Page 1

OPERATION MANUAL

DAKOTA ULTRASONICS

ZZXX--66 DDLL

Ultrasonic Multi-Echo Data

Logging Thickness Gauge

P/N P-306-0002 Rev 1.10, March 2019

Page 2

Page 3

CONTENTS

CHAPTER ONE INTRODUCTION ...................................................................... 1

DISCLAIMER ......................................................................................................................... 1

1.1

CHAPTER TWO KEYPAD, MENU, DISPLAY & CONNECTORS ..................... 2

2.1

ON/OFF/ENTER KEY… ..................................................................................................... 2

2.2

PRB 0 KEY… ....................................................................................................................... 2

2.3

CAL KEY…. ......................................................................................................................... 3

DATA KEY… ....................................................................................................................... 3

2.4

2.5

CLR KEY…. ......................................................................................................................... 3

2.6

+/- INCREMENT/DECREMENT KEY’S…. .................................................................................. 3

2.7

MULTI KEY…. ..................................................................................................................... 3

2.8

MENU KEY… ...................................................................................................................... 3

2.9

THE DISPLAY ....................................................................................................................... 5

THE TRANSDUCER .............................................................................................................. 6

2.10

2.11

TOP & BOTTOM END CAPS ................................................................................................. 8

CHAPTER THREE PRINCIPALS OF ULTRASONIC MEASUREMENT ......... 10

3.1

TIME VERSUS THICKNESS RELATIONSHIP ............................................................................. 10

3.2

SUITABILITY OF MATERIALS ................................................................................................. 10

RANGE OF MEASUREMENT AND ACCURACY .......................................................................... 10

3.3

3.4

COUPLANT ......................................................................................................................... 10

3.5

TEMPERATURE ................................................................................................................... 11

3.6

MEASUREMENT MODES ...................................................................................................... 11

CHAPTER FOUR SELECTING THE MEASUREMENT MODE ....................... 14

4.1

WHICH MODE & TRANSDUCER DO I USE FOR MY APPLICATION? ............................................ 14

CHAPTER FIVE MAKING MEASUREMENTS ................................................. 16

5.1

PROBE ZERO ...................................................................................................................... 16

5.2

MATERIAL CALIBRATION ..................................................................................................... 18

CHAPTER SIX THROUGH PAINT MEASUREMENT - MULTI MODE ............ 2 5

6.1

INTRODUCTION ................................................................................................................... 25

MULTI MODE TRANSDUCERS .............................................................................................. 25

6.2

CHAPTER SEVEN VELOCITY GAUGE ........................................................... 27

7.1

VELOCITY GAUGE (VX) ....................................................................................................... 27

Page 4

7.2 CALIBRATION TO A KNOWN THICKNESS ................................................................................ 28

7.3

CALIBRATION TO A KNOWN VELOCITY .................................................................................. 29

CHAPTER EIGHT ADDITIONAL FEATURES ................................................. 31

8.1

GAIN ................................................................................................................................. 31

8.2

HIGH SPEED SCAN ............................................................................................................. 32

8.3

ALARM ............................................................................................................................... 33

8.4

DIFFERENTIAL .................................................................................................................... 34

8.5

UNITS ................................................................................................................................ 35

8.6

LITE ................................................................................................................................... 36

BEEP ................................................................................................................................. 37

8.7

8.8

ZERO ................................................................................................................................. 38

8.9

VELOCITY (VX) .................................................................................................................. 39

8.10

PROBE DIAMETER & FREQUENCY ..................................................................................... 40

8.11

LOCK ............................................................................................................................... 41

FACTORY DEFAULTS ........................................................................................................ 42

8.12

CHAPTER NINE DATA STORAGE ................................................................. 44

9.1

INTRODUCTION .................................................................................................................. 44

9.2

OPENING A DATA FILE ........................................................................................................ 44

9.3

STORING A MEASUREMENT ................................................................................................ 45

CLEARING A FILE ............................................................................................................... 46

9.4

9.5

CLEAR ALL FILES ............................................................................................................... 47

CHAPTER TEN DATA TRANSFER & POWER OPTIONS.............................. 49

10.1

CONNECTIVITY ................................................................................................................. 49

10.2

OPENING A FILE ............................................................................................................... 49

10.3

COPYING/OPENING FILES ................................................................................................. 49

LINE POWER .................................................................................................................... 50

10.4

APPENDIX A - VELOCITY TABLE .................................................................. 51

APPENDIX B- APPLICATION NOTES ........................................................... 53

Page 5

CHAPTER ONE

INTRODUCTION

The Dakota Ultrasonics model ZX-6 DL is a basic dual element thickness gauge with

through paint measurement capability, and the ability to locate blind surface pitting

and internal defects/flaws in materials. Based on the same operating principles as

SONAR, the ZX-6 DL is capable of measuring the thickness of various materials with

accuracy as high as 0.001 inches, or 0.01 millimeters. The principle advantage of

ultrasonic measurement over traditional methods is that ultrasonic measurements

can be performed with access to only one side

Dakota Ultrasonics maintains a customer support resource in order to assist users

with questions or difficulties not covered in this manual. Customer support may be

reached at any of the following:

Dakota Ultrasonics Corporation

1500 Green Hills Road, #107

of the material being measured.

Scotts Valley, CA 95066

Tel: (831) 431-9722

Fax: (831) 431-9723

www.dakotaultrasonics.com

1.1 Disclaimer

Inherent in ultrasonic thickness measurement is the possibility that the instrument will

use the second rather than the first echo from the back surface of the material being

measured. This may result in a thickness reading that is TWICE what it should be.

Responsibility for proper use of the instrument and recognition of this phenomenon

rest solely with the user of the instrument. Other errors may occur from measuring

coated materials where the coating is insufficiently bonded to the material surface.

Irregular and inaccurate readings may result. Again, the user is responsible for

proper use and interpretation of the measurements acquired.

1

Page 6

CHAPTER TWO

KEYPAD, MENU, DISPLAY & CONNECTORS

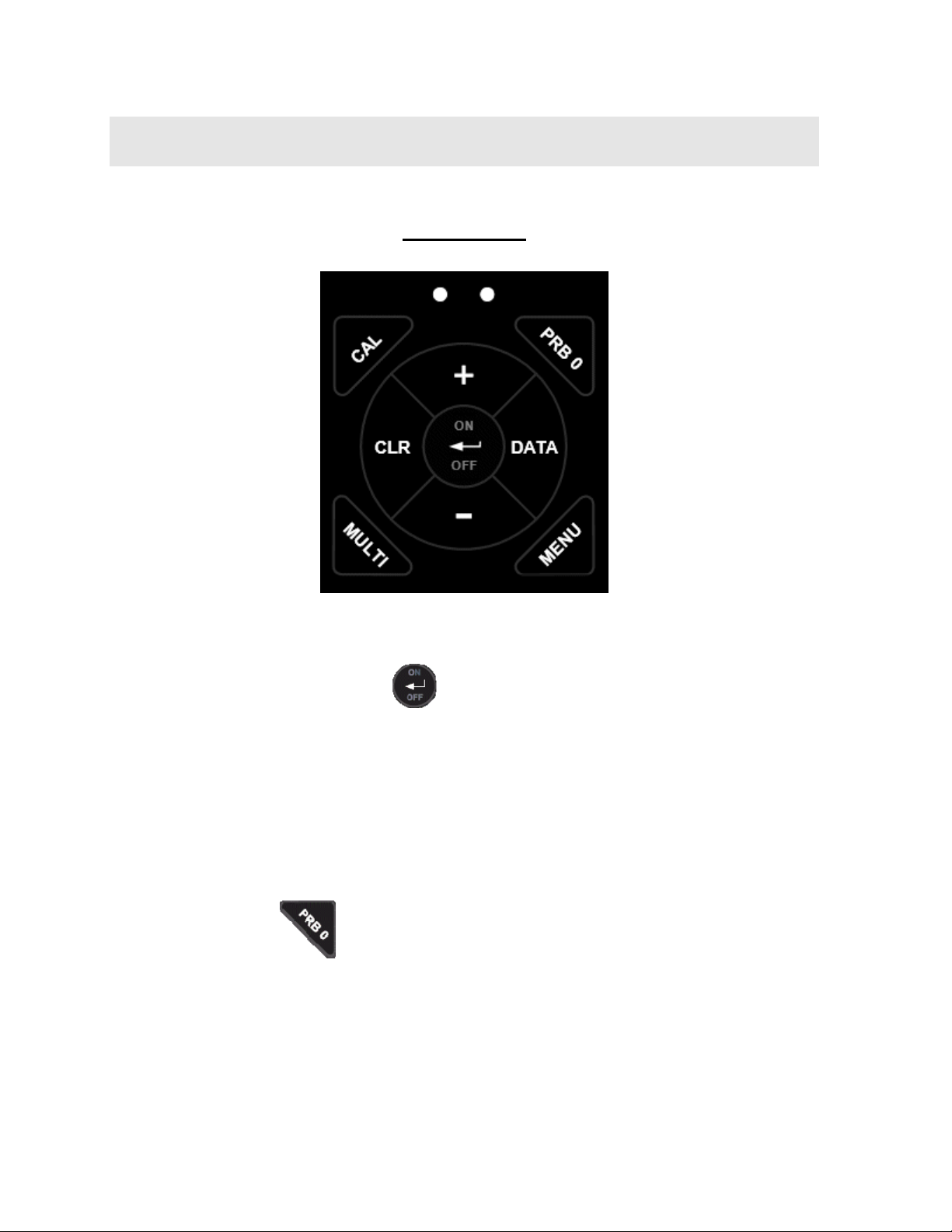

The Keypad

2.1 ON/OFF/ENTER Key

The ON/OFF/ENTER key powers the unit ON or OFF. Since the same key is also

used as an ENTER key, the gauge is powered off by pressing and holding down the

key until the unit powers off.

Once the gauge is initially powered on, this key will function as the ENTER key,

similar to a computer keyboard. This key will be used to select or set a menu option.

Note: Unit will automatically power off when idle for 5 minutes. All current settings

are automatically saved prior to powering off.

2.2 PRB 0 Key

The PRB 0 key is used to “zero” the ZX-6 DL in much the same way that a

mechanical micrometer is zeroed. If the gauge is not zeroed correctly, all of the

measurements that the gauge makes may be in error by some fixed value. Refer to

page 38 for a further explanation of this important feature.

