64 kg)

10"

-11 red

-21 amber

Fouls/Player

Fouls

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

177 mm

75 lb 34 kg

(142 lb 64 kg)

10"

-11 red

-21 amber

Captions

H7"

W9'-0"

D7"

178 mm

2743 mm

177 mm

45 lb 20 kg

(86 lb 39 kg)

10"

-11 red

-21 amber

Unpowered

12 Specifications

Page 19

2.5 Model MS-2018

Model

Section

Dimensions

(Height, Width,

Depth)

Weight

Uncrated

(Crated)

Digit Size

Digit Color

Maximum

Wattage

Power

Amps per

Line

(Single

Phase)

Driver

Number and

Address

MS-2018

Clock/Score

H2'-4"

W9'-0"

D7"

914 mm

2743 mm

177 mm

75 lb 34 kg

(142 lb 64 kg)

10"

-11 red

-21 amber

300 W

120 V AC

2.5 A

A1

71

Player/Penalty

H2'-4"

W9'-0"

D7"

914 mm

2743 mm

177 mm

85 lb 39 kg

(161 lb 161 kg)

10"

-11 red

-21 amber

600 W

120 V AC

5.0 A

A2

72

Captions

H7"

W9'-0"

D7"

177 mm

2743 mm

177 mm

25 lb 11 kg

(47 lb 21 kg)

None

Unpowered

Shots on Goal

H1'-2"

W9'-0"

D7"

356 mm

2743 mm

177 mm

45 lb 20 kg

(86 lb 39 kg)

10"

-11 red

-21 amber

Unpowered

Specifications 13

Page 20

Page 21

Section 3: Mechanical Installation

Mechanical Installation involves installing concrete footings and steel beams, attaching the

caption sections to the digit sections, and mounting the digit modules to the structure. These

steps are described in the following sections.

3.1 Installing Beams and Footings

Reference Drawings:

Beam & Footing Recommendations, MS-2014-11 ...... Drawing A-165553

Beam & Footing Recommendations, MS-2015-11 ...... Drawing A-165559

Beam & Footing Recommendations, MS-2018-11 ...... Drawing A-165561

Beam & Footing Recommendations, MS-2016-11 ...... Drawing A-175539

Beam & Footing Recommendations, MS-2017-11 ...... Drawing A-214370

Beam & Footing Recommendations, FB-2006-11/21 .. Drawing A-221087

These drawings specify the number of beams and the recommended spacing between

them. The drawings also indicate the size of beams required to support the

scoreboard at different heights under various wind speed conditions. All of the beam

specifications illustrate ‘‘W’’ shape steel beams (wide-flange I-beams). The first

number indicates the front-to-rear depth of the beam, and the second number

indicates the weight in pounds per foot of length.

Column and footing size dimensions provided with the drawings can help in

estimating installation costs. They are estimates only and are not intended for

construction purposes. Be sure that your installation complies with local building

codes and is suitable for your particular soil and wind conditions.

The columns and footings and all connection details must be designed and certified

by a professional engineer licensed to practice in the state in which scoreboard will

be installed. Daktronics does not assume any liability for any installation derived

from the information provided in this manual or for those designed and installed

by others.

3.2 Installing Captions Modules

Reference Drawing:

Caption Module Detail .................................................. Drawing A-130840

Attach the caption module to the digit module before attaching the digit module to

the beam support.

The caption modules are attached to the top or bottom of a digit module with No.10

machine screws. Refer to Drawing A-130840. With Models MS-2014-11 and MS2018-11, attach the caption module to the top of the player/penalty module. With

model FB-2006-11, attach the caption module to the top of the statistics module.

Mechanical Installation 15

Page 22

Before attaching the caption module, note its orientation. The top and bottom flanges

for holding the caption panel are different sizes. Be sure the module is oriented so

that the deeper flange, or guide, is toward the top.

The scoreboard modules are shipped with the 5" vinyl captions applied, but the

displays are also equipped with the guides needed for use with the optional custom

panels. To insert a caption panel, fit the top edge of the caption into the module's

upper guide, and then slide the bottom edge under the lower flange. Refer to

Drawing A-130840. The construction of the flanges allows the caption panels to be

lifted out for changing, rather than having to slide them out one end.

The caption panels must be properly positioned in relation to the scoreboard digits

for different activities. Refer to the scoreboard options in Appendix B for details on

changeable captions.

3.3 Mounting Digit Modules

Reference Drawings:

Beam Mounting Procedure .......................................... Drawing A-194664

Beam Mounting, Side View ......................................... Drawing A-194671

Beam Mounting, Top View .......................................... Drawing A-194674

Beam Mt., Rear, Vert. Display ..................................... Drawing A-194677

Scoreboard digit modules may be mounted directly to a wall, to universal mounting

struts (channels), or to some other support structure. Modular construction permits

varied configurations, and the unique requirements of each facility will determine the

setup and anchoring method best suited for the display. This manual addresses only

beam mounting.

