Page 1

Petroleum Price Displays

DF-2100 Series

Single-face 10" to 60"

Installation and Operation Manual

ED-16637 Rev 1 5 June 2007

Website: www. daktronics.com

Tel: 866-343-3122 Fax: 605-697-4444

331 32nd Ave PO Box 5128 Brookings SD 57006

Page 2

ED-16637

Project-1356

Rev 1 – 5 June 2007

Please fill in the information below for this DataMaster display and controller.

Use it for reference when calling Daktronics for assistance. Refer to the cover

page of the manual for Daktronics Customer Call Center contact information.

Display Serial No. _____________________________________________

Display Model No. _____________________________________________

Date Installed _________________________________________________

DataMaster Serial No. __________________________________________

DAKTRONICS, INC.

Copyright © 2007

All rights reserved. While every precaution has been taken in the preparation of this manual, the

publisher assumes no responsibility for errors or omissions. No part of this book covered by the

copyrights here on may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

DataMaster

property of their respective owners.

™

and DataTime® are trademarks of Daktronics, Inc. Other trademarks used in this manual are the

Page 3

Reproduction Reference

ED-16637 – P1356

DF-2100 Single-face Series Displays

1. This page is for reproduction reference only and will not be included in the manual.

2. This manual is to be copied on FRONT AND BACK PAGES –8 ½ x 11 paper.

Note: The first and second pages, Cover Page and Copyright Page, use the front of the page

(blank on back). Section heading pages always start on a new page; they never start on

the back of another page.

3. Group and insert the drawings as listed in Appendix A: Reference Drawings. Print all A

drawings back-to-back and all B drawings back-to-back.

4. All sections and Appendices are to be tabbed with the following labels. Wording in bold goes on

the labels.

Section 1: Introduction

Section 2: Mechanical Installation

Section 3: Electrical Installation

Section 4: Diagnostics and Troubleshooting

Section 5: Parts Replacement

Section 6: RC-100 Controller

Section 7: DM-100 Controller

Section 8: RC-50 Controller

Section 9: POS Interface Installation and Operation

Appendix A: Reference Drawings

5. Use a blue window cover and a blue back.

6. Punch all pages, window cover, and back cover along the left edge and bind with a spiral binder.

7. Please direct questions and suggestions to Engineering Support.

Page 4

Page 5

Table of Contents

Section 1: Introduction................................................................................................................. 1

1.1 Product Overview................................................................................................................... 1

Model Number................................................................................................................. 2

1.2 Drawing and Label Information...........................................................................................2

Section 2: Mechanical Installation..............................................................................................3

2.1 Shop Drawings........................................................................................................................3

2.2 Specifications ........................................................................................................................... 4

2.3 Lifting the Displays ................................................................................................................5

Section 3: Electrical Installation..................................................................................................7

3.1 Power Installation...................................................................................................................8

Grounding ........................................................................................................................8

Power Disconnect ............................................................................................................9

Power Installation............................................................................................................9

3.2 Signal Connection .................................................................................................................10

LED Drivers....................................................................................................................10

Signal Wiring.................................................................................................................. 10

Address Dip Switch Settings........................................................................................10

3.3 Power Up Self-test ................................................................................................................11

Section 4: Diagnostics and Troubleshooting..........................................................................13

4.1 Component Location and Access .......................................................................................13

4.2 Diagnostics.............................................................................................................................14

Driver LEDs....................................................................................................................14

Power On Self-Test ........................................................................................................14

4.3 Troubleshooting ....................................................................................................................15

Section 5: Parts Replacement...................................................................................................17

5.1 Replacement Parts List.........................................................................................................17

5.2 Instructions for Replacing Parts..........................................................................................20

Replacing a Digit Panel.................................................................................................20

Replacing a Digit Segment ...........................................................................................20

Replacing a Driver.........................................................................................................21

5.3 Daktronics Exchange and Repair & Return Programs ....................................................21

Exchange Program.........................................................................................................21

Repair & Return Program.............................................................................................22

Table of Contents i

Page 6

Section 6: DM-100 Controller.....................................................................................................23

6.1 DM-100 Overview.................................................................................................................23

Replacement Parts List..................................................................................................23

6.2 Connecting the DM-100 to the Display..............................................................................24

6.3 DataMaster Insert and Code................................................................................................25

6.4 Petroleum Price Display Operation....................................................................................25

Petroleum Price Display Startup .................................................................................26

Petroleum Price Controller Operation ........................................................................27

Modifying Price Line Settings......................................................................................27

Menu Items .....................................................................................................................28

Modem Settings..............................................................................................................28

Display Status.................................................................................................................29

Set Time...........................................................................................................................30

Dimming .........................................................................................................................31

Update Display ..............................................................................................................32

Section 7: RC-50 Controller .......................................................................................................33

7.1 RC-50 Operation....................................................................................................................33

Editing the Display ........................................................................................................33

Section 8: RC-100 Controller .....................................................................................................35

8.1 Petroleum Price Display Operation....................................................................................35

Petroleum Price Display Startup .................................................................................35

RC-100 Controller Operation .......................................................................................36

Modifying Price Line Settings......................................................................................37

Dimming .........................................................................................................................38

Section 9: POS Interface Installation and Operation...............................................................41

9.1 System Installation................................................................................................................41

9.2 Configuring the DM-100 for Gilbarco G-Site Interface....................................................42

Preparation .....................................................................................................................42

Configuration .................................................................................................................42

9.3 Configuring the DM-100 for Allied Interface....................................................................43

Preparation .....................................................................................................................43

Configuration .................................................................................................................43

9.4 Configuring the DM-100 for PAM 1000 Interface ............................................................44

Preparation .....................................................................................................................44

Configuration .................................................................................................................44

9.5 Changing Prices Manually...................................................................................................45

Appendix A: Reference Drawings .................................................................................................47

ii Table of Contents

Page 7

List of Figures

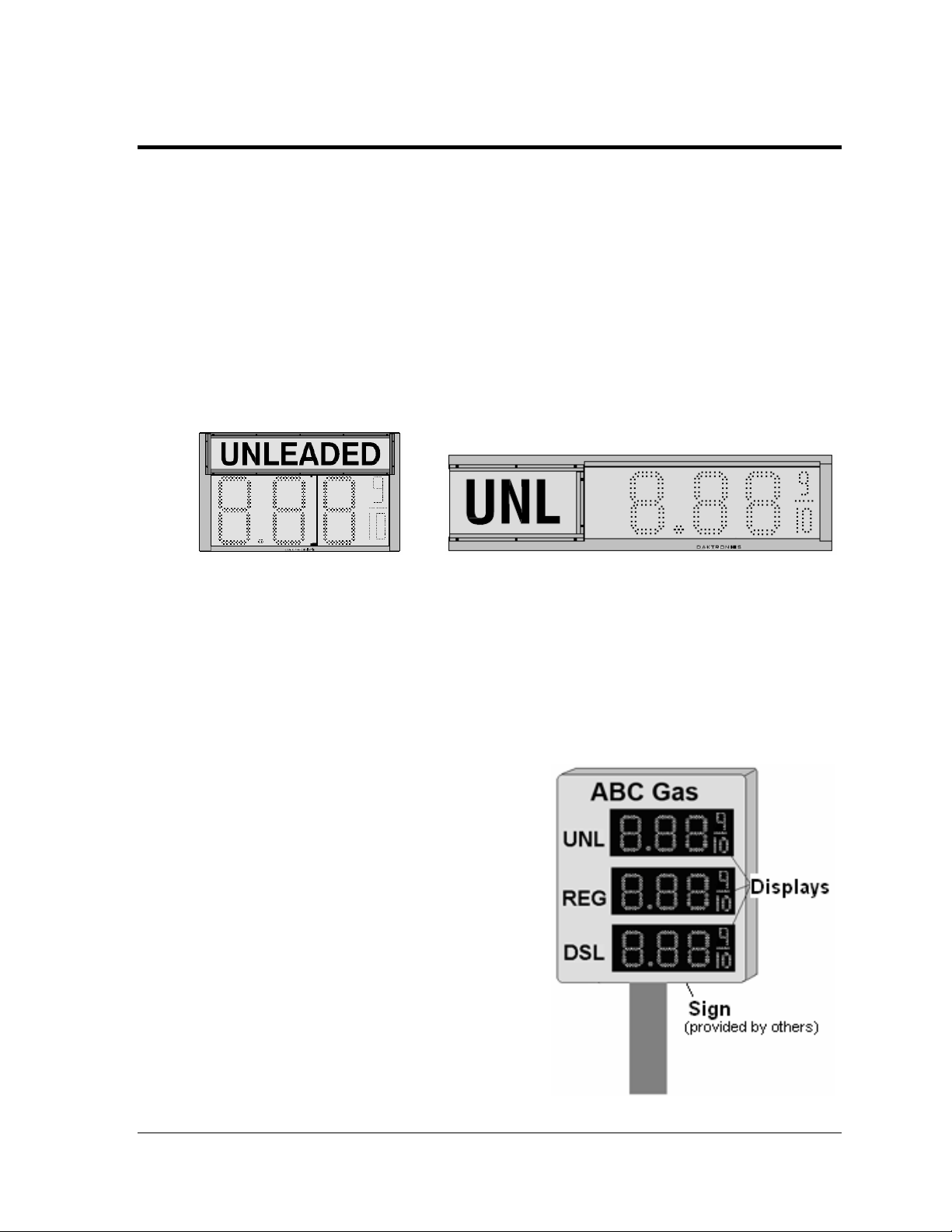

Figure 1: DF-2100 with Top Caption DF-2100 with Side Caption.....................................................1

Figure 3: Sign with Digit Displays...........................................................................................................1