2

Page 7

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

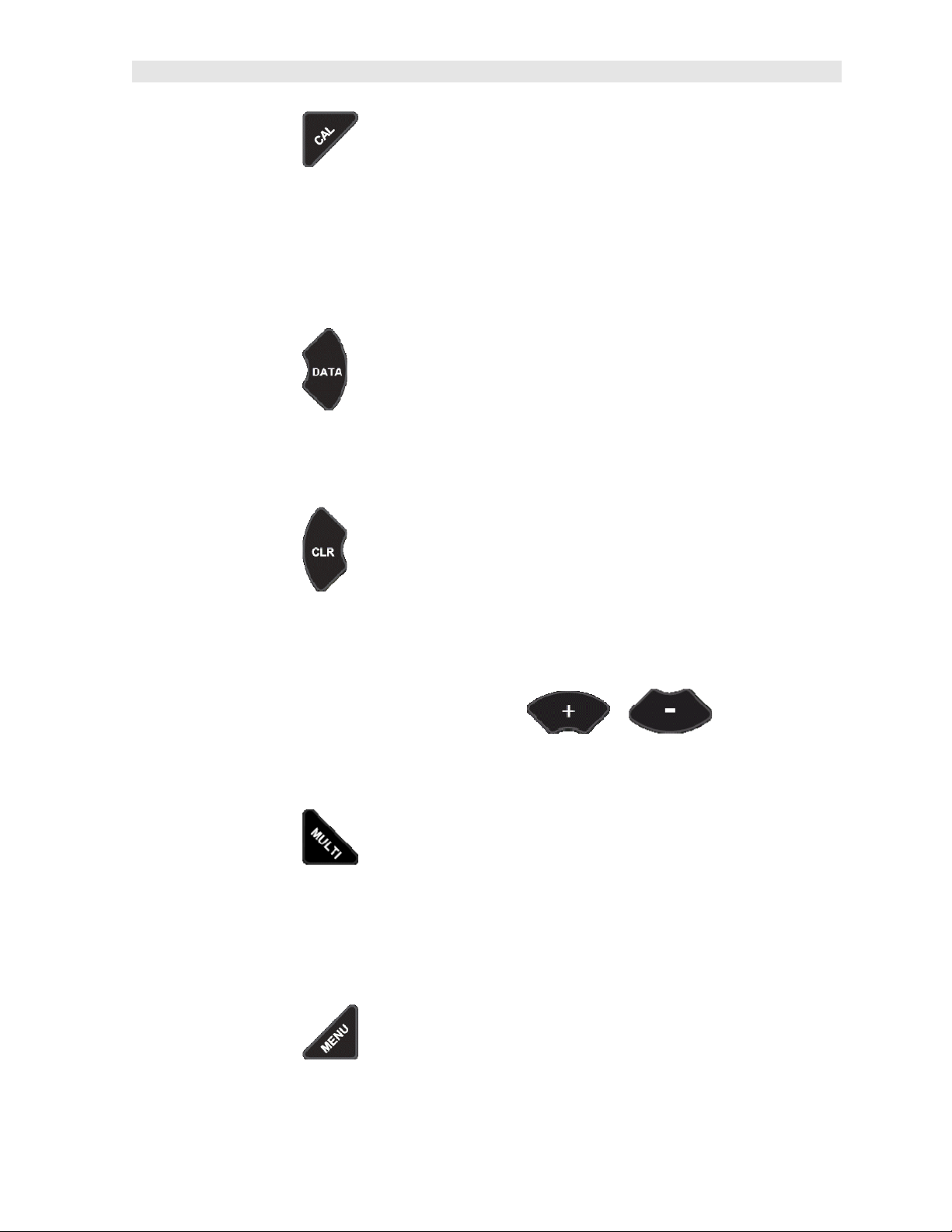

2.3 CAL Key

The CAL key is used to enter and exit the ZX-6 DL's calibration mode. This mode is

used to adjust the sound velocity value that the ZX-6 DL will use when calculating

thickness. The tool will either calculate the sound-velocity from a sample of the

material being measured, or allow a known velocity value to be entered directly. This

provides increased linearity between transducers. Refer to page 19 for an

explanation on the various calibration options.

2.4 DATA Key

The DATA key accesses the data logging section of the ZX-6 DL, which consists of

50 sequential (single column) files with 250 storage locations per file. Refer to page

44 for an explanation on the various calibration options.

2.5 CLR Key

The CLR key is used in conjunction with the data logging section to clear a single

stored memory location. Refer to page 44 for an explanation on the various

calibration options.

2.6 +/- Increment/Decrement Key’s

The +/- Keys are used to increment/decrement values, navigate menus, select menu

options, and navigate data files and storage locations.

2.7 MULTI Key

The MULTI key toggles between pulse-echo (P-E) and echo-echo (E-E)

measurement modes. (P-E) is used primarily for flaw and pit detection, while (E-E) is

used for through paint and coatings measurement without having to remove the

paint/coating and eliminating any error as a result of the paint/coating. Refer to page

25 for an explanation on the various calibration options.

2.8 MENU Key

3

Page 8

Dakota Ultrasonics

The MENU key is used to access and set all of the additional features of the ZX-6 DL

that are not at the top level of the keypad with a dedicated key. The features and

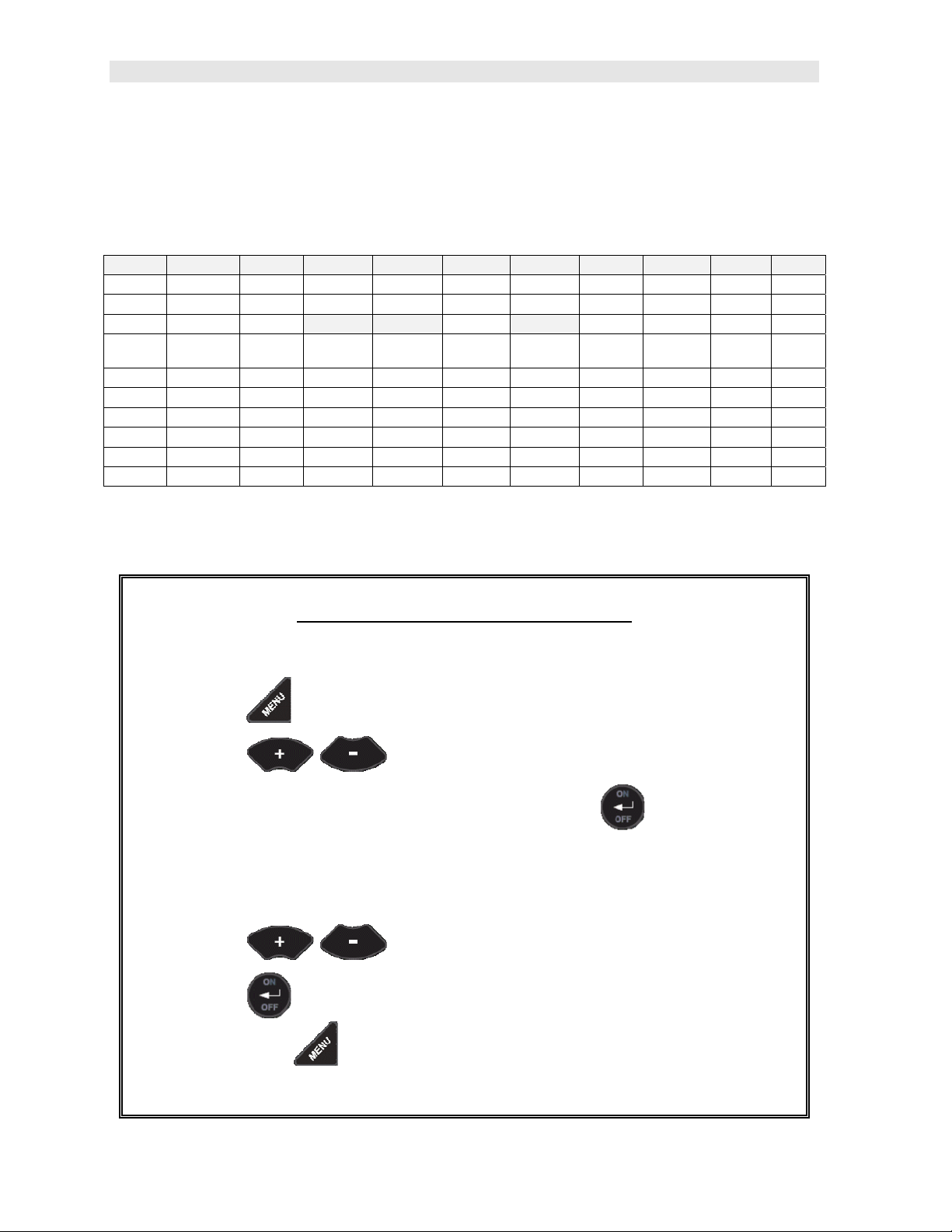

setting are outlined in the table below:

Menu Feature Items:

Gain Matl Scan Alarm Diff Unit Lite Beep Zero VX Probe

VLOW Aluminum On On On English On On Manual On .18 5

LOW Steel Off Off Off Metric Off Off Auto Off .18 5

MED Stainless Options Options Options .25 5

HIGH Iron Set Lo Set

Nominal

VHI Plexiglass Set Hi Med .50 3

PVC High .50 5

Plastic

Poly Urea

User 1

User 2

Lo .25 7

Here’s a quick overview of navigating through the various features in MENU:

Navigating the Features in Menu

1) Press the key once to enter the sub menu items.

2) Press the keys to toggle through the features.

3) To enable or edit the status of any feature, press the key.

4) The edit icon will start blinking to indicate that the ZX-6 DL is currently in

EDIT mode.

5) Press the keys to toggle through the setting options.

6) Press the key to accept changes and return to the top level of

features, or the key at any time to abort changes and return the

measurement screen.