Daktronics recommends using universal mounting struts, or channels. Use 3/8" bolts

through the holes in both ends of the module frame. For displays with multiple digit

modules, mount the lowest module first and work upward.

Beam Mounting Digit Modules, Outdoor

Because every display is different in terms of module configuration, scoreboard

options, and environment, every installation will be unique. Such beam-mounted

installations require that a qualified engineer provide specifications for both the

reinforced concrete footings and the steel support beams. Two beams are required for

each column of display modules, and they must be set 4'-6" apart, center-to-center.

Installations of vertical displays are shown in Drawing A-194677, which specifies

the overall space requirements for the scoreboards as well as their specific

dimensions.

Each digit module has knockouts in both the rear and the end for power and signal

entrance. Power and signal are brought into one module through these external

knockouts, and connections to other modules are made internally.

16 Mechanical Installation

Page 23

Once the support beams have been installed, the scoreboard-mounting procedure is

typically a five-step process. Refer to Drawing A-194664 for notes and illustration of the

basic procedure.

1. If you haven't already done so, attach the caption module to the top of the

player/penalty module (MS-2014-11) or to the top of the statistics module (FB2006-11.) The caption module is fastened with screws to the top of the powered

module, but it does not attach directly to the beam.

2. Begin the installation by attaching mounting brackets to the top and bottom of

the lowest digit module (the player/penalty section in the MS-2014-11 display,

the shots on goal section in the MS-2018-11 or the statistics digit section in the

FB-2006-11). Fasten the brackets to the modules by inserting 10-24 x 5/8"

screws through the holes in each bracket and threading into the captivated nuts

in the back of the module.

3. With the brackets attached, position the module against the beam and secure it

with the 15"-long threaded rods and the other washers and nuts provided. These

1/2-13 x 15" threaded rods, or mounting bolts, do not go through the beam but

pass along either side; no drilling is required. Refer to Drawings A-194671 and

A-194674. The square nuts go inside the bracket, and the hex nuts are used

inside the rear mounting angles that straddle the back of each support beam.

Tighten the assembly with a 3/4" socket, taking care not to over tighten.

4. Position the clock/score module above the caption module. Attach the mounting

brackets to the clock/score section as described in Step 2, and then secure the

module to the beams with bolts, washers, and nuts, as described in the Step 3.

5. Join the caption and clock/score modules together at the ends by inserting

screws up through the holes in the top of the lower module and into the

captivated nuts in the bottom of the upper module.

For scoreboard models other than MS-2014-11, the building process continues in the

same manner for any remaining modules. Caption modules are attached directly to

their adjoining digit modules and do not accept beam mounting brackets. Refer to

Drawing A-194671.

Mechanical Installation 17

Page 24

Page 25

Section 4: Electrical Installation

Electrical installation consists of the following process:

Providing power and ground to a disconnect near the scoreboard;

Routing power and ground from the main disconnect to the scoreboard power and

signal termination points;

Connecting the scoreboard ground to a grounding electrode at the scoreboard location;

Routing control signal cable from the control location to the scoreboard location;

Routing power and control signal cable into the initial module; and

Making connections to the adjoining modules.

These steps are described in greater detail in the following sections.

Note: Only qualified individuals should perform power routing and termination to the

display. It is the responsibility of the electrical contractor to ensure that all electrical work

meets or exceeds local and national codes.

4.1 Power

The charts in Section 2 list circuit specifications and power requirements for the

sections listed in this manual. Refer to the following sections for details of display

power installation.

Daktronics outdoor LED scoreboards have been designed for easy access to

components, and the power and control signal hookup has been simplified. Front

panels are removable to allow access to digits, cabling, and other electronic

components.

Correct power installation is imperative for proper display operation. The

subsections that follow give details of display power installation. Only qualified

individuals should attempt to complete the electrical installation; untrained personnel

should not attempt to install these displays or any of the electrical components.

Improper installation could result in serious damage to the equipment and could be

hazardous to personnel.

Grounding

Reference Drawing:

Schematic; Gen III Outdoor LED,

16 Column Drvr ............................................... Drawing A-177931

Displays MUST be grounded according to the provisions outlined in Article 250

of the National Electrical Code and according to the specifications in this manual.

Daktronics recommends a resistance-to-ground of 10 ohms or less.

The contractor performing the electrical installation can verify ground resistance.

Daktronics Sales and Service personnel can also provide this service.

Electrical Installation 19

Page 26

The display system must be connected to an earth electrode installed at the display.

Proper grounding is necessary for reliable equipment operation. It also protects the

equipment from damaging electrical disturbances and lightning. The display must be

properly grounded, or the warranty will be void. Refer to the schematic, Drawing

A-177931, for information on where to connect the grounding wire. The connection

is illustrated in the "Pwr In" detail of the Master Configuration portion of the

schematic.