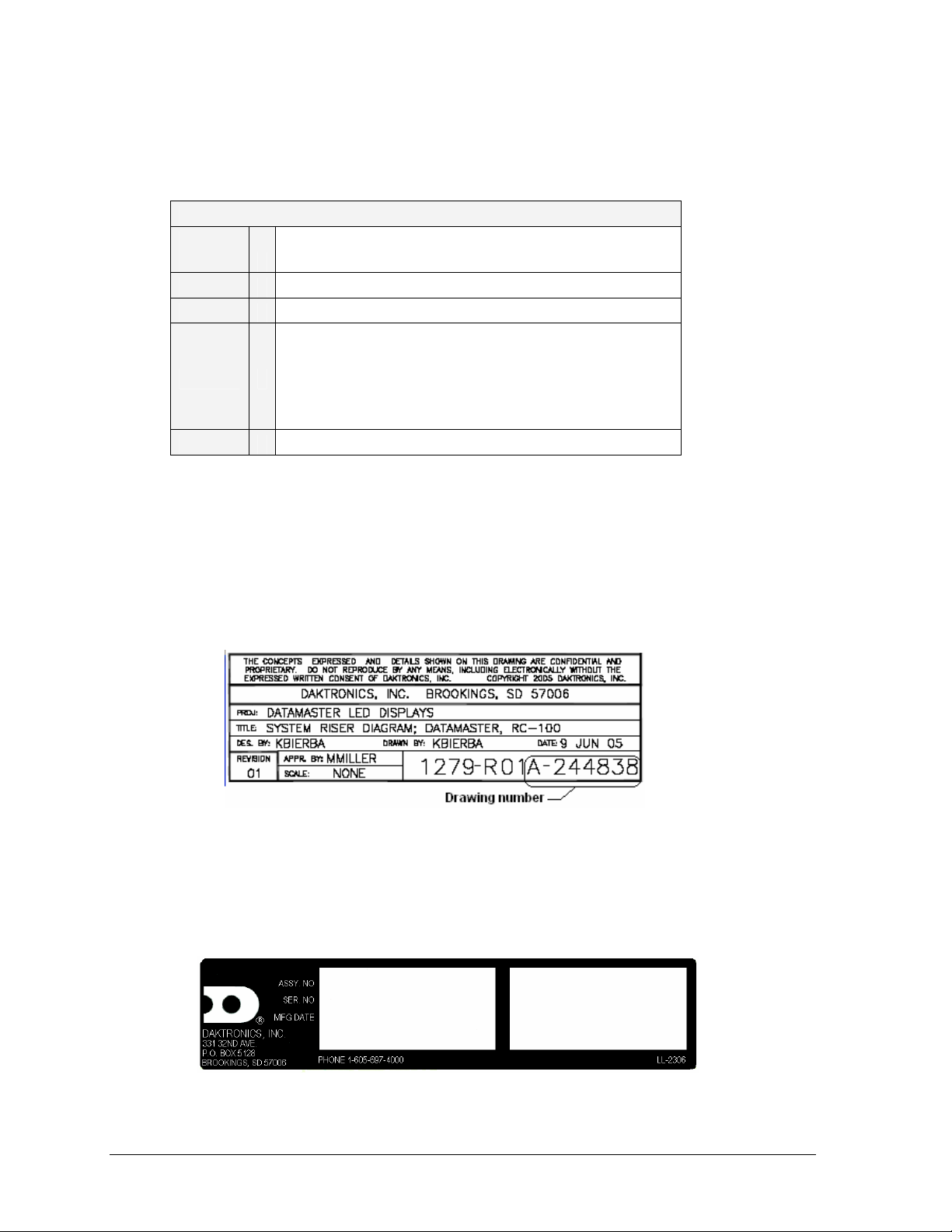

Figure 4: Daktronics Drawing Label.......................................................................................................2

Figure 5: Display Identification Label .....................................................................................................2

Figure 6: Lifting the Display....................................................................................................................5

Figure 7: Power and Signal Routing.......................................................................................................7

Figure 8: Power Connection...................................................................................................................9

Figure 9: Example of Power Pigtail Location..........................................................................................9

Figure 10: Driver...................................................................................................................................10

Figure 11: Dip Switches........................................................................................................................10

Figure 12: Inside View of Left Panel, Single-door Display...................................................................13

Figure 13: Inside View of Top Panel, Two-door Display......................................................................13

Figure 14: Driver Diagnostics...............................................................................................................14

Figure 15: Digit Assembly.....................................................................................................................20

Figure 16: Digit Segments....................................................................................................................20

Figure 16: Driver...................................................................................................................................21

Figure 17: DataMaster (DM) 100..........................................................................................................23

Figure 18: Wire Control Outdoor..........................................................................................................24

Figure 19: Wire Control from Building Location ...................................................................................24

Figure 20: DM-100 Insert......................................................................................................................25

Figure 21: RC-50 Controller .................................................................................................................33

Figure 22: RC-100 Controller...............................................................................................................35

List of Figures iii

Page 8

Page 9

Section 1: Introduction

This manual explains the installation, maintenance, and operation of Daktronics DataMaster™ DF2100 Outdoor LED Petroleum Price Displays. If questions arise regarding the safety, installation,

operation, or service of these systems, contact Daktronics Customer Service at the contact numbers

listed on the cover page of this manual.

1.1 Product Overview

DataMaster Petroleum Price displays are part of a family of Daktronics products designed

for easy installation, readability, and reliability. Microprocessor control assures consistent

operation and accuracy. These displays are available in two full-cabinet styles, with a backlit

caption either above the digits or to the left of the digits, as shown in Figure 1.

Figure 1: DF-2100 with Top Caption DF-2100 with Side Caption

DataMaster displays use light-emitting diodes (LEDs) to illuminate their numeric digits.

LEDs are high-intensity, low-energy lighting units that use a semiconductor to transform

electrical current into light. All DataMaster displays may be configured with red, amber, or

green LEDs. Because of their LED technology, the displays consume little power, some

barely more than a household lamp.

The DataMaster outdoor LED displays have been designed for use with a DataMaster

hand-held controller, a radio controlled RC-100 system, or the RC-50 mini remote control.

In this manual, the complete structure will be

referred to as a "sign." Each sign typically

consists of a number of digit displays. Refer to

Figure 2.

Figure 2: Sign with Digit Displays

™

100

Introduction 1

Page 10

Model Number

The DataMaster model number for these displays is described as follows:

DF-

2100 =

HH =

C =

X# =

SF =

Outdoor digit display with backlit ID panel

Digit height in inches

LED Color- R (Red), A (Amber), or G (Green)

Illuminated product ID, options:

L# - Left product panel,

# indicates nominal cabinet width (ft)

T# - Top product panel,

# indicates nominal cabinet width (ft)

SF – Single Face, one cabinet

DF-2100-HH-C-X#-SF

1.2 Drawing and Label Information

Drawings are sometimes referenced at the beginning of a section. Daktronics identifies

drawings with a number which is located in the bottom right corner of each drawing (Figure

3). This reference number includes the last set of digits and the letter preceding them. The

drawing in this example would be referred to as Drawing A-244838.

Figure 3: Daktronics Drawing Label

The serial and model numbers of a Daktronics display can be found on the ID label inside the

display. The label will be similar to the one shown in Figure 4. When calling Daktronics

Customer Service, please have this information available to ensure that your request is

serviced as quickly as possible. For future reference, note the display model number, serial

number, and installation date inside the front page of this manual.

Figure 4: Display Identification Label

2 Introduction

Page 11

Section 2: Mechanical Installation

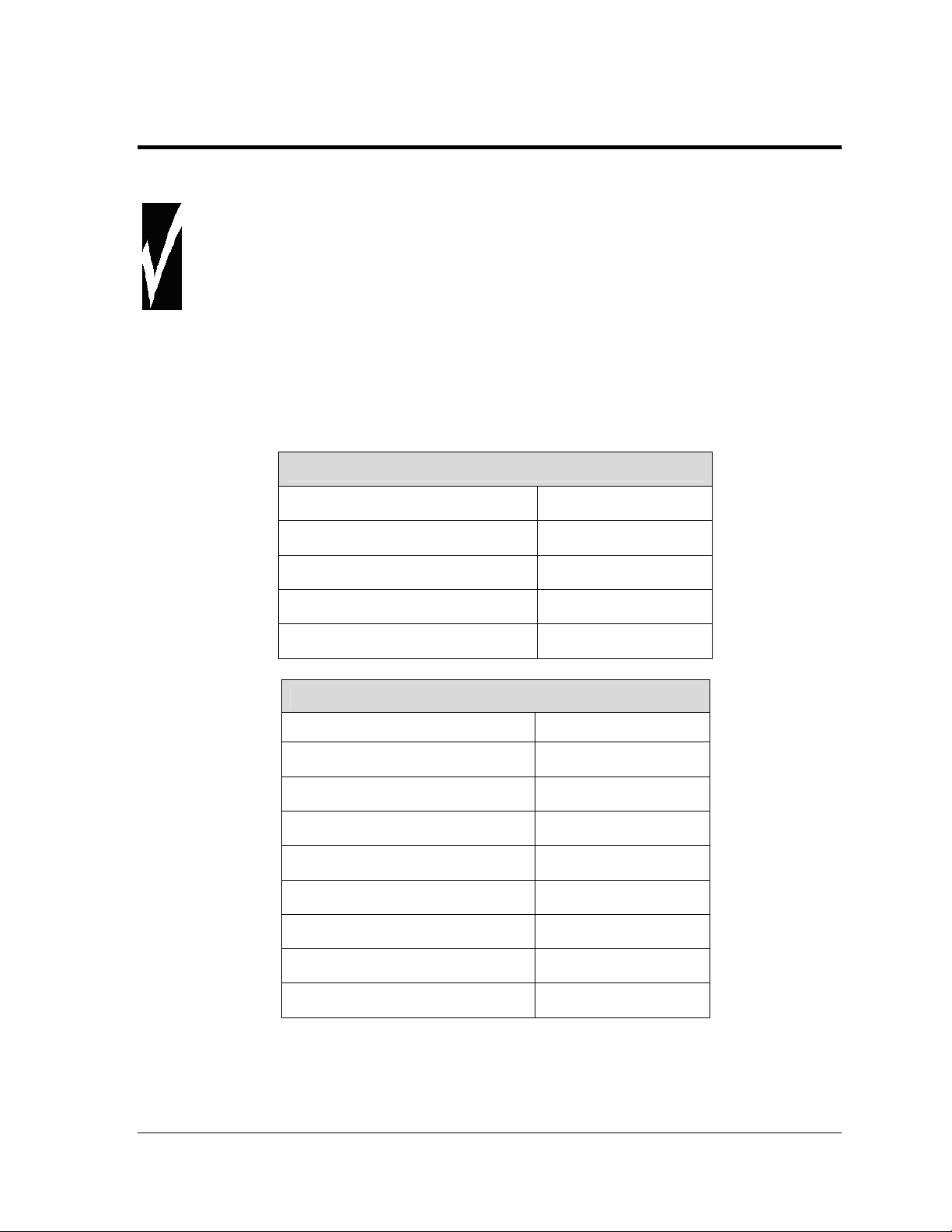

Important Safeguards

• Read and understand these instructions before installing the display.

• Do not drop the controller or allow it to get wet.

• Properly ground the display with a ground rod at the sign location.

• Disconnect power when servicing the display.

• Do not modify the display structure or attach any panels or coverings without the written

consent of Daktronics, Inc.

2.1 Shop Drawings

The table below gives the shop drawing number for each display model. All drawings are

inserted into Appendix A.