4

Page 9

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

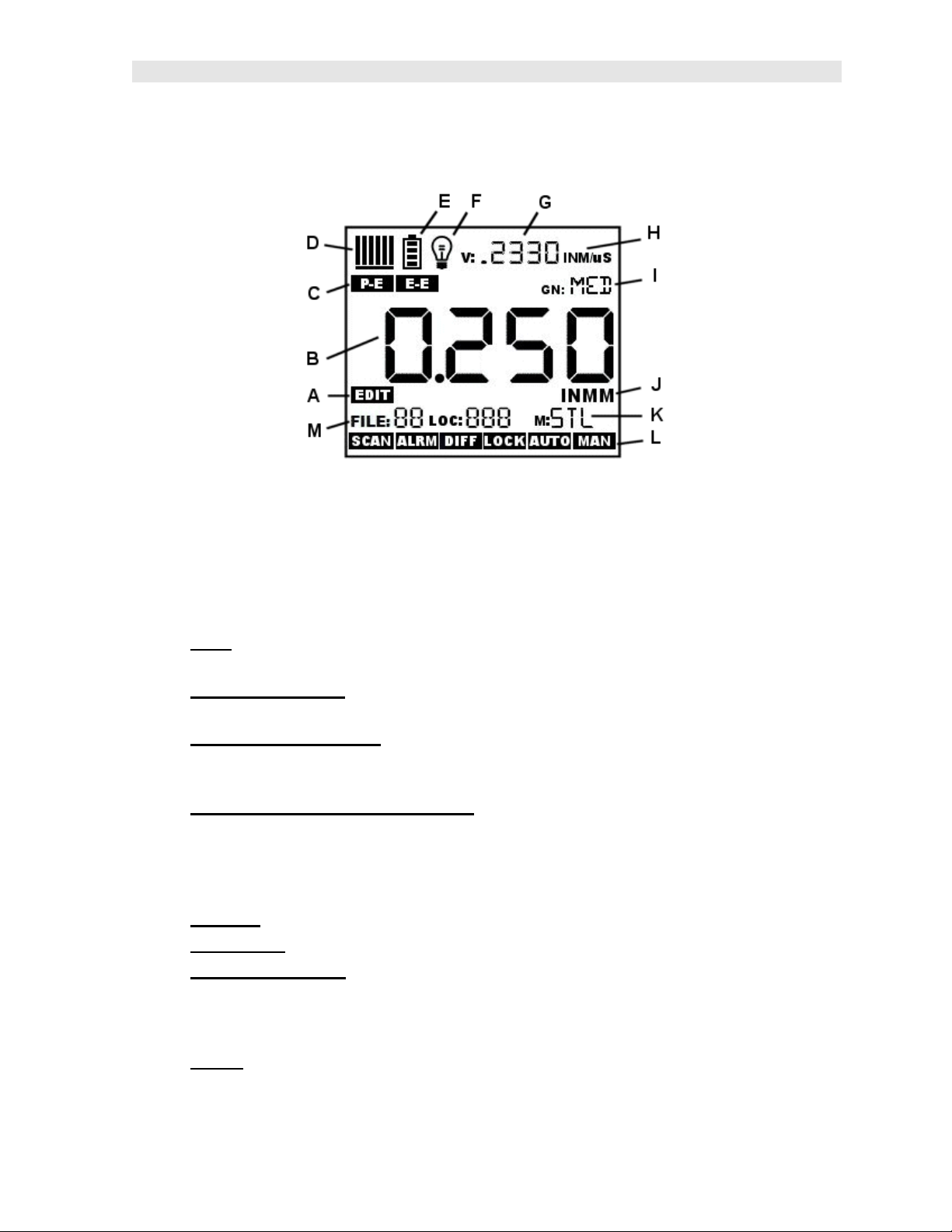

2.9 The Display

The ZX-6 DL uses a custom glass LCD backlit low temperature display for use in a

variety of climate conditions. It contains graphic icons, as well as both 7 and 14

segment display areas. Let’s take a closer look and what all these things are telling

us:

A. Edit: This icon will be displayed, and blinking, to let a user know when they

are in an edit mode to change a value or setting.

B. Large 7 segment: The thickness measurement, velocity or alpha message

will be displayed in this area.

C. Measurement Modes: This group of icons indicates which measurement

mode the ZX-6 DL is currently using. The modes are pulse-echo, for flaw and

pit detection, and echo-echo for through paint and coating measurements.

D. Stability/Repeatability Indicator:

thickness measurement as a reference for the validity of the measurement.

The ZX-6 DL takes multiple measurements per second, and when all the

vertical bars are illuminated, it’s a reference that the same thickness value is

reliably being measured multiple times per second.

E. Battery: Indicates the amount of battery life the ZX-6 DL has remaining.

F. Backlight : When this icon is illuminated, it indicates the backlight is on.

G. Small 7 Segment:

through a given medium/material, is displayed in this area, informing the user

what material the ZX-6 DL is currently calibrated too. This area is also used

for alpha messages in the menu and edit modes.

H. Units: This combination of icons are illuminated in different sequences to

inform the user what measurement units are currently being displayed in the

small 7 segment area.

The material velocity, speed the sound wave travels

This is used in conjunction with the

5

Page 10

Dakota Ultrasonics

I. Small 14 Segment: Displays the current gain setting of the ZX-6 DL. MED is

the default, with the options of VLOW, LOW, MED, HIGH, VHI (40dB to 52db

gain range with MED at 46dB).

J. Units: This combination of icons are illuminated in different sequences to

inform the user what measurement units are currently being displayed in the

large 7 segment area. The plus/minus icon is illuminated when the DIFF

(differential) feature is activated.

K. Small 14 Segment: The material type is displayed in this area. If it is set to a

value of one of the materials in our material list, it will be displayed in alpha

characters indicating the material type. Otherwise it will be set to CUST,

indicating custom material type.

L. Features: The icons illuminated in this row across the bottom of the LCD

display which features are currently enabled. For a complete list of the menu

features in the ZX-6 DL, Refer to page 4 for a list. The ZX-6 DL can be locked

once calibrated, to avoid accidently changing the calibration. When this icon is

illuminated, the ZX-6 DL is in lock mode. Refer to page 41 for an explanation

on locking the ZX-6 DL.

M. File/Loc: This area is exclusively for the data storage section of the ZX-6 DL.

The icons and segment fields represent the current file open, and the current

storage location in the file. Refer to page 44 for an explanation of the data

storage feature in the ZX-6 DL.

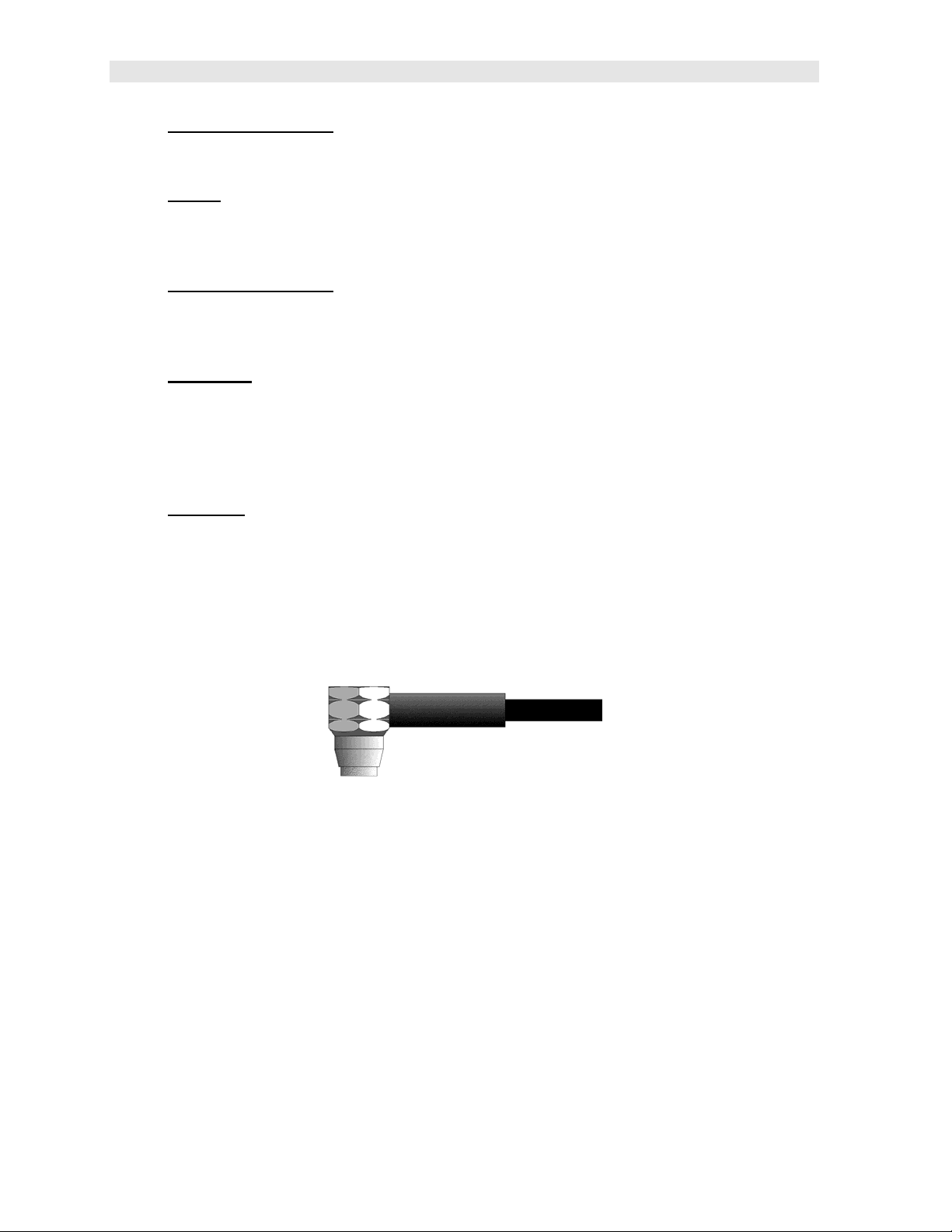

2.10 The Transducer

The Transducer is the “business end” of the ZX-6 DL. It transmits and receives

ultrasonic sound waves that the ZX-6 DL uses to calculate the thickness of the

material being measured. The transducer connects to the ZX-6 DL via the attached

cable, and two coaxial connectors. When using transducers manufactured by Dakota

Ultrasonics, the orientation of the dual coaxial connectors is not critical: either plug

may be fitted to either socket in the ZX-6 DL.

The transducer must be used correctly in order for the ZX-6 DL to produce accurate,

reliable measurements. Below is a short description of the transducer, followed by

instructions for its use.

6

Page 11

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

This is a bottom view of a typical transducer. The two semicircles of the wear face

are visible, as is the barrier separating them. One of the semicircles is responsible

for conducting ultrasonic sound into the material being measured, and the other

semicircle is responsible for conducting the echoed sound back into the transducer.

When the transducer is placed against the material being measured, it is the area

directly beneath the center of the wear face that is being measured.