The material for an earth-ground electrode differs from region to region and may

vary according to conditions present at the site. Consult the National Electrical

Code and any local electrical codes that may apply. The support structure of the

display cannot be used as an earth-ground electrode. The support is generally

embedded in concrete, and if it is in earth, the steel is usually primed or it corrodes,

making it a poor ground in either case.

Power Installation

There are two considerations for power installation: installation with ground and

neutral conductors provided, and installation with only a neutral conductor provided.

These two power installations differ slightly, as described in the following

paragraphs:

Installation with Ground and Neutral Conductors Provided

For this type of installation, the power circuit must contain an isolated earth-ground

conductor.

Under this circumstance, do not connect neutral to ground at the disconnect or at the

display. This would violate electrical codes and void the warranty. Use a disconnect

so that all hot lines and neutral can be disconnected. The National Electrical Code

requires the use of a lockable power disconnect within sight of or at the display.

Installation with Only a Neutral Conductor Provided

Installations where no grounding conductor is provided must comply with Article

250-32 of the National Electrical Code. If the installation in question meets all of the

requirements of Article 250-32, the following guidelines must be observed:

Connect the grounding electrode cable at the local disconnect, never at the

display driver/power enclosure.

Use a disconnect that opens all of the ungrounded phase conductors.

20 Electrical Installation

Page 27

4.2 Power and Signal Connection

Figure 3: Power Terminal Block

Reference Drawings:

Schematic, Gen III Outdoor LED,

16 Column Driver ................................................... Drawing A-177931

Driver; Gen III LED, 16 Col Master .............................. Drawing A-178197

Route power and signal cables into the scoreboard from the rear. There are two

knockouts for conduit connection in the back. All power and signal wiring terminates

at the driver enclosure. Drawing A-178197 illustrates the 16-column driver used in

Daktronics outdoor LED scoreboards.

To gain access to the driver enclosure, open the access door or digit panel and

remove the cover from the enclosure. Refer to the component locations drawings for

the access location for your scoreboard.

Connect power and signal cables at the appropriate locations on the driver enclosure

panel, shown in Drawings A-178197 and

A-177931.

The conventional power termination panel has been

eliminated from Daktronics outdoor scoreboards;

the power feeder circuit connects directly to a

terminal block in the driver enclosure, as shown in

Figure 3. The terminal block is located in the lower

right corner of the enclosure. Connect the power

wires as shown in the illustration. Refer to the

driver engineering drawing and the schematics

listed at the beginning of this section for additional

wiring details. The schematics include a detailed

illustration of the power termination.

Note: Driver enclosures in some earlier Daktronics scoreboards included a 120

V power receptacle. There is no 120 V receptacle in Generation III displays. If you

want power to operate the control console at the scoreboard for troubleshooting,

Daktronics recommends that you have the installation electrician provide a 120 V

outlet close to the disconnect box specifically for this purpose.

Route signal cabling to the signal surge arrestor card in the upper left corner of the

driver enclosure. The connections are labeled to permit easy installation.

Electrical Installation 21

Page 28

At the Signal In terminal block on the printed circuit board (PCB), connect the red

Figure 4: Signal Surge Arrestor Card

signal wire to the positive terminal, the black to the negative terminal, and the shield

(silver) wire to the shield terminal.

It is important that the shield wire is

properly connected to the shield

terminal on the signal surge

arrestor card. Figure 4 on the

previous page illustrates the PCB

and the terminal blocks.

For signal cable, Daktronics

recommends, as a minimum, singlepair, shielded cable, 22 AWG

(Daktronics part number W-1077).

Two-pair shielded cable

(Daktronics part W-1234) is

preferred.

Connections Between Sections

Note: The power and signal interconnect harnesses referenced in the following

section are factory-installed and in place. Only the final connection between

scoreboard modules is required for field installation. This information is presented

to document the complete installation procedure.

Models MS-2014 and MS-2018 have been configured to operate with a master/slave

driver system. Master and slave drivers function identically, but slave drivers lack

the power terminal block and signal surge arrestor card. The two drivers have been

designed to simply plug into each other via an interconnect harness, the slave

receiving redriven power and signal from the master driver. Larger scoreboards can

have as many drivers as they require.

All driver interconnect harnesses are factory installed. No additional connection is

necessary (The harness emerges from the bottom of the master driver enclosure, and

the J42 jack from the master is connected to the slave's P43 plug.). Likewise, signal

cables from drivers to digit also have been factory-installed, and no additional

connection is necessary.

For access and connection, refer to the component locations drawings and follow this

procedure:

1. Begin electrical installation by routing power and signal cables into the

scoreboard through the rear of the clock/score section. There are two

knockouts for conduit connection on the back panel. There are knockouts

on the side of the cabinet as well, if connection there is more desirable.