Single-faced displays with left side captions

Drawing Title/Display Type Drawing Number

Shop Drawing, DF-2100-10-L5-SF Drawing B-304066

Shop Drawing, DF-2100-13-L6-SF Drawing B-304229

Shop Drawing, DF-2100-18-L8-SF Drawing B-304719

Shop Drawing, DF-2100-24-L10-SF Drawing B-304808

Single-faced displays with top captions

Drawing Title/Display Type Drawing Number

Shop Drawing, DF-2100-10-T3-SF Drawing B-303105

Shop Drawing, DF-2100-13-T3.5-SF Drawing B-303309

Shop Drawing, DF-2100-18-T5.5-SF Drawing B-303675

Shop Drawing, DF-2100-24-T6-SF Drawing B-303900

Shop Drawing, DF-2100-24-T8-SF Drawing B-303983

Shop Drawing, DF-2100-36-T8-SF Drawing B-269576

Shop Drawing, DF-2100-48-T11-SF Drawing A-236905

Shop Drawing, DF-2100-60-T14-SF Drawing A-232509

Mechanical Installation 3

Page 12

2.2 Specifications

DataMaster Petroleum Price Double-Faced Displays with Left Caption

Model Dimensions Weight Digit Size

DF-2100-10-R-L5-SF

DF-2100-10-A-L5-SF

DF-2100-10-G-L5-SF

DF-2100-13-R- L6- SF

DF-2100-13-A-L6- SF

DF-2100-13-G- L6- SF

DF-2100-18-R- L8- SF

DF-2100-18-A-L8- SF

DF-2100-18-G- L8- SF

DF-2100-24-R- L10- SF

DF-2100-24-A-L10- SF

DF-2100-24-G- L10- SF

DF-2100-10-R-T3-SF

DF-2100-10-A-T3-SF

DF-2100-10-G-T3-SF

DF-2100-13-R-T3.5-SF

DF-2100-13-A-T3.5-SF

DF-2100-13-G-T3.5-SF

DF-2100-18-R-T5-SF

DF-2100-18-A-T5- SF

DF-2100-18-G-T5- SF

DF-2100-24-R-T6- SF

DF-2100-24-A-T6- SF

DF-2100-24-G-T6- SF

DF-2100-36-R-T10-SF

DF-2100-36-A-T10-SF

DF-2100-36-G-T10-SF

DF-2100-48-R-T11-SF

DF-2100-48-A-T11-SF

DF-2100-48-G-T11-SF

DF-2100-60-R-T14-SF

DF-2100-60-A-T14-SF

DF-2100-60-G-T14-SF

H1’-3”, W5’-0”, D0’-6”

(381 x 1524 x 152 mm)

H1’-6", W6’-0", D0’-6"

(457x 1829 x 152 mm)

H2’-0", W8’-0", D0’-6"

(610 x 2438 x 152 mm)

H2’-6", W10’-0", D0’-6"

(762 x 3048 x 152 mm)

H1’-9", W3’-0", D0’-6"

(533 x 914 x 152 mm)

H2’-2", W3’-6", D0’-6"

(660 x 1067 x 152 mm)

H3’-0", W5’-0", D0’-6"

(914 x 1524 x 152 mm)

H4’-0", W6’-0", D0’-6"

(1219 x1829 x152 mm)

H5’-6", W8’-0", D0’-8"

(1676 x 2438 x 203 mm)

H7’-0", W11’-0", D0’-8"

(2134 x 3353 x 203 mm)

H9’-0", W14’-0", D0’-8"

(2743 x 4267 x 203 mm)

50 lb

(23 kg)

60 lb

(27 kg)

70 lb

(32kg)

80 lb

(36 kg)

45 lb

(20 kg)

55 lb

(25 kg)

100 lb

(45 kg)

110 lb

(50 kg)

190 lb

(86 kg)

350 lb

(159 kg)

600 lb

(272 kg)

10”

(254 mm)

13"

(330 mm)

18"

(457 mm)

24"

(610 mm)

10"

(254 mm)

13"

(330 mm)

18"

(457 mm)

24"

(610 mm)

36"

(914 mm)

48"

(1219 mm)

60"

(1524 mm)

Maximum

Power

120 W 120 VAC

135 W

275 W =

Red, Amber

350 W =Green

275 W =

Red, Amber

350 W =Green

135 W 120 V AC

150 W 120 V AC

275 W =

Red, Amber

350 W =Green

275 W =

Red, Amber

350 W =Green

1300 W 120 V AC

1336 W 120 V AC

1636 W 120 V AC

Circuit

15 A

120 VAC

15 A

120 VAC

15 A

120 VAC

15 A

15 A

15 A

120 V AC

15 A

120 V AC

15 A

15 A

15 A

15 A

4 Mechanical Installation

Page 13

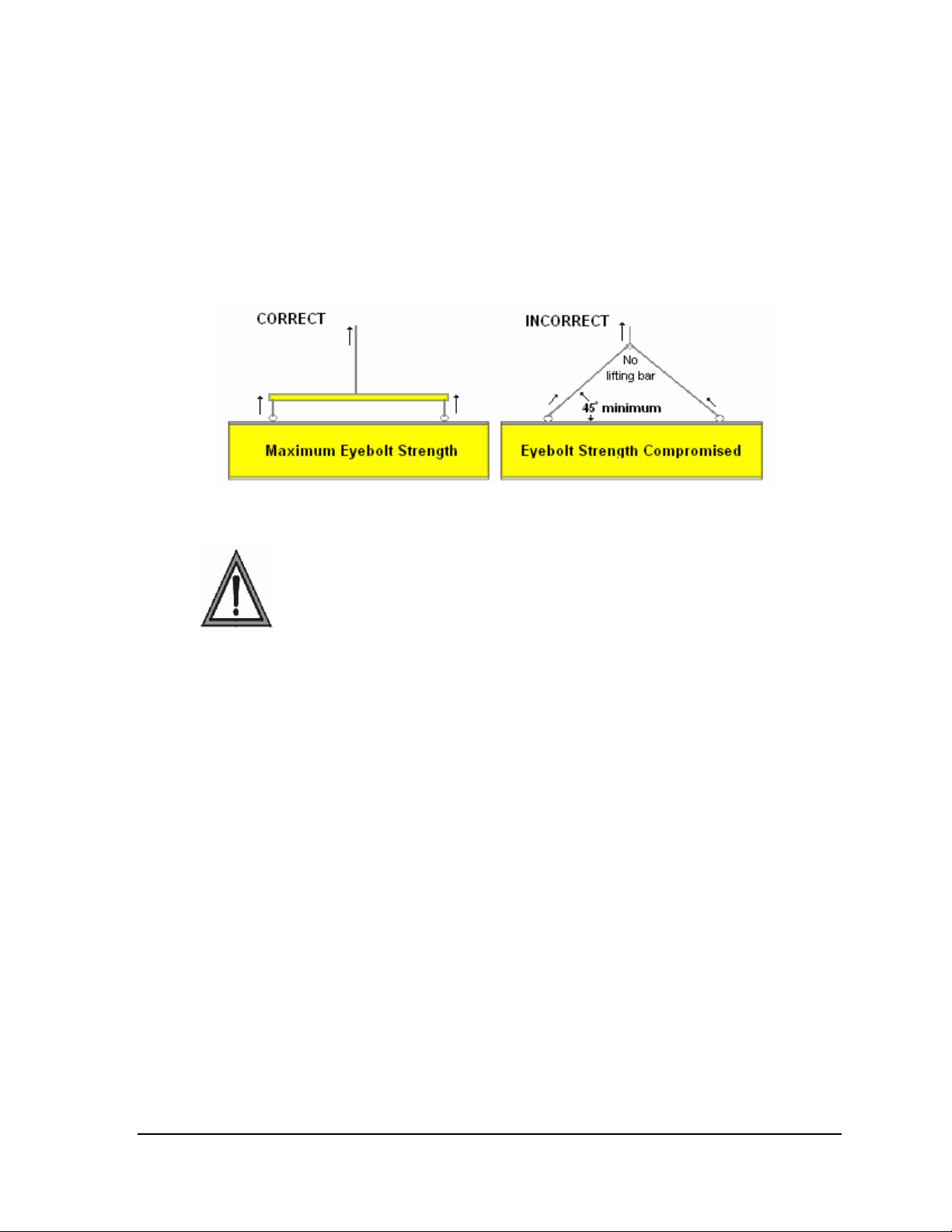

2.3 Lifting the Displays

While DataMaster outdoor digit displays are designed for pole mounting, every installation

will be different. Actual site demands will dictate the appropriate mounting method.

Daktronics strongly recommends using a spreader or lifting bar to lift the display. Using a

spreader bar ensures that the force on the eyebolts is straight up, minimizing lifting stress.

Figure 5 illustrates the correct and incorrect lifting methods.

Figure 5: Lifting the Display

Note: Daktronics assumes no liability for display damage or injury resulting from

incorrect setup or incorrect lifting methods.

Eyebolts are intended for lifting during installation only. Do not attempt to

permanently support the display by the eyebolts.

Eyebolts may be removed once the display is in place. The bolt sizes and threads vary based

on the size and weight of the display. Common bolts used are 1/4"-20, 3/8"-16, 1/2"-13, and

5/8"-11.

RC-100 Controller 5

Page 14

Page 15

Section 3: Electrical Installation

Reference Drawing:

Specifications; Gas Price Driver, 4 Col........................................................... Drawing A-250728

Wiring Schematic, DF-2000/4000 Series........................................................ Drawing A-263988

Address Dip Switch Settings........................................................................... Drawing B-256001

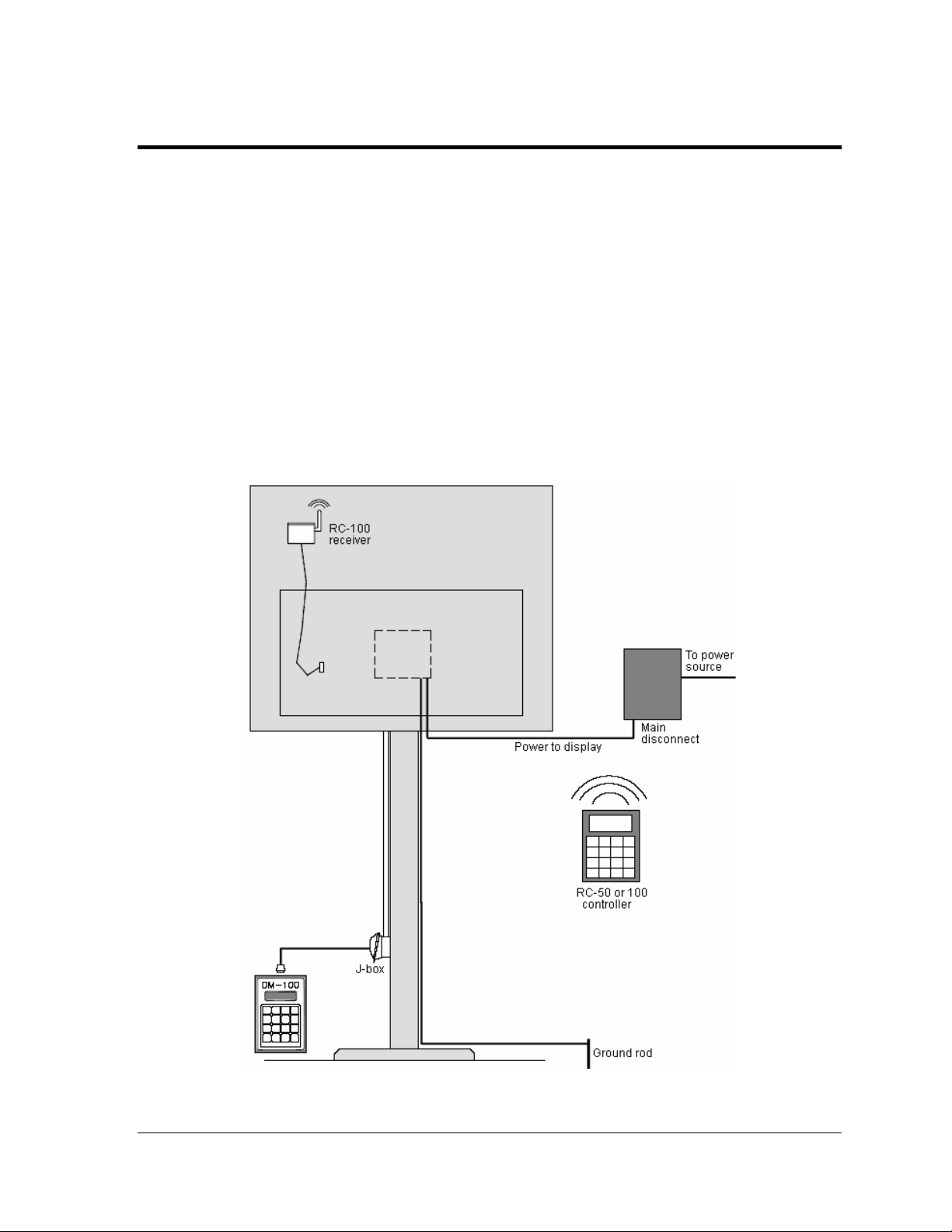

Electrical installation consists of the following processes, as illustrated in Figure 6:

• providing power and ground to a disconnect near the display.

