Page 1

DataMaster™ Outdoor LED

Gasoline Price Displays

DF-1024/DF-1026 Series

DF-1200 Series

Installation and Operation Manual

ED-15177 Rev 2 – 27 April 2005

332 32nd Ave PO Box 5128 Brookings SD 57006

Tel 605-697-4036 or 877-605-1113 Fax 605-697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

Page 2

Page 3

ED-15177

Product 1319

Rev 2 – 27 April 2005

DAKTRONICS, INC.

Copyright © 2004-2005

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered by

the copyrights hereon may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

DataMaster™ and DataTime® are trademarks of Daktronics, Inc. Other trademarks used in this manual are

the property of their respective owners.

Page 4

Page 5

Reproduction Reference

ED-15177 – P1319

DataMaster Gasoline Price Displays

1. This page is for reproduction reference only and will not be included in the manual.

2. This manual is to be copied on FRONT AND BACK PAGES –8 ½ x 11 paper.

3. Note: The first and second page, cover page and copyright page, use the front of the page (blank

on back). Section heading pages always start on a new page; they never start on the back of

another page.

4. Insert the drawings into Appendix A. Use the drawing list in Appendix A to print and arrange the

drawings. Print C-size as B-size.

5. Insert ED-13481 within Appendix B.

6. Insert ED-13965 within Appendix C.

7. Insert ED-13960 within Appendix D.

8. Use a blue window cover and a blue back.

9. Punch all pages, window cover and back cover along the left edge and bind with a binder.

10. Please direct questions and suggestions to Engineering Support.

Page 6

Page 7

Table of Contents

Section 1: Introduction..................................................................................... 1-1

1.1 Safety Precautions.......................................................................................1-3

1.2 Network Concepts.......................................................................................1-3

Current Loop........................................................................................1-3

Radio ....................................................................................................1-3

Modem .................................................................................................1-4

1.3 Product Overview........................................................................................1-4

1.4 Component Identification............................................................................1-5

1.5 Daktronics Nomenclature............................................................................1-6

Section 2: Mechanical Installation.................................................................. 2-1

2.1 Mechanical Installation Overview...............................................................2-1

2.2 Lifting the Display.......................................................................................2-3

Section 3: Electrical Installation ..................................................................... 3-1

3.1 Preparing for Power/Signal Connection......................................................3-1

3.2 Power and Grounding Connections.............................................................3-1

Power....................................................................................................3-1

Grounding ............................................................................................3-3

3.3 Lightning Protection....................................................................................3-4

3.4 Signal Connection .......................................................................................3-4

Current Loop (Direct)...........................................................................3-5

Radio (Direct).......................................................................................3-7

Modem (Indirect) .................................................................................3-9

Host/Client Definitions and Address Settings....................................3-10

Section 4: Maintenance and Troubleshooting............................................... 4-1

4.1 Cabinet Specifications.................................................................................4-1

4.2 Component Location and Access................................................................4-1

4.3 Service and Diagnostics ..............................................................................4-2

Replacing a Digit..................................................................................4-2

Replacing a Digit Segment...................................................................4-3

Segmentation and Digit Designation....................................................4-4

Replacing an LED Driver .....................................................................4-4

Replacing a Signal Surge Board...........................................................4-6

Replacing a Modem..............................................................................4-7

4.4 Light Sensor Location .................................................................................4-8

4.5 Troubleshooting...........................................................................................4-9

Power On Self-Test:...........................................................................4-11

4.6 Replacement Parts .....................................................................................4-11

4.7 Daktronics Exchange and Repair and Return Programs............................4-14

Table of Contents i

Page 8

Section 5:

Appendix A: Reference Drawings ......................................................................A-1

Gas Price Display Operation..........................................................5-1

5.1 DataMaster 100 Overview...........................................................................5-1

5.2 DataMaster™ Insert and Code......................................................................5-1

5.3 Gas Price Display Operation .......................................................................5-2

Gas Price Display Startup.....................................................................5-2

Menu Items...........................................................................................5-4

Gas Price Controller Operation ............................................................5-4

Modifying Price Line Settings..............................................................5-5

Edit Price Line 1-5................................................................................5-5

LED Test ..............................................................................................5-6

Modem Settings....................................................................................5-6

Display Sequence .................................................................................5-7

Set Time................................................................................................5-7

Dimming...............................................................................................5-8

Radio Settings.......................................................................................5-9

5.4 POS Installation and Interface...................................................................5-10

Hardware Installation:........................................................................5-10

Configuring the DM100 for Gilbarco G-Site Interface......................5-11

Changing Prices:.................................................................................5-12

Appendix B: DataMaster Frequently Asked Questions (FAQ) ........................B-1

Appendix C: DataMaster Gasoline Price Quick Installation Reference.......... C-1

Appendix D: DataMaster Gasoline Price Quick Start Reference..................... D-1

ii Table of Contents

Page 9

List of Figures

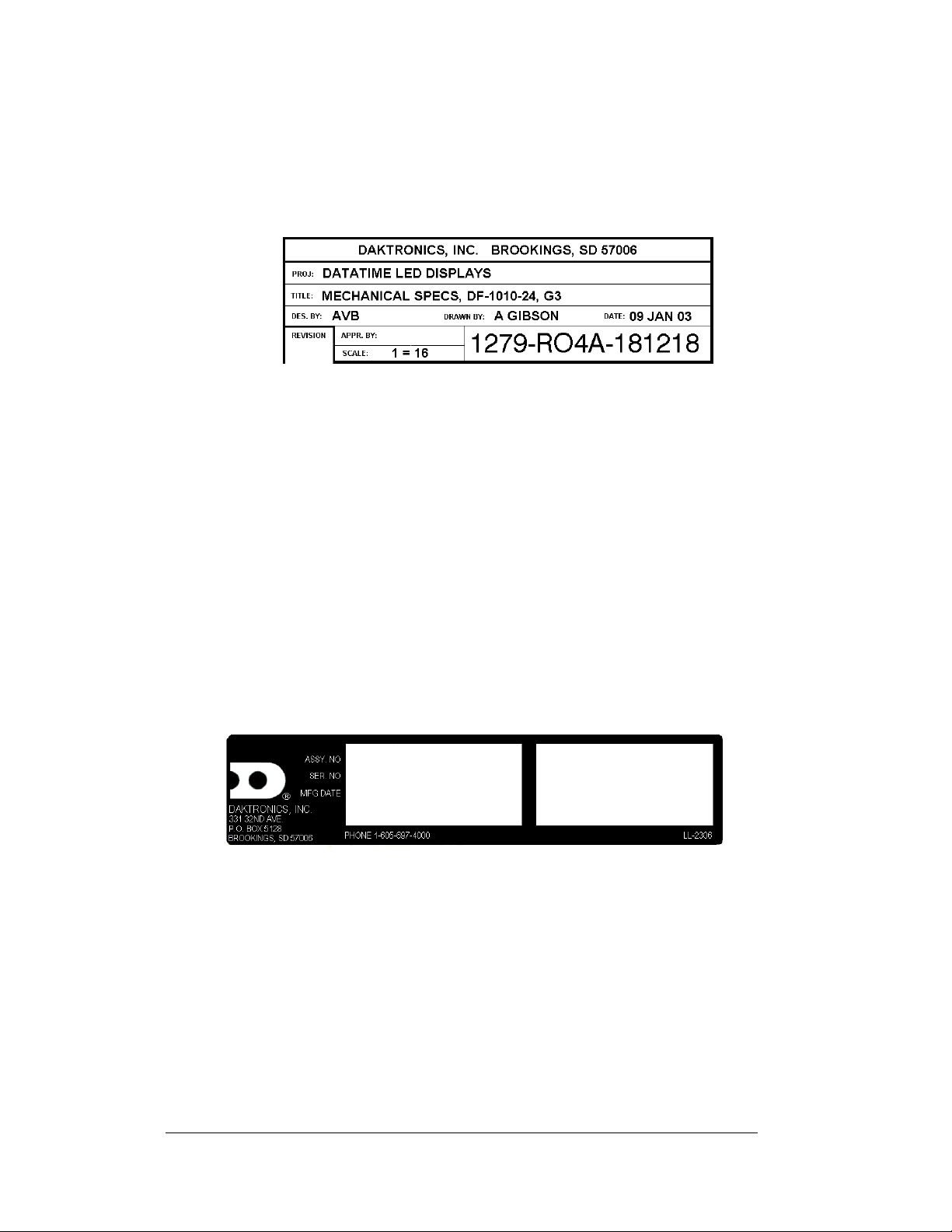

Figure 1: Daktronics Drawing Label .................................................................................. 1-2

Figure 2: Display Identification Label................................................................................1-2

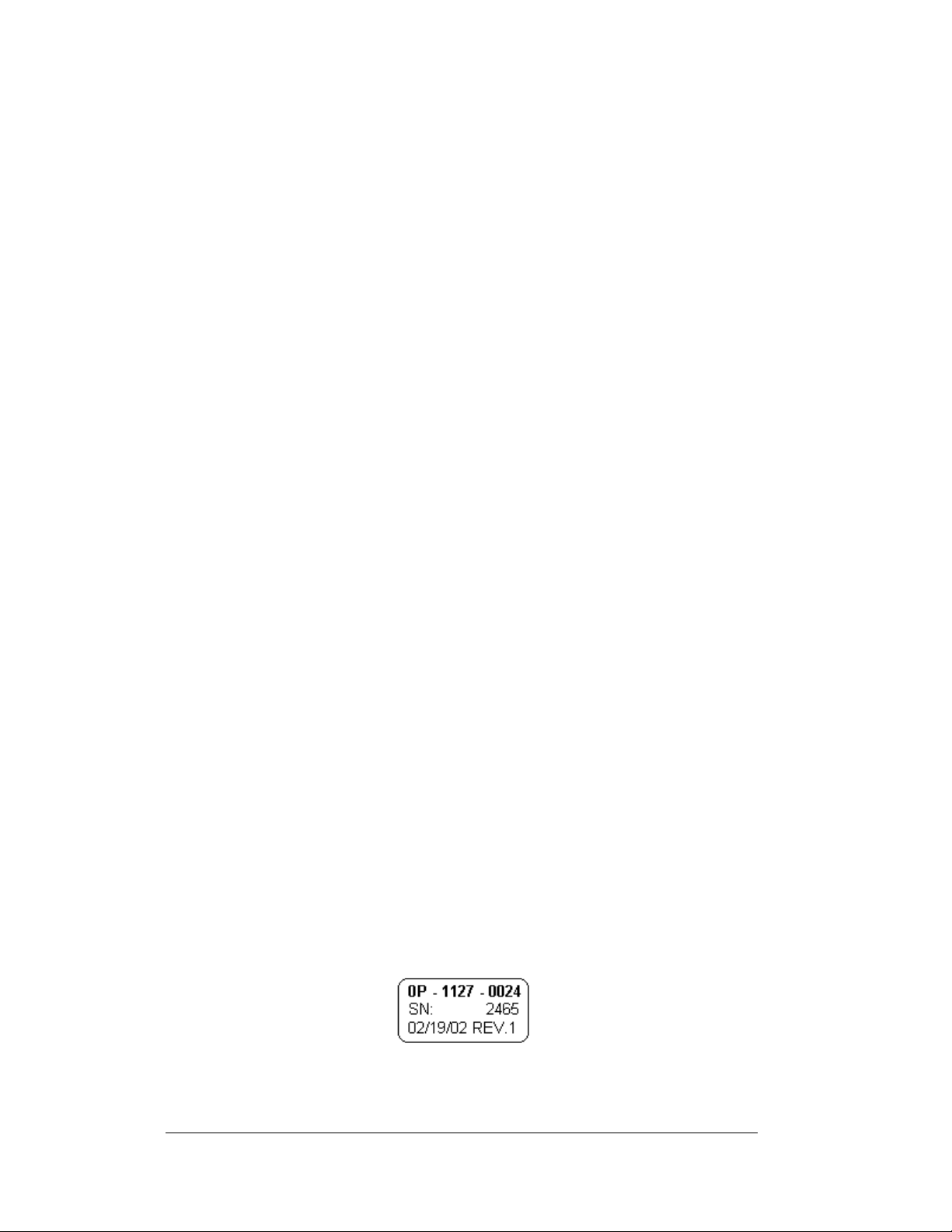

Figure 3: Typical Label.......................................................................................................1-6

Figure 4: Lifting the Display...............................................................................................2-3

