Page 1

OPERATION MANUAL

DAKOTA ULTRASONICS

PPVVXX--BB

Precision Visual Thickness Gauge

P/N P-195-0002 Rev 1.0, September 2014

Page 2

Dakota Ultrasonics

Page 3

CHAPTER ONE INTRODUCTION ...................................................................... 1

CHAPTER TWO QUICK STARTUP GUIDE ....................................................... 2

CHAPTER THREE KEYBOARD, MENU, & CONNECTOR REFERENCE ....... 11

CHAPTER FOUR PRINCIPALS OF ULTRASONIC MEASUREMENT ............ 20

CHAPTER FIVE SELECTING THE MEASUREMENT MODE .......................... 23

CHAPTER SIX MAKING MEASUREMENTS .................................................... 26

CHAPTER SEVEN USING THE DIGITS & B-SCAN DISPLAYS ...................... 38

CHAPTER EIGHT THRU PAINT MEASUREMENT TECHNIQUE ................... 51

CHAPTER NINE ADDITIONAL FEATURES OF THE PVX-B ........................... 52

CHAPTER TEN DATA STORAGE – SETUP, EDIT, & VIEW GRIDS ............... 57

CHAPTER ELEVEN SETUPS – CREATE, STORE, EDIT, & RECALL ............ 74

CHAPTER TWELVE USING THE UTILITY SOFTWARE ................................. 81

APPENDIX A - VELOCITY TABLE ................................................................... 82

APPENDIX B - SETUP LIBRARY ..................................................................... 84

Page 4

Page 5

CHAPTER ONE

INTRODUCTION

The Dakota Ultrasonics model PVX-B is a precision ultrasonic thickness gauge with a

time based B-Scan and alpha numeric data logger. Based on the same operating

principles as SONAR, the PVX-B is capable of measuring the thickness of various

materials with accuracy as high as 0.0001 inches, or 0.001 millimeters. The

principle advantage of ultrasonic measurement over traditional methods is that

ultrasonic measurements can be performed with access to only one side

material being measured.

Dakota Ultrasonics maintains a customer support resource in order to assist users

with questions or difficulties not covered in this manual. Customer support may be

reached at any of the following:

of the

Dakota Ultrasonics Corporation

1500 Green Hills Road, #107

Scotts Valley, CA 95066 USA

Telephone: (831) 431-9722

Facsimile: (831) 431-9723

www.dakotaultrasonics.com

1.1 Disclaimer

The PVX-B is a full-featured precision thickness gauge with a great deal of features

and measurement modes allowing a great deal of control over the functionality and

electronic performance of the instrument. As this provides the user greater control

and versatility for a variety of applications, it also requires that the user be

comfortable with the operation of these features and modes when operating the

instrument. It is strongly recommended that the contents of this manual be read in its

entirety. It is also recommended that a sufficient amount of time be allocated to

working with the instrument in a test environment prior to use in the field.

Responsibility for proper use of the instrument and recognition of this phenomenon

rest solely with the user of the instrument.

1

Page 6

Dakota Ultrasonics

CHAPTER TWO

QUICK STARTUP GUIDE

Turn the PVX-B on and off using the switch located on the bottom right corner of the

keypad. When PVX-B is initially turned on, a flash logo and blinking lights will be

displayed prior to entering into the main measurement screen. Note: This section is

primarily written as a basic startup guide only.

2.1 Selecting the Transducer Type

The first step in using the PVX-B is to select the transducer type stored in a setup.

There are 18 factory setups containing different transducer types that can be loaded,

modified and stored in a new setup location. By selecting the transducer type from a

predefined setup list, the PVX-B can recall specific properties about the transducer,

setup the display area and predefined scope settings. Note: Once the transducer

has been selected, the PVX-B will store and recall this setup, containing the

transducer type, every time the PVX-B is powered on/off. This setup will only change

if the user physically selects another setup from the list. Therefore, if you have

previously gone through this section and selected the appropriate setup, proceed to

the next section. Use the following steps to select your setup (transducer type):