• routing power and ground from the main disconnect to the display driver/power enclosure.

• connecting the display ground to a ground rod at the sign location.

• routing the control signal cable from the control location to the sign location. Signal options

include the DM-100, RC-100, and RC-50.

Each of these steps is covered in the following section.

Figure 6: Power and Signal Routing

Electrical Installation 7

Page 16

3.1 Power Installation

Only qualified individuals should perform power termination to the display.

It is the responsibility of the electrical contractor to ensure that all electrical

work meets or exceeds local and national codes.

Daktronics DataMaster displays have been designed for simple hook-up of power and

signal. Correct power installation is imperative for proper display operation. Improper

installation could result in serious damage to the equipment and could be hazardous to

personnel.

The DataMaster outdoor displays require a dedicated, 120 V circuit for incoming power. The

display itself has no breakers or fuses. Refer to Drawing A-263988 and to the chart in Section

2 to determine maximum power requirements for this model.

It is critical that the display circuit be fused at 15 A, and that all conductors used must

be designed to pass a 15 A current in normal operation. Failure to meet wiring and

over-current protection device requirements is a violation of the National Electrical

®

Code

and will void the display warranty.

Grounding

Displays MUST be grounded according to the provisions outlined in Article 250 of

the National Electrical Code and according to the specifications in this manual.

The display system must be connected to an earth electrode installed at the display. Proper

grounding is necessary for reliable equipment operation. It also protects the equipment from

damaging electrical disturbances and lightning. The display must be properly grounded or

the warranty will be void. Refer to Schematic Drawing A-263988.

Important points about grounding:

• Follow local and national codes: The material of an earth-ground electrode differs from

region to region and from conditions present at the site. Consult the National Electrical Code

and any local electrical codes that may apply.

• Support structure cannot be used as an earth-ground electrode: The support is generally

embedded in concrete. If embedded in earth, the steel is either primed or it corrodes, making

it a poor ground.

• One grounding electrode for each display face: The grounding electrode is typically one

grounding rod for each display face. Other grounding electrodes as described in Article 250

of the National Electric Code may be used.

• Resistance to ground 10 ohms or less: This is required by Daktronics for proper display

performance. If the resistance to ground is higher than 10 ohms, it will be necessary to install

additional grounding electrodes to reduce the resistance. The grounding electrode should be

installed within 25 feet of the base of the display. The grounding electrode must be connected

to the ground wire inside the display.

8 Electrical Installation

Page 17

Power Disconnect

The National Electrical Code requires the use of a lockable power disconnect within sight of

or at the display. Follow these guidelines for correct connection:

• Connect the grounding electrode cable at the local disconnect, never at the display

driver/power enclosure.

• Use a disconnect that opens all of the ungrounded phase conductors.

In order for this device to provide protection, the power must be disconnected when the

display is not in use. The controller should also be disconnected from power and from the

signal j-box when the system is not being used. The same surges that may damage the

display's driver can also damage the controller's circuit.

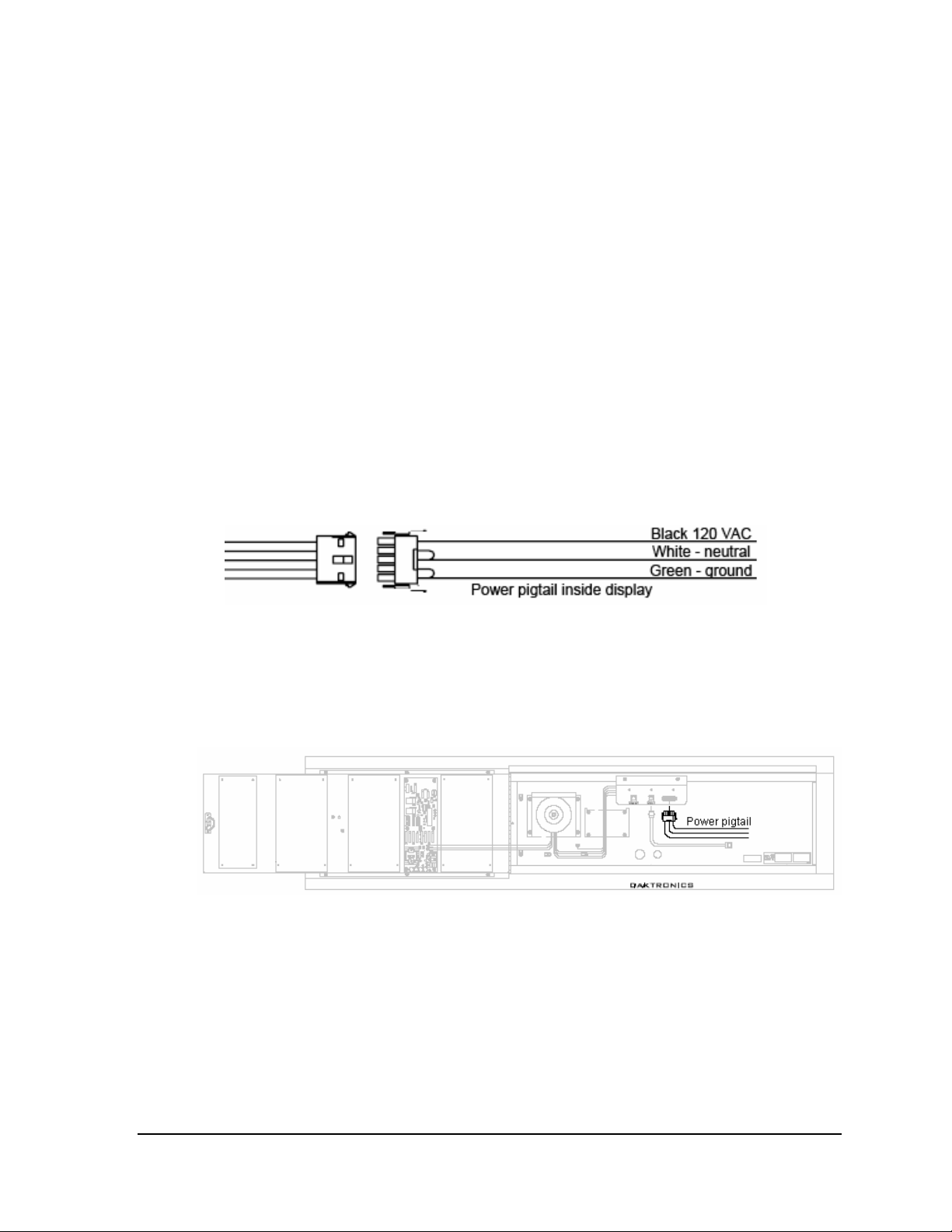

Power Installation

For this type of installation, the power circuit must contain an isolated earth-ground

conductor. Power connects to the pigtail inside the display (Figure 7). The pigtail has three

wires: black (120 V AC line), white (neutral) and green (ground), and a 5-pin plug on one

end. The plug is connected to the mating plug on the transformer. Use wire nuts to connect

power wires to the pigtails.

Figure 7: Power Connection

To access the power pigtail inside the display, open the latch access fasteners on the digit

panels. Smaller models have a single door that opens from the right. Larger models have two

doors that open near the center. Use a screwdriver to turn the fasteners a half-turn

counterclockwise to open the panel. Remove two wing nuts to open the left panel, if present.

Figure 8: Example of Power Pigtail Location

Electrical Installation 9

Page 18

3.2 Signal Connection

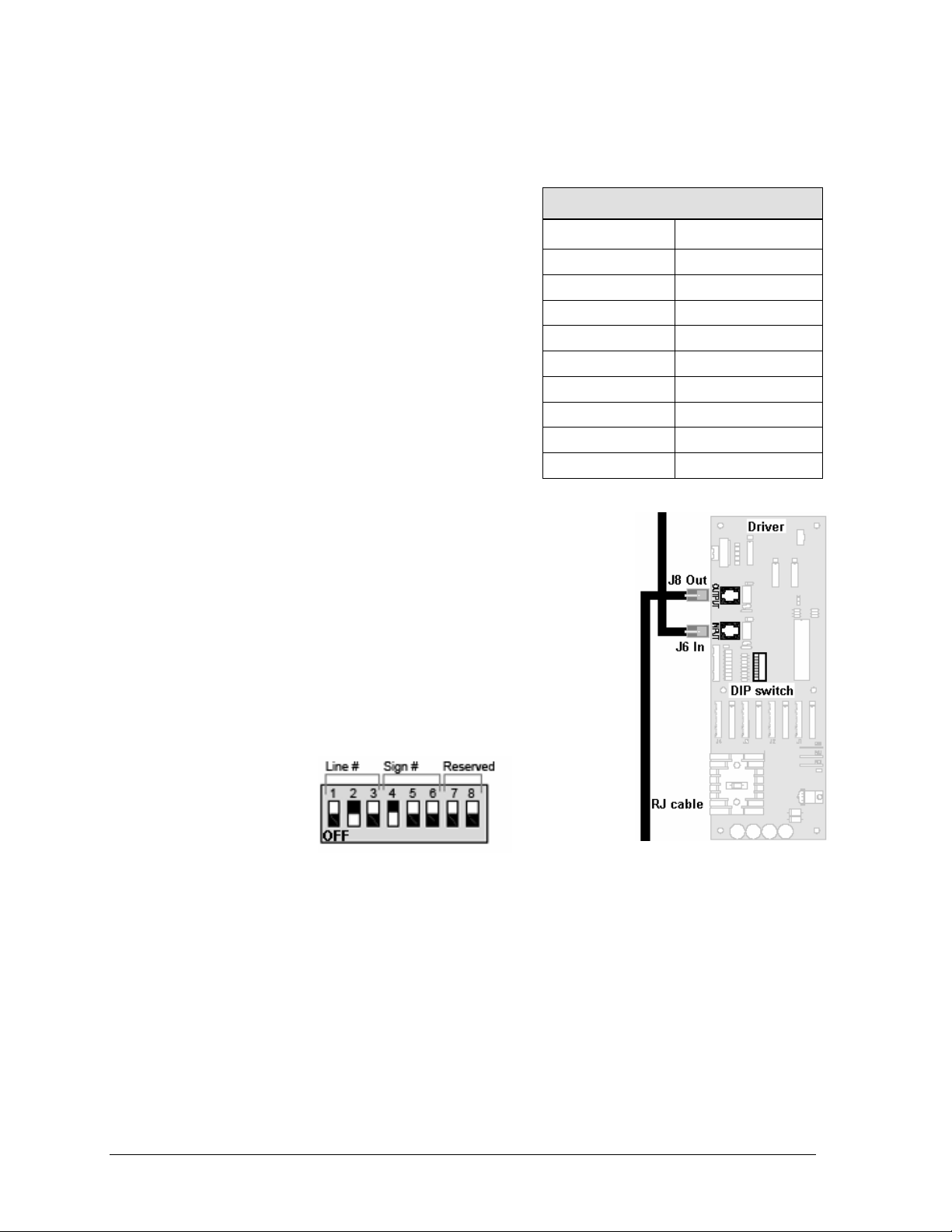

LED Drivers

In the display, the LED driver performs the task of

switching digits on and off. One driver at each sign

installation is designated as the “host driver.” This

driver receives its signal directly from the controller

on the Signal In connector J6. The Signal Out

connector J8 is used to connect to “client drivers,”

the drivers in other displays in this network.