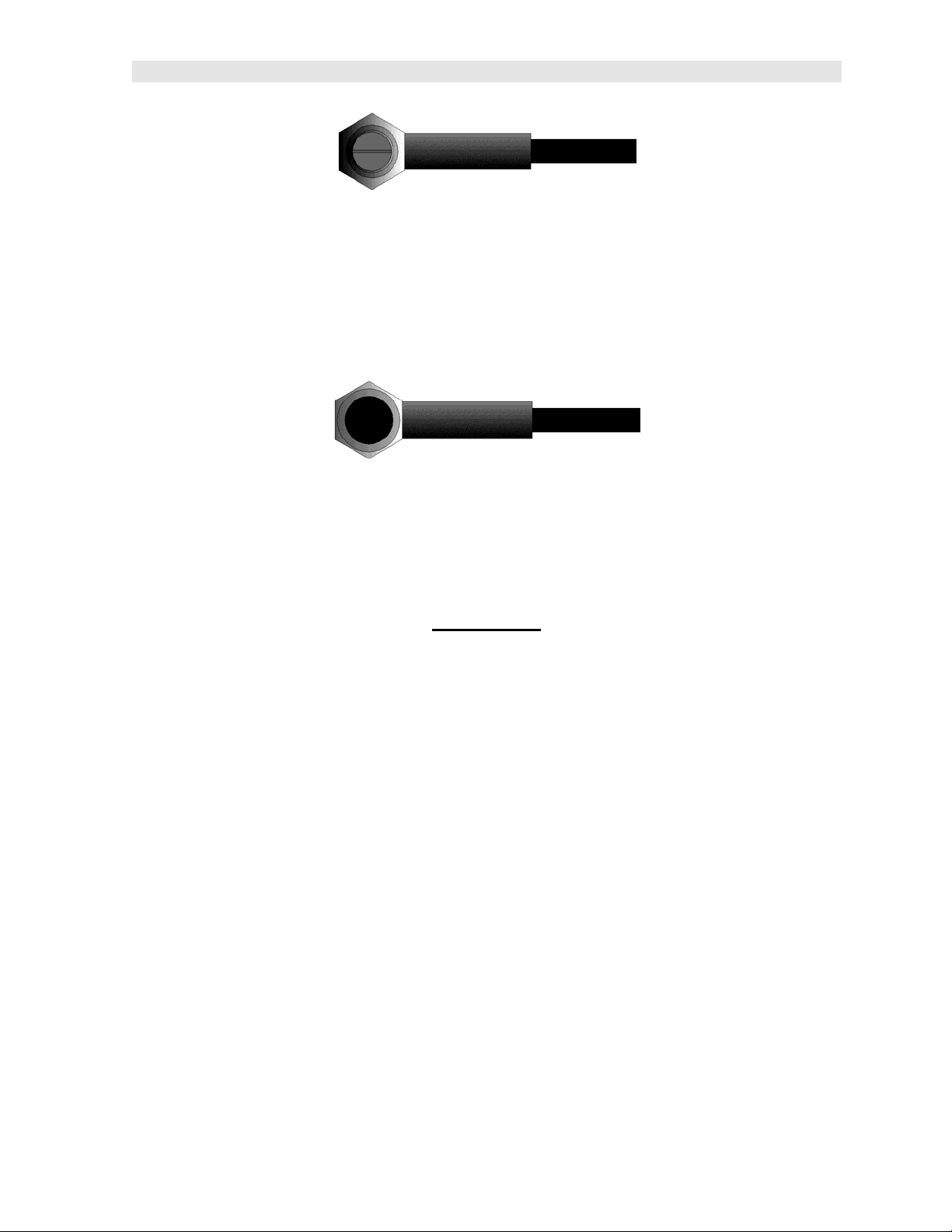

This is a top view of a typical transducer. Press against the top with the thumb or

index finger to hold the transducer in place. Moderate pressure is sufficient, as it is

only necessary to keep the transducer stationary, and the wear face seated flat

against the surface of the material being measured.

Measuring

In order for the transducer to do its job, there must be no air gaps between the wearface and the surface of the material being measured. This is accomplished with the

use of a "coupling" fluid, commonly called "couplant". This fluid serves to "couple", or

transfer, the ultrasonic sound waves from the transducer, into the material, and back

again. Before attempting to make a measurement, a small amount of couplant

should be applied to the surface of the material being measured. Typically, a single

droplet of couplant is sufficient.

After applying couplant, press the transducer (wear face down) firmly against the

area to be measured. The Stability Indicator should have six or seven bars

darkened, and a number should appear in the display. If the ZX-6 DL has been

properly "zeroed" (see page 16) and set to the correct sound velocity (see page 18),

the number in the display will indicate the actual thickness of the material directly

beneath the transducer.

If the Stability Indicator has fewer than five bars darkened, or the numbers on the

display seem erratic, first check to make sure that there is an adequate film of

couplant beneath the transducer, and that the transducer is seated flat against the

material. If the condition persists, it may be necessary to select a different transducer

7

Page 12

Dakota Ultrasonics

(size or frequency) for the material being measured. See page 14 for information on

transducer selection.

While the transducer is in contact with the material that is being measured, the ZX-6

DL will perform four measurements every second, updating its display as it does so.

When the transducer is removed from the surface, the display will hold the last

measurement made.

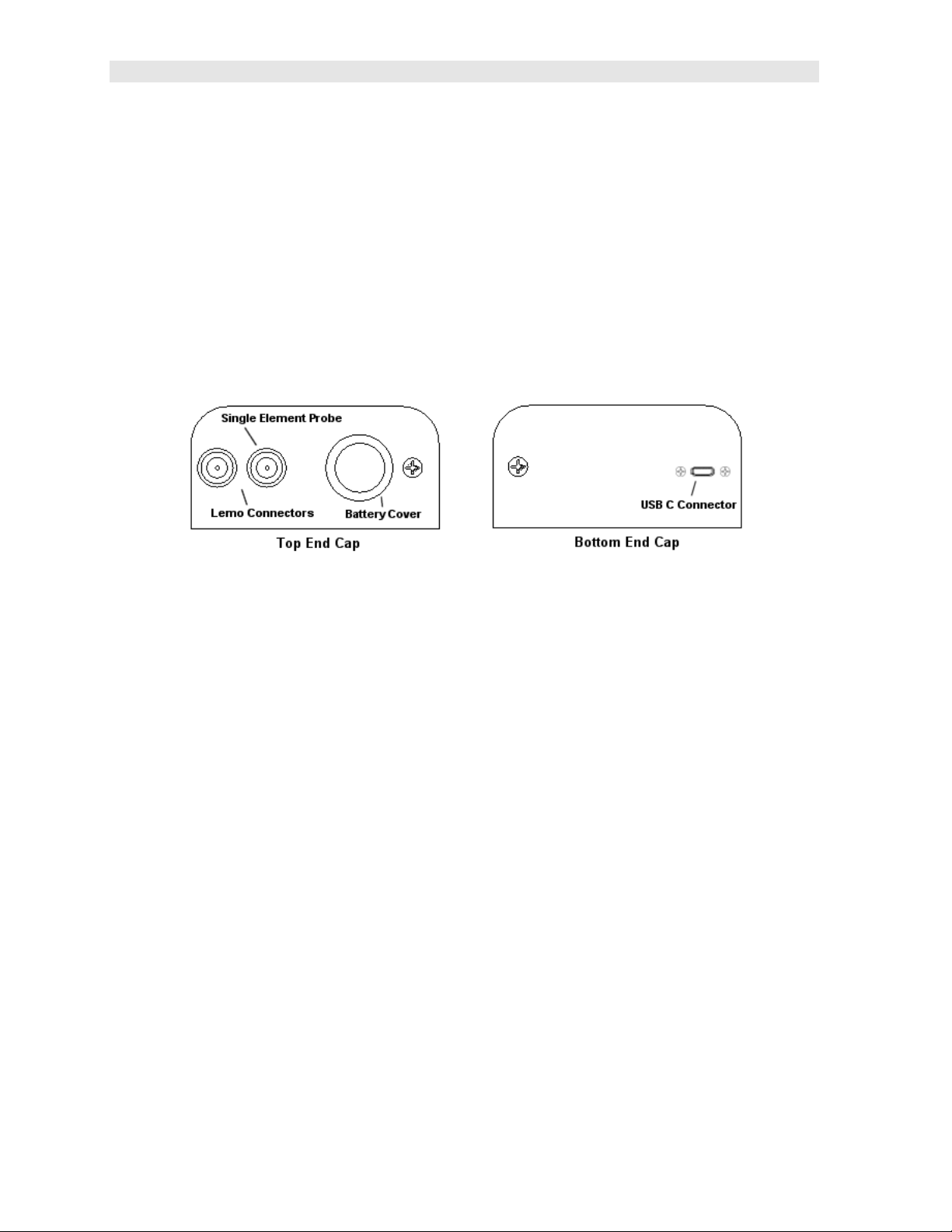

2.11 Top & Bottom End Caps

The top & bottom end panels are where all connections are made to the ZX-6 DL.

The diagram above shows the layout and description of the connectors:

Transducer Connectors

Refer to Diagram: The transducer connectors and battery cover/probe zero disk are

located on the ZX-6 DL’s top end cap. The transducer connectors are of type Lemo

“00”.

Note: There is no polarity associated with connecting the transducer to the ZX-6 DL,

it can be plugged into the gauge in either direction.

Probe Zero Disk & Battery Cover

Refer to Diagram: The Battery cover is the large round disk shown in the diagram.

Note: This same disk is also used as a probe zero disk when the zero feature is set

to the ‘manual’ option. Simply remove the cover when replacing the batteries (2 AA

cells). When performing a manual probe zero function, simply place the transducer

on disk making firm contact. Important: Be sure the battery polarity is correct,

which can be found on the back label of the ZX-6 DL.

Note: Rechargeable batteries can be used, however they must be recharged outside

of the unit in a standalone battery charger.

USB-C Connector

Refer to Diagram: The USB-C connector, located on the bottom end cap, is a mini

type C female connector. It is designed to connect directly from the ZX-6 DL to a

8

Page 13

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

standard USB type A port on a PC. The cable supplied with the ZX-6 DL is a USB

type C to a USB type A (pt# N-003-0330). See page 49 for information on

connectivity.

Note: This connector is also used to upgrade the ZX-6 DL with the latest version of

firmware.

9

Page 14

CHAPTER THREE

PRINCIPALS OF ULTRASONIC MEASUREMENT

3.1 Time versus thickness relationship

Ultrasonic thickness measurements depend on measuring the length of time it takes

for sound to travel through the material being tested. The ratio of the thickness

versus the time is known as the sound velocity. In order to make accurate

measurements, a sound velocity must be determined and entered into the

instrument.

The accuracy of a thickness measurement therefore depends on having a consistent

sound velocity. Some materials are not as consistent as others and accuracy will be

marginal. For example, some cast materials are very granular and porous and as a

result have inconsistent sound velocities.

While there are many different ultrasonic techniques to measure thickness, which will

be discussed below, all of them rely on using the sound velocity to convert from time

to thickness.

3.2 Suitability of materials

Ultrasonic thickness measurements rely on passing a sound wave through the

material being measured. Not all materials are good at transmitting sound.

Ultrasonic thickness measurement is practical in a wide variety of materials including

metals, plastics, and glass. Materials that are difficult include some cast materials,

concrete, wood, fiberglass, and some rubber.

3.3 Range of measurement and accuracy

The overall measurement capabilities, based on the wide variety of materials, is

determined by the consistency of the material being measured

The range of thickness that can be measured ultrasonically depends on the material

type and surface, as well as the technique being used and the type of transducer.

The range will vary depending on the type of material being measured.

Accuracy, is determined by how consistent the sound velocity is through the sound

path being measured, and is a function of the overall thickness of the material. For

example, the velocity in steel is typically within 0.5% while the velocity in cast iron

can vary by 4%.

3.4 Couplant

All ultrasonic applications require some medium to couple the sound from the

transducer to the test piece. Typically a high viscosity liquid is used as the medium.

The sound frequencies used in ultrasonic thickness measurement do not travel

through air efficiently. By using a liquid couplant between the transducer and test

piece the amount of ultrasound entering the test piece is much greater.

10

Page 15

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

3.5 Temperature

Temperature has an effect on sound velocity. The higher the temperature, the slower

sound travels in a material. High temperatures can also damage transducers and

present a problem for various liquid couplants.

Since the sound velocity varies with temperature it is important to calibrate at the

same temperature as the material being measured.

Normal temperature range

Most standard transducers will operate from 0F to 250F.

High temperature measurements

Special transducers and couplants are available for temperatures above 250F up to

1000F with intermittent contact. It is necessary to cool the transducer by

submerging it in water between measurements.