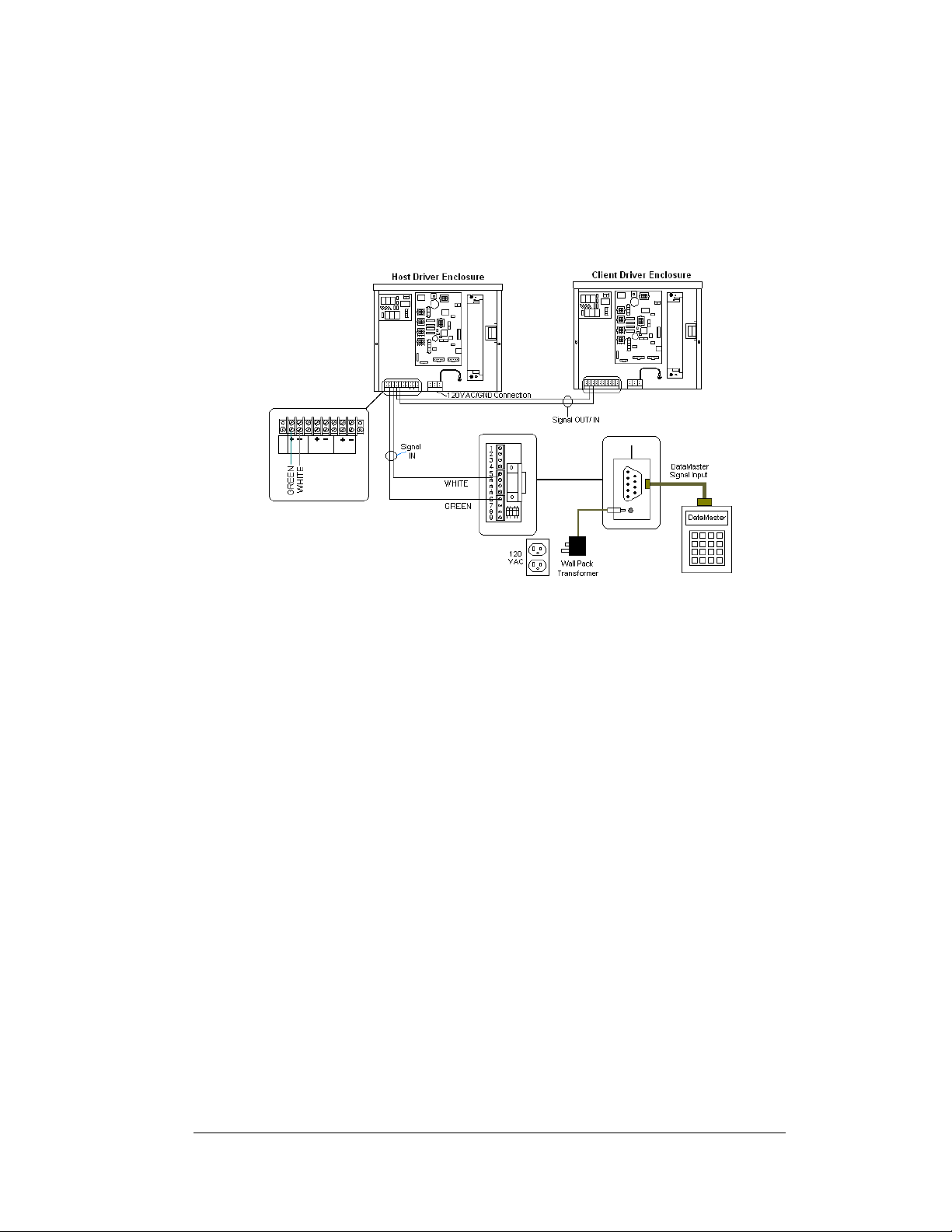

Figure 5: DataMaster Driver Enclosure with 4-Column Driver ......................................... 3-4

Figure 6: Direct, Current Loop Layout...............................................................................3-5

Figure 7: Direct Current Loop Connection.........................................................................3-6

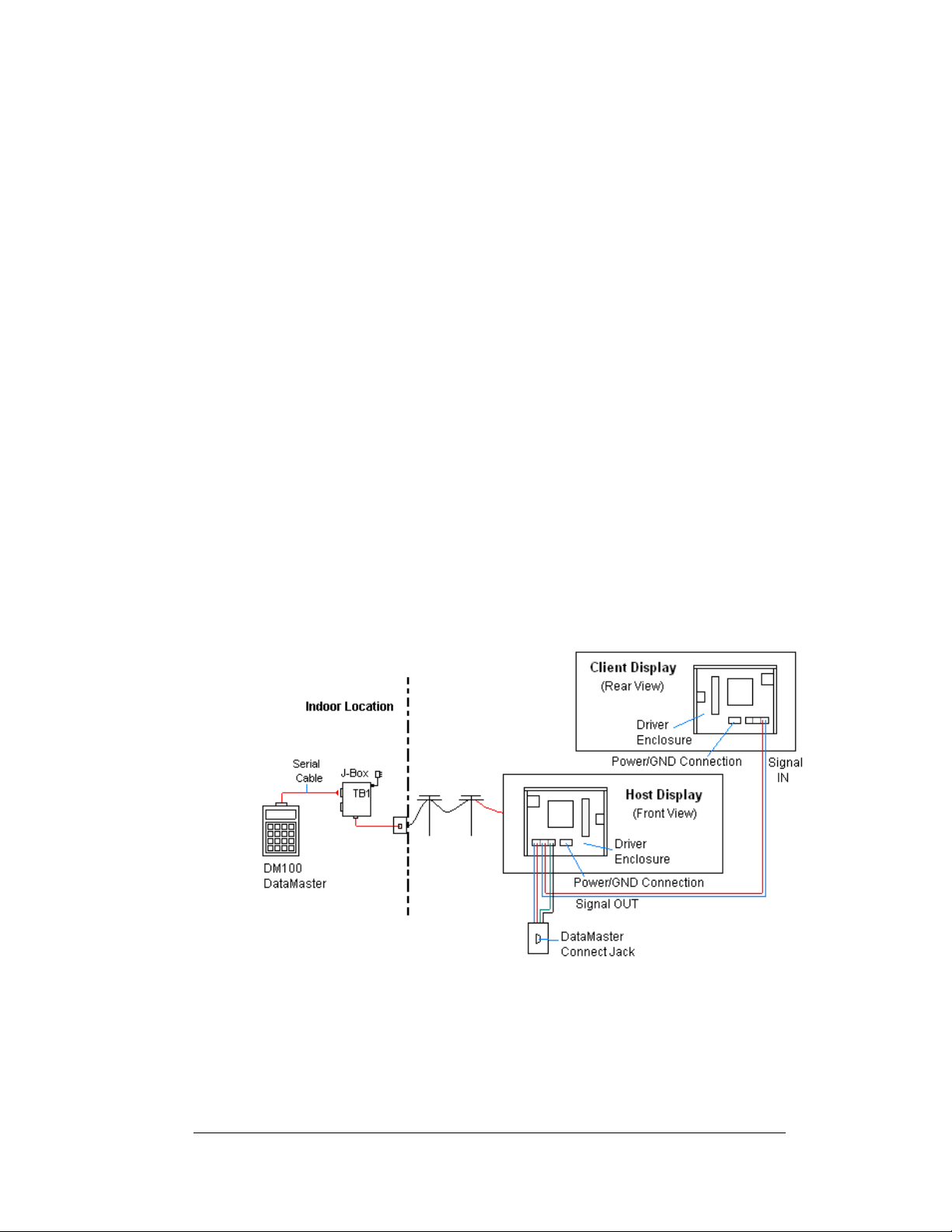

Figure 8: Direct Connection from Indoor Location............................................................3-7

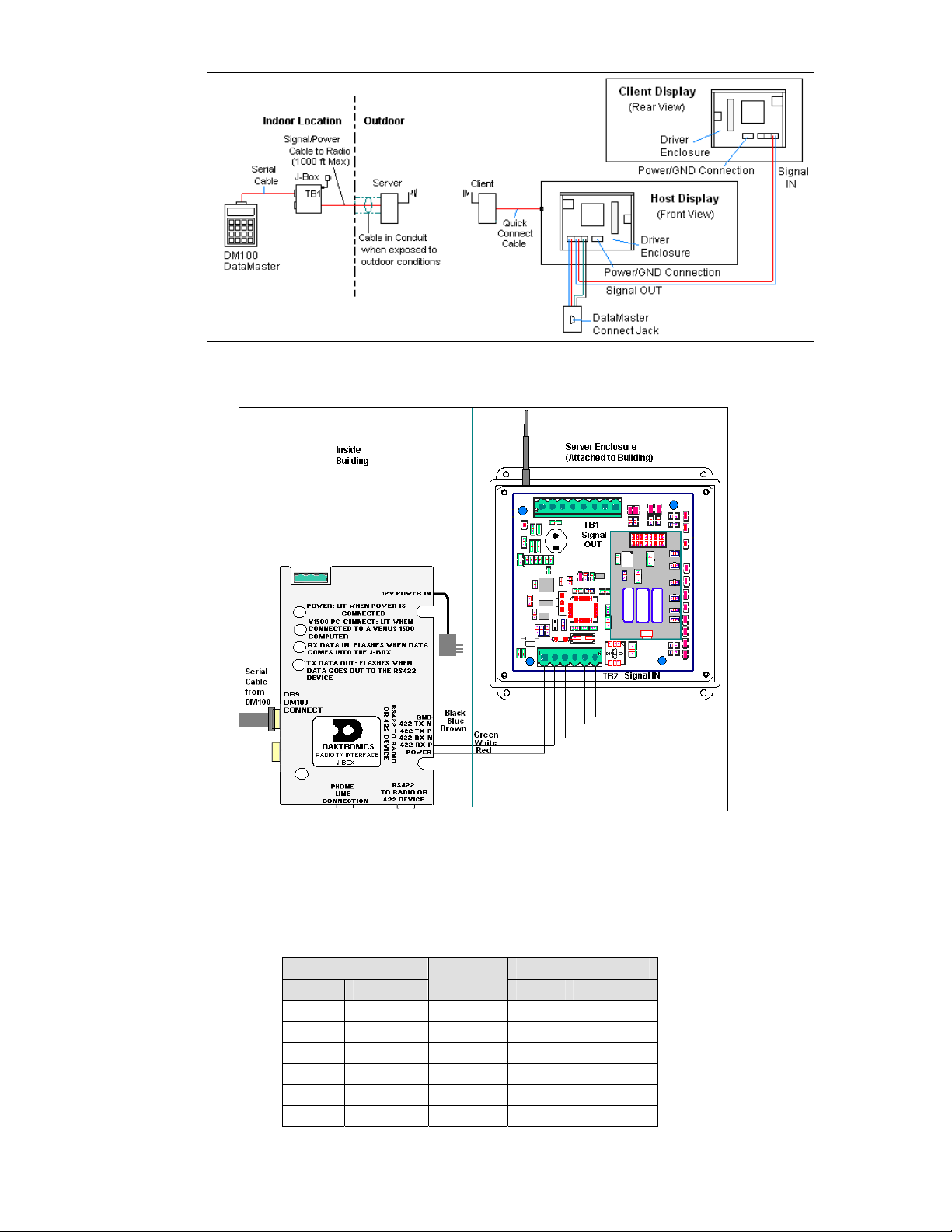

Figure 9: Radio Controlled Display Layout........................................................................3-8

Figure 10: Direct Current Loop Connection.......................................................................3-8

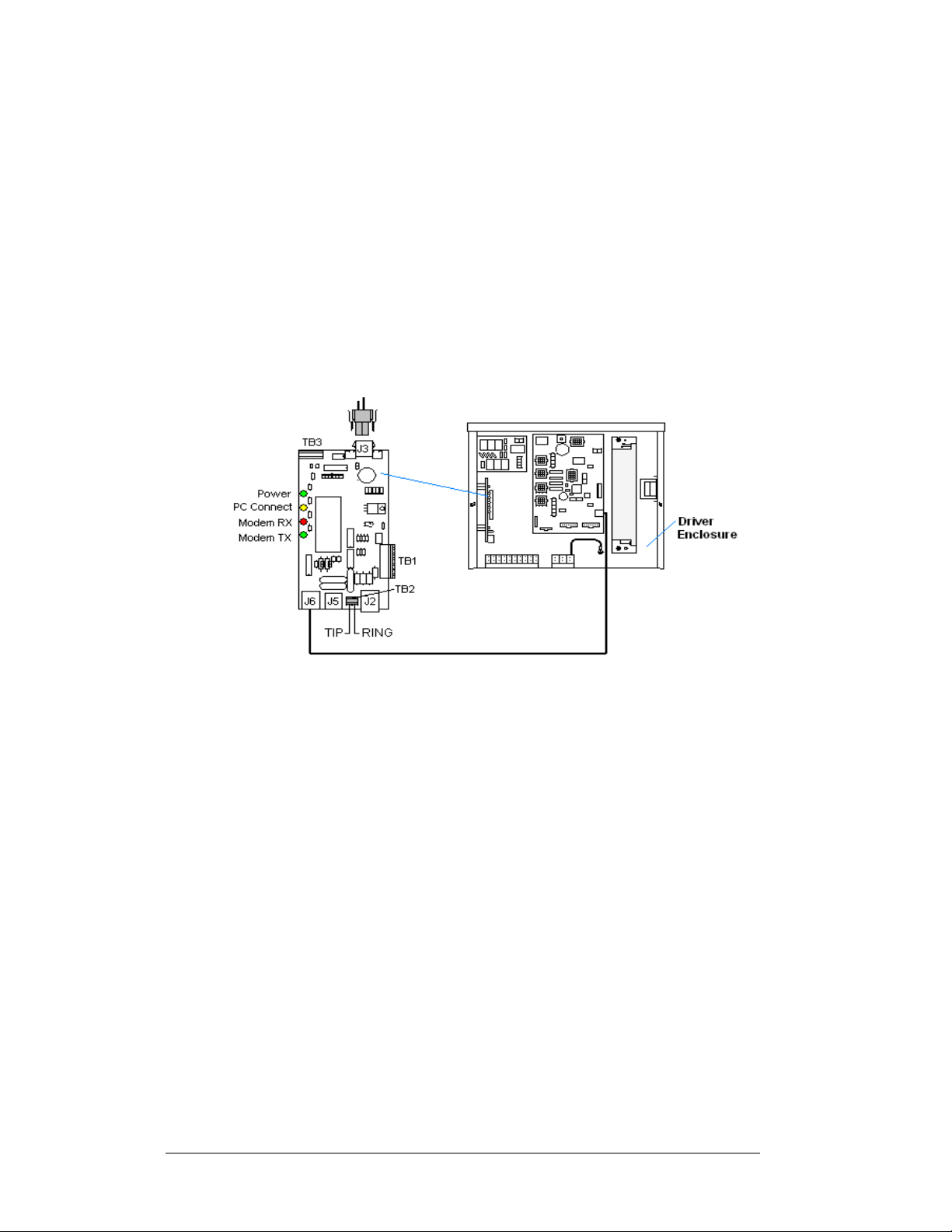

Figure 11: Modem Controlled Display Layout...................................................................3-9