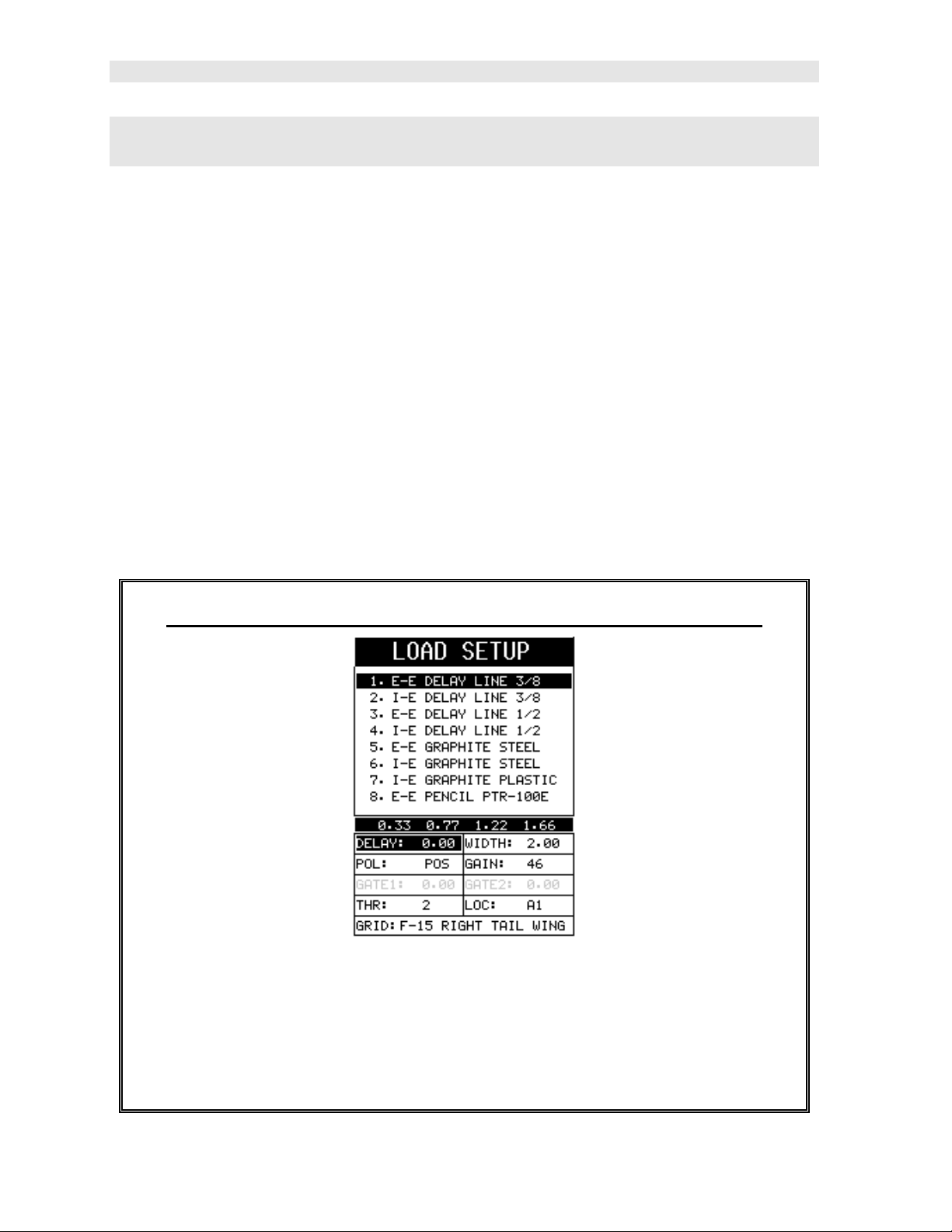

Selecting a Setup for use with a specific Transducer Type

1) Press the MULTI MODE key once to activate the load setup list containing

the transducer types and settings.

2) Use the UP and DOWN arrow keys to scroll through the setup list until the

target setup is highlighted.

2

Page 7

PVX-B Precision Visual Thickness Gauge

3) Press the ENTER key to display the confirmation screen.

4) Press the OK key to select the setup and return to the measure screen, or

ESC to cancel the selecting a setup.

2.2 Calibration

The next step is to calibrate the PVX-B to the material and transducer being used. If

a sound velocity is not known, the PVX-B can be calibrated to a known thickness

sample. This demo will briefly explain each of possible calibration techniques. Read

through the various calibration techniques and select one of the following:

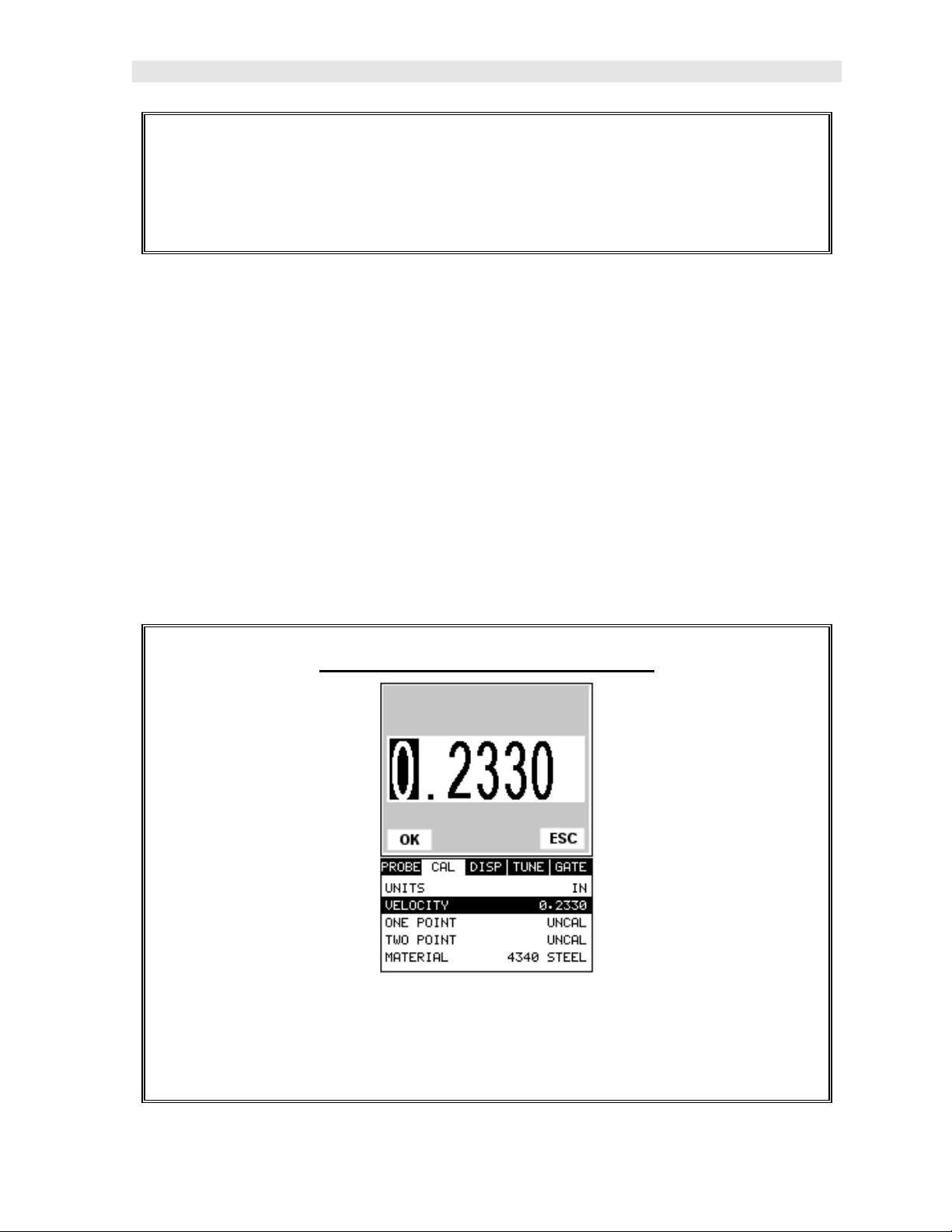

Known Velocity

If the material velocity is known, the user may wish to simply enter the velocity

number into the PVX-B, rather than have the PVX-B calculate the velocity value

using a know thickness. The steps for entering the velocity are outlined below:

Using a Known Material Velocity

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items.

3

Page 8

Dakota Ultrasonics

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VELOCITY is highlighted.