Modes and temperature errors

In addition to errors caused by velocity changing with temperature, some modes

(measurement techniques) are affected more than others. For example, dual

element pulse-echo mode has larger errors due to changes in the temperature of the

transducer. However, multi-echo techniques offer temperature compensation help to

minimize these errors.

3.6 Measurement Modes

This section will cover the different measurements modes of the ZX-6 DL, the

transducers required, and the reasons for using specific modes:

Pulse-Echo (P-E) Mode:

Pulse-echo mode measures from the initial pulse (sometimes referred to as an

artificial zero) to the first echo (reflection). In this mode, either an automatic or

manual zero can be performed depending on the zero probe setting. If the manual

mode has been selected, the transducer is placed on the reference disk located on

top of the ZX-6 DL, and the PRB 0 key pressed to establish a zero point for the

transducer connected. If the Auto Zero feature is enabled, simply pressing the PRB

0 key will perform an electronic zero to establish the same zero point.

In pulse-echo mode, errors can result from surface coatings and temperature

variations. Since pulse-echo only requires one reflection, it is the most sensitive

mode for measuring flaw/defects when measuring heavily corroded metals.

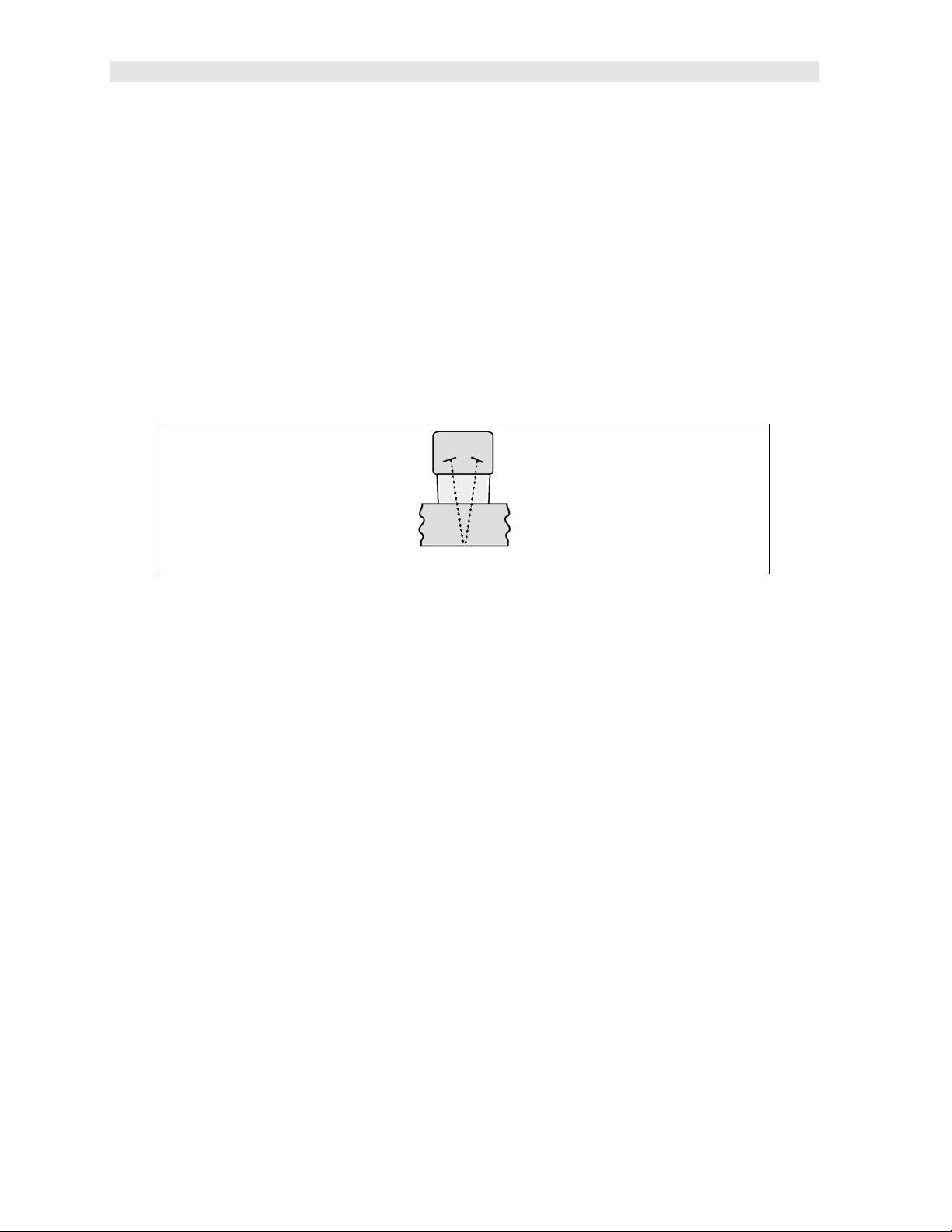

V-Path Correction

Dual element delay line transducers have two piezoelectric elements focused

towards one another at a slight angle, mounted on a delay line. One element is used

for transmitting sound, while the other element receives the sound reflection. The

11

Page 16

Dakota Ultrasonics

two elements and their delay lines are packaged in a single housing but acoustically

isolated from each other with an insulated sound barrier. This allows the transducer

the ability to achieve very high sensitivity for detecting small defects. Also, the

surface of the test material does not have to be as flat in order to obtain good

measurements.

Dual element transducers are normally used in pulse-echo mode for finding defects,

and in echo-echo mode for through coating measurements.

Dual element delay line transducers are have a usable range of 0.025” and up,

depending on the material, frequency, and diameter.

A limitation of dual element delay-line transducers is the V shaped sound path.

Because the sound travels from one element to another, the time versus thickness

relationship is non-linear. Therefore, a correction table in the instruments software is

used to compensate for this error.

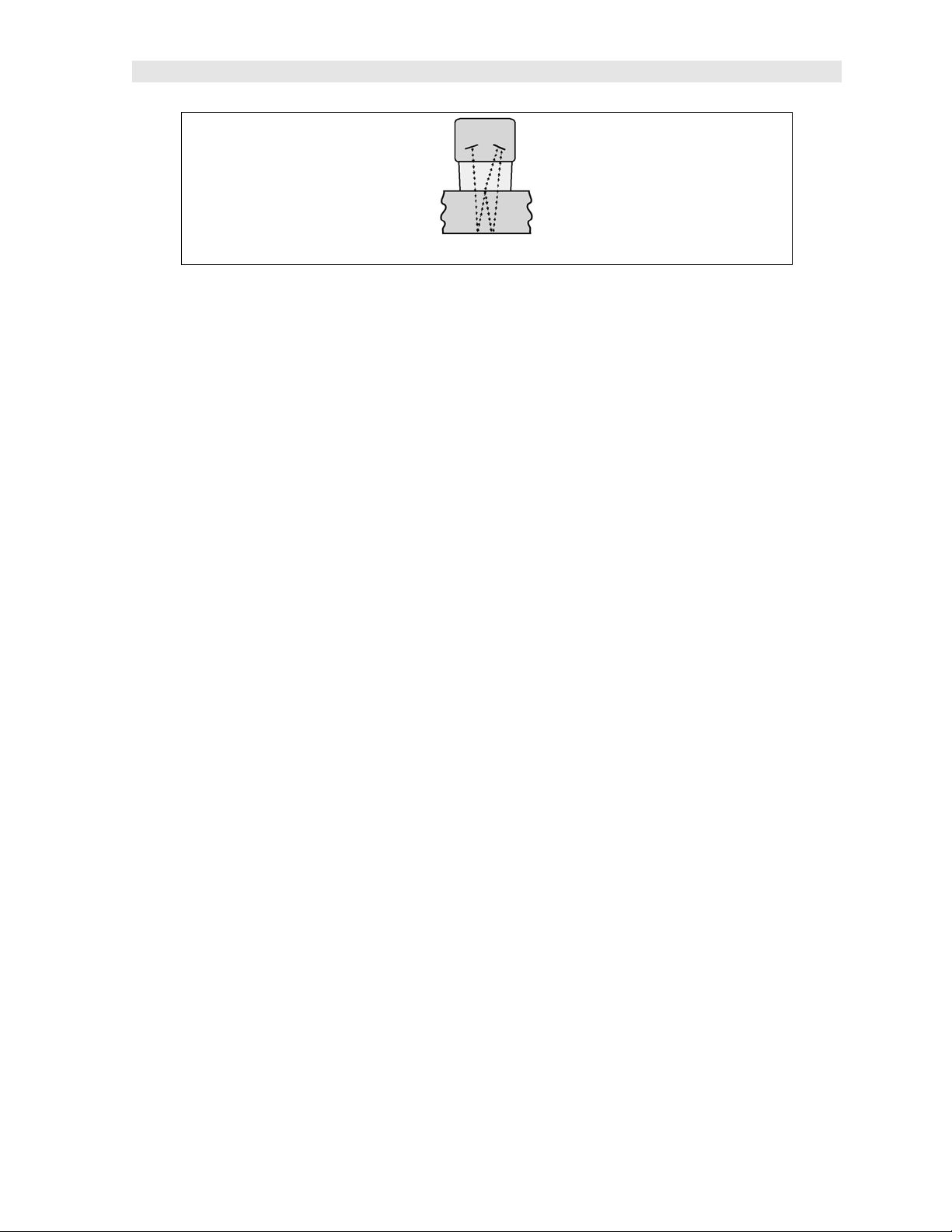

Dual Element Transducer showing V-path of signal

Searching for small defects

Dual element delay line transducers are especially useful in searching for small

defects. In pulse-echo mode with high amplifier gain, very small defects can be

located. As a result, this configuration is commonly used for corrosion inspections.

The dual element style transducer will find wall deterioration, pits, cracks, and any

porosity pockets during tank and pipeline inspections.

Echo-Echo (E-E) Mode – Through Paint

The echo-echo mode measures between the first and second return

echoes/reflections. This technique is commonly used when measuring through a

surface coating and measuring only the second layer of material. Tanks and pipes

commonly have a protective coating applied to the surface. Echo-echo mode will

enable the user to measure just the steel without having to remove the coating. The

disadvantage is that two return echoes are required to effectively measure the test

material. Additionally, echo-echo mode does not have the capability to find defects.

Therefore, both modes will commonly be used; echo-echo mode to find the nominal

thickness of the material without removing the coating, and pulse-echo to locate

defects.

12

Page 17

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

Dual Element Transducer in Echo to Echo mode

13

Page 18

CHAPTER FOUR

SELECTING THE MEASUREMENT MODE

4.1 Which mode & transducer do I use for my application?

High penetration plastics and castings

The most common mode for these types of applications is pulse-echo. Cast iron

applications require 1 - 5MHz frequencies, and cast aluminum requires a 7 - 10MHz

frequency depending on the thickness. Plastics typically require lower frequencies

depending on the thickness and make-up of the material as well. Larger diameters

offer greater penetration power based on the size of the crystal.

Corrosion & Pit Detection in steel and cast materials

Pulse-echo mode is commonly used for locating pits and defects. Typically a 5MHz

transducer, or higher, will be used for these types of applications. Use low

frequencies for greater penetration and use higher frequencies for better resolution.