Other communication types are initially connected

as shown in the chart: J11 (Radio, RC-100 system)

and J12 (RC-50 receiver). These initial connections

are then routed to the J6 Input jack. Refer to

Drawings A-250728 for a complete listing of driver

connector functions and wiring pin numbers.

4-Column LED Driver

Connector No. Function

J1 – 4 Digits

J5 Not loaded

J6 CL Input

J7 Program

J8 CL Output

J9 Not loaded

J10 Modem

J11 Radio

J12 RC-50 Input

Signal Wiring

Signal wires are terminated with a telephone-type RJ14

connector. Route the cable from the jack in the j-box to J6 on the

host driver (Figure 9). Run another RJ14 connector from J8

(Output) to the next (client) display, connecting at J6 (Input).

Follow this sequence to all displays in the sign network.

Address Dip Switch Settings

Every driver, either host or client, must have a unique address.

The address is set by moving the individual toggle switches in

the eight-position dip switch case located on the driver (Figure

10). The dark area shows that the switch has been pushed down.

In the example, switches 2 and 4 are on.

Figure 10: Dip Switches

Figure 9: Driver

Addresses allow the user to set both line number (switches 1-3) and sign number (switches 4-

6) in as many as eight sign groups. All displays with the same line number will show the

same price.

Refer to Drawing B-256001 for an illustration of the client/host driver setups and for a chart

showing line number and sign number settings.

10 Electrical Installation

Page 19

3.3 Power Up Self-test

Every time the display is powered up, it will run through a verification sequence. This is a

good way to check that the displays are set up and working correctly. The following items

will be shown on the digit displays. The second column explains the significance of each

item.

Information shown

on display

Meaning of information

rNN

XLY

Revision number of software

X = sign #; L is constant, Y = line #

Electrical Installation 11

Page 20

Page 21

Section 4: Diagnostics and Troubleshooting

Important Notes

Disconnect power before doing any repair or maintenance work on the display.

Allow only qualified service personnel access to internal display electronics.

Disconnect power when not using the display.

Daktronics displays are built for long life and require little maintenance. However, at times, displays

may not work correctly. Use this section to define the problems and find solutions.

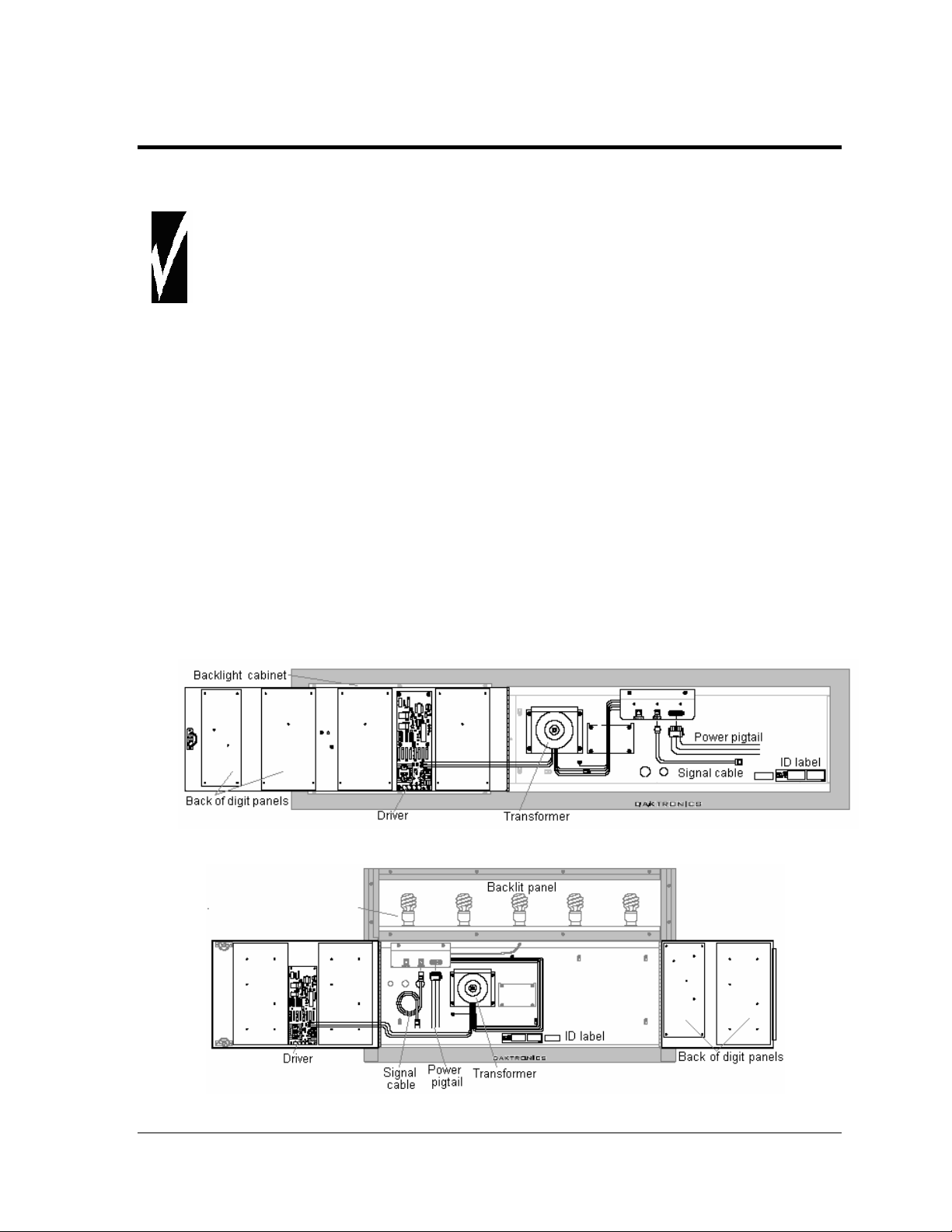

4.1 Component Location and Access

To access the components of these displays, open the latch access fasteners on the digit

panels. Some models have one door that opens from the right. Other models have two doors

that open near the center. Use a screwdriver to turn the fasteners a half-turn

counterclockwise to open the panel. Remove two wing nuts to open the left panel, if present.

The internal components of the display are located as shown in Figure 11 and Figure 12. The

driver is typically mounted between two digit boards. The power pigtail will be connected to

the power source wiring with wire nuts.

Note: Disconnect power before servicing the display. Disconnect power, also, when the

display is not in use.

Figure 11: Inside View of Left Panel, Single-door Display

Figure 12: Inside View of Top Panel, Two-door Display

Diagnostics and Troubleshooting 13

Page 22

4.2 Diagnostics

Driver LEDs

The driver inside the display contains three LEDs that provide information

about the working of the display. Refer to Figure 13 for their location. These

LEDs can help pinpoint problems with driver set-up or operation.

The LEDs give the following information:

LED Color Status

DS1 Green Continuous light when driver has power.

DS2 Red Blinks when driver receives signal.

DS3 Amber Blinks when driver is running.

Power On Self-Test

A useful troubleshooting tool is the power on self-test performed by the host

driver every time the display powers up: The display should show the

information listed in the left column. Every “X” in the chart refers to a

number.

Information shown

on display

rNN

XLY

Meaning of information

Revision number of software

X = sign #; L is constant, Y = line #

Figure 13: Driver

Diagnostics

14 Diagnostics and Troubleshooting

Page 23

4.3 Troubleshooting

This section lists potential problems with the display, indicates possible causes, and suggests

corrective action. This list does not include every possible problem, but it does represent

some of the more common situations that may occur. (Refer to the appropriate manual for a

list of potential problems with add-on or separately mounted message centers.

Symptom/

Condition

Possible Cause Solution

No displays in the

sign will light

Multiple line sign

with all lines

showing same

prices

Digit will not light • Black wire to digit broken.

Segment or several

LEDs will not light

Segment or digit

stays lit

• Power incorrectly set up.

• Addresses not set correctly.

• Addresses not set

correctly.

• Poor contact at driver

connection.

• Driver malfunction.

• Broken LEDs.

• Driver failure.

• Broken wire between

driver and digit.

• Poor contact at driver

connector.

• Driver failure.

• Short circuit on digit.

• Open display with host driver

and check Power LED

(Section 4.2).

• Check each driver to verify

correct address settings

(Section 3.2).

• Set up different address for

each line of sign (Section 3.2).

• Replace harness.

• Clean contacts.

• Replace driver.

• Replace segment or digit.

• Replace driver.

• Replace harness.

• Clean contact or replace

harness.

• Replace driver.

• Replace harness.

Data appears in the

wrong place on the

sign

Data appears on the

wrong line of the

display

Display shows "E4". • No Message Error: This

• Signal connections are

not correct.

• Incorrect address settings

on drivers.

code is shown when no

messages are

downloaded to the

display.

• Reconnect signal wiring to

drivers (Section 3.2).

• Change addresses on drivers

(Section 3.2).

• Download a new message to

the display using the [Update

Display] key on the

DataMaster 100 controller.

Diagnostics and Troubleshooting 15

Page 24

Page 25

Section 5: Parts Replacement

Daktronics Petroleum Price Displays are built for long life and easy maintenance. On occasion,

however, a part may need to be replaced. In that case, follow these steps.

1. Find the part number label on a part or refer to the list in Section 5.1 for the correct part

number.

2. Read Section 5.3, Daktronics Exchange and Repair & Return Programs, for step-by-step

instructions on obtaining a new part.

3. When the part is received, follow the instructions in this section for replacing it.

5.1 Replacement Parts List

Description

Daktronics Part

No.