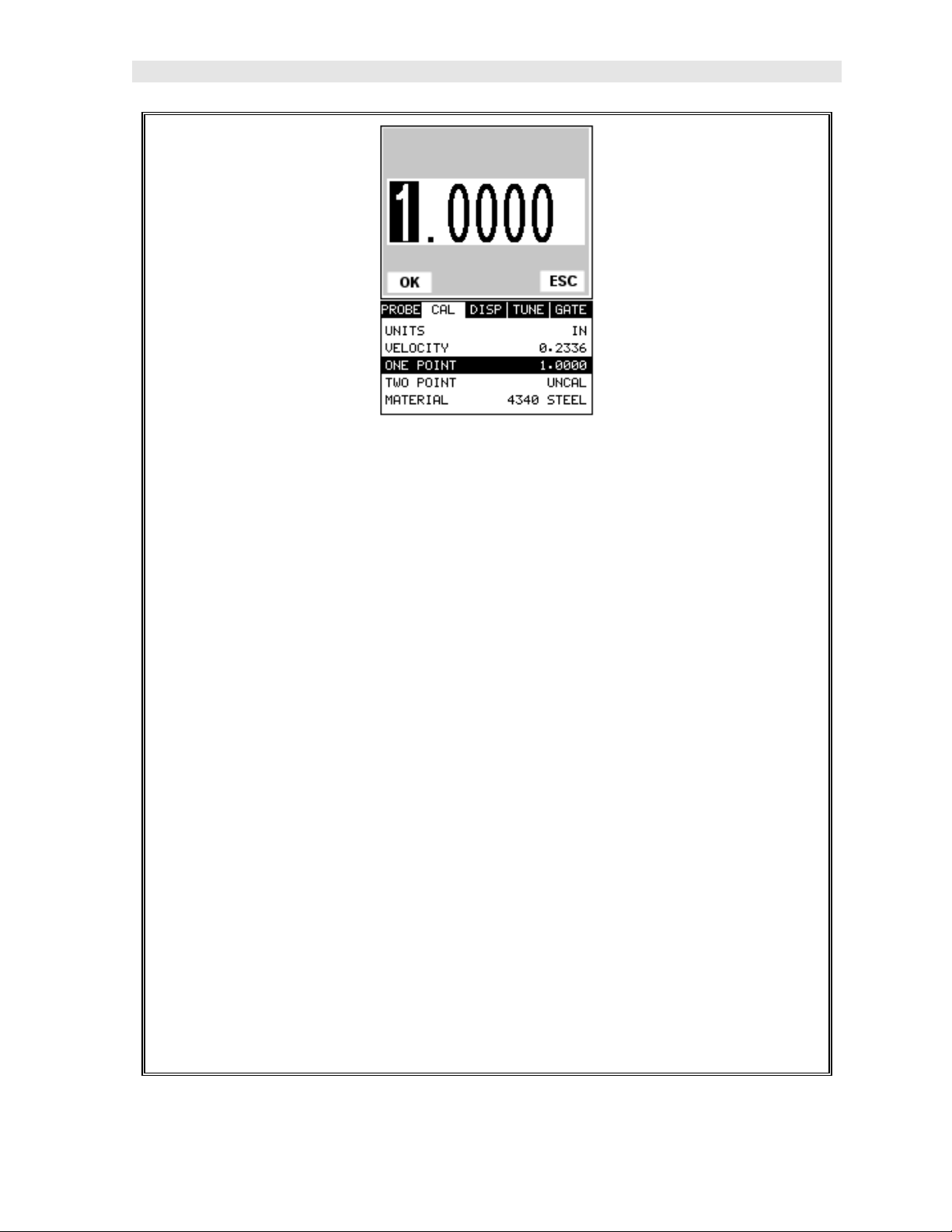

3) Press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the velocity number is correctly displayed.

7) Press the OK key to set the velocity and return to the menu screen, or ESC

to cancel entering the velocity.

8) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Known Thickness

Sometimes the sound velocity of a material is not known. In this case a sample with

a known thickness can be used to determine the sound velocity. It would be very

handy to carry a set of mechanical calipers to use in conjunction with the PVX-B for

calibration in the field:

Using a Known Thickness

4

Page 9

PVX-B Precision Visual Thickness Gauge

1) Physically measure an exact sample of the material or a location directly on

the material to be measured using a set of calipers or a digital micrometer.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material. Be sure that the

reading is stable and the repeatability indicator, in the top left corner of the

display, is fully lit and stable. Press the MENU key once to activate the

menu items tab. Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the CAL menu is highlighted and

displaying the submenu items.

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ONE POINT is highlighted.

4) Press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the known thickness value is correctly displayed.

5

Page 10

Dakota Ultrasonics

8) Press the OK key to calculate the velocity and return to the menu screen, or

ESC to cancel entering the velocity.

9) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the

calibration point. The thickness reading should now match the known

thickness. If the thickness is not correct, repeat the steps above.

6

Page 11

PVX-B Precision Visual Thickness Gauge

Basic Material Type

If the material velocity is unknown, and a sample thickness cannot be taken from the

material, the user may opt to choose a basic material type from a list with

approximate velocity numbers. It’s important to note that these velocities will not

always be an exact representation of the material being tested. Use these values

only if a close approximation is acceptable. Follow the steps below to select a basic

material type:

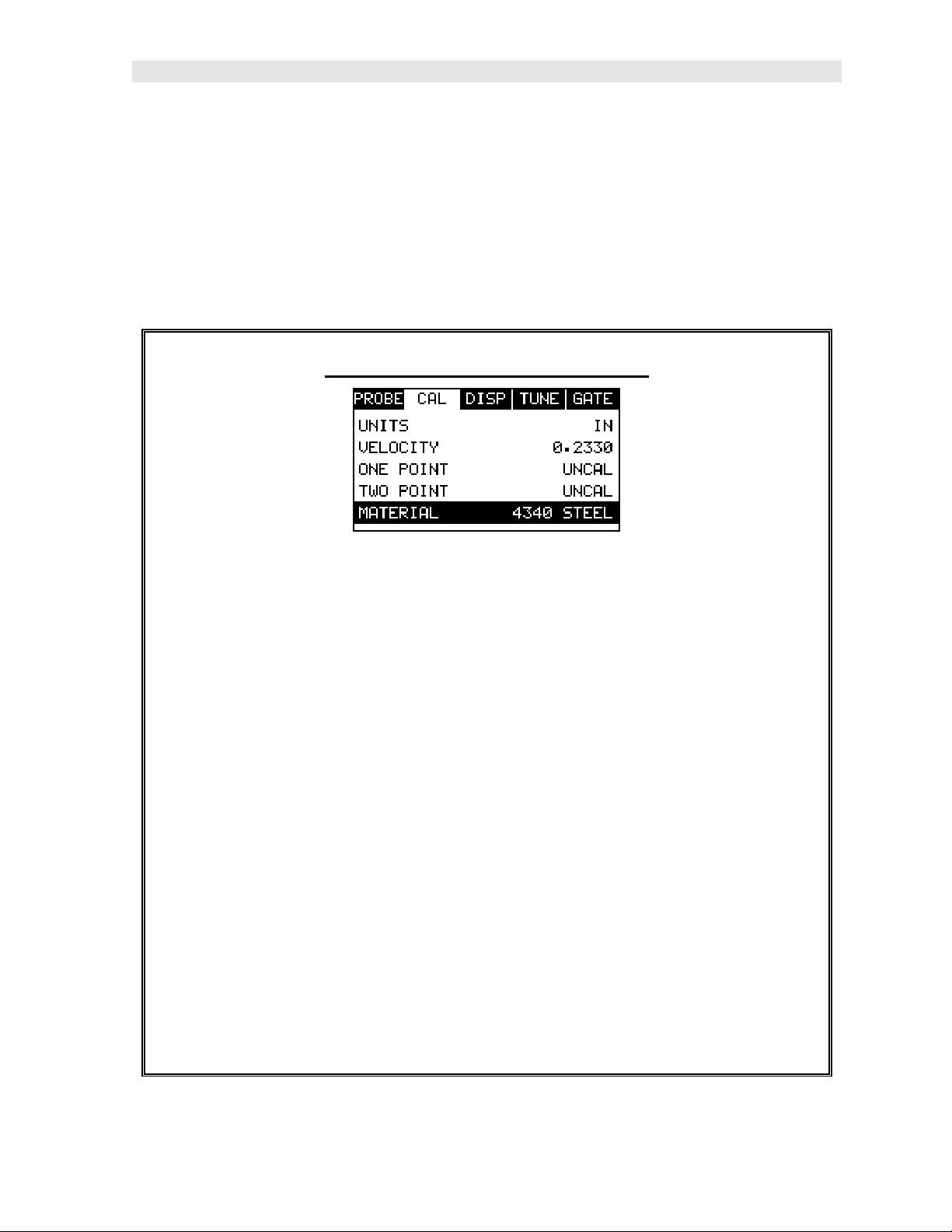

Selecting a Basic Material Type

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATERIAL is highlighted.

3) Press the ENTER key to display the list of material types.

4) Press the UP and DOWN arrow keys to scroll through the material list until

the appropriate material is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to select the material and return to the menu screen, or

ESC to cancel the material selection.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

7

Page 12

Dakota Ultrasonics

2.3 Measure

The PVX-B is now ready to measure. There are two different measurement view

options, each with a specific purpose. The steps below outline how to toggle

between the different view mode options:

Selecting the Measurement View Option

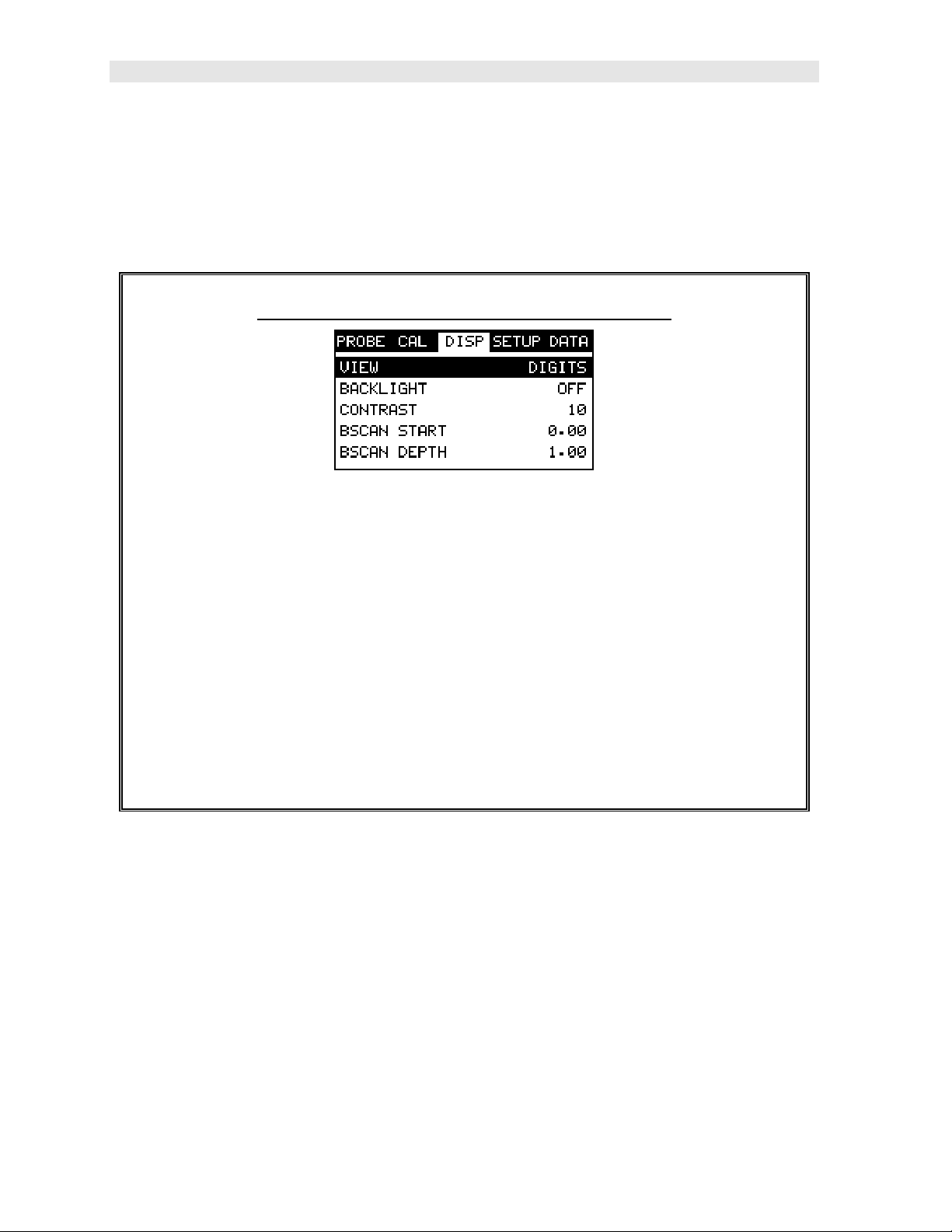

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VIEW is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the view options.

4) Once the view is displayed, press the MEAS key to return to measurement

mode.

DIGITS: Is a general digital view of the thickness value using a larger font size.