Measuring Material & Coatings

The pulse-echo coating mode should be used when both material and coating

thickness are required, while still requiring the ability to detect flaws and pits. A

special coating style transducer is required for use in this mode. There are a variety

of coating transducers in various frequencies available from Dakota.

Thru Paint & Coatings

Often times, users will be faced with applications where the material will be coated

with paint or some other type of epoxy material. Since the velocity of the coating is

approximately 3 times slower than that of steel, pulse-echo mode will result in an

error if the coating or paint is not completely removed. By using echo-echo mode,

the user is able to successfully measure through both the coating and steel, and

completely eliminate the thickness of the paint or coating. Therefore, the steel can

be measured without having to remove the coating prior to measuring. Users will

often use pulse-echo mode and echo-echo mode in conjunction when performing

inspections on coated materials.

Thru coating measurements require special high damped transducers. The most

common transducers are the 3.5, 5, and 7.5MHz hi damped transducers. These

transducers are suitable for use in both pulse-echo and echo-echo modes. This

conveniently enables the user to accurately measure overall material thickness using

the thru Coating mode, and then conveniently switch to pit detection mode without

changing transducers. The ¼” 5MHz Hi damped transducer is the most commonly

used transducer for standard thru coating applications.

14

Page 19

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

Thin materials

Pulse echo mode and a high frequency transducer is commonly used for these types

of applications. The most common transducers are the 7.5MHz and 10MHz models

with extra resolution. The higher frequencies provide greater resolution and a lower

minimum thickness rating overall.

High temperature

Special 5 MHz High temperature transducers are available for these types of

applications. Both pulse-echo and echo-echo modes will also work for these

applications. However, echo-echo mode will eliminate error caused by temperature

variations in the transducer.

Noisy Material

Materials such as titanium, stainless steel, and aluminum may have inherent surface

noise issues or mirroring effect. Higher frequency transducers 7 – 10MHz offer

improved resolution to avoid erroneous measurements.

Restricted access

Measuring materials with extreme curvatures or restricted access are best suited for

higher frequencies and smaller diameter transducers.

15

Page 20

CHAPTER FIVE

MAKING MEASUREMENTS

The steps involved in making measurements are detailed in this section. The

following sections outline how to setup and prepare your ZX-6 DL for field use.

An automatic or manual zero must always be performed. The auto zero is an ‘off

block’ electronic zero that does not require a zero reference standard. This will most

always be the zero option of choice, as it makes the zeroing process very easy and

convenient to perform. However, the manual zero option offers better accuracy in

terms of a reference point. If the manual zero option is enabled, the probe zero must

be measured on the reference disk (battery disk) attached to the top of the

instrument. The zero compensates for variations in the transducer. In either mode

the sound velocity must be determined, and is used to convert the transit time to a

physical length. The sound velocity can be selected from a material chart in the

manual, selected from a short list of common materials in the ZX-6 DL, or for greater

precision determined from a sample of the test material that has been mechanically

measured. To enter the velocity from a table, look up the material on the chart in the

appendix of this manual and refer to the section below on Calibration to a Known

Velocity. To determine the velocity of a single sample, refer to the Material

Calibration section on page 18.

When measuring curved materials, it’s more accurate to calibrate from two test

points, one at the minimum limit of the target thickness and one at the maximum limit.

In this case the reference disk mounted to the ZX-6 DL is not used. This is called

two-point calibration and is described on page 21.

5.1 Probe zero

Setting the zero point of the ZX-6 DL is important for the same reason that setting the

zero on a mechanical micrometer is important. It must be done prior to calibration,

and should be done throughout the day to account for any temperature changes in

the probe. If the ZX-6 DL is not zeroed correctly, all the measurements taken may be

in error by some fixed value. The zero can only be performed with the

measurement mode set to pulse-echo (P-E). Therefore, if the ZX-6 DL is to use the

echo-echo (E-E) measurement mode and a manual zero is being performed, the ZX-

6 DL will argue by briefly displaying the message “NO PRB0”.

Important note: The internal zero setting of the ZX-6 DL, used for the auto zero

mode, can be reset at anytime by performing a “manual zero”, and immediately

followed by performing an “auto zero”.

The ZX-6 DL is equipped with two zero options:

1) Off Block Zero (Automatic Probe Zero) – When this feature is enabled the

ZX-6 DL will do an electronic zero automatically, eliminating the need for a

zero disk or reference standard.

16

Page 21

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

2) On Block Zero (Manual Probe Zero) – When this feature is enabled the

transducer must be placed on the probe zero disk (battery cover) located on

the top of the unit.

Both zero procedures are outlined as follows:

Performing an Auto Probe Zero (Off Block)

1) Press the key to perform the auto zero. “AUTO” will be displayed on

the screen and flashing CLn/Prb (clean probe).

2) Make sure the couplant is wiped clean from the tip of the transducer to avoid

any zero error.

3) Press the key to perform the zero.

Performing a Manual Probe Zero (On Block)

Note: When the zero probe option is set to manual, the probe zero disk

(battery cap) located on the top of the gauge will be used as a zero standard.

1) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the disk (battery cover) located at the top of the unit to

obtain a measurement.

17

Page 22

Dakota Ultrasonics

2) Be sure all six repeatability/stability bars in the top left corner of the display

are fully illuminated and stable, and last digit of the measurement is toggling

only +/- .001” (.01mm).

3) Press the key to perform the manual zero. “PRB0” will briefly be

displayed on the screen, indicating the zero calculation is being performed.

5.2 Material Calibration

In order for the ZX-6 DL to make accurate measurements, it must be set to the

correct sound velocity of the material being measured. Different types of materials

have different inherent sound velocities. For example, the velocity of sound through

steel is about 0.233 inches per microsecond, versus that of aluminum, which is about

0.248 inches per microsecond. If the gauge is not set to the correct sound velocity,

all of the measurements the gauge makes will be erroneous by some amount.

The One Point calibration is the simplest and most commonly used calibration

method - optimizing linearity over large ranges. The Two Point calibration allows for

greater accuracy over small ranges by calculating both the probe zero, as well as the

material velocity. The ZX-6 DL provides three simple methods for setting the sound-

velocity outlined below:

Known Velocity

If the material velocity is known, it can be manually entered into the ZX-6 DL, rather

than have the ZX-6 DL calculate the velocity value using a known thickness of the

same material type. The steps for entering the velocity are outlined below:

Using a Known Material Velocity

1) With the transducer free from contact with the material, press the key

to display the current velocity.

18

Page 23

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

2) Use the

value.

Note: The longer the keys are pressed and held, the faster the value will

increment/decrement.

Note: Pressing the key prior to pressing the key will abort the cal

routine without saving any changes.

3) Press the key to set the velocity value and return to the measurement

screen. The new velocity value will be shown at the top of the display.

keys to scroll the velocity to the known target

Known Thickness

Often times the exact sound velocity of a material is unknown. However, a sample

with one or two known thicknesses can be used to determine the sound velocity. As

previously discussed, the ZX-6 DL has a one or two point calibration option. The one

point calibration option is most suited for linearity over large ranges. When using the

one point option, the calibration should be perform on the thickest side of the

measurement range for the best linearity for that range. For example, if the

measurement range is .100” (2.54mm) to 1.0” (25.4mm), the user should calibrate on

a known thickness sample close to 1.0” (25.4mm). Note: It’s always handy to carry

a set of mechanical calipers to use in conjunction with the ZX-6 DL for calibration of

various materials in the field:

One Point Calibration

Note: Be sure that a probe zero has been performed prior to performing this

calibration procedure.

1) Physically measure an exact sample of the material, or a location directly on

the material to be measured, using a set of calipers or a digital micrometer.

19

Page 24

Dakota Ultrasonics

Note: A sample or location on the test piece should be used as close to the

maximum thickness of the test range to minimize error.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material. Be sure that the

reading is stable and the repeatability indicator in the top left corner of the

display is fully lit and stable.

3) Press the key to enter the calibration edit screen displaying the current

measurement value.

4) Use the keys to scroll to the known thickness value.

Note: The longer the keys are pressed and held, the faster the value will

increment/decrement.

Note: Pressing the key prior to pressing the key will abort the cal

routine without saving any changes.

5) Once the known thickness value is being displayed, press the key to

display the calculated material velocity edit screen.

Note: The calculated velocity can be edited, if needed, by pressing the

keys to scroll and edit the velocity value.

6) Press the key to set the calculated material velocity and return to the

measurement screen.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the

calibration point and verify the thickness. If the thickness is not correct, repeat

the steps above.

20

Page 25

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

Two Known Thicknesses

The two point calibration should be considered when an application requires

improved accuracy over a small measurement range based on tolerance

requirements. This calibration option calculates both the ‘probe zero’ and ‘velocity

value. If the two point option is used, a probe zero is not required. For example, if

the measurement range was .080” (2.03mm) to .250” (6.35mm), two known samples

or locations on the test material would be needed for the minimum and maximum

boundaries of the test range. Using the range above, a one point calibration would

be performed at .250” (6.35mm) and a two point calibration at .080” (2.03mm), or

something close to the min/max values of the measurement range.

Note: The ZX-6 DL also offers the capability of setting the ‘probe zero’ to use any

reference standard as the ‘probe zero’ standard. For clarification, if it’s desired to use

a one inch reference of a specific material type as the ‘zero’ reference, performing

the first point of a two-point calibration sets the internal zero of the ZX-6 DL. This

should be used only in manual probe zero mode “on block”.

The following steps outline this procedure:

Two Point Calibration

1) Physically measure a minimum and maximum calibration point of the exact

sample material, or locations directly on the material to be measured, using

a set of calipers or a digital micrometer.

Note: A sample or location on the test piece should be used as close to the

minimum and maximum thickness of the test range to minimize error and

improve linearity.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with either the minimum or maximum sample or actual test

material. Be sure that the reading is stable and the repeatability indicator in

the top left corner of the display is fully lit and stable.

21

Page 26

Dakota Ultrasonics

3) Press the key to enter the calibration edit screen displaying the current

measurement value.

4) Use the keys to scroll to the known thickness value.

Note: The longer the keys are pressed and held, the faster the value will

increment/decrement.

Note: Pressing the key prior to pressing the key will abort the cal

routine without saving any changes.

5) Once the known thickness value is being displayed, press the key to

display “1 of 2”, which sets the zero value and returns to the measurement

screen.

Note: The internal zero of the ZX-6 is now set. The procedure above can be

used to set the internal zero of the ZX-6 to use any reference standard as

the ‘probe zero’ standard if desired.

6) Repeat steps 2-4 on the second test point/location.

7) Press the key to display the calculated velocity edit screen.

Note: The calculated velocity can be edited, if needed, by pressing the

keys to scroll and edit the velocity value.

8) Press the key to set the calculated material velocity and return to the

measurement screen.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the

calibration points. The thickness readings should now match the known

22

Page 27

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

thickness values with minimal error. If the thicknesses are not correct, repeat

the steps above.