Figure 12: Phone line Connection to Display Modem...................................................... 3-10

Figure 13: Host, Signal Out to Client, Signal In...............................................................3-11

Figure 14: Common Address Settings..............................................................................3-12

Figure 15: DataMaster Gas Price Display with Door Panels Open ....................................4-2

Figure 16: Digit Assembly..................................................................................................4-3

Figure 17: Segmented Digit Panel......................................................................................4-3

Figure 18: Digit Designation...............................................................................................4-4

Figure 19: 4-column Digit Driver.......................................................................................4-5

Figure 20: Signal Surge Suppression Board.......................................................................4-7

Figure 21: Modem Board....................................................................................................4-7

Figure 22: Internal Light Sensor.........................................................................................4-8

Figure 23: DataMaster 100 .................................................................................................5-1

Figure 24: DataMaster 100 Insert LL-2551........................................................................5-2

List of Figures i

Page 10

Page 11

Section 1: Introduction

This manual explains the installation, maintenance and troubleshooting of the Daktronics

DataMaster™ DF-1024/DF-1026 and DF-1200 LED Gasoline Price Displays. For questions

regarding the safety, installation, operation, or service of this system, please refer to the

telephone numbers listed on the cover page of this manual.

This manual is divided into 9 sections: Introduction, Mechanical Installation, Electrical

Installation, Maintenance and Troubleshooting, Gas Price Display Operation, Appendix A,

Appendix B, Appendix C and Appendix D.

• Introduction covers the basic information needed to make the most of the rest of

this manual – take time to read the entire introduction as it defines terms and

explains concepts used throughout the manual.

• Mechanical Installation provides general guidance on display mounting.

• Electrical Installation gives general guidance on terminating power and signal

cables at the display.

• Maintenance and Troubleshooting addresses such things as removing basic

display components, troubleshooting the display, performing general maintenance

and exchanging display components.

• Gas Price Display Operation section gives a product overview of the DataMaster

controller used to program the Gas Price display.

• Appendix A lists the drawings referenced within this manual.

• Appendix B lists the Frequently Asked Questions when operating this display.

• Appendix C provides information and drawings as a quick reference for installing

the display.

• Appendix D contains a quick reference to the DataMaster when operating the Gas

Price displays.

Daktronics identifies manuals by an ED number located on the cover page of the manual. For

example, this manual would be referred to as ED-15177.

Listed below are a number of drawing types commonly used by Daktronics, along with the

information each is likely to provide.

• System Riser Diagrams: overall system layout from DataMaster control location to

display.

• Electrical and Mechanical Speciation Drawings: driver enclosure locations,

mounting information, display dimensions; power and signal entrance points, and

access method (front or rear).

• Schematics: power wiring, signal wiring, panel board or power termination panel

assignments, signal termination panel assignments, and transformer assignments.

Introduction 1-1

Page 12

Figure 1, below, illustrates the Daktronics drawing label. The drawing number is

located in the lower-right corner of each drawing. Listing the last set of digits and

the letter preceding them identifies drawings in the manual. In the example below,

the drawing would be referred to as Drawing A-181218. Reference drawings are

inserted in alphanumeric order in Appendix A.

Figure 1: Daktronics Drawing Label

All references to drawing numbers, appendices, figures, or other manuals are

presented in bold typeface, as shown below.

“Refer to Drawing A-181218 for the display dimensions.”

Additionally, drawings referenced within a particular section are listed at the

beginning of that section as shown in the following example:

Reference Drawing:

Mechanical Specs, DF-1010-24, G3.....................Drawing A-181218

The model numbers of a Daktronics display can be found on the ID label on the

display. The label will be similar to the one shown in

Figure 2. When calling

Daktronics Customer Service, please have this information available to ensure that

your request is serviced as quickly as possible.

Figure 2: Display Identification Label

Daktronics displays are built for long life and require little maintenance. However,

from time to time, certain display components may need replacing. The

Replacement Parts List in Section 4-11 provides the names and part numbers of

components that may require replacement during the life of the display. Most display

components have a white label that lists the part number. The component part

number is in the following format: 0P-____-____ (component) or 0A-____-____

(multi-component assembly).

Following the Replacement Parts List is an explanation of Daktronics Exchange

and Repair and Return Programs. Refer to these instructions if any display

component needs replacement or repair.

1-2 Introduction

Page 13

1.1 Safety Precautions

Important Safeguards:

1. Read and understand these instructions before installing your

display.

2. Do not drop the controller or allow it to get wet.

3. Properly ground the display with a ground rod at the sign

location.

4. Disconnect power when the display is not in use.

5. Disconnect power when servicing the display.

6. Do not modify the display structure or attach any panels or

coverings without the express written consent of Daktronics,

Inc.

1.2 Network Concepts

The concept of using LED displays as a cost effective, high impact method of

communication is rapidly growing throughout many industries and businesses. The

common thread of most requests is a means of programming and controlling the

displays in a variety of ways.

There are three communication methods available: Current Loop, Radio, and

Modem.

Current Loop

The DataMaster controller connects to the Gas Price Display either from a j-box

located outside near the display or from an indoor location. The communication

method is current-loop to the host display, and from the host to the client. Currentloop is a standard communication method that uses a maximum cable length of 600

meters (approximately 2000 feet). Refer to Section 3 for additional information and

connections.

Radio

The radio network is a standard communication method that uses radio waves at

high frequencies to transmit signal. The radio network has a maximum distance of

450 meters (approximately 1,500 feet). A nearly straight line-of-sight path must be

maintained between the Server Radio connected to the DataMaster controller,

through a signal converter, and the Client Radio connected to the display. Refer to

Section 3 (Electrical Installation) and the Section 5 (Gas Price Display Operation)

for additional information.

Introduction 1-3

Page 14

Modem

The modem is a standard communication interface that utilizes standard phone

transmission lines. The phone company assigns each phone line a number that the

modem uses to communicate between the DataMaster and display. Each modem

network needs to have a dedicated phone line assigned to it. Refer to Section 3

(Electrical Installation) and the Section 5 (Gas Price Display Operation) for

additional information.

1.3 Product Overview

DataTime and DataMaster displays are part of a family of Daktronics digit products

designed for easy installation, readability and reliability.

The DataTime/DataMaster Series includes:

• Gasoline Price Displays: gas price signs with three standard digits,

decimal, and

• Rate Displays: two- or four-digit signs, typically used to display

hotel/motel room rates or commodity prices.

• Lottery Displays: three-digit signs typically used to display lottery

jackpots.

• Parking Garage Displays: four-digit display used for parking locations

requiring a DataMaster, switch inputs or third-party software.

• Event Counters: These displays are typically used to count to a designated

goal. They will count either up or down, and can be up to nine digits long.

• Time & Temperature Displays: Automatic Time & Temp signs capable of

displaying temperatures in Fahrenheit or Celsius (three digits, degree

symbol, and F and C character) and 12- or 24-hour time.

The DataMaster series includes gasoline, rate and parking displays, along with

lottery and event counters. The DataTime series name is used for time and

temperature displays only.

These displays have the following features:

• These displays use LEDs to illuminate their numeric digits.

• Power usage for individual displays in this series is a maximum 300 W. All

models have a 120 V power requirement.

• All DataMaster displays are configured with red, amber or green LEDs.

• DataMaster cabinets are constructed of heavy-gauge aluminum.

• Digit faceplates are black, and they are set directly into the surface of the

display.

• Mounting weights and dimensions for each model are listed in Section 2 of

this manual.

• The DataMaster outdoor LED displays have been designed for use with a

DataMaster

for display control. Section 5 of this manual provides operating

instructions.

9

/

fraction.

10

™

100 hand-held controller. The device uses a keyboard insert

1-4 Introduction

Page 15

The DataMaster model numbers are described as follows: DF-102X-HH-C

DF-102X =

HH

C

Outdoor Digit Display (1024 full cabinet with top backlit ID panel

or 1026 full cabinet with left side backlit product ID panel)

=

Digit height in inches (10, 13, 18, 24, 36, 48 and 60)

=

LED Color- R (Red), A (Amber), G (Green - 13”, 18”, and 24”)

1.4 Component Identification

The following list includes some of the more commonly used terms when

referring to these displays. Because Daktronics occasionally alters standard design

to meet customer needs, the actual display design may vary slightly from the

illustrations below.

This is only a brief overview. Refer to Section 4 for additional information on

maintaining the various display components.

Client: The client display contains a client driver that receives signal from the

“host” driver on the Signal IN terminals. These drivers can re-drive signal to other

client drivers.

DataMaster Controller (DM100): The handheld keyboard-like device used to set

the time, date, hold times, dimming etc. on the Gas Price display. See Section 5 for

more information on the DataMaster controller.

Display Address: The display address is an identification number assigned to each

driver in a network. The address is set using an 8-position binary switch on the

driver board. For single-line signs such as a Time & Temp display, the address will

typically be “1”. For Gas Price displays, the top display is often set to address “1 ”

and the others are set to “2”, “3” etc. The address will be displayed each time the

display powers up.

Digit Circuit Board: The LEDs are mounted to a circuit board, which mounts to the

back of a digit panel. Problems with individual digits, segments or LEDs may

require accessing or replacing this board.

Host/Primary: The host display contains the host driver which relays signal directly

from the DataMaster controller on its Signal IN terminals. It is the only driver

connected to the temperature/light sensor. The Signal OUT terminals are used to

connect to the client driver. The host driver is selected by inserting the protocol 4plug into the protocol jack.

LED (light emitting diode): LEDs are high-intensity, low-energy lighting units.

Introduction 1-5

Page 16

Mirror/slave: receives power and a digit harness from the master but does not have

a driver.

Power Supply: Converts AC line voltage from the load center to low DC voltage

for one or more digit circuit boards.

Protocol plug: The protocol 4-plug is inserted in the 5-pin protocol jack to select the

host driver for a set of host-client displays.

1.5 Daktronics Nomenclature

To fully understand some Daktronics drawings, such as schematics, it is necessary to

know how various components are labeled in those drawings. You will find this

information useful when trying to communicate maintenance or troubleshooting

efforts.

The following labeling formats might be found on various Daktronics drawings:

• “TB _ _” denotes a termination block for power or signal cable.

• “E _ _” denotes a grounding point.

• “J _ _” denotes a power or signal jack.

• “P _ _” denotes a power or signal plug for the opposite jack.

Finally, Daktronics part numbers are commonly found on drawings. Those part

numbers can be used when requesting replacement parts from Daktronics Customer

Service. Take note of the following part number formats. (Not all possible formats

are listed here.)

• “0P- _ _ _ _- _ _ _ _” denotes an individual circuit board, such as a driver

board.

• “0A-_ _ _ _ - _ _ _ _” denotes an assembly, such as a circuit board and the

plate or bracket to which it is mounted. A collection of circuit boards

working as a single unit may also carry an assembly label.

• “W- _ _ _ _ ” denotes a wire or cable. Cables may also carry the assembly

numbering format in certain circumstances. This is especially true for

ribbon cables.

Most circuit boards and components within this display carry a label that lists the

part number of the unit. If a circuit board or assembly is not listed in the

Replacement Parts List in Section 4.6, use the label to order a replacement. A

typical label is shown in

Figure 3. The part number is in bold.

1-6 Introduction

Figure 3: Typical Label

Page 17

g

(

Section 2: Mechanical Installation

Note: Daktronics does not guarantee the warranty in situations where the display is

not in a constant environment.

Daktronics engineering staff must approve any changes that may affect the weathertightness of the display. If any modifications are made, detailed drawings of the

changes must be submitted to Daktronics for evaluation and approval, or the

warranty may be void.

Daktronics is not responsible for installations of structural integrity of support

structures done by others. It is the customer’s responsibility to ensure that a

qualified structural engineer approves the structure and any additional hardware.

2.1 Mechanical Installation Overview

Mechanical installation typically consists of mounting the display and any

accompanying panels to the support structure.