BSCAN: The Time Based B-Scan provides the user with a cross sectional view of

the material being tested. This mode is useful when there is concern regarding the

profile of the blind surface.

Once the view has been selected according to the application requirements, the

BSCAN START (B-ST) and BSCAN DEPTH (B-DEP) of the screen will potentially

need to be adjusted if the view has been set to BSCAN. Use the following steps to

adjust these settings directly from the measurement screen as follows:

8

Page 13

PVX-B Precision Visual Thickness Gauge

Adjusting the Start (B-ST) & Depth (B-DEP)

1) Press the MEAS key once to activate the measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the either the B-ST or B-DEP cell is highlighted.

2) Use the UP, DOWN, LEFT, or RIGHT arrow keys to scroll the DELAY and

WIDTH values.

3) Repeat steps 1 & 2 until the range is correctly being displayed.

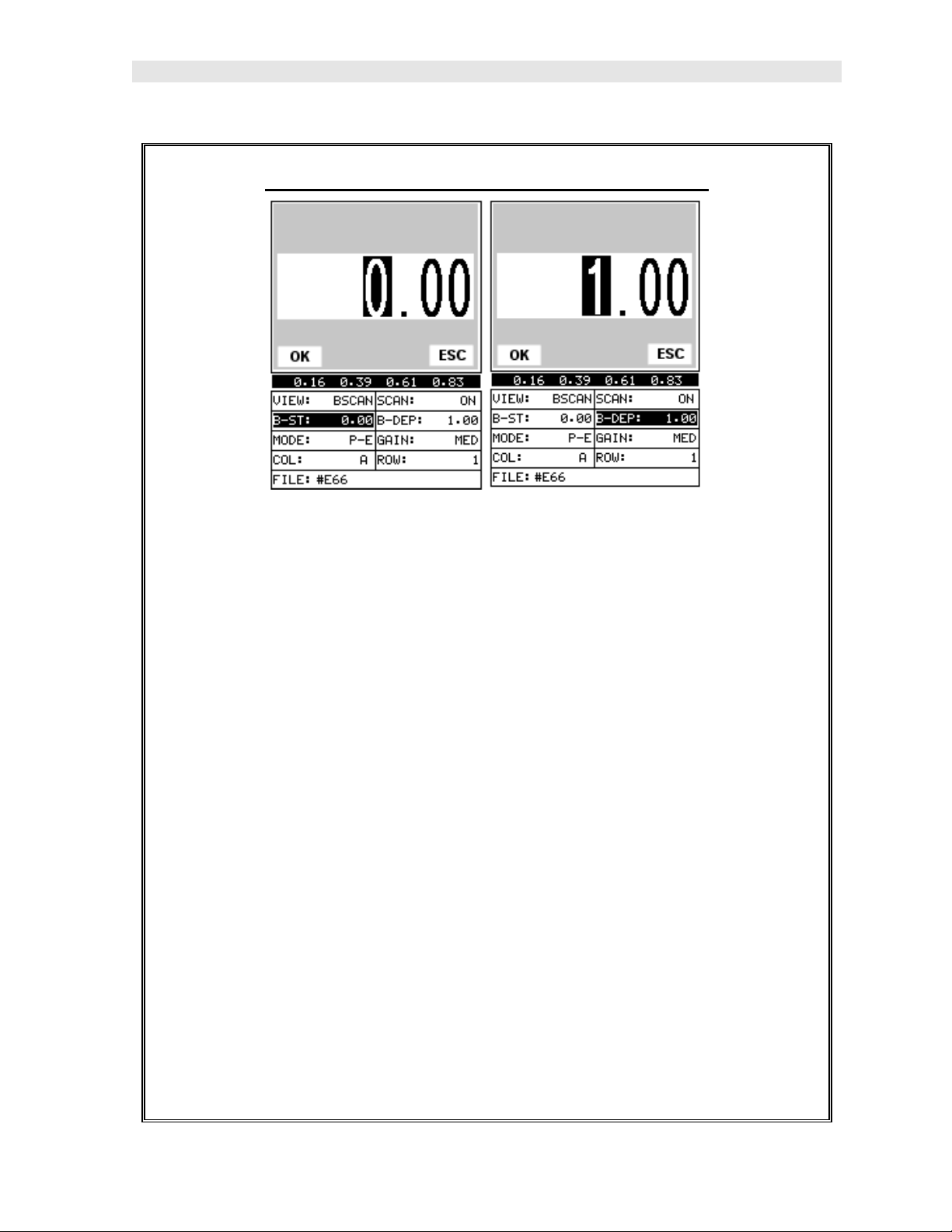

Alternatively, the B-ST and B-DEP values can be changed using the Digit Edit

Box as follows:

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the either the B-ST or B-DEP cell is highlighted.

2) Press the ENTER key to display the digits edit box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the B-ST or B-DEP value is correctly displayed.

9

Page 14

Dakota Ultrasonics

6) Press the OK key to set the B-ST and B-DEP value and return to the

measure screen, or ESC to cancel entering the B-ST or B-DEP value.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Note: The B-ST & B-DEP can also be adjusted from the menu tab items.

However, using the hot menu keys is the easiest method.

In the upper left corner of each of the mode photos above, is the repeatability

indicator. The repeatability indicator is represented by six vertical bars and

represents how repeatable the measurements are. In regular measurement mode,

the PVX-B makes 4 measurements a second. In scan mode, the PVX-B makes 32

measurements a second. When the PVX-B is idle, only the left vertical bar and the

underline will be displayed. However, when the PVX-B is making a measurement,

five or six of the bars should be displayed on the repeatability indicator. If fewer than

five bars are showing, the PVX-B is having difficulty achieving a stable measurement

and the thickness value displayed is potentially be unstable.