Basic Material Type

If the material velocity is unknown, a sample thickness cannot be taken directly from

the material, but the general type of material is known, selecting a basic material type

from the common material (MATL) list in the ZX-6 DL would offer a reasonable

approximation of the thickness. There are 9 common materials and 2 user

programmable settings available. It’s important to note that these velocities will not

always be an exact representation of the material being tested. Use these values

only if a close approximation is acceptable. Follow the steps below to select a basic

material type:

Selecting a Basic Material Type

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

MATL feature is being displayed.

3) Press the key to edit the material setting. The edit icon will be

illuminated and flashing.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving any changes.

4) Use the keys to scroll through the material options.

23

Page 28

Dakota Ultrasonics

ALUMINUM

(2024)

STEEL (4340)

in/µs m/s

0.250 6350

0.233 5918

STAINLESS (303)

CAST IRON

PLEXIGLASS

PVC

POLYSTYRENE

POLYURETHANE

USER PROGRAMMABLE

0.223 5664

0.180 4572

0.106 2692

0.094 2388

0.092 2337

0.070 1778

5) When the desired MATL setting is displayed, press the key to set the

material velocity and return to the measurement screen.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving any changes.

6) If USR1 or USR2 were selected, the velocity edit screen will be displayed

and edit icon illuminated and flashing.

7) Use the keys to scroll to the desired material velocity.

Note: The longer these keys are held, the faster the velocity value is

incremented.

8) When the desired velocity setting is displayed, press the key to set the

material velocity and return to the measurement screen.

9) Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving any changes.

24

Page 29

CHAPTER SIX

THROUGH PAINT MEASUREMENT - MULTI MODE

6.1 Introduction

Through paint measurement is accomplished by measuring the time between two

repeat echoes from the back surface of the material. Since both of these back wall

echoes travel the same path through the paint or coating, the thickness of the coating

is subtracted out of the measurement so that only the actual material thickness is

measured. This avoids having to scrape or remove the coating from materials prior

to inspection. The primary purpose of thru paint measurement is to determine the

actual/nominal material thickness without error from the coating.

Through paint mode cannot be used for flaw or pit detection based on the internal

gating and thresholds. As a result, inspectors will typically use both echo-echo

through paint mode in conjunction with the standard pulse-echo flaw detection mode

for coated material and corrosion inspection. Finally, this mode will only work for

typical epoxy based coatings.

6.2 Multi Mode Transducers

The multi echo measurement technique does have restrictions on the type of dual

element transducers it can use successfully. The key requirement is that the

transducers are “high damped”, which refers to the duration of how long the

transducer rings. In order to improve the low end measurement range, being able to

measure thin materials, the cycles of ring must be limited so they don’t interfere with

the internal gating.

Since the ZX-6 DL is a basic easy to operate gauge without the adjustability you’d

get using an advanced A-Scan scope, specific diameter and frequency options can

be selected as an option in the menu items. The factory default setting is (.25 5) or

0.250” 5MHz, as the most commonly requested transducer. Refer to page 4 for a list

of available high damped transducer diameters and frequencies.

The procedure for activating the through paint (E-E) measurement mode is outlined

as follows:

Echo-Echo Multi Mode

25

Page 30

Dakota Ultrasonics

Note: Be sure that a probe zero and “one point calibration”, or a “two point

calibration” has been performed prior to this procedure.

1) Press the key to toggle between the measurement modes; pulse-echo

(P-E) and echo-echo (E-E) at any time.

Note: An icon will be illuminated in the top left portion of the display to indicate

the measurement mode the ZX-6 DL is currently using.

26

Page 31

CHAPTER SEVEN

VELOCITY GAUGE

7.1 Velocity Gauge (VX)

The ZX-6 DL includes a function to convert the unit into a dedicated velocity gauge.

With this feature enabled, the ZX-6 DL will display all measurements in terms of

velocity, inches per microsecond (IN /s) or meters per second (M /s), rather than

dimensional inches or millimeters. This is primarily useful for rudimentary “nodularity”

testing, as the velocity can be associated with density and used to determine the

hardness/strength of a given material. A casting manufacturer would typically use

this feature to control their processes and make sure the density/hardness is

sufficient for each part and batch within a specified tolerance.

Using this feature will require calibration on a “known” thickness that will remain

consistent at a specific location on a group of parts. The test will always be

performed at the same location for all parts in the group. The velocity will be

determined, and either accepted or rejected depending on the specified tolerances.

The procedure for enabling this feature is outlined below:

Velocity Gauge Option

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

VX feature is being displayed.

3) Press the key to edit the velocity gauge setting. The edit icon will be

illuminated and flashing.

4) Use the keys to toggle velocity on/off.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

27

Page 32

Dakota Ultrasonics

5) When the desired VX setting is displayed, press the key to set the

status and return to the measurement screen.

7.2 Calibration to a known thickness

In order to calibrate the ZX-6 DL a ‘known thickness’ on the material or part will be

used. The same location will be used for all the other parts in the group/batch to

determine the velocity.

The procedure is outlined as follows:

Calibration – Known Thickness

Note: Be sure that a probe zero has been performed prior to performing this

calibration procedure.

1) Physically measure an exact sample of the material, or a location directly on

the material to be measured, using a set of calipers or a digital micrometer.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material. Be sure that the

reading is stable and the repeatability indicator, in the top left corner of the

display, is fully lit and stable.

3) Press the key to enter the calibration edit screen displaying the current

velocity IN /s (M /s) value. The edit icon will be illuminated and flashing.

4) Press the key again to edit the known thickness value. The edit icon

will be illuminated and flashing and the units will be IN or MM, indicating

thickness.

28

Page 33

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

5) Use the keys to scroll to the known thickness value.

Note: The longer the keys are pressed and held, the faster the value will

increment/decrement.

Note: Pressing the key prior to pressing the key will abort the cal

routine without saving any changes.

6) Once the known thickness value is being displayed, press the key to

return to the measurement screen and display the calculated material

velocity.

Note: The known thickness value that was used to calibrate will be displayed in

the top right corner of the display for confirmation.

7.3 Calibration to a known velocity

The velocity can also be directly edited and set to a target velocity value that was

previously determined from a reference standard at an earlier time.

The procedure for directly entering the velocity is outlined below:

Calibration – Known Velocity

Note: Be sure that a probe zero has been performed prior to performing this

calibration procedure.

Note: This procedure requires that the operator know the sound-velocity of the

material to be measured. A table of common materials and their sound-

velocities can be found in Appendix A.

29

Page 34

Dakota Ultrasonics

1) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material. Be sure that the

velocity measurement is stable and the repeatability indicator, in the top left

corner of the display, is fully lit and stable.

2) Press the key to enter the calibration edit screen displaying the current

velocity IN /s (M /s) value. The edit icon will be illuminated and flashing.

3) Use the keys to scroll to the known velocity value.

Note: Pressing the key prior to pressing the key will abort the cal

routine without saving any changes.

4) Once the known velocity value is being displayed, press the key to

display the calculated thickness based on known velocity.

5) Press the key to return to the measurement screen and begin making

measurements.

Note: The known velocity value that was entered will be displayed, and the

thickness value calculated will appear in the top right corner of the display

for confirmation.

30

Page 35

CHAPTER EIGHT

ADDITIONAL FEATURES

8.1 Gain

The gain, or amplification of the return echoes, can be adjusted in the ZX-6 DL to

accommodate a variety of materials and applications. The setting of the gain is

crucial in order to obtain valid readings during the measurement process. Too much

gain may result in erroneous measurements, detecting on noise rather than the

actual material back wall surface. Not enough gain may result in intermittent

detection. It could also result in lack of detection on internal flaws, pits, or porosity.

The gain can be compared to the volume control of a home stereo system. If you

turn it up too much, you can’t hear the music clearly. If it’s turned down too much,

you can’t hear it at all.

The ZX-6 DL has five gain settings (VLOW, LOW, MED, HIGH, VHI). The gain

range is 40dB – 52dB in 3dB increments. The ZX-6 DL has been optimized for the

MED gain setting at 46dB for all common applications. It should be operated in this

mode as standard. However, some applications may require the lower or higher gain

settings. When? The low settings may be necessary for noisy or granular cast

materials. How do I know when to lower the gain? If the reading becomes sporadic

and won’t settle down or resolve on a thickness value because the material is either

very noisy or granular. Setting the gain to a lower less sensitive level, would

potentially offer improved stability.

How do I know when to increase the gain? When a material is difficult to penetrate or

pass sound through. This could be due to the material type, overall thickness, the

transducer diameter and frequency, or a combination of all the above. Turning the

gain up for additional output could improve the ability to obtain a successful

measurement. Another example would be the need to increase overall sensitivity for

locating fine pits or flaws. In any case, the selectable gain settings offer improved

versatility to resolve and overcome potential application issues.

Note: When the echo-echo through paint measurement mode is selected, the

automatic gain control (AGC) is enabled. The dynamic range of the AGC can be

adjusted with the following options (LOW, MED, HIGH), with MED still being the

optimized standard setting as above.

The procedure for editing the gain is outlined as follows:

GAIN

31

Page 36

Dakota Ultrasonics

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

GAIN feature is being displayed.

3) Press the key to edit the gain setting. The edit icon will be illuminated

and flashing.

4) Use the keys to scroll through the gain settings in P-E

(VLOW, LOW, MED, HIGH, VHI), or E-E (LOW, MED, HIGH) until the

desired setting is being displayed.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) Press the key to set the gain and return to the measurement screen.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

8.2 High Speed Scan

The High Speed Scan feature of the ZX-6 DL increases the overall repetition rate to a

maximum of 140Hz with a high speed screen refresh rate of 25 times a second. This

allows for making scanned passes over an arbitrary length of the test material, while

still maintaining a reasonable representation of thickness over the area or region

scanned. The alarm (ALRM) feature, with high and low limits, can be used in

conjunction with high speed scan.

The procedure to use the scan feature is outlined below:

High Speed Scan

32

Page 37

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

SCAN feature is being displayed.

3) Press the key to edit the scan setting. The edit icon will be illuminated

and flashing.

4) Use the keys to toggle scan on/off.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired SCAN setting is displayed, press the key to set the

status and return to the measurement screen.

8.3 Alarm

The Alarm feature of the ZX-6 DL provides a method of setting tolerances, or limits,

for a particular application requirement. This feature may be used for a variety of

applications to verify the material thickness is within the manufacturer specifications.

The settings available are ON/OFF/BEEP, where beep enables the audible beeper.

Both the on and beep settings will illuminate the led alarm lights above the keys on

the keypad. There are two limit values HI/LO, that can be set according to specified

tolerances.

The procedure to use the alarm feature is outlined below:

ALARM

1) Press the key to access the menu items/features.

33

Page 38

Dakota Ultrasonics

2) Use the keys to scroll through the items/features until the

ALRM feature is being displayed.

3) Press the key to edit the alarm status. The edit icon will be illuminated

and flashing.

4) Use the keys to toggle alarm on/off/beep.

5) When the desired ALRM status is displayed, press the key to set the

status and edit the LO limit option.