Both cables terminate inside the driver enclosure.

2. To access the internal components, open the PERIOD panel on the bottom

row of the section and remove the cover from the driver enclosure.

22 Electrical Installation

Page 29

3. Power terminates at the power terminal block in the driver tray. Refer to

Drawing A-177931 for wiring termination details.

4. The signal wires from the scoreboard controller connect directly to the

signal surge arrestor card, which is located on the lower left side of the

master driver on the driver tray. Refer to Drawing A-178197 for the exact

location.

There are also several power and signal interconnect cables in the slave sections of

the scoreboards that must be connected to the master driver in the clock/score

module. This involves routing the cables through the 2" holes in the cabinets during

scoreboard mounting. To complete these connections, refer to the following

instructions.

1. Open the access panels in both the top and bottom modules.

2. An 8' power and signal interconnect cable (0A-1192-1029) links the drivers

in the player/penalty module. The cable connects the J42 jack on the A2

driver assembly to the P43 plug on the A3 driver tray. The plugs and jacks

on the cable are connected to the mating connectors on the driver panel. For

field connection, simply match the numbers on the plugs with the numbers

on the jacks and insert. The connectors are all "keyed" – they can fit into the

jacks in one way only ( Note: This cable is factory-installed).

3. Next, in the player/penalty section, a 4' power and signal interconnect

harness (0A-1192-1028) is connected to the P43 plug on the A2 driver

assembly. Pull the cable up through the knockout in the top of the cabinet,

through the caption module, and into the clock/score module.

( Note: This cable is factory-installed.)

4. In the clock/score module, a second 4' harness (0A-1192-1028) is connected

to J42 on the A1 driver assembly. Pull the cable down to the 2" knockout

area, and connect the jack from this interconnect harness to the plug from

the player/penalty module, which should have been pulled up and into the

top module.

5. Replace covers and panels. If the bottom knockout in the player/penalty

module has been removed, insert a 2" hole plug in the bottom hole of the

lowest module

6. The MS-2018 has an additional shots on goal section that needs to be

connected to the master driver. Route the digit harnesses from the shots on

goal section to the player/penalty section above and plug the harness into

the driver enclosure.

Electrical Installation 23

Page 30

Page 31

Section 5: Maintenance and

Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair or maintenance

work on the scoreboard!

2. Permit only qualified service personnel to access internal

display electronics.

3. Disconnect power when not using the scoreboard.

5.1 Cabinet Specifications

Cabinets for Daktronics outdoor LED scoreboards are constructed of heavy-gauge

aluminum. Dimensions and weights for each model are listed in the chart in Section

2. Removable panels for digits and indicators and for component access are detailed

in each model's component locations drawing, listed in Section 5.2 below.

5.2 Component Location and Access

Reference Drawings:

Component Locations; MS-2015-11/-21, G3 ............... Drawing A-189417

Component Locations; MS-2014-11/-21, G3 ............... Drawing A-189532

Component Locations; MS-2018-11/-21, G3 ............... Drawing A-189535

Component Locations; MS-2016-11/-21, G3 ............... Drawing A-202250

Component Locations; MS-2017-11/-21, G3 ............... Drawing A-214362

Component Locations; FB-2006-11/-21, G3 ................ Drawing A-221085

The component locations drawings illustrate placement of all internal parts as well as

the configuration of the face panels for each of the models in this series.

For front-access scoreboards, all internal electronic components and digits can be

reached by opening a face panel, an access door, or a digit panel on the front of the

display.

To remove a digit, simply unfasten the screws and carefully lift the unit from the

board. You can then remove the harness from the connector on the back of the digit

to completely free the component.

Remove a non-digit access panel the same way: unfasten the top, side or bottom

screws holding it in place.

Maintenance and Troubleshooting 25

Page 32

Component location varies with each scoreboard model, but drivers and power and

16-Column LED Driver

Connector No.

Function

1 – 16

Output to digits and indicators

17

Power and signal input

18

Relay

19

Address

20

Protocol

signal components are typically mounted inside the scoreboard behind an access

panel or a digit.

Note: Disconnect power before servicing the display! Disconnect power, too,

when the display is not in use. Prolonged power-on may shorten the life of some

electronic components.

Replacing A Digit

Reference Drawings:

Digit Service, Stackable Scoreboards................... Drawing A-156994

Digit Assemblies; Gen III LED Digits..................... Drawing B-177679

The digit circuit board, the platform for the LEDs, is mounted to the back of the digit

panel. Refer to Drawings A-156994 and B-177679 for details. Do not attempt to

remove individual LEDs. In the case of a malfunctioning board, replace the entire

face panel.

To remove a scoreboard digit, follow these steps:

1. Open the face panel as described in the preceding section.

2. Disconnect the power/signal connector from the back of the digit. Release

the connector by squeezing together the locking tabs as you pull the

connector free.