Driver & Internal Components for Digits 24" & smaller

Toroid Transformer, Display T-1124

Digit cable, 1 ft. W-1575

Digit cable, 3 ft. W-1576

Digit cable, 4 ft. W-1577

Digit cable, 6 ft. W-1578

Digit cable, 8 ft. W-1579

Gas Price Driver, 4-col 0P-1356-0002

Signal Surge Card 0P-1356-0001

Decimal / Driver, red 0P-1192-0353

Decimal / Driver, amber 0P-1192-0355

Decimal / Driver, green 0P-1192-0354

Driver & Internal Components for Digits 36" & larger

Driver, 4-column MASC, LED 0P-1192-0068

Light sensor 0A-1279-0203

Protocol plug (Protocol 4) 0A-1279-0089

Power supply, 24 V DC, 1 KW A-1856R

Transformer, Pri. 115V; Sec. 10 VCT @1.2A T-1072

Address #1 Plug 0A-1150-0122

8-Segment breakout board 0P-1192-0326

Communication Boards and Accessories

Signal surge suppression board 0P-1110-0011

Modem, RS232 coated, internal, 0P-1279-0003

J-box, signal converter, w/modem 0A-1279-0162

J-box, signal converter, radio 0A-1279-0161

RJ11 to RJ45, M-M, straight, 18” cable 0A-1137-0300

Server Radio, outdoor 0A-1146-0079

Client Radio, w/Quick Connect 0A-1146-0078

Cable, 6-cond., 18 AWG, j-box to Server Radio W-1370

Junction box, outdoor, 9-pin D-male 0A-1196-0093

Junction box, indoor, 9-pin D, male 0A-1196-0099

DM-100 Controller 17

Page 26

Description

RC-50 Radio with overlay 0A-1356-0064

Receiver card 0P-1192-0355

Antenna A-2015

Transformer, wall pack T-1118

RC-100 Price Display insert LL-2617

RC-100 hand held assembly 0A-1110-0046

RC-100 receiver 0A-1110-0045

DM-100 hand-held controller 0A-1196-0088

DM-100 outdoor wired installation kit 0A-1356-0002

DM-100 indoor wired installation kit 0A-1356-0105

Cable, serial, DB9 male to DB9 female W-1267

DM100 Insert Time & Temp/Petroleum Price 0G-164998

Daktronics Part

No.

Digits and Accessories 24” and smaller

10” Digit 7-segment, Red 0P-1192-0356

10” Digit, 7-segment, Amber 0P-1192-0359

10” Digit, 7-segment, Green 0P-1192-0357

13” Digit, 7-segment, Red, 0P-1192-0347

13” Digit, 7-segment, Amber 0P-1192-0348

13” Digit, 7-segment, Green 0P-1192-0349

18” Digit, 7-segment, Red 0P-1192-0341

18” Digit, 7-segment, Amber 0P-1192-0342

18” Digit, 7-segment, Green 0P-1192-0343

22”, Digit segment, Red, Horizontal 0P-1192-0293

22”, Digit segment Amber, Horizontal 0P-1192-0297

22”, Digit segment, Green, Horizontal 0P-1192-0295

24”, Digit segment, Red, Vertical 0P-1192-0372

24”, Digit segment, Amber, Vertical 0P-1192-0374

24”, Digit segment, Green, Vertical 0P-1192-0373

7” 9/10 Red, 14 pin, 24 V 0P-1192-0350

7” 9/10 digit, Amber, 14 pin, 24 V 0P-1192-0351

7” 9/10 digit, Green, 14 pin, 24 V 0P-1192-0352

13”, 9/10 digit, Red, 14 pin, single stroke 0P-1192-0378

13”, 9/10 digit, Amber, 14 pin, single stroke 0P-1192-0379

13”, 9/10 digit, Green, 14 pin, single stroke 0P-1192-0380

13”, 9/10 digit, Red, 14 pin, double stroke 0P-1192-0344

13”, 9/10 digit, Amber, 14 pin, double stroke 0P-1192-0345

13”, 9/10 digit, Green, 14 pin, double stroke 0P-1192-0346

Digits and Accessories 36” and larger

Speed nut, M3 Kingnut black nylon, Push nut HS-1453

Spacer, washer with steel backing HC-1221

Indicator, 4" Red, pc board 0P-1192-0244

Indicator, 4" Amber, pc board 0P-1192-0245

Indicator, 4" Green, pc board 0P-1192-0248

36" Digit segment, Red, Vertical 0P-1192-0208

36” Digit segment, Red Horizontal 0P-1192-0209

36" Digit segment, Amber, Vertical 0P-1192-0222

18 DM-100 Controller

Page 27

Description

36” Digit segment, Amber Horizontal 0P-1192-0223

36” Digit segment, Green, Vertical 0P-1192-0333

36” Digit segment, Green Horizontal 0P-1192-0334

48” Digit segment, Red, Vertical 0P-1192-0212

48” Digit segment, Red Horizontal 0P-1192-0213

48" Digit segment, Amber, Vertical 0P-1192-0226

48" Digit segment, Amber Horizontal 0P-1192-0227

48" Digit segment, Green, Vertical 0P-1192-0337

48" Digit segment, Green, Horizontal 0P-1192-0338

60" 1/2 segment, Red, Vertical 0P-1192-0281

60" 1/2 segment, Red Horizontal 0P-1192-0280

60" 1/2 segment, Amber, Vertical 0P-1192-0283

60" 1/2 segment, Amber Horizontal 0P-1192-0282

60" 1/2 segment, Green, Vertical 0P-1192-0323

60" 1/2 segment, Green, Horizontal 0P-1192-0321

24" 9/10 Red, pc board 0P-1192-0232

24" 9/10 Amber, pc board 0P-1192-0233

24" 9/10 Green, pc board 0P-1192-0325

24” 9/10 Red, w/faceplate 0A-1192-2359

24” 9/10 Amber, w/faceplate 0A-1192-2360

24” 9/10 Green, w/faceplate 0A-1192-3082

Daktronics Part

No.

Additional Replacement Parts

Lamp, 15 W spiral compact fluor. DS-1563

Lamp, 30” T12 fluorescent DS-1034

Lamp, 36” T12 fluorescent DS-1521

Lamp, 42” T12 fluorescent DS-1501

Lamp, 48” T12 fluorescent DS-1036

Lamp, 60” T12 fluorescent DS-1049

Lamp, 72” T12 fluorescent DS-1037

Lamp, 84” T12 fluorescent DS-1038

Lamp, 96” T12 fluorescent DS-1048

Lamps 5’4” DS-1053

Lamps 10’ DS-1213

Ballast, 1.65 A fluorescent A-1368

Ballast, 2.5 A fluorescent A-1369

Ballast, 2.8 A fluorescent A-1370

Ballast 4, 5, 6 lamps (24-48 feet) A-1371

DM-100 Controller 19

Page 28

5.2 Instructions for Replacing Parts

Replacing a Digit Panel

The digit circuit board is the platform for the LEDs and is mounted to the back of the digit

panel. Refer to Figure 14. If some LEDs are not working, do not attempt to remove an

individual LED. Replace the entire digit panel.

To remove a display digit panel, follow these steps:

1. Open the digit panel as described in Section 4.1.

2. Disconnect the power/signal connector from the

back of the digit. Release the connector by

squeezing together the locking tabs as the plug is

pulled free.

3. The digits are secured to the inside of the panel

with fixed machine screws, spacers, and push nuts.

Remove the nuts and lift the digit off the standoff

screws. The push nuts can be removed in several

ways, but Daktronics recommends using a 9/32"

nut driver.

4. Move the new digit into place and install the

pushnuts.

5. Reconnect the power/signal connector plug. Note:

This is a keyed connector and will attach in one way

only. Do not attempt to force the connection!

6. Replace the back panel of the display, latching it

securely.

Figure 14: Digit Assembly

Replacing a Digit Segment

Large digits are constructed in segments, as shown in Figure 15. In this case, it may be

possible to replace only the defective segment. As with smaller digits, the segment circuit

boards are mounted to the back of the digit panel. Do not attempt to remove individual

LEDs. Replace a malfunctioning colon, decimal, or indicator assembly in the same manner.

To remove a digit segment, follow these steps:

1. Open the digit panel as described in Section 4.1.

2. Disconnect the 2-pin power/signal connector from the back

of the individual segment. Release the connector by

squeezing together the locking tabs as the connector is pulled

free.

3. The individual segments are secured to the inside of the

panel with fixed machine screws, spacers, and push nuts.

Remove the nuts and lift the segment off the standoff screws.

4. Position a new segment over the screws and tighten the nuts.

5. Reconnect the power/signal connector. Note: This is a keyed

connector it will attach in one way only. Do not attempt to

force the connection!

6. Close and secure the digit panel and test the display.

20 DM-100 Controller

Figure 15: Digit Segments

Page 29

Replacing a Driver

The driver is mounted to the front panel between digit boards.

The back panel will need to be removed to replace the driver.

To replace a driver, follow these steps:

1. Open the display as described in Section 4.2.

2. Disconnect and label all connectors from the driver.

Release each connector by squeezing together the locking

tabs and pulling on the plug.

3. Remove the screws and nuts securing the driver to the

inside of the enclosure.

4. Carefully lift the driver from the display.

5. Move the new driver into place and fasten securely.

6. Reconnect all the connectors. Note: Remember that these

are keyed connectors and will attach in one way only. Do

not attempt to force the connections.

7. Replace the back panel and securely fasten the latches.

8. Test the display to make sure that it is working correctly.

Figure 16: Driver

5.3 Daktronics Exchange and Repair & Return Programs

To serve customers’ repair and maintenance needs, Daktronics offers both an Exchange

Program and a Repair & Return Program.

Before Contacting Daktronics

Fill in this chart before calling Customer Service:

Display Serial No. ___________________________________

Display Model No. __________________________________

Date Installed ______________________________________

DataMaster Serial No. _______________________________

Exchange Program

Daktronics unique Exchange Program is a quick service for replacing key parts in need of

repair. If a part requires repair or replacement, Daktronics sends the customer a replacement,

and the customer sends the defective part to Daktronics. This decreases display downtime.

To participate in the Exchange Program, follow these steps,

1. Call Daktronics Customer Service: 866-343-3122

DM-100 Controller 21

Page 30

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the problem part which is being

replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. A charge will be made for the replacement part immediately, unless a qualifying

service agreement is in place.

In most circumstances, the replacement part will be invoiced at the time it is shipped.

4. If the replacement part does not solve the problem, return the part within 30

working days or the full purchase price will be charged.

If the equipment is still defective after the exchange was made, please contact

Customer Service immediately. Daktronics expects immediate return of an exchange

part if it does not solve the problem. The company also reserves the right to refuse

parts that have been damaged due to acts of nature or causes other than normal wear

and tear.

Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Phone: 866-343-3122 Fax: 605-697-4444

2. Receive a Return Materials Authorization (RMA) number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing. Daktronics does not recommend Styrofoam peanuts in

packaging.

4. Enclose:

your name

address

phone number

the RMA number

a clear description of symptoms

Shipping Address

Daktronics Customer Service

PO Box 5128

331 32nd Avenue

Brookings, SD 57006

22 DM-100 Controller

Page 31

Section 6: DM-100 Controller

This section describes the set up and operation of the DataMaster 100 (DM-100) Controller. The DM100 may be used with either an indoor or outdoor j-box, both of which are explained in this section.

Note also the information on the DataMaster Insert.

Reference Drawing:

Address Dip Switch Settings........................................................................... Drawing B-256001

Insert, LL-2551 Price/T&T Display.................................................................. Drawing A-167856

6.1 DM-100 Overview

The DataMaster 100 Series controller, shown in Figure 9, is a

hand-held controller designed to operate Daktronics LED

DataMaster

ABS plastic, making it a durable and convenient control

option. The console’s liquid crystal display (LCD) guides the

user through the operation of the system.

The DM-100 can be configured to display petroleum price,

motel rates, and time and temperature data. Refer to

Drawing B-256001 for information on possible control

options and connection procedures.