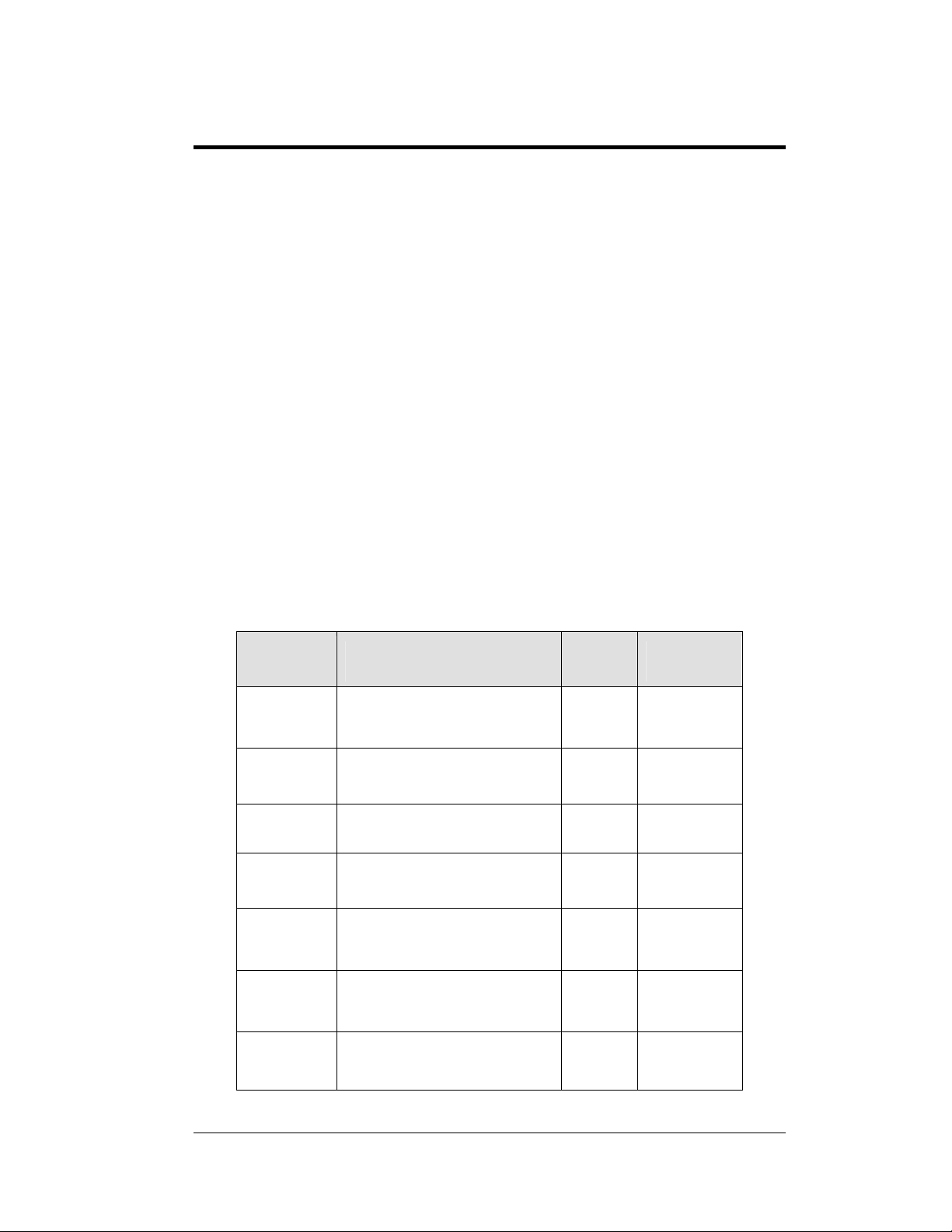

The table below shows all of the weights and dimensions for each model in this

series. Models are listed in order by digit size

Full Cabinet Models with backlit product ID panel above digits

Dimensions and Weight

Model

DF-1024-10

DF-1024-13

DF-1024-18 H3’-0", W5’-0", D6"

(914 mm, 1524 mm, 152 mm)

DF-1024-24

DF-1024-36

(1219 mm, 1829 mm, 152 mm)

(1676 mm, 2438 mm, 203 mm)

Dimensions

Height, Width, Depth

H1’-9", W3’-0", D6"

(533 mm, 914 mm, 152 mm)

H2’-2", W3’-6", D6"

(660mm, 1067 mm, 152 mm)

H4’-0", W6’-0", D6"

H5’-6", W8’-0", D8"

Weight Digit Size

35 lb

16 kg

45 lb

20 kg

80 lb

36 k

120 lb

54 kg

190 lb

73 kg

10"

(254 mm)

13"

(330 mm)

18"

457 mm)

24"

(610 mm)

36"

(914 mm)

DF-1024-48

DF-1024-60 H9’-0", W14’-0", D8"

H7’-0", W11’-0", D8"

(2134 mm, 3353 mm, 203 mm)

(2743 mm, 4267 mm, 203 mm)

320 lb

145 kg

590 lb

268 kg

48"

(1219 mm)

60"

(1524 mm)

Electrical Installation 2-1

Page 18

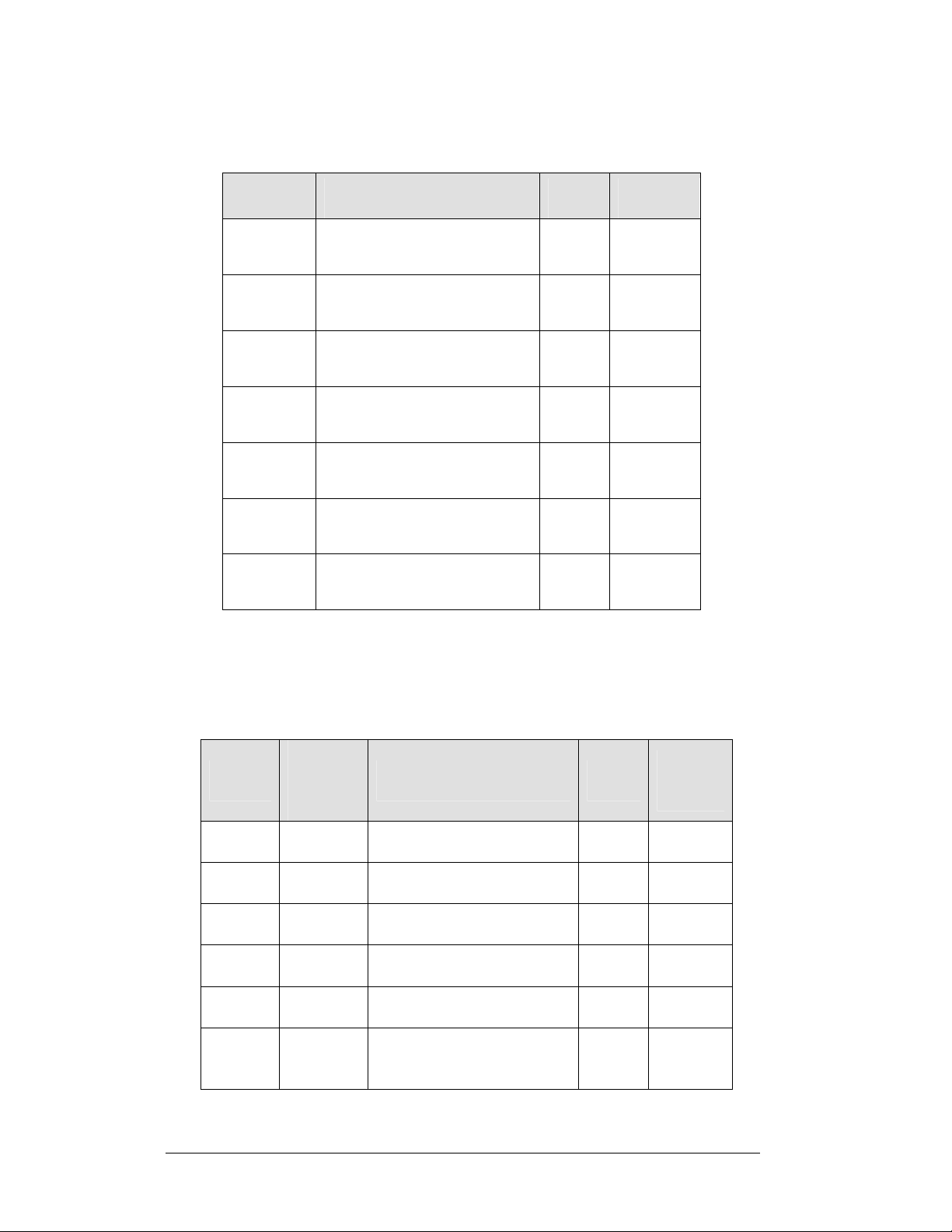

Full Cabinet Models with backlit product ID panels left of digits

Dimensions and Weight

Model

DF-1026-10

DF-1026-13

Dimensions

H1’-3", W5’-0", D6"

(381 mm, 1524 mm, 152 mm)

H1’-6", W6’-0", D6"

(457 mm, 1829 mm, 152 mm)

Weight Digit Size

40 lb

18 kg

50 lb

23 kg

10"

(254 mm)

13"

(330 mm)

DF-1026-18 H2’-0", W8’-0", D6"

(610 mm, 2438 mm, 152 mm)

80 lb

36 kg

18"

(457 mm)

DF-1026-24

DF-1026-36

DF-1026-48 H4’-6", W16’-6", D8"

H2’-6", W10’-0", D6"

(762 mm, 3048 mm, 152 mm)

H3’-6", W13’-0", D8"

(1067 mm, 3962 mm, 203 mm)

(1372 mm, 5029 mm, 203 mm)

120 lb

54 kg

190 lb

73 kg

320 lb

145 kg

24"

(610 mm)

36"

(914 mm)

48"

(1219 mm)

DF-1026-60

H6’-0", W20’-0", D8"

(1829 mm, 6096 mm, 203 mm)

590 lb

268 kg

60"

(1524 mm)

Full Cabinet Models with backlit product ID panels below digits, or on the

left- Dimensions and Weight

# of

Model

products

displayed

Dimensions

Weight

DF-1202

DF-1203

DF-1204

DF-1205

DF-1206

DF-1207

2

4

2

3

3

2

H3’-3", W9’-4. 50", D6"

(991 mm, 2858 mm, 152 mm)

H6’-0", W7’-7 .20", D6"

(1829 mm, 2316 mm, 152 mm)

H2’-3", W7’-7. 20", D6"

(686 mm, 2316 mm, 152 mm)

H2’-3", W9’-4. 50", D6"

(686 mm, 2858 mm, 152 mm)

H6’-0", W9’-4. 50", D8"

(1829 mm, 2858 mm, 203 mm)

H5’-0", W9’-4. 50", D8"

(1524 mm, 2858 mm, 203 mm)

160 lb

73 kg

240 lb

109 kg

100 lb

45 kg

110 lb

50 kg

300 lb

136 kg

250 lb

113 kg

(457 mm)

(330 mm)

(254 mm)

(254 mm)

(457 mm)

(610 mm)

Digit

Size

18”

13”

10”

10”

18”

24”

2-2 Electrical Installation

Page 19

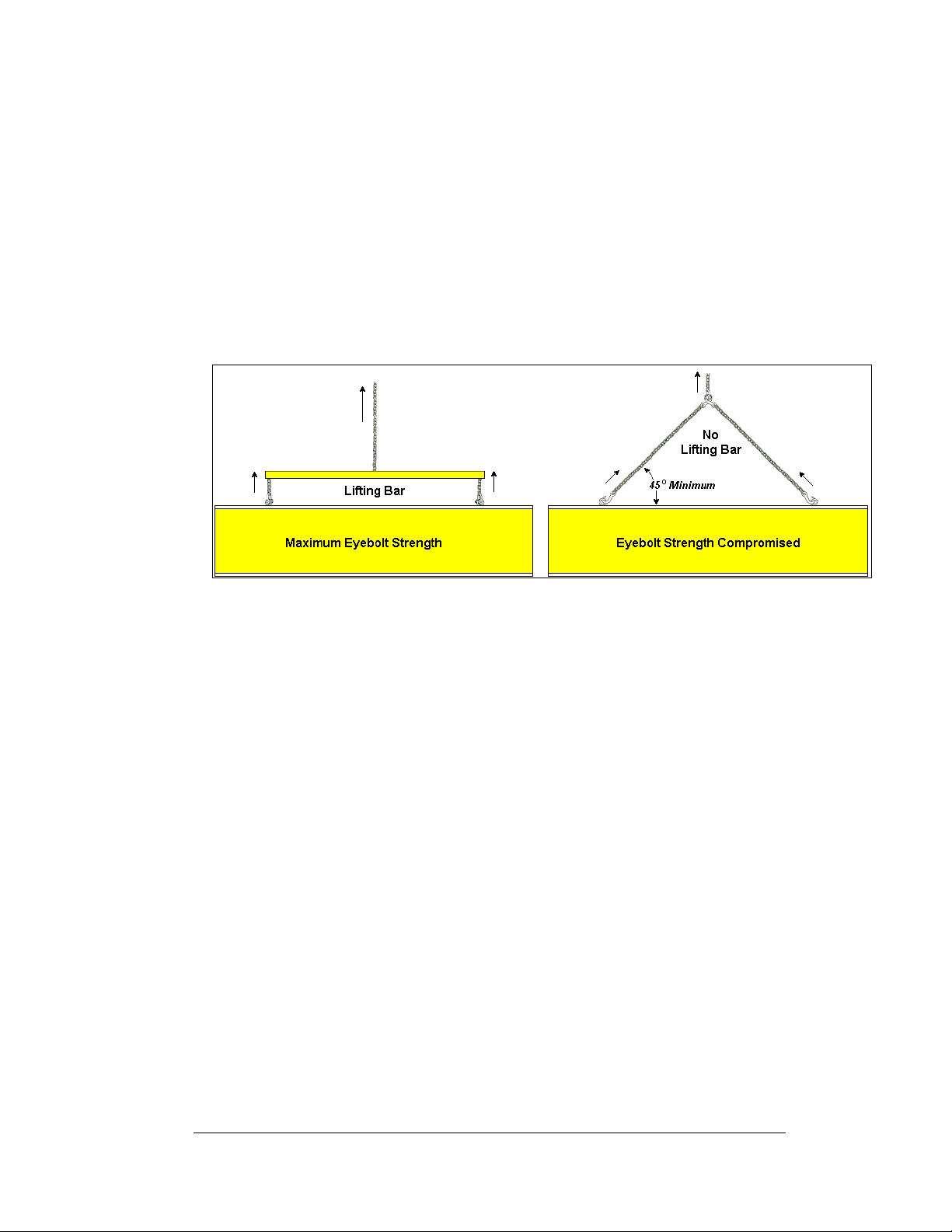

2.2 Lifting the Display

Model DF- displays are shipped equipped with 3/8" eyebolts that are used for

lifting and positioning the modules. Eyebolts are located along the top outer

edges of the cabinet.