3. The digits are secured to the inside of the panel with fixed machine screws,

spacers, and push nuts.

4. Remove the nuts and lift the digit off the standoff screws. (The push nuts

can be removed in several ways, but Daktronics recommends using a 9/32"

nut driver.)

5. Position a new digit over the screws and tighten the nuts.

6. Reconnect the power/signal connector.

Note: This is a keyed connector. It will attach in one way only.

Do not attempt to force the connection!

7. Close and secure the digit panel and test the scoreboard.

5.3 LED Drivers

26 Maintenance and Troubleshooting

In the scoreboard, the LED drivers

perform the task of switching

digits on and off. Refer to

Drawing A-178197. Each driver

has up to 19 connectors providing

power and signal inputs to the

circuit and outputs to the digits and

indicators. The connectors

function as shown in the table at

right.

Page 33

Output connectors 1 through 16 each have nine pins. Pin 7 provides power (hot) to

Figure 5: 16 Column Driver Enclosure

the digit or indicators wired to that connector. The other eight pins provide switching

connections.

For the scoreboard to receive signal and function properly, the driver must be set to

the correct address. This address is set with jumper wires in a 12-pin plug which

mates with a jack on the driver. Refer to Drawing A-115078 for a listing of the

wire/pin connections for driver addresses 1 – 128.

Replacing a Driver

Drivers are typically mounted inside the scoreboard and immediately behind a digit,

but location and mounting varies with the model of the scoreboard. Refer to the

component locations drawings at the beginning of this section for the location of

your scoreboard driver. All scoreboards in this manual are front-accessible.

Each driver is enclosed with a power supply and signal terminal block. Before a

failed driver can be reached, the enclosure must be accessed.

Follow the steps below to remove a driver.

1. Open the digit panel or scoreboard face panel as described in Section 5.2.

2. Remove the cover from the driver enclosure.

3. Disconnect all connectors from the driver. Release each connector by

squeezing together the locking tabs as you pull the connector free.

Note: When reconnecting, remember that these are keyed connectors

and will attach in one way only. Do not attempt to force the connections.

4. Remove the screws, nuts, or wing nuts securing the driver to the inside of

the enclosure. Refer to Figure 5.

5. Carefully lift the driver from the display and place it on a clean, flat surface.

Maintenance and Troubleshooting 27

Page 34

5.4 Segmentation and Digit Designation

Figure 6: Digit Designation

Reference Drawing:

Digit Service, Stackable Scoreboards ......................... Drawing A-156994

In each digit, certain LEDs always go on and off together. These groupings of LEDs

are referred to as segments. The Digit Segments A-G detail on Drawing A-156994

shows which connector pin number is wired to each digit segment, as well as the

wiring color code used throughout the display (illustrated at lower left on drawing).

The component locations drawings in

Section 5.2 specify the driver connectors

controlling the digits. Numbers

displayed in hexagons in the upper half

of each digit, as shown in Figure 6,

indicate which connector is wired to that

digit. (The lower number in the square

indicates nominal digit size.) The

drawings listed at the beginning of this

section also indicate digit designation

and specify the harnesses used for each

of the digit/driver connections.

5.5 Lightening Protection

The use of a disconnect near the scoreboard to completely cut all current-carrying

lines significantly protects the circuits against lightning damage. The National

Electrical Code also requires the disconnect. In order for this system to provide

protection, the power must be disconnected when the scoreboard is not in use. The

control console should also be disconnected from power and from the signal junction

box when the system is not in use. The same surges that may damage the

scoreboard’s driver can also damage the console’s circuit.

5.6 Troubleshooting

This section lists potential problems with the scoreboard and indicates possible

causes and corrective actions. This list does not include every possible problem, but

does represent some of the more common situations that may occur.

28 Maintenance and Troubleshooting

Page 35

Symptom/Condition

Possible Cause

Scoreboard will not light

Console not connected or poor connection

No power to control console

No power to the scoreboard

Garbled display

Internal driver logic malfunction

Control console malfunction

Digit will not light

Black wire to digit broken

Poor contact at driver connection.

Driver malfunction

Segment will not light

Broken LED or connection

Driver shift register failure

Broken wire between driver and digit

Poor contact at driver connector

Segment stays lit

Driver shift register failure

Short circuit on digit

Date appears in the wrong

place on the scoreboard

Incorrect address settings on drivers (consult

tables and set correct addresses)

5.7 Replacement Parts

Description

Part No.

LED driver, 16-col,

outdoor

0P-1192-0011

Harness, address, 12-pin

0A-1150-0064

Horn, 12 V DC, 2 A

DS-1389

Signal/surge arrestor

0P-1110-0011

Power supply, 24 V, 150 W, 86-132

V input

A-1720

Terminal block, 3-pos

TB-1059

Connector box, 2-screw type

EC-1008

Jack, power outlet, 3-pin, female

J-1021

Arrow indicators, penalty,

red LED

0P-1192-0249

(Continued on next page)

Maintenance and Troubleshooting 29

Page 36

(Continued from previous page)

Description

Part No.