DIGITS B-SCAN

10

Page 15

CHAPTER THREE

KEYBOARD, MENU, & CONNECTOR REFERENCE

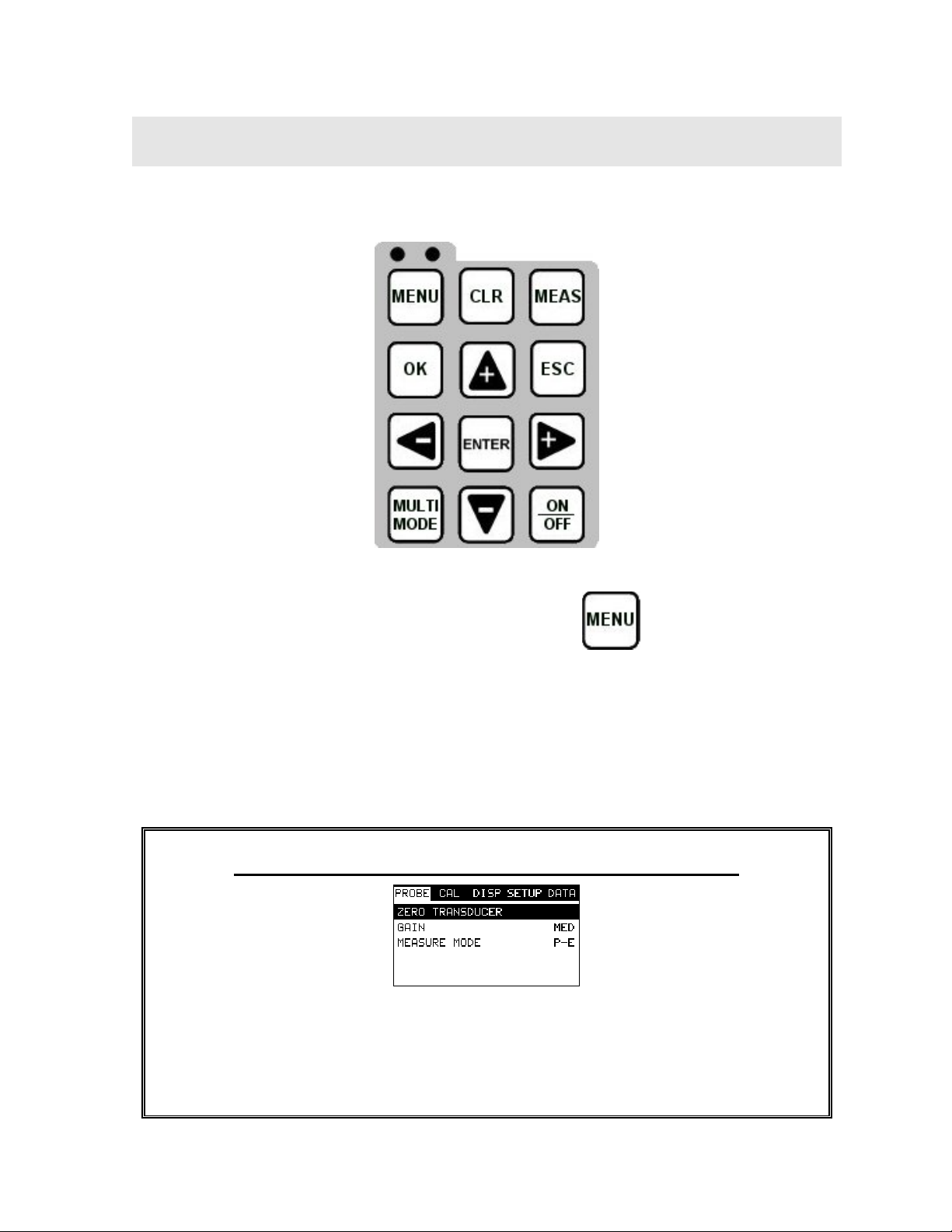

3.1 Menu Key (Operation & Sub Menus )

The Menu key activates the primary menu structure containing 9 menu tab groups.

These tab groups then contain sub menu items, or functions. The sub menu items

have been organized in tab groups according to how closely they are related to the

individual tab group names. Let’s first get familiar with how to move around in these

tabs before continuing on to the sub menu functions. This procedure is outlined

below:

Activating and Getting Around in the Menu Items

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left

until the desired tab group is highlighted and displaying the submenu items.

11

Page 16

Dakota Ultrasonics

Now that your familiar with activating and moving amongst the tab groups, let’s have

a look at how to move around in the sub menu items as follows:

Getting Around in the Sub Menu Items

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until the desired function is highlighted.

2) Depending on which function is highlighted, use the LEFT, RIGHT, and

Enter keys to scroll the options or activate the Digit Edit and List Box

options.

The sections to follow will provide the user with an explanation of the sub menu

functions:

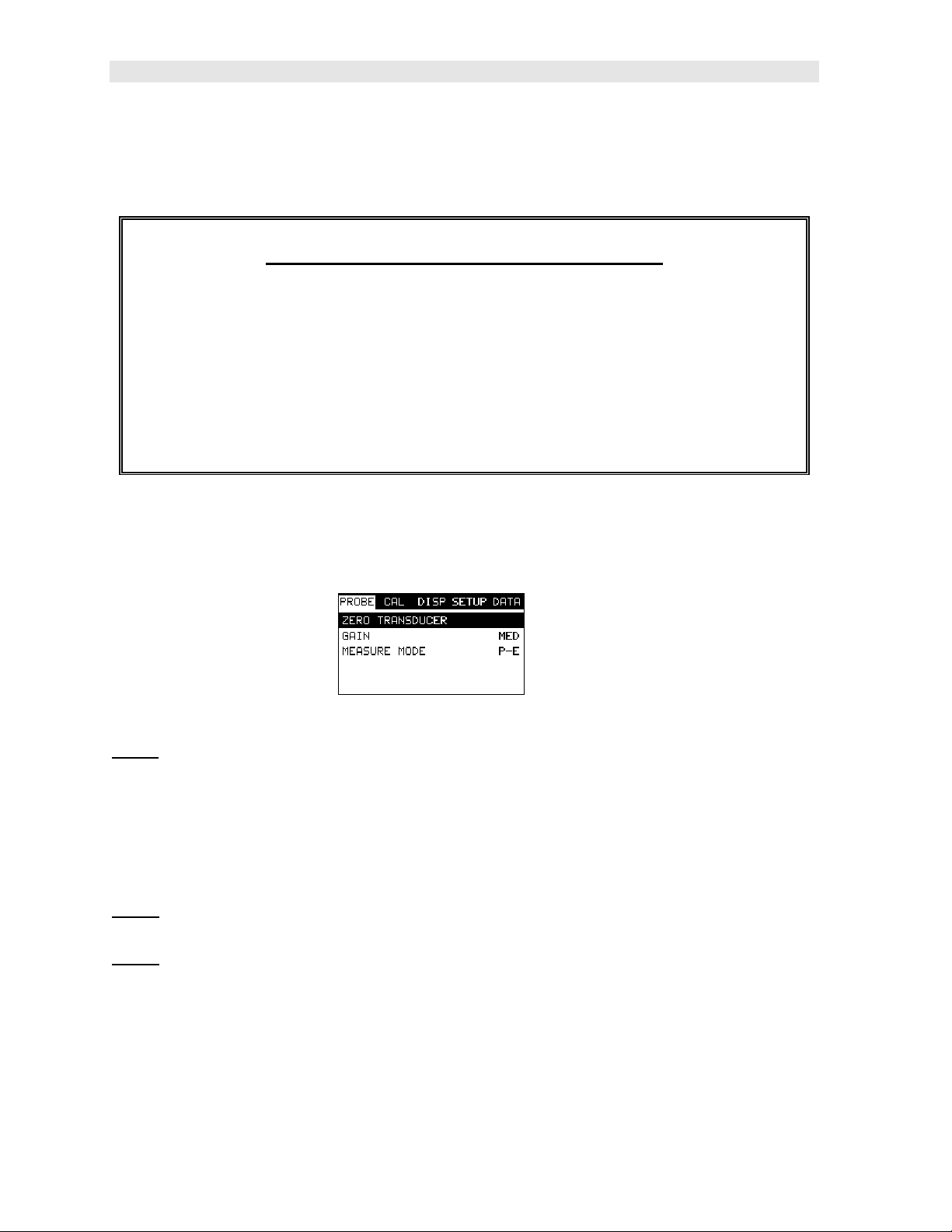

3.2 Probe – Menu

Zero: The PVX-B is zeroed in much the same way that a mechanical micrometer is

zeroed. If the PVX-B is not zeroed correctly, all of the measurements made using

the PVX-B may be in error by some fixed value. Refer to the section on page 29, for

an explanation of this important procedure.

Note: This function is only used when using a contact style transducer with a pulseecho contact setup selected. All the other transducer types use multiple echo

modes, and the zero function is not needed.

Gain:

the volume up or down on a stereo receiver. Refer to page 48 for further info.

AGC:

interface-echo and echo-echo modes only. This is much like turning the volume up

or down on a stereo receiver. However, the PVX-B will automatically control how

much the volume is turned up or down. Alternatively, the AGC can be manually

controlled using the same procedures as GAIN described above. Refer to page 48

for further info.

Increases or decreases the overall amplitude of the signal. Much like turning

The PVX-B is equipped with an automatic gain control when operating in

12

Page 17

PVX-B Precision Visual Thickness Gauge

Measure Mode: Used to select the measurement mode for different application

requirements. The modes are P-E (pulse-echo), P-E GT(pulse-echo w/gate), and EE(echo-echo). Note: I-E or Interface echo mode is also a multiple echo mode that

uses two gates like E-E mode(echo-echo). Refer to page 21 for further info.

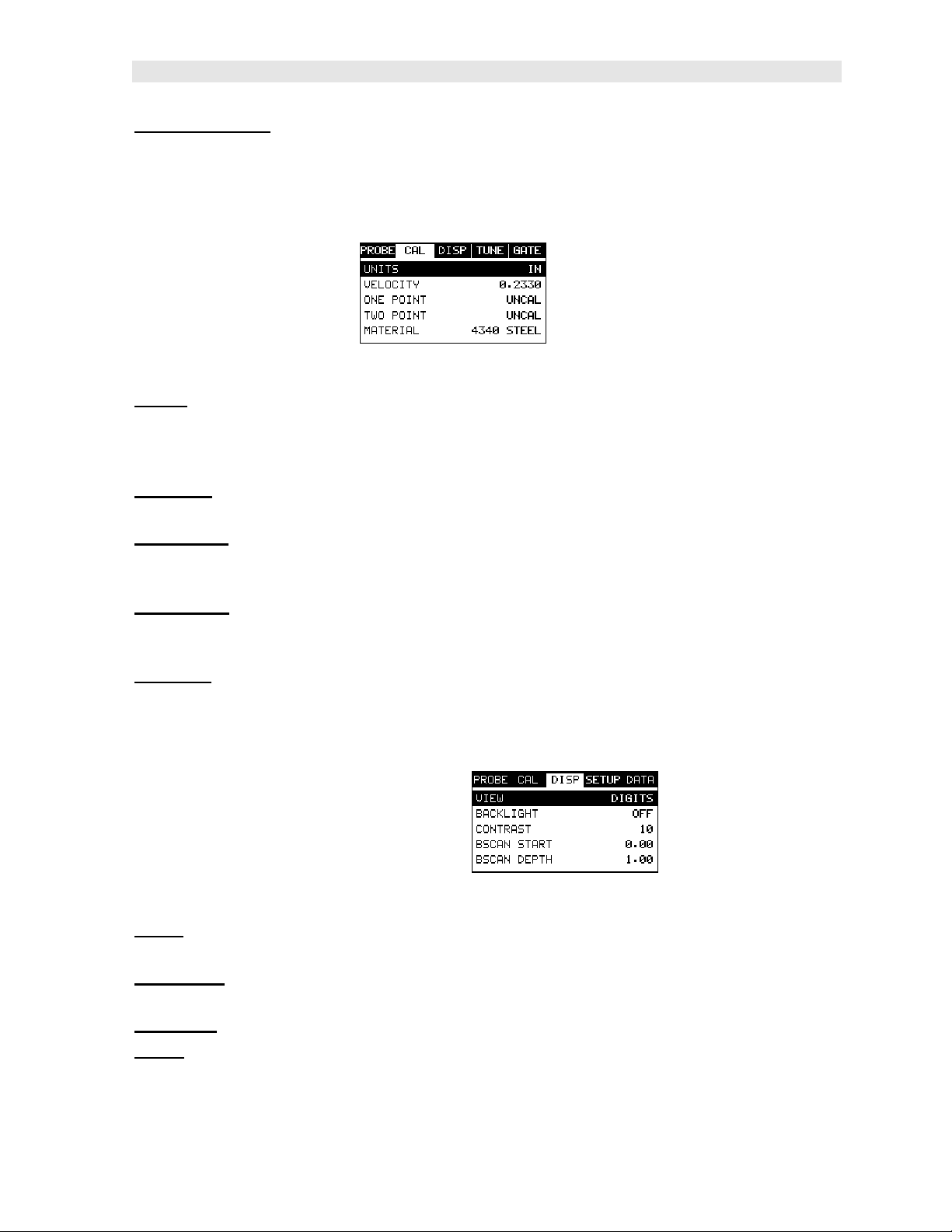

3.3 CAL – Menu

Units:

readout will change from inches to millimeters (IN, IN HR, MM, MM HR). The high

resolution options are indicated with HR following the units, and offer an additional

decimal place of overall resolution (i.e. IN = .001” and IN HR = .0001”).