Daktronics strongly recommends using a spreader bar, or lifting bar, to lift the

display. Using a spreader bar ensures that the force on the eyebolts is straight up,

minimizing lifting stress.

incorrect (right example) method for lifting a display. Lift the display as shown on

the left, with a lifting bar. Be sure to use every lifting point provided.

Figure 4 illustrates both the correct (left example) and the

Figure 4: Lifting the Display

Note: Daktronics assumes no liability for display damage or injury resulting

from incorrect setup or incorrect lifting methods.

Eyebolts are intended for lifting during installation only. Do not attempt to

permanently support the display by the eyebolts.

In installations where an ad panels or some other display section may be added to the

base display, the lower section is installed first and secured to the support beams,

and then the upper section is placed atop or above the lower sign section and

attached to the beams. There may be cables extending from the top of the lower

section. Guide these cables into the hole in the bottom of the upper section for later

connection.

Installers may remove the lift eyebolts once the display is in place. When removing

the eyebolts, adequately seal the holes using bolts and sealing washers. Smaller

displays use

3

/8"-16 bolts, larger displays use 1/2"-13 bolts into the holes. In addition,

inspect the top and sides of the display for any holes or openings that may allow

moisture to enter the display, and plug and seal those opening s with silicone.

Electrical Installation 2-3

Page 20

Page 21

Section 3: Electrical Installation

Daktronics outdoor displays are UL listed and tested to CSA standards for outdoor use.

Contact Daktronics with any questions regarding the testing procedures.

Only qualified individuals should perform power routing and termination to the

display. It is the responsibility of the electrical contractor to ensure that all

electrical work meets or exceeds local and national codes.

3.1 Preparing for Power/Signal Connection

Reference Drawing:

Quick Install, DF-1020 Gas Price Displays..................Drawing A-189768

Electrical installation consists of the following processes:

• Providing power and ground to a disconnect near the display.

• Routing power and ground from the main disconnect to the display

driver/power enclosure.

• Connecting the display ground to a grounding electrode at the sign location.

• Routing the control signal cable from the control location to the sign

location.

Drawing A-189768 provides detailed instructions for power and signal connections

for the DataMaster Gas Price displays, including hook-up of the connections

between host and client displays. Refer to this drawing before undertaking any part

of the electrical installation.

3.2 Power and Grounding Connections

Correct power and grounding installation is imperative for proper display operation.

The subsections that follow give details of display power installation. Only qualified

individuals should attempt to complete the electrical installation. Improper

installation could result in serious damage to the equipment and could be

hazardous to personnel.

Power

Daktronics DataMaster displays have been designed for easy access to components,

and the power and control signal hookup. Front panels are removable or hinged to

allow access to the digits, cabling, and other electronic components.

The DataMaster, Gas Price displays require a dedicated, 120 V circuit for incoming

power. The display itself has no breakers or fuses.

Electrical Installation 3-1

Page 22

WARNING: It is critical that the display circuit be fused at 15 A, and that all

conductors used must be designed to pass a 15 A current in normal operation.

Failure to meet wiring and over current protection device requirements is a

violation of the National Electrical Code

®

and will void the display warranty.

The tables below show the circuit specifications and maximum power requirements

for each model. Models are listed in order by digit size.

Full Cabinet Model - Gas Price Displays – Power Requirements

Model

DF-1024-10/

DF-1026-10

Digit Size Maximum

Wattage

10"

(254 mm)

350 W

Circuit

120 V AC

3 A

DF-1024-13/

DF-1026-13

DF-1024-18/

DF-1026-18

DF-1024-24/

DF-1026-24

DF-1024-36/

DF-1026-36

13"

(330 mm)

18"

(457 mm)

24"

(610 mm)

36"

(914 mm)

350 W

350 W

350 W

600 W

120 V AC

3 A

120 V AC

3 A

120 V AC

3 A

120 V AC

5 A

DF-1024-48/

DF-1026-48

DF-1024-60/

DF-1026-60

48"

(1219 mm)

60”

(1524 mm)

600 W

600 W 120 V AC

120 V AC

5 A

5 A

3-2 Electrical Installation

Page 23

Grounding

Reference Drawings:

Enclosed Driver, 4 Column Reference ........................Drawing A-184918

Displays MUST be grounded according to the provisions outlined in Article 250 of

the National Electrical Code and according to the specifications in this manual.

Daktronics requires a resistance-to-ground of 10 ohms or less.

The contractor performing the electrical installation can verify ground resistance.

Technicians from Daktronics Sales and Service offices can also provide this service.

The display system must be connected to an earth electrode installed at the display.

Proper grounding is necessary for reliable equipment operation. It also protects the

equipment from damaging electrical disturbances and lightning. The display must

be properly grounded, or the warranty will be void. Refer to Drawing A-184918, for

information on where to connect the grounding wire. Connection at the driver

enclosure terminal block is illustrated at the bottom of the drawing.

The material for an earth-ground electrode differs from region to region and may

vary according to conditions present at the site. Consult the National Electrical Code

and any local electrical codes that may apply. The support structure of the display

cannot be used as an earth-ground electrode. The support is generally embedded in

concrete, and if it is in earth, the steel is usually primed or it corrodes, making it a

poor ground in either case.

Power Installation

There are two considerations for power installation: installation with ground and

neutral conductors provided, and installation with only a neutral conductor provided.

These two power installations differ slightly, as described in the following

paragraphs:

Installation with Ground and Neutral Conductors Provided

For this type of installation, the power circuit must contain an isolated earth-ground

conductor. Under this circumstance, do not connect neutral to ground at the

disconnect or at the display. This would violate electrical codes and void the

warranty. Use a disconnect so that all hot lines and neutral lines can be disconnected.

The National Electrical Code requires the use of a lockable power disconnect within

sight of or at the display.

Installation with Only a Neutral Conductor Provided

Installations where no grounding conductor is provided must comply with Article

250-32 of the National Electrical Code. If the installation in question meets all of the

requirements of Article 250-32, the following guidelines must be observed:

• Connect the grounding electrode cable at the local disconnect, never at the

display driver/power enclosure.

• Use a disconnect that opens all of the ungrounded phase conductors.

Electrical Installation 3-3

Page 24

3.3 Lightning Protection

The use of a disconnect near the display to completely cut all current-carrying lines

significantly protects the circuits against lightning damage. The National Electrical

Code also requires it. In order for this device to provide protection, the power must

be disconnected when the display is not in use. The control console should also be

disconnected from power and from the signal j-box when the system is not being

used. The same surges that may damage the display's driver can also damage the

driver console's circuit.

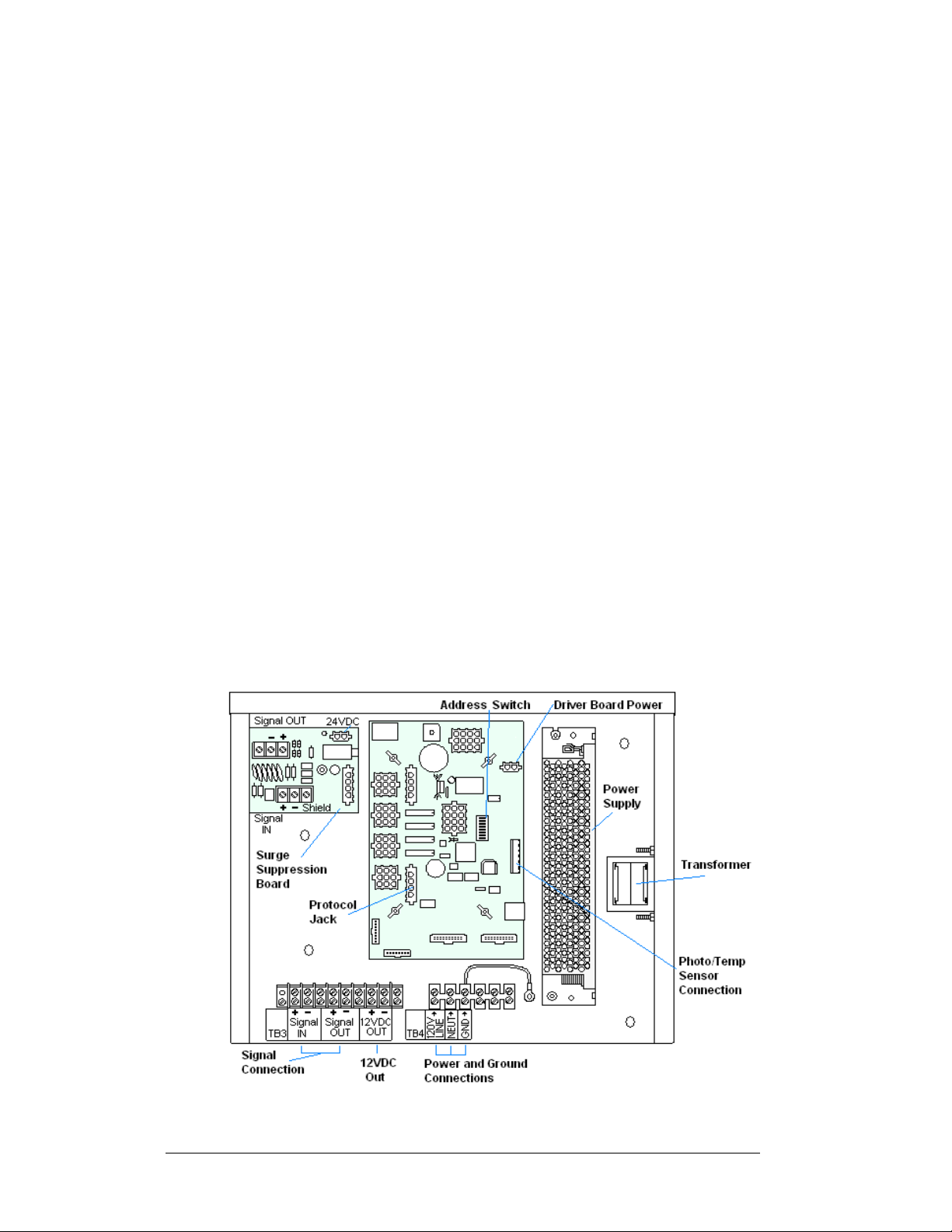

3.4 Signal Connection

Reference Drawings

4 Column MASC LED Driver Specifications................ Drawing A-166216

8 Column MASC LED Driver Specifications................ Drawing A-167237

16 Col. MASC Driver Specification..............................Drawing A-184475

Enclosed Driver, 4 Column Reference........................Drawing A-184918

Quick Install, DF-1020 Gas Price Displays.................Drawing A-189768

Route power and signal cables into the display from the side or rear. There are

knockouts for

and on the back panels. All power and signal wiring terminates at the driver

enclosure.

1

/2" and 3/4" conduit fittings on the sides of all DataMaster cabinets

Figure 5: DataMaster Driver Enclosure with 4-Column Driver

3-4 Electrical Installation

Page 25

To gain access to the driver enclosure, open the access door and remove the cover

from the enclosure. Refer to the Electrical Specifications Drawings for the access

location for your sign. For smaller digit displays, access to the interior components is

gained by removing the screws from the hinged door. In the larger digit displays,

there are door latches that allow access to the interior components by removing the

digits.

Refer to Drawing A-189768 for a complete review of power and signal connections

for Gasoline Price displays. Drawings A-184918, A-167237 and A-184475 illustrate

and provide connection specifications for the different drivers used in DataMaster

Gas Price displays. The power and signal connections, illustrated in

similar for all three drivers.