Arrow indicators, penalty,

amber LED

0P-1192-0250

Digit, 10", red LED, 7-seg

0P-1192-0251

Digit, 10" ones, amber LED,

2-seg

0P-1192-0252

Digit, 10" amber LED, 2 segment

0P-1192-0288

Digit, 10" red LED, 2 segment

0P-1192-0287

Possession indicator, red LED

0P-1192-0249

Possession indicator, amber LED

0P-1192-0250

Bonus indicator, red LED

0P-1192-0289

Bonus indicator, amber LED

0P-1192-0290

Breakout board

0P-1192-0019

5.8 Daktronics Exchange and Repair and Return

Market Description

Customer

Service

Number

Schools (including community/junior colleges), religious

organizations, municipal clubs and community centers

877-605-1115

Programs

Exchange Program

The Daktronics Exchange Program is a service for quickly replacing key components

in need of repair. If a component fails, Daktronics sends a replacement part to the

customer who, in turn, returns the failed component to Daktronics. This decreases

equipment downtime. Customers who follow the program guidelines explained

below will receive this service.

Before Contacting Daktronics

Display Serial Number: ___________________________________________

Display Model Number: __________________________________________

Job/Contract Number: ___________________________________________

Date Installed: ___________________________________________________

Daktronics Customer ID Number: _________________________________

To participate in the Exchange Program, follow these steps:

1. Call Daktronics Customer Service.

30 Maintenance and Troubleshooting

Page 37

Universities and professional sporting events, live events

for auditoriums and arenas

866-343-6018

2. When the exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the problem part being

replaced.

a. Package the old part in the same shipping materials in which the

replacement part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. The defective or unused parts must be returned to Daktronics within 5

weeks of initial order shipment.

If any part is not returned within five (5) weeks, a non-refundable invoice

will be presented to the customer for the costs of replenishing the exchange

parts inventory with a new part.

Daktronics reserves the right to refuse parts that have been damaged due to

acts of nature or causes other than normal wear and tear.

Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To

send a part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Refer to the appropriate market phone number in the chart on the

previous page.

Fax: 605-697-4444

2. Receive a case number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during

shipment.

Electronic components, such as printed circuit boards, should be

placed in an antistatic bag before boxing. Daktronics does not

recommend using packing ‘peanuts’ when shipping.

4. Enclose:

name

address

phone number

the case number

a clear description of symptoms

Maintenance and Troubleshooting 31

Page 38

Shipping Address

Daktronics Customer Service

[Case #]

201 Daktronics Drive, Dock E

Brookings, SD 57006

Daktronics Warranty and Limitation of Liability

The Daktronics Warranty and Limitation of Liability is located in Appendix C. The

Warranty is independent of Extended Service agreements and is the authority in

matters of service, repair, and display operation.

32 Maintenance and Troubleshooting

Page 39

Appendix A: Reference Drawings

Drawing Title Drawing Number

Caption Module Detail .................................................................................... A-130840

Digit Service, Stackable Scoreboards ............................................................ A-156994

Beam and Footing Recommendations, MS-2014 .......................................... A-165553

Beam and Footing Recommendations, MS-2015 .......................................... A-165559

Beam and Footing Recommendations, MS-2018 .......................................... A-165561

Beam and Footing Recommendations, MS-2016 .......................................... A-175539

Digit Assemblies; Gen III LED Digits .............................................................. B-177679

Schematic; Gen III Outdoor LED, 16 Col Drvr ................................................ A-177931

Driver; Gen III Outdoor LED, 16 Col Master ................................................... A-178197

Component Locations; MS-2015, G3 ............................................................. A-189417

Layout View; MS-2015, G3 ............................................................................. A-189437

Layout View; MS-2014, G3 ............................................................................. A-189446

Layout View; MS-2018, G3 ............................................................................. A-189492

Component Locations; MS-2014, G3 ............................................................. A-189532

Component Locations; MS-2018, G3 ............................................................. A-189535

Beam Mounting, Procedure ............................................................................ A-194664

Beam Mounting Side View ............................................................................. A-194671

Beam Mounting, Top View ............................................................................. A-194674

Beam Mounting, Rear View, Vertical Display ................................................. A-194677

Layout View; MS-2016-11, G3 ....................................................................... A-202065

Component Locations; MS-2016-11/-21, G3 .................................................. A-202250

Layout View; MS-2017-11, G3 ....................................................................... A-213041

Component Locations; MS-2017-11/-21, G3 .................................................. A-214362

Beam and Footing Recommendations, MS-2017 .......................................... A-214370