Note: When the carrier delivers this Daktronics order, open

displays. This lightweight controller is encased in

the packages and inspect for shipping damage such as

rattles and dents. See that all equipment is included as

shown on the packing slip. If deficiencies are found,

immediately report them to Daktronics. Save all

packing materials in case warranty repair or exchange

is needed.

Figure 17: DataMaster (DM) 100

Replacement Parts List

The following is a list of possible replacement parts for the DM-100 controller. When reordering a part, be sure to use its corresponding part number. To obtain a part from

Daktronics, refer to Section 5.3 for instructions.

DM-100 Controller 23

Description Daktronics Part No.

Wall pack transformer T-1118

DM-100 controller

Control Insert LL-2551

Cable, DB-9 male to DB-9 female, 10' W-1267

0A-1196-0088

Page 32

6.2 Connecting the DM-100 to the Display

The DataMaster displays may be controlled from a location inside a building or from the

base of the display, depending on customer preference. Drawing B-256001 and the

subsections that follow provide greater detail on both installations using signal wire.

Wire Control from the Base of the Sign

This outdoor control option (Figure 18) permits operation of the

sign from the base of the display. The controller is connected to

an outdoor junction box mounted on the display pole, which

routes the signal to the sign through one 2-pair cable, 22 AWG.

Cable is in conduit where required.

This control option does not require the controller to be

connected to a power outlet. In this configuration, the DM-100

uses the sign as a power source.

To operate the display using this setup, connect the 9-pin to 9pin cable from the DM-100 controller to the 9-pin j-box mounted

on the display pole.

Figure 18: Wire Control Outdoors

Wire Control from a Building Location

The indoor control option is illustrated in Figure 19.

The handheld controller is connected to an indoor

junction box (j-box), which routes the signal to the

sign through one 2-pair cable, 22 AWG. Cable is in

conduit where required.

To operate the display using this setup, connect the

9-pin to 9-pin cable from the DM-100 controller to the

9-pin j-box, and plug the controller's wall pack

transformer into a 120 VAC outlet.

Figure 19: Wire Control from Building Location

24 DM-100 Controller

Page 33

6.3 DataMaster Insert and Code

The DM-100 uses a keypad insert to program rate

information into Daktronics LED DataMaster Rate

Displays. The DM-100 insert illustrated in Figure 20 is

used to control the displays.

If an insert is lost or damaged, make a copy of the insert

from Drawing A-167856 located in Appendix A. Cut this

to size and slide it into the DM-100 pocket. Use this as a

reference until a replacement is received.

To start the controller and use the insert to program

information into the display driver, read the next section

carefully to fully understand operation instructions.

Figure 20: DM-100 Insert

6.4 Petroleum Price Display Operation

The DM-100 controller can be configured to program petroleum price variances displayed on

the LED DataMaster Petroleum Price sign. The instructions provided in this section discuss

the functions the operator uses to control the Petroleum Price display.

DM-100 Controller 25

Page 34

Petroleum Price Display Startup

To operate the DataMaster Petroleum Price displays, the DM-100 must first be programmed

to the gas price function. Use the [Set Function] key on start-up. Use the following table as a

guide to start-up procedures.

LCD Screen Action

CURRENT

FUNCTION

GAS PRICE

CHANGE

FUNCTION?

PRESS SET

FUNCT

SELECT

FUNCTION

GAS PRICE ↓↑

The DM-100 handheld controller should now be ready for use. The controller will

“remember” the last function setting, so this step should only need to be done with a new

controller, or one that is configured for different displays. To operate the DM-100, press any

of the keys listed in the following gas price sections.

Plug the wall pack transformer into a 120 V AC

power outlet and connect it to the

This display appears briefly.

This message appears next on the screen.

If GAS PRICE was shown on the bottom line of

the LCD during startup, do nothing. The

controller will automatically default to previous

Gas Price settings.

If a function other than GAS PRICE was shown

on the bottom line of the LCD during startup,

press the

LCD prompt is displayed.

Press the arrow up or down keys<↑↓> until the

gas price option is shown. Press the [Enter] key

to accept.

[Set Function] key while the second

DM-100.

26 DM-100 Controller

Page 35

Petroleum Price Controller Operation

The Petroleum Price Controller LCD display will default to showing the current display

settings on power up. The following text will be shown on the LCD.

LCD Screen Action

LINE PRICE

1 ↓ $1.23 9/10

<EDIT> TO

MODIFY

1 ↓ $1.23 9/10

The display will toggle between these two

screens.

Press the up or down arrow keys <

through the current setting for any of the lines

on the display.

Press the [Enter/Edit] key to modify any of the

line settings.

↑↓> to scroll

Modifying Price Line Settings

The gas price can be modified either by pressing the [Edit] key during operation or by using

the [Menu] key (refer to Menu Items chart following this screen). The following keys

identify items to be edited:

L = Current line number to be edited

D.CC = Current dollars and cents value to edit

T = Current tenths of cent value to edit

LCD Screen Action

EDIT LINE L

$D.CC T/10 ↓

DM-100 Controller 27

Press any of the number keys to edit the price

value for this line. Press the down arrow key <

to modify the value of the 1/10-cent data for this

line (read Note following).

Press [Enter] to accept the new value or press

[Clear] to abort the changes.

Note: The flashing asterisk on the LCD shows

the current data being edited.

Many displays do not have a changeable 1/10cent digit. Changing the tenths-cent value from 9

on these digits will make the digit appear

incorrect.

↓>

Page 36

Menu Items

Pressing the [Menu] key accesses the following settings:

Use Menu items 1-5 to edit the price on each line of the display. Lines are typically numbered

top to bottom with 1 being the top of the display. For further details, refer to Modifying

Price Line Settings discussed previously in this section.

For more information about the Modem Settings submenu, refer to ED-13953: DataMaster

Modem Installation Manual. For additional information about the Display Status or the Set

Time submenus, refer to ED-13894: DataTime Radio Installation Manual. This manual

provides complete details on installation and setup for a bi-directional radio system.

Key Setting

1 Price Line 1

2 Price Line 2

3 Price Line 3

4 Price Line 4

5 Price Line 5

6 LED Test?

7 Display Option

8 Modem Settings

9 Display Status

10 Set Time 12HR

Modem Settings

The following items for a modem can be set using the DM-100:

Key Setting

1 Dial Number

2 Dial out prefix

3 Disconnect time

4 Multiple Dial

28 DM-100 Controller

Page 37

Display Status

The Display Status menu item can be used with a bi-directional display setup to get display

status back from the driver. The controller will cycle through various LCD message screens,

illustrated below and on the following page, that show display status. Press [Clear] at any

time to exit the Display Status submenu.

LCD Screen Action

Display status

Get status?

Driver Firmware

version x.x

Current day/time

mm/dd/yy

HH:MM

Last reset time

Mm/dd/yy hh:mm

Current temp

Xx ºf

TEMP SENSOR

OFFSET Xx ºC

Press [Enter] to get the status of the display that is

connected to the DM-100.

The LCD will scroll through the status sent back from

the display. Following is a list of responses:

Firmware Version

This is the firmware version programmed on the host

MASC driver in the display.

Current Day/Time

This is the Day/Time value set in the driver. The time

format used will be 24-hour.

Note: To set the Day/Time, see the "Set Time"

section of your DataTime display system's

operation manual.

Last Reset Time

This time represents the last time the driver was

reset. Note that the time format used will be

24-hour.

Current Temp

This is the temperature read at the display by the

temp sensor. (This value does not include the offset,

if applicable).

Temp Sensor Offset

This is the temp sensor offset value programmed

into the driver.

DM-100 Controller 29

Page 38

Set Time

This allows the time and date to be set with the DM-100.

LCD Screen Action

SET TIME–12HR

HH:MM AM ↓

HH – Current hours value

MM – Current minutes value

AM – Current AM/PM setting (not shown when

24-hour time is selected)

Using the number keys, enter the Time in the

12-hour (or 24-hour) format. Press the down

arrow key <↓> to modify the AM/PM setting.

Note: The flashing asterisk shows the current

data being edited.

To save changes, press the [Enter] key when

finished editing.

Press the [Clear] key to cancel changes.

After setting the time you will need to set the date. If the date is already correct, enter

through the date and press [Enter] to send the time to the display.

LCD Screen Action

DIM level xx

0=dim

Dim Level

• This is the intensity level of the display; 0 is the

63=bright

Dimming mode

Automatic

Dimming Mode

This is the current mode of dimming used by the

display.

• Automatic Dimming – The light sensor controls

• Manual Dimming – The DM-100 console is used to

dimmest setting, and 63 is the brightest setting.

dimming.

enter all display dimming information.

30 DM-100 Controller

Page 39

Dimming

The dimming level of the Rate display can be adjusted in two ways. A light sensor, mounted

on each driver, can detect the level of ambient light at the display location and dim the sign's

LEDs accordingly. This function is known as automatic dimming. When the manual

dimming function is selected, the LEDs remain at the same level of brightness regardless of

the level of light detected at the display.

To select either of these functions, press [Dimming]. The current setting is shown on the

bottom line of the LCD.

LCD Screen Action

DIMMING

AUTOMATIC ↓

If AUTOMATIC dimming is selected, the following LCD prompt will be shown:

LCD Screen Action

SET AUTO

DIMMING

MAX INTENSITY?

Press the down arrow key <↓> to toggle

through dim settings:

Automatic – The display automatically dims

based on the light detected at the display

Manual – The display dimming level is set

manually. Once set, this value remains

regardless of the level of light detected at the

display.

Press the [Enter/Edit] key to edit the auto

dimming max intensity. This is the maximum

intensity that the display will use in full-bright

modes (during daylight hours).

Press [Clear] to keep the current auto dimming

maximum setting.

DM-100 Controller 31

Page 40

The following LCD prompt is shown for either Manual or Automatic dimming selections:

LCD Screen Action

INTENSITY XX↓↑

ENTER TO SET

XX – Current intensity (1-16)

Max Intensity - 16

Press the up or down arrow key <↑ ↓> to

modify the current intensity of the display

(Note: The DataMaster must be connected to

the display)

Press [Enter] to accept this intensity. If the

manual-dimming mode is selected, this will be

the new intensity for the display. If the

automatic dimming mode is selected, the

display will illuminate in full-bright mode, which

is the maximum intensity level.

Update Display

Once connected to the display with a j-box, radio, or modem, press

[Update Display] to display the new sequence on the display. This button will also allow for

a preview of the new sequence on the LCD.

32 DM-100 Controller

Page 41

Section 7: RC-50 Controller

The RC-50 controller can be configured to program petroleum price variances displayed on the LED

DataMaster Petroleum Price sign. The instructions provided in this section discuss the functions used

by the operator to control the Petroleum Price display.

Reference Drawing:

RC-50 Quick install Guide............................................................................... Drawing A-257189

7.1 RC-50 Operation

The RC-50 controller can control four unique prices on multiple signs. The instructions

provided in this section discuss the functions used by the operator to control the rate display.

Editing the Display

To edit the price on the display, press and hold any button for five

seconds. When the sign is in Edit mode, the decimal LEDs blink.

On the RC-50, each pair of buttons corresponds to a price line on the

display. Each line is numbered to indicate the corresponding line on

the display.

Increasing the price

To increase the price by one cent, press [+] for the corresponding line.