Current Loop (Direct)

Reference Drawings:

Riser Diagram, Outdoor Wire Control..........................Drawing A-164988

Riser Diagram, Indoor Wire Control.............................Drawing A-175342

Enclosed Driver, 4 Column..........................................Drawing A-184918

Quick Install, DF-1020 Gas Price Displays..................Drawing A-189768

A direct controlled display uses a current loop connection from the j-box at the base

of the display to the driver enclosure in the sign. All the power and signal wiring

terminate at the driver enclosure. The DataMaster hand-held controller receives its

power from the display. The display layout is shown in

164988.

Figure 6: Direct, Current Loop Layout

Figure 5, are

Figure 6 and Drawing A-

Electrical Installation 3-5

Page 26

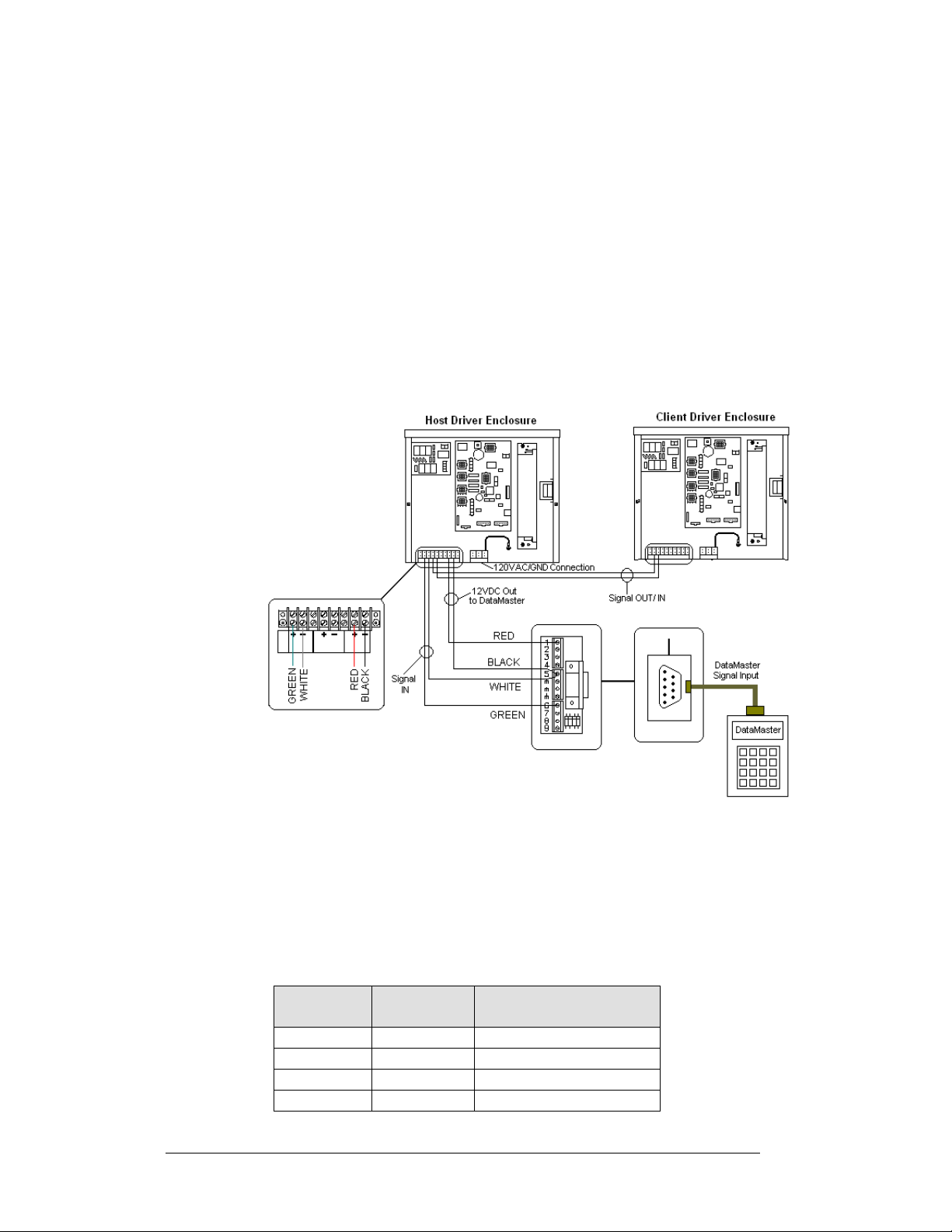

Note: The cable from the j-box to the display needs to be routed through conduit or

the display pole to protect it from weather and vandalism.

1. Mount the j-box near the display.

2. Route a 4-conductor, 22 AWG, shielded cable through conduit from the j-box

to the driver enclosure in the host display. (Distance limit from the j-box to

the display is 50 ft.)

3. Connect the signal/power cable from the j-box to the driver enclosure as

shown in

Figure 7 and listed in the table. Refer to Drawings A-175342 and

A-184918 for additional information.

4. Using a DB9M to DB9F serial cable, plug the DataMaster controller into the

J-box, connected to the Host Display Driver Enclosure

Figure 7: Direct Current Loop Connection

J-Box to Driver Enclosure Input Jack

J-Box

Pin#

Pin 1 Red 12V DC Out (+) pin 7

Pin 5 Black 12 V DC Out (-) Pin 8

Pin 5 White Signal IN (-) Pin 2

Pin 6 Green Signal IN (+) Pin 1

Cable

Color

Enclosure Terminal

Block

3-6 Electrical Installation

Page 27

If using the DataMaster handheld controller at an indoor location, only the two, 22

AWG, signal wires (white and green) will need to be connected to the j-box. A wall

pack transformer, plugs into the indoor j-box, and provides power to the DataMaster

controller. The distance from the indoor j-box to the host driver can be up to 2000 ft.

Refer to

Figure 8 and Drawing A-175342 for system layout and signal connections.

Figure 8: Direct Connection from Indoor Location

Radio (Direct)

Reference Drawings:

Quick Install, DF-1020 Gas Price Displays..................Drawing A-189768

System Riser Diagram, Server/Client Setup................Drawing A-199834

A radio controlled display uses the DataMaster controller inside connected to a jbox. The j-box is then wired to a server radio attached to the building. A second

radio, called the client is connected to the Gas Price display. The DataMaster handheld controller and server radio receive their power from the j-box. A wall pack

transformer powers the j-box. The client radio receives its power from the display.

The display layout is shown in Figure 9

1. Using the DB9M to DB9F serial cable, connect from the DataMaster

controller to the J-box, at the “DB9 Male, DataMaster 100 connect” jack.

2. Using an 18-AWG, 6-conductor, shielded cable, (W-1370) connect from

the j-box jack labeled “RS422 to Radio or 422 Device” to the TB1 jack

on the Server radio, mounted to the building. See

below for cable connections from the j-box to the radio.

3. Plug the wall pack transformer into the j-box and then into a 120V

grounded outlet.

4. Mount the Client radio on the display or display pole, and within 25 feet

of the display.

5. Plug the quick connect cable from the client radio into the 6-pin quick

connect jack on the side of the Gas price display.

and Drawing A-199834.

Figure 10 and the table

Electrical Installation 3-7

Page 28

Figure 9: Radio Controlled Display Layout

Figure 10: Direct Current Loop Connection

Connection from J-box to Server Radio Enclosure

J-Box TB2 on Server

Pin# Function

Pin 1 Power Red Pin 1 Power

Pin 2 422 RX-P White Pin 2 422 TX-P

Pin 3 422 RX-N Green Pin 3 422 TX-N

Pin 4 422 TX-P Brown Pin 4 422 RX-P

Pin 5 422 TX-N Blue Pin 5 422 RX-N

Pin 6 GND Black Pin 6 GND

Cable

Color

Pin# Function

3-8 Electrical Installation

Page 29

Notes:

1. The cable from the client radio to the display can to be routed through

conduit or the display pole to protect it from weather and vandalism. The

cable is weather and sunlight resistant.

2. The Server and Client radios must have a clear line-of-sight path and not

be more than 1500 feet apart.

3. A current-loop j-box is often mounted at the base of the display pole in

case of problems with communication though the radio network.

4. For additional connection and operation information see ED13894:

DataMaster Radio Installation Manual

Modem (Indirect)

Reference Drawings:

Modem Installation; 4 col MASC Drvr. Enc..................Drawing A-177039

Quick Install, DF-1020 Gas Price Displays..................Drawing A-189768

System Riser Diagram, Modem Setup ........................Drawing A-200552

A modem controlled display uses a DataMaster controller connected to a

modem/j-box, to call a second modem in the Gas Price display. The DataMaster

hand-held controller will receive its power from the j-box. A wall pack transformer

powers the j-box. The display layout is shown in

Figure 11 and Drawing A-200552.

Figure 11: Modem Controlled Display Layout

Electrical Installation 3-9

Page 30

1. Using the DB9M to DB9F serial cable, connect from the DataMaster

controller to the modem/j-box, at the “DB9 Male, DataMaster 100

connect” jack.

2. Connect a phone line from a phone junction box to the modem/j-box jack

labeled “Phone Line Connection”.

3. Plug the wall pack transformer into the modem/j-box and then into a

120V grounded outlet.

4. At the display, the local phone company must provide a dedicated phone

line to the display and identity the color used for the “Tip ” wire and

which color is for the “Ring”.

5. The Tip and Ring phone wires will terminate to TB2 on the modem as

shown in Figure 12 and Drawing A-177039. If a phone cable is used, it

will plug into J5.

Figure 12: Phone line Connection to Display Modem

Notes:

1. A current-loop j-box is often mounted at the base of the display pole for

communication in the case of problems with the phone line.

2. The phone line and display power cannot be routed though the same

conduit.

3. For additional operation and connection information see ED13953:

DataMaster Modem Installation Manual

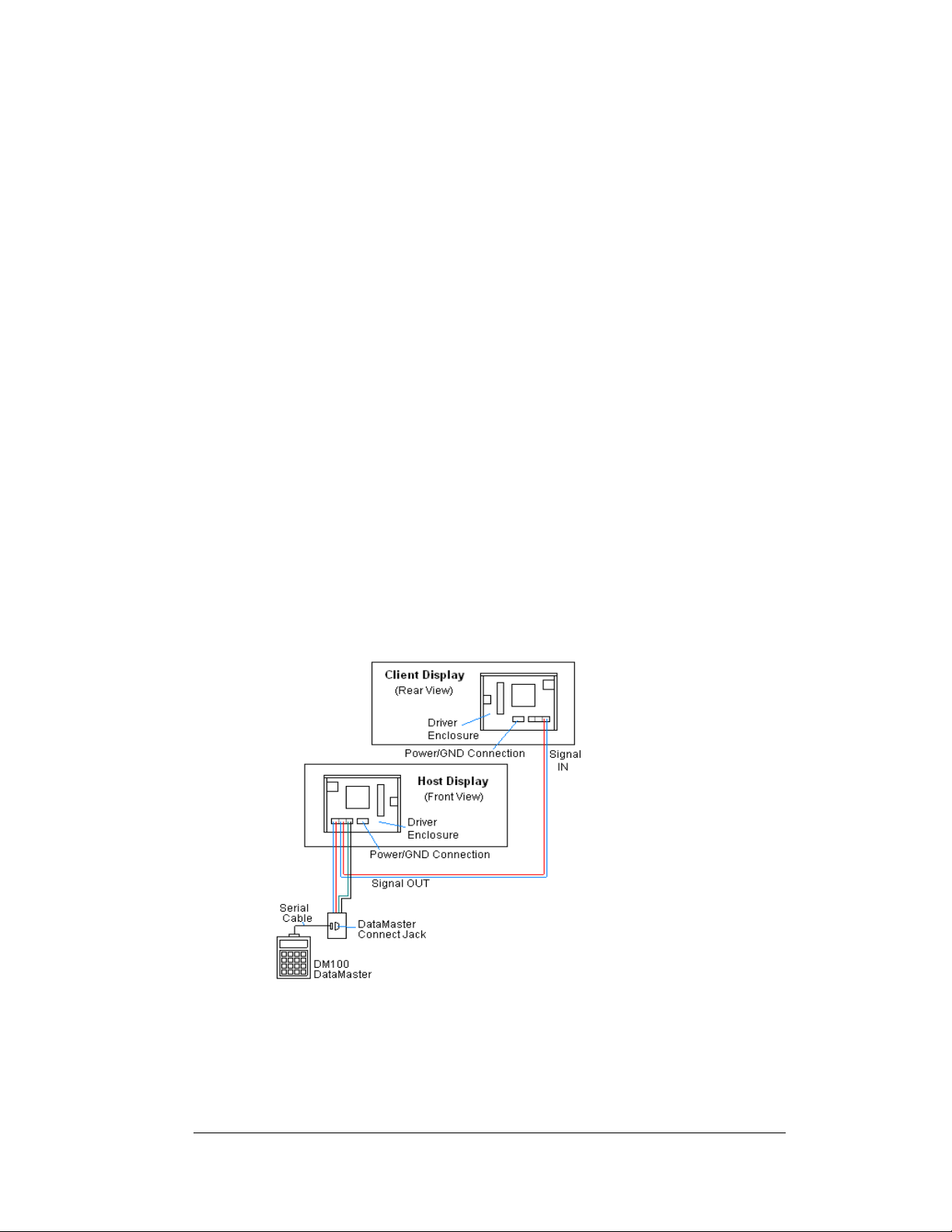

Host/Client Definitions and Address Settings

Reference Drawings:

Host/Client and Master/Slave Definitions .............Drawing A-168376

4 Column MASC LED Driver Specifications.........Drawing A-166216

8 Column MASC LED Driver Specifications.........Drawing A-167237

16 Col. MASC Driver Specifications..................... Drawing A-184475

Address settings, MASC drivers...........................Drawing A-227502

3-10 Electrical Installation

Page 31

Host/Client Definitions

One driver at each sign installation is designated as the “host driver.” This driver

receives its signal directly from the controller on the “Signal IN” terminals, and it is

the only driver that is connected to the light sensor. The “Signal OUT” terminals are

used to connect to “client drivers.” Refer to Drawing A-168376 and

Figure 13 for an

illustration of the host/client display connection.