6) Use the keys to scroll the LO limit value to the target value.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes to the LO limit value.

7) When the target LO limit is displayed, press the key to set the value

and advance to setting HI limit option.

8) Use the keys to scroll the HI limit value to the target value.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes to the HI limit value.

9) When the target HI limit is displayed, press the key to set the value

and return to the measurement screen.

8.4 Differential

The Differential Mode of the ZX-6 DL provides the user with the ability to set a

nominal value, according to what the expected thickness should be, and measure the

+/- difference from the nominal value entered. This feature is typically used in QA

incoming inspections on pipes, plate stock, coils, etc.

34

Page 39

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

The steps below outline how to enable and enter the nominal value to use this

feature:

Differential

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

DIFF feature is being displayed.

3) Press the key to edit the differential status. The edit icon will be

illuminated and flashing.

4) Use the keys to toggle differential on/off.

5) When the desired DIFF setting is displayed, press the key to set the

status and edit the NOMINAL value.

6) Use the keys to scroll the NOMINAL value to the target

value.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes to the NOMINAL value.

7) When the target value is displayed, press the key to set the value and

return to the measurement screen.

8.5 Units

The ZX-6 DL will operate in both English (inches) or Metric (millimeters) units.

The procedure to select the units is outlined as below:

35

Page 40

Dakota Ultrasonics

Units

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

UNIT feature is being displayed.

3) Press the key to edit the units setting. The edit icon will be illuminated

and flashing.

4) Use the keys to toggle English or Metric units.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired UNIT setting is displayed, press the key to set the

units and return to the measurement screen.

8.6 Lite

The ZX-6 DL uses a custom glass segmented display that is equipped with a

backlight for use in low light conditions. The options are on/off/auto, where the auto

setting only lights the display when the gauge is coupled to the material and receiving

a measurement.

The steps below outline how to toggle the options:

Backlight

36

Page 41

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

LITE feature is being displayed.

3) Press the key to edit the light setting. The edit icon will be illuminated

and flashing.

4) Use the keys to toggle status on/off/auto.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired LITE setting is displayed, press the key to set the

status and edit the BRT (brightness) option.

6) Use the keys to scroll through the BRT (LO, MED, HI)

options.

7) When the desired BRT setting is displayed, press the key to set the

brightness and return to the measurement screen.

8) Note: Pressing the key prior to pressing the key will abort to

the measurement screen without saving changes.

8.7 Beep

The ZX-6 DL also has a feature to use the internal beeper, most commonly used with

the alarm feature, for the key strokes on the keypad. When enabled, pressing any of

the keys on the keypad will sound the beeper.

The procedure to enable the keyboard beeper feature is outlined below:

37

Page 42

Dakota Ultrasonics

Beeper

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

BEEPER feature is being displayed.

3) Press the key to edit the beeper setting. The edit icon will be

illuminated and flashing.

4) Use the keys to toggle the beeper on/off.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired BEEP setting is displayed, press the key to set the

status and return to the measurement screen.

8.8 Zero

There are two transducer zeroing options available in the ZX-6 DL; auto and manual.

The AUTO zero can be performed automatically without using a reference standard

to zero the gauge, while the MANUAL option requires a reference standard like the

battery disk at the top of the gauge. Additionally, the gauge can be set to use

another reference standard if needed. Refer to page 38 for a complete explanation

of the probe zero options.

The procedure to select the zero option only, is outlined below:

Zero (Auto/Manual)

38

Page 43

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

ZERO feature is being displayed.

3) Press the key to edit the zero setting. The edit icon will be illuminated

and flashing.

4) Use the keys to select the auto/man option.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired ZERO setting is displayed, press the key to set the

status and return to the measurement screen.

8.9 Velocity (VX)

When the velocity setting (VX) is enabled, the ZX-6 DL will display the material

velocity as the primary measurement quantity instead of dimensional thickness. The

feature is generally used for basic “nodularity” testing, as velocity is a key part of

density for determining hardness. An example might be casting manufacturers

where the density/hardness will determine the strength of the material.

When this feature is enabled, the ZX-6 DL is operating in reverse to the standard

option of the gauge. Only the ‘one point’ calibration can be used with this feature

active, and a manual or auto zero is still required. The ZX-6 DL can be calibrated by

entering the known velocity or entering the know thickness of the material at a given

position on the test material. Refer to the ‘making measurements’ section on page

27 for a complete explanation of the zero and one point calibration procedure.

The procedure to enable the velocity feature is outlined below:

Velocity Gauge

39

Page 44

Dakota Ultrasonics

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

VX feature is being displayed.

3) Press the key to edit the setting. The edit icon will be illuminated and

flashing.

4) Use the keys to select the on/off option.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired VX setting is displayed, press the key to set the

status and return to the measurement screen.

8.10 Probe Diameter & Frequency

The PROB feature was added to improve linearity when using a specific probe

diameter and frequency. The default standard setting is (.25 5) 0.250” 5MHz Hi

Damped, and works reasonably well using a general correction curve for all of our

dual element transducers in the range. However, selecting the exact diameter and

frequency of the transducer will offer additional linearity (accuracy). The five options

found in our range of transducers are (.18 5, .18 7, .25 5, .25 7, .50 3, .50 5),

diameter followed by frequency (inches). All of our transducer diameters and

frequencies are marked on top of the transducer housing.

The procedure to select the probe/transducer diameter and frequency is outlined

below:

Probe

40

Page 45

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

1) Press the key to access the menu items/features.

2) Use the keys to scroll through the items/features until the

PROB feature is being displayed.

3) Press the key to edit the diameter/frequency setting. The edit icon will

be illuminated and flashing.

4) Use the keys to select the diameter/frequency option.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving changes.

5) When the desired PROB setting is displayed, press the key to select

the probe type and return to the measurement screen.

8.11 Lock

The lock feature was built into the ZX-6 DL for the purpose of locking the operators

out of editing any of the gauge settings, for purposes of consistency between

operators. When the lock feature is enabled, the gauge calibration functionality

cannot be altered, as well as any of the individual features in the gauge. The only

keys that are always unlocked are the power and probe zero keys, as these must

remain unlocked for measurement functionality.

The procedure to enable/disable the lock feature is outlined below:

Lock

41

Page 46

Dakota Ultrasonics

1) With the ZX-6 DL powered off, press and hold down the key while

powering the ZX-6 DL on . The lock icon will be illuminated on the

display.

2) To unlock the ZX-6 DL repeat step one, but hold down the key

while powering the ZX-6 DL on .

8.12 Factory Defaults

The ZX-6 DL can be reset to factory defaults at any time to restore the original gauge

settings. This should only be used if the gauge is not functioning properly, or

perhaps multiple features have been enabled and a clean start is needed.

The procedure to reset the gauge is outlined below:

Factory Reset

1) With the ZX-6 DL powered off, press and hold down the and

keys while powering the ZX-6 DL on .

Note: Once the measurement screen is displayed the and can be

released.

2) Press the keys to scroll through the factory setting options.

3) Make a note of the “MEDI” & “ZERO” settings prior to performing a reset.

These values will need to be entered back in the gauge following the reset.

4) Press the keys to scroll “REST” (reset).

42

Page 47

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

5) Press the key to edit the reset option.

6) Press the keys to toggle YES, followed by pressing

to reset the gauge.

7) Repeat the steps above to set “MEDI” & “ZERO” back to their original

settings noted in step three above.

43

Page 48

CHAPTER NINE

DATA STORAGE

9.1 Introduction

The ZX-6 DL is equipped with a basic and convenient sequential style data logger

that’s intuitive to operate. By ‘sequential’ meaning a single column of 250

measurements and a total of 40 individual files, for a total storage capacity of 10,000

measurements. These files can then be transferred to a PC using the USB-C to USB

type A cable included in the kit. When ZX-6 DL is connected to a PC, it will show up

in the list of drives as an external hard drive, or “thumb” drive. Open the external

gauge drive, and copy the files to and from the gauge and PC.

The file format is .csv (comma separated) and can be opened using any text editor,

spreadsheet editor, or Dakota’s proprietary PC software supplied with the gauges.

Only files with at least one measurement stored in the file will appear in the external

drive folder.

9.2 Opening a Data File

Open Data File

1) Press the key to access the data files and display the current file open.

2) Press the key to edit which file to open. The edit icon will be

illuminated and flashing.

3) Use the keys to scroll through the files.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without saving any changes.

44

Page 49

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

4) When the desired FILE is displayed, press the key to open the file and

return to the measurement screen.

Note: The FILE and LOC (location) will be displayed in lower left portion of the

measurement screen.

9.3 Storing a Measurement

Now that a file has been selected and opened, the ZX-6 DL is ready to store

measurements.

The following procedure outlines this process:

Storing Data

1) Use the keys to scroll to the desired location to store a

measurement.

2) Press the key to store a measurement and advance to the next

location (LOC).

3) Repeat steps 1 and 2 as needed.

Note: If an area exists where a measurement cannot be obtained successfully,

press the key to store OBST (obstruction) in the location. Pressing the

again will clear the location.

Note: If a measurement has been previously stored in a location, scrolling to

that location will display the measurement currently stored, and show MEM

45

Page 50

Dakota Ultrasonics

(memory) in the top right corner of the display. If the key is pressed

to store another measurement at that location, FULL will briefly be

displayed on the screen indicating a measurement has already been stored

at that location. Pressing the key will clear the previously stored

measurement from the location. Pressing the key will now store the

new measurement.

9.4 Clearing a File

If a file contains a large number of previously stored measurements, and has already

been downloaded, the file will need to be cleared of its measurements.

The following procedure outlines this process:

Clear File

1) Press the key to access the data files and display the current file open.

2) Press the key to edit which file will be cleared. The edit icon will be

illuminated and flashing.

3) Use the keys to scroll to the file that will be cleared.

4) When the desired FILE is being displayed, press the key to select the

file to be cleared.

5) Use the keys to scroll to CLR (clear).

46

Page 51

ZX- 6 DL Ultrasonic Multi-Mode Thickness Gauge

6) Press the key to display the confirmation screen. CLR? will be

displayed, as well as a flashing Yes/No option.

7) Press the key for YES, and the key for NO. The edit icon

will be illuminated and flashing.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without clearing the file.

8) Press the key to confirm Yes/No selection and return to the

measurement screen.

Note: If Yes was selected a BUSY message will briefly be displayed

confirming the file is being cleared.

9.5 Clear All Files

If a number of files in the ZX-6 DL contain old data, or data that has been previously

downloaded, clearing all the files might prove an efficient option.

The following procedure outlines this process:

Clear Files

1) Press the key to access the data files and display the current file open.

2) Use the keys to scroll to the CLR ALL option.

47

Page 52

Dakota Ultrasonics

3) Press the key to display the confirmation screen. CLR ALL is

displayed, as well as a flashing Yes/No option.

4) Press the key for YES, and the key for NO. The edit icon

will be illuminated and flashing.

Note: Pressing the key prior to pressing the key will abort to the

measurement screen without clearing the files.

5) Press the key to confirm Yes/No selection and return to the