Note: Make sure the display is in Edit mode.

Decreasing the price

To decrease the price, press [-] for the corresponding line.

Note: Make sure the display is in Edit mode.

Turbo mode

To rapidly increase or decrease a price, press and hold the button for

the corresponding line.

Note: When a button is not pressed for more than 10 seconds, the

display exits the Edit Mode. The prices are saved and the

display returns to its normal state.

Figure 21: RC-50 Controller

RC-50 Controller 33

Page 42

Page 43

Section 8: RC-100 Controller

The RC-100 controller can be configured to program petroleum price variances displayed on the LED

DataMaster Petroleum Price sign. The instructions provided in this section discuss the functions used

by the operator to control the Petroleum Price display.

Note: Although multiple wireless handheld controllers may be connected to a single wireless base

station server, the rate display application allows for only one handheld device to be connected at a

time.

Reference Drawing:

System Riser Diagram; RC-100, DataMaster................................................. Drawing A-244838

8.1 Petroleum Price Display Operation

The RC-100 controller can be configured to program petroleum

price variances displayed on the LED DataMaster Petroleum Price

sign. Refer to Drawing A-244838 for correct set-up of the RC-100

system.

Figure 22: RC-100 Controller

Petroleum Price Display Startup

To operate the DataMaster Petroleum Price displays, the RC-100 must first be programmed

to the gas price function. Use the [Set Function] key on startup. Use the following table as a

guide to startup procedures.

LCD Screen Action

CURRENT

FUNCTION

GAS PRICE

RC-100 Controller 35

•

Plug the wall pack transformer into a 120 V

AC power outlet and connect it to the RC-100.

• This display appears briefly.

Page 44

CHANGE

FUNCTION?

PRESS SET

FUNCT

SELECT

FUNCTION

GAS PRICE ↓↑

The RC-100 handheld controller should now be ready for use. The controller will

“remember” the last function setting, so this step should only need to be done with a new

controller or one that is configured for different displays. To operate the RC-100, press any of

the keys listed in the following petroleum price sections.

•

This message appears next on the screen.

• If “GAS PRICE” was shown on the bottom line

of the LCD during startup, do nothing. The

controller will automatically default to previous

Gas Price settings.

• If a function other than “GAS PRICE” was

shown on the bottom line of the LCD during

startup, press the [Set Function] key while

the second LCD prompt is displayed.

Press the arrow up or down keys<↑ ↓> until

•

the gas price option is shown. Press the

[Enter] key to accept.

RC-100 Controller Operation

The Petroleum Price Controller LCD display will default to showing the current display

settings on power up. The following text will be shown on the LCD.

LCD Screen Action

LINE PRICE

1 ↓ $1.23 9/10

<EDIT> TO

MODIFY

1 ↓ $1.23 9/10

•

The display will toggle between these two

screens.

• Press the up or down arrow keys <↑ ↓> to

scroll through the current setting for any of the

lines on the display.

• Press the [Enter/Edit] key to modify any of

the line settings.

36 RC-100 Controller

Page 45

Modifying Price Line Settings

The petroleum price can be modified either by pressing the [Edit] key during operation

(previous section) or using the [Menu] key (see Menu Items). Refer to the following key to

identify the item to be edited.

L = Current line number to be edited

D.CC = Current dollars and cents value to edit

T = Current tenths of cent value to edit

LCD Screen Action

EDIT LINE L

$D.CC T/10 ↓

• Press any of the number keys to edit the price

value for this line. Press the down arrow key

↓> to modify the value of the 1/10-cent data

<

for this line (see note below).

• Press [Enter] to accept the new value or press

[Clear] to abort the changes.

• Note: The flashing asterisk on the LCD shows

the current data being edited.

• Many displays do not have a changeable 1/10-

cent digit. Changing the tenths-cent value from

9 on these digits will make the digit appear

incorrect.

RC-100 Controller 37

Page 46

Dimming

The dimming level of the rate display can be adjusted in two ways. A temperature/light

sensor mounted near the display can detect the level of ambient light at the display location

and dim the sign's LEDs accordingly. This function is known as automatic dimming. When

the manual dimming function is selected, the LEDs remain at the same level of brightness

regardless of the level of light detected at the display. To select either of these functions,

press [Dimming]. The current setting is shown on the bottom line of the LCD.

LCD Screen Action

DIMMING

AUTOMATIC ↓

SET AUTO

DIMMING

MAX INTENSITY?

INTENSITY

XX↓↑

ENTER TO SET

XX – Current intensity (1-16)

Max Intensity - 16

Press the down arrow key <↓> to toggle

•

through dim settings:

• Automatic – The display automatically dims

based on the light detected at the display

• Manual – The display dimming level is set

manually. Once set, this value remains

regardless of the level of light detected at the

display.

• Blank Sign – The display can be blanked

out without powering down. Refer to the

blank sign section for details.

Press the [Enter/Edit] key to edit the auto

•

dimming max intensity. This is the maximum

intensity that the display will use in full-bright

modes (during daylight hours.)

• Press [Clear] to keep the current auto

dimming maximum setting

Press the up or down arrow key <↑ ↓> to

•

modify the current intensity of the display

(Note: The DataMaster must be connected

to the display)

• Press [Enter] to accept this intensity. If

manual dimming mode is selected, this will

be the new intensity for the display. If the

automatic dimming mode is selected, the

display will illuminate in full-bright mode,

which is the maximum intensity level.

38 RC-100 Controller

Page 47

DIMMING

BLANK SIGN ↓

BLANK THE

SIGN?

<ENT> YES

<CLR> NO

Press [Enter] to accept this option.

•

The next LCD dialog will ask whether to

•

blank the screen or escape. The LCD

toggles between Yes and No. Pressing

[Clear] resumes normal operation; pressing

[Enter] actually blanks the sign.

RC-100 Controller 39

Page 48

Page 49

Section 9: POS Interface Installation and

Operation

A Point of Sale (POS) interface option is available with DataMaster LED Petroleum Price Displays.

Displays with this option automatically update when product prices are changed in the POS.

Displays with the POS interface option will be supplied with a POS Interface Kit (see table below for

part numbers).

9.1 System Installation

P.O.S. Interface

Type

Gilbarco G-Site 0A-1279-0400 0A-1279-0402 200195

Gilbarco PAM 1000 0A-1279-0452 0A-1279-0229 224628

Allied 0A-1279-0443 0A-1279-0144 215840

Verifone Sapphire 0A-1279-0146 0A-1279-0145 200195

Interface Kit

Required

Interface Cable Riser Diagram

1. Ensure that the P.O.S. system has a price sign output port. Refer to the P.O.S. manuals to

enable and/or configure the port.

2. Locate the following parts:

a) POS Interface Kit containing:

i) DataMaster 100 w/POS option (0A-1196-0133)

ii) Wall mounting bracket for DM-100 (0M-200082)

iii) POS Interface Cable (refer to table 7-1 for part number)

iv) POS riser diagram (refer to table 7-1)

b) 10′ cable, DB9 to DB9 (W-1267)

c) Indoor junction box (0A-1196-0099) for direct wired installations or Radio Interface

junction box (0A-1279-0161) for wireless installations.

d) Wallpack transformer (T-1118).

3. Mount the wall bracket (0M-200082) to provide convenient storage for the DM-100

controller. When using the wall-mount bracket for the DM-100, ensure that clearance is

sufficient above the bracket to allow the DM-100 to be removed from the bracket with

both cables attached. Also ensure that the POS interface cable will reach from the DM100 location to the price sign output of the POS. Fasten the wall-mount bracket if desired.

The DM-100 can be permanently attached to the wall mounting bracket by removing the

two screws in the bottom edge of the DM-100, sliding the DM-100 into the wall mount

bracket, and reinstalling the screws through the slots in the bottom bracket flange.

4. Mount the junction box (refer to step 1.c. above). Ensure that the DB9 to DB9 cable (W-

1267) will reach from the DM-100 to the junction box.

5. Complete junction box to sign or junction box to radio wiring as shown on the riser

diagram (drawing 200195).

6. Attach the P.O.S interface cable to the P.O.S price sign port. Coil any excess cable and

cable-tie it out of the way.

POS Interface 41

Page 50

7. Attach the DB9 to DB9 cable (W-1267) to the junction box as shown on the riser diagram.

Coil any excess cable and cable-tie it out of the way.

8. Plug the transformer (T-1118) into an outlet and connect the output to the power jack on

the j-box.

9. Verify that the DM-100 is running. Send a price change to the sign to check

communications between the sign and the DM-100.

9.2 Configuring the DM-100 for Gilbarco G-Site Interface

Preparation

The DM-100 function must be set to “GAS PRICE.” The current function of the

DM-100 is displayed during power up. To change the function, cycle power to the DM-100,

and press the <SET FUNCTION> key when prompted.

Configuration

1. Press the [Menu] key and use the <Ï> and <Ð> keys to scroll to the POS SETTINGS

menu item.

POS SETTINGS

ENT TO MODIFY ↓↑

Press [Enter].

2. Select the POS type by using the <Ï> and <Ð> keys to scroll to GILBARCO GSITE.

POS INTERFACE

GILBARCO GSITE ↓↑

Press [Enter].

3. Each price in the Gilbarco G-Site is uniquely identified by ‘price category’. Each price

category corresponds to the price assigned to a particular grade/service level/price

level. Use the menu shown below to configure which price category you would like

displayed on each line of the display.

PRICE CATEGORY

LINE 1 : 1 ↓↑

Use the <Ï> and <Ð> keys to select a price category to be displayed on line 1 of the sign.

Press [Enter] to accept the setting. Pressing [Enter] when the price category displayed is

<None> will cause the price sign to ignore POS data for this line. (This may be useful for

configuring some lines of a price sign to receive manual price changes only).

4. Select a price category to be displayed on each line of the sign, and press [Menu], or

[Esc/Clear] when finished. The POS interface configuration is complete.

42 POS Interface

Page 51

9.3 Configuring the DM-100 for Allied Interface

Preparation

The DM-100 function must be set to GAS PRICE. The current function of the

DM-100 is displayed during power up. To change to function, cycle power to the DM-100,

and press the [Set Function] key when prompted.

Configuration

1. Press the [Menu] key and use the <Ï> and <Ð> keys to scroll to the POS SETTINGS

menu item.

POS SETTINGS

ENT TO MODIFY ↓↑

Press [Enter].

2. Select the POS type by using the <Ï> and <Ð> keys to scroll to ALLIED.

POS INTERFACE

ALLIED ↓↑

Press [Enter].

3. Each price in Allied is uniquely identified by grade, service level, and price level. Use the

<Ï> and <Ð> keys to select a grade for the line. If a line is not used, select [None

Displayed].

Press [Enter].

4. Use the <Ï> and <Ð> keys to select a service level for the line.

Press [Enter].

5. Use the <Ï> and <Ð> keys to select a price level (cash or credit).

GRADE ON LINE 1

GRADE 1 ↓↑

SERVICE LINE 1

SELF SERVE ↓↑

PRICE LINE 1

CASH PRICE ↓↑

Press [Enter].

6. Select a grade/service level/price level for each line of the sign, and press [Menu] or

[Esc/Clear] when finished. The POS interface configuration is complete.

POS Interface 43

Page 52