Figure 13: Host, Signal Out to Client, Signal In

Select the host driver by inserting the Protocol 4 plug into the 5-pin protocol jack

(J20.) For protocol jack location, refer to Drawings A-166216, A-167237 or A-

184475 on your specific display driver.

The 12 V DC terminals connected to the host driver (see “Signal Connections” in

Figure 5) run to the controller junction box. This output is used to power the

DataMaster 100 controller.

All other drivers in the display system are client drivers. These drivers receive signal

from the host driver on the Signal IN terminals and can re-drive this signal to other

“client drivers” on the Signal OUT terminals.

Some multiple-module signs use “mirror displays.” These displays do not contain a

driver and may use either the client or host digit outputs. Refer to Drawing A-

168376 for an illustration of the host/client driver and primary/mirror display setups.

Some displays only use one driver for multiple product lines in one common cabinet.

In this case, the signal to each line is already connected.

Address Settings

The address of each driver is set using an 8-position DIP-switch (S1), and the

address is based on that driver’s position in the sign or display system. If a single-

line sign is used, the address will typically be Address “01.” Th is means that switch

1 is turned “ON” and the remaining 7 switches are in the “OFF” position. This is the

default address set when each display is shipped. In multiple-product displays, the

address determines which line of information is shown on the driver’s digits. The

switch is set using a binary address. Use the table and the examples for setting the

address. Drawing A-227502 shows how to set the address on the drivers used in

DataTime and DataMaster products.

Electrical Installation 3-11

Page 32

Figure 14: Common Address Settings

Binary Address Settings

Address

1 2 3 4 5 6 7 8

1 ON OFF OFF OFF OFF OFF OFF OFF

2 OFF ON OFF OFF OFF OFF OFF OFF

3 ON ON OFF OFF OFF OFF OFF OFF

4 OFF OFF ON OFF OFF OFF OFF OFF

5 ON OFF ON OFF OFF OFF OFF OFF

6 OFF ON ON OFF OFF OFF OFF OFF

7 ON ON ON OFF OFF OFF OFF OFF

8 OFF OFF OFF ON OFF OFF OFF OFF

9 ON OFF OFF ON OFF OFF OFF OFF

10 OFF ON OFF ON OFF OFF OFF OFF

11 ON ON OFF ON OFF OFF OFF OFF

12 OFF OFF ON ON OFF OFF OFF OFF

13 ON OFF ON ON OFF OFF OFF OFF

14 OFF ON ON ON OFF OFF OFF OFF

15 ON ON ON ON OFF OFF OFF OFF

Note: Some older drivers set the address of each driver using an address plug

(Daktronics part # 0A-1279-0122) in J19. The address, either using a switch or a

plug, needs to be set for each driver.

3-12 Electrical Installation

Page 33

Section 4: Maintenance and

Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair or maintenance

work on the display!

2. Allow only qualified service personnel access to internal

display electronics.

3. Disconnect power when not using the display.

4.1 Cabinet Specifications

Reference Drawings:

Mechanical Specification Drawings.........................Refer to Appendix A

Cabinets for the Daktronics outdoor LED digit displays are constructed of heavygauge aluminum. Exact dimensions and weights for each model are listed in the

chart in Section 2. Hinged panels for servicing digits and indicators and for

component access are detailed in each model's Mechanical Specifications Drawing.

4.2 Component Location and Access

Reference Drawings:

Electrical Specification Drawings.............................Refer to Appendix A

Mechanical Specification Drawings.........................Refer to Appendix A

Displays in the DataMaster Gas Price series are made up of two main components:

the circuit boards that make up the digits and the driver enclosure.

Display Digits:

• A single circuit board makes up the digits for the 10”, 13” and 18” digits

• The digits for 24”, 36”, 48” and 60” are made up of LED segments

Each host or primary display (the mirror does not contain a driver enclosure)

contains an enclosure that includes the following devices:

• Display Driver

• 24V DC power supply

• 10V AC transformer

• Signal/Power Input Terminal Jack

• Signal Board (Surge board on direct displays or a modem)

• Light (photo) sensor

Maintenance and 4-1

Troubleshooting

Page 34

For the front-access modules in this series, all internal electronic components and

digits can be reached by opening either the left hinged access door on the front of the

display or removing digits.

For the 10”, 13”, 18”, and 24” displays the hinged door swings outward when the two

screws on the display face panel are removed, as shown in

displays, the enclosure is reached by removing one of the digits from the face of the

display. Since component placement varies slightly with each DataMaster model

consult your model's Electrical and Mechanical Specifications Drawings.

Figure 15. For the larger

Figure 15: DataMaster Gas Price Display with Door Panels Open

Note: Disconnect power before servicing the display! Disconnect power, too,

when the display is not in use. Prolonged power-on may shorten the life of some

electronic components.

4.3 Service and Diagnostics

Replacing a Digit

The digit circuit board, the platform for the LEDs, is mounted to the back of the digit

panel. Do not attempt to remove individual LEDs. In the case of a malfunctioning

board, replace the entire digit panel (10”, 13” and 18” displays). Refer to Figure 16

for the digit assembly.

To remove a display digit, follow these steps:

1. Open the digit panel as described in the preceding section.

2. Disconnect the power/signal connector from the back of the digit. Release

the connector by squeezing together the locking tabs as you pull the

connector free.

4-2 Maintenance and

Troubleshooting

Page 35

3. The digits are secured to the

inside of the panel with fixed

machine screws, spacers, and

push nuts. Remove the nuts

and lift the digit off the

standoff screws. (The push

nuts can be removed in several

ways, but Daktronics

recommends using a

9

/32" nut

driver.)

4. Position a new digit over the

screws and tighten the nuts.

5. Reconnect the power/signal

connector. Note: This is a

keyed connector it will attach

Figure 16: Digit Assembly

in one way only. Do not

attempt to force the

connection!

6. Close and secure the digit

panel and test the display.

Replacing a Digit Segment

When a digit segment malfunctions, in most cases it is necessary to replace just that

segment board. The larger digits, 24", 36", 48" and 60” as shown in Figure 17

made up of LED segments. As with smaller digits, the digit segment circuit boards

are mounted to the back of the digit panel. Do not attempt to remove individual

LEDs.

To remove a digit segment, follow these steps:

1. Open the digit panel as described

above.

2. Disconnect the 2-pin

power/signal connector from the

back of the individual segment.

Release the connector by

squeezing together the locking

tabs as you pull the connector

free.

3. The individual segments are

secured to the inside of the panel

with fixed machine screws,

spacers, and push nuts. Remove

the nuts and lift the segment off

the standoff screws.

Figure 17: Segmented Digit Panel

(Rear View)

4. Position a new segment over the

screws and tighten the nuts.

, are

Maintenance and 4-3

Troubleshooting

Page 36

5. Reconnect the power/signal connector. Note: This is a keyed connector it

will attach in one way only. Do not attempt to force the connection!

6. Close and secure the digit panel and test the display.

Replace a malfunctioning colon, decimal, or indicator assembly in the same

manner.

Segmentation and Digit Designation

Reference Drawing:

Segmentation, 7 Segment Bar Digit.............................. Drawing A-38532

Electrical Specification Drawings .............................Refer to Appendix A

In each digit, certain LEDs always

go on and off together. No matter if

they are made up of one circuit

board, or separate boards, these

groupings of LEDs are referred to

as “segments”. Drawing A-38532

illustrates digit segmentation. It

also details which connector pin is

wired to each digit segment and the

wiring color code used throughout

the display.

The Electrical Specification

Drawings specify the driver

connectors controlling the digits.

Figure 18: Digit Designation

Numbers displayed in hexagons in

the upper half of each digit, as shown in Figure

18, indicate which connector or

connectors are wired to that digit. Larger digits, like the 36" digits shown in

, are each wired to two connectors. (Digits for a 48” and 60” displays use four

18

connectors for each digit.)

Figure

Replacing an LED Driver

Reference Drawings:

4 Column MASC LED Driver Specifications................ Drawing A-166216

8 Column MASC Driver Specifications........................ Drawing A-167237

16 Col. MASC Driver Specification..............................Drawing A-184475

Electrical Specification Drawings .............................Refer to Appendix A

Mechanical Specification Drawings..........................Refer to Appendix A

Drivers are typically mounted inside the display enclosure and behind a digit, but the

location and mounting varies by model. Refer to the Electrical and Mechanical

Specification Drawing for the location of your driver. All displays in the DataTime

and DataMaster series are front-accessible.

4-4 Maintenance and

Troubleshooting

Page 37

To replace the driver in the display enclosure:

1. Open the digit panel or display face panel as described in Section 4.2.

2. Remove the cover from the driver enclosure.

3. It is helpful to have the cables labeled as to which was removed from which

connector.

4. Disconnect all connectors from the driver. Release each connector by

squeezing together the locking tabs as you pull the connector free. Note:

When reconnecting, remember that these are keyed connectors and will

attach in one way only. Do not attempt to force the connections.

5. Remove the wing nuts securing the driver to the inside of the enclosure.

6. Carefully lift the driver from the display and place it on a clean, flat surface.

7. Follow the steps in reverse order to attach a new driver.

Figure 19: 4-column Digit Driver

DataMaster Gas Price displays may use 4-, 8-, or 16-column drivers, depending on

the model and size of digits. Each 16-column driver is so named because it has 16

outputs to digits as compared to the 8- and 4-column drivers.

Figure 19 identifies the

major functions for a 4-column driver. (Major functions are the same on 8- and 16column drivers.)

In the display, the LED drivers perform the task of switching digits on and off. Refer

to Drawings A-166216, A-167237, and A-184475 for a complete listing of

connector functions and wiring pin numbers for the correct driver for your display.

Maintenance and 4-5

Troubleshooting

Page 38

The following table lists the functions of the various jacks, including those that are

not used in this application.

LED Driver Jack Functions

Jack No. Function

J1-J4 (4-column)

J1-J8 (8-column)

J1-J16 (16-column)

J17

Digits Output

Signal/Power Input

J18, J21, J22, J25, J26, J27,

J20

J23

J24

TB1

J19

J28

Protocol-5 Location

12 VDC Power Out

Modem

CAN (light sensor)

Address Plug (older drivers only)

Jacks not used in this application

The display line controlled by the driver is set with a DIP-switch that is set at the

factory before shipment. (Note: Some older drivers use a 12-pin address plug

inserted in J19). Most DataMaster displays ship with the “Line 1” addr ess already

set. Displays that have multiple products or lines in one common cabinet, the proper

address is set during manufacturing.

Replacing a Signal Surge Board

Reference Drawings:

Enclosure Driver, 4 Column Reference....................... Drawing A-183775

Electrical Specification Drawings .............................Refer to Appendix A

Mechanical Specification Drawings..........................Refer to Appendix A

The surge board is mounted inside the display enclosure and behind a digit, but

location and mounting varies by model. Refer to the Electrical and Mechanical

Specification Drawing for the location of your surge board. All displays are frontaccessible.

1. Open the digit panel or display face panel as described in Section 4.2.

2. Remove the cover from the driver enclosure.

3. Disconnect all connectors from the surge board. Release each connector

by squeezing together the locking tabs as you pull the connector free.

Note: When reconnecting, remember that these are keyed connectors and

will attach in one way only. Do not attempt to force the connections.

4. Remove the nuts securing the driver to the inside of the enclosure.

5. Carefully lift the surge board from the display and place it on a clean, flat

surface.

6. Follow the steps in reverse order to attach a new driver.

4-6 Maintenance and

Troubleshooting

Page 39

In the display, the signal surge

suppression board is an inline

device used to filter the

current loop data line. It

suppresses surges down to a

low voltage to protect the

display’s controller. Refer to

Drawing A-184918 for the

location of the surge board

inside the driver enclosure.

The surge board is pre-wired

before the display is shipped.

Figure 20: Signal Surge Suppression Board

Note: The surge suppressor must be firmly connected to the driver enclosure, and

the display must be properly grounded in order to be effective.

Replacing a Modem

Reference Drawings:

Modem Installation; 4 col MASC Driver Enc............................... A-177039

Electrical Specification Drawings.............................Refer to Appendix A

Mechanical Specification Drawings.........................Refer to Appendix A

If a modem is included with the display, it is mounted inside the display enclosure,

behind a digit, and near the driver but the location and mounting varies by model.

Refer to Drawing A-177039 and the Electrical and Mechanical Specification

Drawings for the location of the modem. All displays in this series are frontaccessible.

1. Open the digit panel or display face panel as

described in Section 4.2.