Layout View; FB-2006-11, G3 ........................................................................ A-221063

Component Locations; FB-2006-11/-21, G3 .................................................. A-221085

Beam and Footing Recommendations, FB-2006-11/-21 ................................ A-221087

Reference Drawings 33

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Appendix B: Scoreboard Options

Drawing Title Drawing Number

Horn, 12 V DC w/Filter .................................................................................... B-111265

Caption Module Detail .................................................................................... A-130840

Scoreboard Options 35

Page 70

Page 71

Page 72

Page 73

Appendix C: Daktronics Warranty and

Limitation of Liability

Appendix C 37

Page 74

Page 75

Copyright © Daktronics, Inc. SL-02374 Rev 10 02-Mar-2009 Page 1 of 2

DAKTRONICS

WARRANTY AND LIMITATION OF LIABILITY

This Warranty and Limitation of Liability (the “Warranty”) sets forth the warranty provided by Daktronics with respect to the Equipment. By

accepting delivery of the Equipment, Purchaser agrees to be bound by and accept these terms and conditions. All defined terms within

the Warranty shall have the same meaning and definition as provided elsewhere in the Agreement.

DAKTRONICS WILL ONLY BE OBLIGATED TO HONOR THE WARRANTY SET FORTH IN THESE TERMS AND CONDITIONS UPON RECEIPT OF FULL

PAYMENT FOR THE EQUIPMENT.

1. Warranty Coverage

2. Exclusion from Warranty Coverage

A. Daktronics warrants to the original end-user that the Equipment will be free from Defects (as defined below) in materials and

workmanship for a period of one (1) year (the “Warranty Period”). The warranty period shall commence on the earlier of: (i) four

weeks from the date that the equipment leaves Daktronics’ facility; or (ii) Substantial Completion as defined herein. The warranty

period shall expire on the first anniversary of the commencement date.

“Substantial Completion” means the operational availability of the Equipment to the Purchaser in accordance with the

Equipment’s specifications, without regard to punch-list items, or other non-substantial items which do not affect the operation of

the Equipment.

B. Daktronics’ obligation under this Warranty is limited to, at Daktronics’ option, replacing or repairing, any Equipment or part

thereof that is found by Daktronics not to conform to the Equipment’s specifications. Unless otherwise directed by Daktronics,

any defective part or component shall be returned to Daktronics for repair or replacement. Daktronics may, at its option,

provide on-site warranty service. Daktronics shall have a reasonable period of time to make such replacements or repairs and

all labor associated therewith shall be performed during regular working hours. Regular working hours are Monday through

Friday between 8:00 a.m. and 5:00 p.m. at the location where labor is performed, excluding any holidays observed by either

Purchaser or Daktronics.

C. Daktronics shall pay ground transportation charges for the return of any defective component of the Equipment. If returned

Equipment is repaired or replaced under the terms of this warranty, Daktronics will prepay ground transportation charges back to

Purchaser; otherwise, Purchaser shall pay transportation charges to return the Equipment back to the Purchaser. All returns must

be pre-approved by Daktronics before shipment. Daktronics shall not be obligated to pay freight for any unapproved return.

Purchaser shall pay any upgraded or expedited transportation charges.

D. Any replacement parts or Equipment will be new or serviceably used, comparable in function and performance to the

original part or Equipment, and warranted for the remainder of the Warranty Period. Purchasing additional parts or Equipment

from the Seller does not extend this Warranty Period.

E. Defects shall be defined as follows. With regard to the Equipment (excepting LEDs), a “Defect” shall refer to a material

variance from the design specifications that prohibit the Equipment from operating for its intended use. With respect to LEDs,

“Defects” are defined as LED pixels that cease to emit light. The limited warranty provided by Daktronics does not impose any

duty or liability upon Daktronics for partial LED pixel degradation. Nor does the limited warranty provide for the replacement or

installation of communication methods including but not limited to, wire, fiber optic cable, conduit, trenching, or for the purpose

of overcoming local site interference radio equipment substitutions.

THIS LIMITED WARRANTY IS THE ONLY WARRANTY APPLICABLE TO THE EQUIPMENT AND REPLACES ALL OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SPECIFICALLY, EXCEPT AS PROVIDED HEREIN, THE SELLER

UNDERTAKES NO RESPONSIBILITY FOR THE QUALITY OF THE EQUIPMENT OR THAT THE EQUIPMENT WILL BE FIT FOR ANY PARTICULAR

PURPOSE FOR WHICH PURCHASER MAY BE BUYING THE EQUIPMENT. ANY IMPLIED WARRANTY IS LIMITED IN DURATION TO THE

WARRANTY PERIOD. NO ORAL OR WRITTEN INFORMATION, OR ADVICE GIVEN BY THE COMPANY, ITS AGENTS OR EMPLOYEES,

SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS LIMITED WARRANTY.