2. Remove the cover from the driver enclosure.

3. Disconnect all connectors from the modem. Release

each connector by squeezing together the locking

tabs as you pull the connector free. Note: When

reconnecting, remember that these are keyed

connectors and will attach in one way only. Do not

attempt to force the connections.

4. Remove the nuts securing the modem to the inside

of the enclosure.

5. Carefully lift the modem from the display and place

it on a clean, flat surface.

6. Follow the steps in reverse order to attach a new

modem.

The modem has four LEDs.

Figure 21: Modem Board

Maintenance and 4-7

Troubleshooting

Page 40

1. The power LED (DS1) should remain lit while power is applied to the

modem.

2. The modem RX (DS3) and TX (DS4) LEDs are normally off, but will flash

when communicating.

3. The carrier detect LED (DS5) will light when the modem has established

communication to another modem.

The modem board also has several input and output jacks:

1. TB2 is a phoenix connector to terminate the Tip and Ring wires.

2. J3 is the AC power input into the modem board from the transformer in the

driver enclosure.

3. J6 is the RS232, RJ45 output jack from the modem board to the display

driver.

4. J5 is an RJ11 jack for termination of a pre-terminated phone line (if

needed).

5. J2, TB1, and TB3 are not used in this application.

4.4 Light Sensor Location

Reference Drawing:

Light Sensor Installation, G3 ....................................... Drawing A-183775

Mechanical Specification Drawings..........................Refer to Appendix A

Displays in the DataMaster series use a light sensor to regulate sign dimming

functions. Use Drawing A-183775 and the following instructions to replace the light

sensor in your DataMaster Gasoline Price display. If the sign or sign system has

more than one display, the light sensor is found in the host/primary display only.

1. Open the digit panel or display face panel as

described in Section 4.2.

2. Locate the

of the display. The location of the plug varies by

model. Refer to the Mechanical Specifications

Drawings for model-specific information.

3. There are two 6-32 studs above and below the

plughole. The internal light sensor assembly

(Daktronics part #0A-1279-0203) is positioned on

the studs, with the clear lens toward the front of

the cabinet and the cable at the bottom. Secure the

sensor with the provided plastic wing nuts.

4. Route the signal cable to the driver and insert the

6-postion plug into the mating jack on the

driver, TB1.

5. Close the hinged access doors and replace the

screws.

5

/8" sensor plughole on the front panel

Figure 22: Internal Light Sensor

4-8 Maintenance and

Troubleshooting

Page 41

4.5 Troubleshooting

This section lists potential problems with the display, indicates possible causes, and

suggests corrective action. This list does not include every possible problem, but it

does represent some of the more common situations that may occur. (Refer to the

appropriate manual for a list of potential problems with add-on or separately

mounted message centers.)

Symptom/Condition Possible Cause

Entire Display Fails to Work • Check for proper line voltage at termination

Cannot communicate with

Display via Current Loop

Cannot communicate with

Display via Radio

Cannot communicate with

Display via Modem

panel

• Check connections from power supply to driver

• Check power LED on driver

• Check connections at J-box and display

• Make sure DataMaster is receiving power

• Check serial cable from DataMaster to J-box

• Remove screws and plug DataMaster directly

into the J-box

• Check for power to signal converter connected

to Server

• Check wire connections from signal converter to

Server

• Check connections from Client to display

• Make sure display and DataMaster have power

• Make sure modem at display is connecting via

phone line

• Make sure display and DataMaster have power

Garbled display • Internal driver logic malfunction

• DataMaster malfunction

Digit will not light • Black wire to digit broken

• Poor contact at driver connection

• Driver malfunction

Segment will not light • Broken LED or connection

• Broken wire between driver and digit

• Poor contact at driver connector

Segment stays lit • Driver shift register failure

• Short circuit on digit

Data appears in the wrong place

on the display, wrong data on a

particular line of the display

• Incorrect address settings on drivers (Refer to

“Power On Self-Test” in the following section,

and consult tables to set correct addresses.)

Maintenance and 4-9

Troubleshooting

Page 42

Some DataMaster displays have their own built-in troubleshooting mechanism.

Failures that may occur in the display driver are described using codes. In the event

a sign malfunctions, a failure code registers by displaying an “E(x)” value on the

first two digits of the display. “E” simply indicates an error, and the letter “x”

represents the actual code number. Refer to the following table for a description of

each failure code and for possible solutions.

Note: The LCD screen on the DataMaster 100 controller will not show the failure

codes described in the table below. Failure codes will only be displayed on the

DataMaster sign.

Failure Code Description Possible Solution

E1 Protocol Setting Error: There is an

unsupported driver protocol

setting.

E2 Time Error: There is no valid time

stored in the driver; it may be a

failure of the real-time clock on

board or other timekeeping

device.

E3 Temp Error: There is no response

from the temp sensor or light

sensor, or general temp sensor

failure.

E4 No Message Error: This code is

shown when there are no

messages downloaded to the

display

E5 No Line Number Selected Error:

The driver for this line has a

Protocol 4 plug installed in J20,

but all address switches are

“OFF”. (Note: In some older

drivers this happens when no

address plug installed is in J19.)

Check the value set in the protocol

plug of the driver (J20).

Set the time in the display using the

Set Time menu option on the

DataMaster 100 controller.

(DataMaster Time & Temp displays

only)

Check the temp sensor location and

verify all connections. Refer to the

instruction sheet for the CAN

Temperature/Light Sensor

mounting, ED13364.

Note: The temp sensor takes

approximately 10 seconds to

initialize on power-up. The sign will

display this error until initialization is

complete.

Download a new message to the

display using the <DISPLAY

SEQUENCE> key on the

DataMaster 100 controller.

Set the line number by setting the

binary address on S1 (or installing

the correct plug in J19). The

Protocol 4 plug designates this

driver as the “host.” If this is not the

host, remove the Protocol 4 plug

from J20.

4-10 Maintenance and

Troubleshooting

Page 43

Power On Self-Test:

A useful troubleshooting tool is the power on self-test the host driver performs every

time it powers up:

• If the signal wiring between each controller is correct, the first two digits of

each driver will display “Ad” momentarily, and the first digit will then flash

three numbers indicating the decimal address that is set with the address

plug in J19. (If a client driver displays “A <number>,” followed by “P

<number>,” it is not receiving “signal in,” and is performing its own selftest.)

• Next, the first two digits of each line will display “Lx”, where “x” is the

line number that the driver is set to control (set with address plug).

• Finally, each line will display “1234…” according to the column number of

each of its digits. Every line should show “1” on the left-most digit, and all

digits should be numbered consecutively from left to right. If this is not the

case, either the wrong address plug is installed, or the driver or digit harness

is connected incorrectly.If there is no address set (or address plug installed)

in the host driver, the host driver will display “E5,” and all client drivers

will continually cycle through the power on self-test.

4.6 Replacement Parts

Refer to the following table for Daktronics replacement parts.

Driver, 4-column MASC, LED 0P-1192-0068

Driver, 8-column MASC, LED 0P-1192-0082

Driver, 16-column, MASC, LED 0P-1192-0086

Light sensor P-1279-203

Protocol plug (Protocol 4) 0A-1279-0089

Power supply, 24 V DC, 150 W A-1720

Transformer, Pri. 115V; Sec. 10 VCT @1.2A T-1072

Transformer, wall pack (for DataMaster 100 and

signal converter)

Address #1 Plug 0A-1150-0122

Communication Boards and Accessories

Signal surge suppression board 0P-1110-0011

Modem, RS232 coated, internal, 0P-1279-0003

J-box, signal converter, w/modem 0A-1279-0162

Description

Daktronics

Part No.

T-1118

Maintenance and 4-11

Troubleshooting

Page 44

J-box, signal converter, radio 0A-1279-0161

RJ11 to RJ45, M-M, straight, 18” cable 0A-1137-0300

Server Radio, outdoor 0A-1146-0079

Client Radio, w/Quick Connect 0A-1146-0078

Cable, 6-cond., 18 AWG, j-box to Server Radio W-1370

Transformer, wall pack (for j-box/signal converter) T-1118

DataMaster 100 Controller Parts

DataMaster 100 hand-held controller 0A-1196-0088

Junction box, outdoor, DB9-M 0A-1196-0093

Junction box, indoor, DB9-M, w/power jack 0A-1196-0099

DataMaster 100 outdoor wired installation kit 0A-1279-0087

DataMaster 100 indoor wired installation kit 0A-1279-0103

Transformer, wall pack (for DataMaster 100) T-1118

Cable, serial, DB9 male to DB9 female W-1267

DM100 Insert Time & Temp/Gas Price 0G-164998

Digits and Accessories

Speed nut, M3 Kingnut black nylon, Push nut HS-1453

Spacer, washer with steel backing HC-1221

Digit, 10" 7-segment, red, pc board 0P-1192-0255

Digit, 10" 7-segment, amber, pc board 0P-1192-0256

Digit, 7" 9/10, red, pc board 0P-1192-0253

Digit, 7" 9/10, amber, pc board 0P-1192-0254

Decimal, 10" red, pc board (used in DF-1020-10) 0P-1192-0278

Decimal, 10" amber, pc board (used in DF-1020-10) 0P-1192-0279

Digit, 13" red, pc board 0P-1192-0200

Digit, 13" amber, pc board 0P-1192-0214

Digit, 13” 7-segment, red, w/faceplate 0A-1192-2223

Digit, 13” 7-segment, amber, w/faceplate 0A-1192-2224

Decimal, 13" red, pc board (used in DF-1020-13) 0P-1192-0238

Decimal, 13" amber, pc board (used in DF-1020-13) 0P-1192-0239

Digit, 13" and 18”, 9/10, red, pc board 0P-1192-0234

Digit, 13" and 18”, 9/10, amber, pc board 0P-1192-0235

Digit, 18" 7-segment, red, pc board 0P-1192-0202

Digit, 18" 7-segment, amber, pc board 0P-1192-0216

4-12 Maintenance and

Troubleshooting

Page 45

Digit, 18" 7-segment, red, w/ faceplate 0A-1192-2227

Digit, 18" 7-segment, amber, w/ faceplate 0A-1192-2228

Digit, 24" 7-segment, red, w/ faceplate 0A-1192-2231

Digit, 24" 7-segment, amber, w/ faceplate 0A-1192-2232

Digit segment, 24" red, vert 0P-1192-0204

Digit segment, 24" red horiz 0P-1192-0205

Digit segment, 24" amber, vert 0P-1192-0218

Digit segment, 24" amber horiz 0P-1192-0219

Digit, 24" 9/10 red, w/faceplate 0A-1192-2359

Digit, 24" 9/10 amber, w/faceplate 0A-1192-2360

Digit, 36" 7-segment, red, hinged 0A-1279-0195

Digit, 36" 7-segment, amber, hinged 0A-1279-0196

Digit segment, 36" red, vert 0P-1192-0208

Digit segment, 36" red horiz 0P-1192-0209

Digit segment, 36" amber, vert 0P-1192-0222

Digit segment, 36" amber horiz 0P-1192-0223

Digit, 48" 7-segment, red, hinged 0A-1279-0181

Digit, 48" 7-segment, amber, hinged 0A-1279-0182

Digit segment, 48" red, vert 0P-1192-0212

Digit segment, 48" red horiz 0P-1192-0213

Digit segment, 48" amber, vert 0P-1192-0226

Digit segment, 48" amber horiz 0P-1192-0227

Digit segment, 60" red, vert 0P-1192-0281

Digit segment, 60" red horiz 0P-1192-0280

Digit segment, 60" amber, vert 0P-1192-0283

Digit segment, 60" amber horiz 0P-1192-0282

Digit, 24", 36”, 48”, 60” 9/10 red, pc board 0P-1192-0232

Digit, 24", 36”, 48”, 60” 9/10 amber, pc board 0P-1192-0233

Indicator, 2" red, pc board (used in 18" and 24" displays) 0P-1192-0228

Indicator, 2" amber, pc board (used in 18" and 24" displays) 0P-1192-0229

Indicator, 4" red, pc board (used in 36" and 48" displays) 0P-1192-0244

Indicator, 4" amber, pc board (used in 36" and 48" displays) 0P-1192-0245

Indicator, 4" red w/ face plate (used in 36" and 48" displays) 0A-1192-2434

Indicator, 4" amber w/ face plate (used in 36" and 48" displays) 0A-1192-2435

Maintenance and 4-13

Troubleshooting

Page 46

Ballast 1-2 lamps (4-12 feet) A-1368

Ballast 2, 3, 4 lamps (6-12 feet) A-1369

Ballast 2, 3, 4 lamps (12-24 feet) A-1370

Lamps 2’ DS-1034

Lamps 3’ DS-1035

Lamps 3’6” DS-1501

Lamps 4’ DS-1036

Lamps 5’ DS-1049

Lamps 5’4” DS-1053

Lamps 6’ DS-1037

Lamps7’ DS-1038

Lamps 8’ DS-1048

Lamps 10’ DS-1213

4.7 Daktronics Exchange and Repair and Return

Programs

To serve customers' repair and maintenance needs, Daktronics offers both an

Exchange Program and a Repair and Return Program. Daktronic unique Exchange

Program is a quick, economical service for replacing key components in need of

repair. If a component fails, Daktronics sends the customer a replacement, and the

customer, in turn, sends the failed component to Daktronics. This not only saves