THIS LIMITED WARRANTY IS NOT TRANSFERABLE.

The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for:

A Any damage occurring, at any time, during shipment of Equipment unless otherwise provided for in the Agreement. When

returning Equipment to Daktronics for repair or replacement, Purchaser assumes all risk of loss or damage, and agrees to use

any shipping containers that might be provided by Daktronics and to ship the Equipment in the manner prescribed by

Daktronics;

B. Any damage caused by the unauthorized adjustment, repair or service of the Equipment by anyone other than personnel of

Daktronics or its authorized repair agents;

Page 76

Copyright © Daktronics, Inc. SL-02374 Rev 10 02-Mar-2009 Page 2 of 2

C. Damage caused by the failure to provide a continuously suitable environment, including, but not limited to: (i) neglect or

misuse, (ii) a failure or sudden surge of electrical power, (iii) improper air conditioning or humidity control, or (iv) any other cause

other than ordinary use;

D. Damage caused by fire, flood, earthquake, water, wind, lightning or other natural disaster, strike, inability to obtain materials

or utilities, war, terrorism, civil disturbance or any other cause beyond Daktronics’ reasonable control;

E. Failure to adjust, repair or replace any item of Equipment if it would be impractical for Daktronics personnel to do so because

of connection of the Equipment by mechanical or electrical means to another device not supplied by Daktronics, or the

existence of general environmental conditions at the site that pose a danger to Daktronics personnel;

F. Any statements made about the product by salesmen, dealers, distributors or agents, unless such statements are in a written

document signed by an officer of Daktronics. Such statements as are not included in a signed writing do not constitute

warranties, shall not be relied upon by Purchaser and are not part of the contract of sale;

G. Any damage arising from the use of Daktronics products in any application other than the commercial and industrial

applications for which they are intended, unless, upon request, such use is specifically approved in writing by Daktronics; or

H. Any performance of preventive maintenance.

3. Limitation of Liability

4. Assignment of Rights

5. Dispute Resolution

6. Governing Law

7. Availability of Extended Service Agreement

Daktronics shall be under no obligation to furnish continued service under this Warranty if alterations are made to the Equipment

without the prior written approval of Daktronics.

It is specifically agreed that the price of the Equipment is based upon the following limitation of liability. In no event shall

Daktronics (including its subsidiaries, affiliates, officers, directors, employees, or agents) be liable for any special, consequential,

incidental or exemplary damages arising out of or in any way connected with the Equipment or otherwise, including but not

limited to damages for lost profits, cost of substitute or replacement equipment, down time, lost data, injury to property or any

damages or sums paid by Purchaser to third parties, even if Daktronics has been advised of the possibility of such damages. The

foregoing limitation of liability shall apply whether any claim is based upon principles of contract, tort or statutory duty, principles

of indemnity or contribution, or otherwise.

In no event shall Daktronics be liable to Purchaser or any other party for loss, damage, or injury of any kind or nature arising out of

or in connection with this Warranty in excess of the purchase price of the Equipment actually delivered to and paid for by the

Purchaser. The Purchaser’s remedy in any dispute under this Warranty shall be ultimately limited to the Purchase Price of the

Equipment to the extent the Purchase Price has been paid.

The Warranty contained herein extends only to the original end-user (which may be the Purchaser) of the Equipment and no

attempt to extend the Warranty to any subsequent user-transferee of the Equipment shall be valid or enforceable without the

express written consent of Daktronics.

Any dispute between the parties will be resolved exclusively and finally by arbitration administered by the American Arbitration

Association (“AAA”) and conducted under its rules, except as otherwise provided below. The arbitration will be conducted

before a single arbitrator. The arbitration shall be held in Brookings, South Dakota. Any decision rendered in such arbitration

proceedings will be final and binding on each of the parties, and judgment may be entered thereon in any court of competent

jurisdiction. This arbitration agreement is made pursuant to a transaction involving interstate commerce, and shall be governed

by the Federal Arbitration Act.

The rights and obligations of the parties under this warranty shall not be governed by the provisions of the United Nations

Convention on Contracts for the International Sales of Goods of 1980. Both parties consent to the application of the laws of the

State of South Dakota to govern, interpret, and enforce all of Purchaser and Daktronics rights, duties, and obligations arising

from, or relating in any manner to, the subject matter of this Warranty, without regard to conflict of law principles.

For Purchaser’s protection, in addition to that afforded by the warranties set forth herein, Purchaser may purchase extended

warranty services to cover the Equipment. The Extended Service Agreement, available from Daktronics, provides for electronic

parts repair and/or on-site labor for an extended period from the date of expiration of this warranty. Alternatively, an Extended

Service Agreement may be purchased in conjunction with this warranty for extended additional services. For further information,

contact Daktronics Customer Service at 1-800-DAKTRONics (1-800-325-8766).

Loading...

Loading...