Velocity: Function to calibrate the PVX-B by setting the velocity to a known material

velocity. Refer to page 31 for further info.

One Point: Performs a single point calibration. This option allows the user to

automatically calculate the velocity by entering a known sample thickness. Refer to

page 33 for further info.

Two Point: Performs a two-point calibration. This option allows the user to

automatically calculate the velocity by entering a second known sample thickness.

Refer to page 34 for further info.

Material: Select the material velocity from a chart of basic material types, when a

known sample thickness or material velocity cannot be obtained. Refer to page 37 for

further info.

Toggle between English or Metric units and low and hi resolutions. The

3.4 DISP (display) – Menu

View:

page 39 for further info.

Backlight: Selectable OFF, ON, AUTO, or INVERT backlight option. The INVERT

option is actually a screen inversion that toggles background and foreground colors.

Contrast:

B-ST:

Refer to page 41 for further info.

Selectable BSCAN (cross section), and DIGITS (large digits) views. Refer to

Adjustable display contrast for variable light conditions.

Provides the user the ability to change the start position of the B-SCAN view.

13

Page 18

Dakota Ultrasonics

B-DEP: Provides the user the ability to change the overall depth of the viewable

measurement area. It functions a lot like a zoom on a camera. Refer to page 41 for

further info.

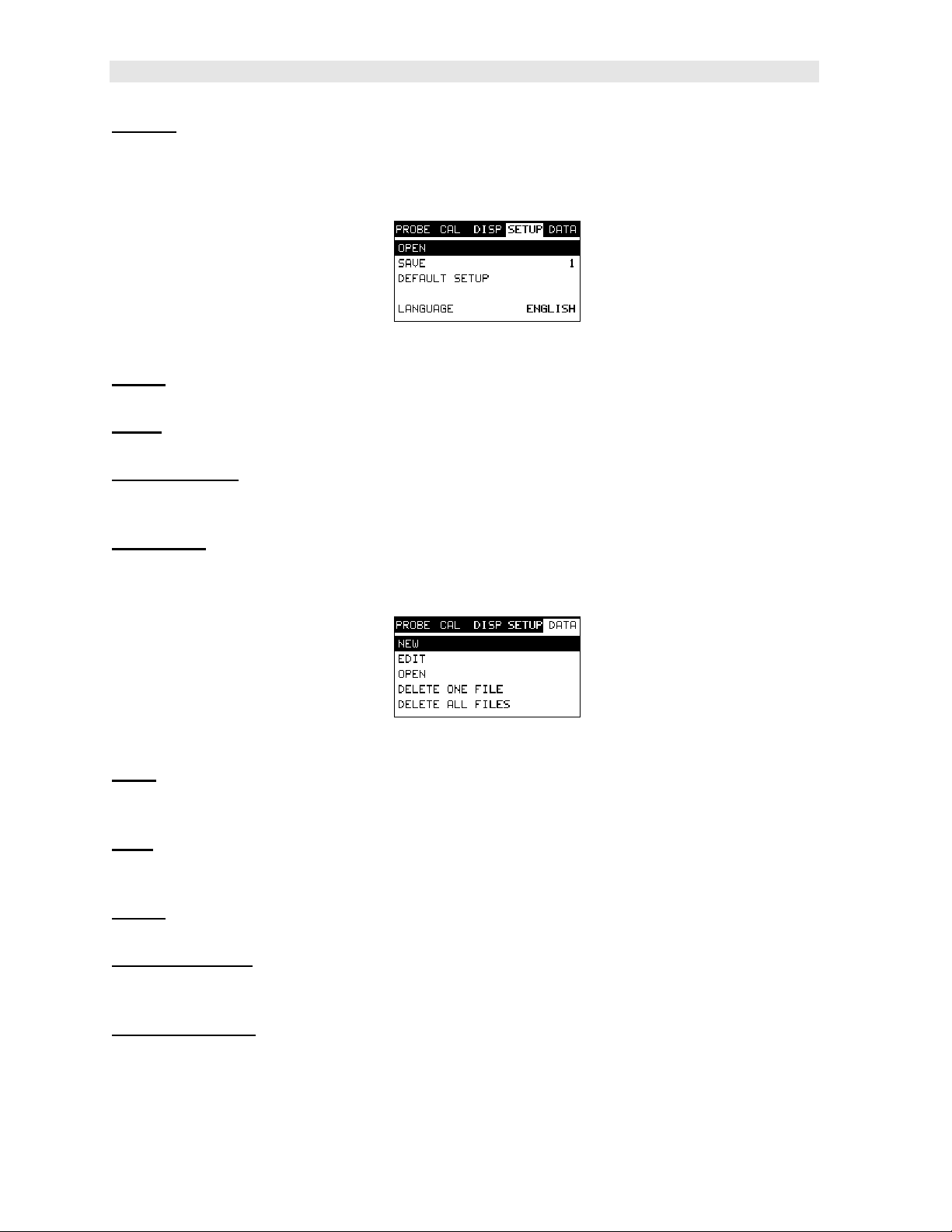

3.5 SETUP – Menu

Open:

These setups can be recalled and used at any time. Refer to page 74 for further info.

Save:

modified or created by the user. Refer to page 76 for further info.

Default Setup: Loads a basic default setup. Use only as a last resort when the

setups in the PVX-B have been corrupted and a computer is not accessible. Refer to

page 79 for further info.

Language: Provides the user with three different language options: English,

German, and Spanish. Refer to page 52 for further info.

Displays a list of factory and user defined setups currently stored in memory.

Provides the user with the ability to save a custom setup that has been

3.6 DATA – Menu

Allows the user the ability to create a new alpha numeric grid with custom

New:

parameters, rows, and columns depending on their application reporting

requirements. Refer to page 57 for further info.

Edit: Gives the user the ability to change parameters of grid that have been

previously saved. Note: Pre-defined coordinates cannot be changed once they have

been created. Refer to page 69 for further info.

Open:

exist in memory from a list of grids. Refer to page 71 for further info.

Delete One File:

individual grid from a list of multiple grids previously saved in memory. Refer to page

67 for further info.

Delete All Files:

currently stored in memory. Refer to page 67 for further info.

This function provides the user with the ability to recall grids that currently

This function provides the user with the ability to delete one

This function provides the user with the ability to delete all grids

14

Page 19

PVX-B Precision Visual Thickness Gauge

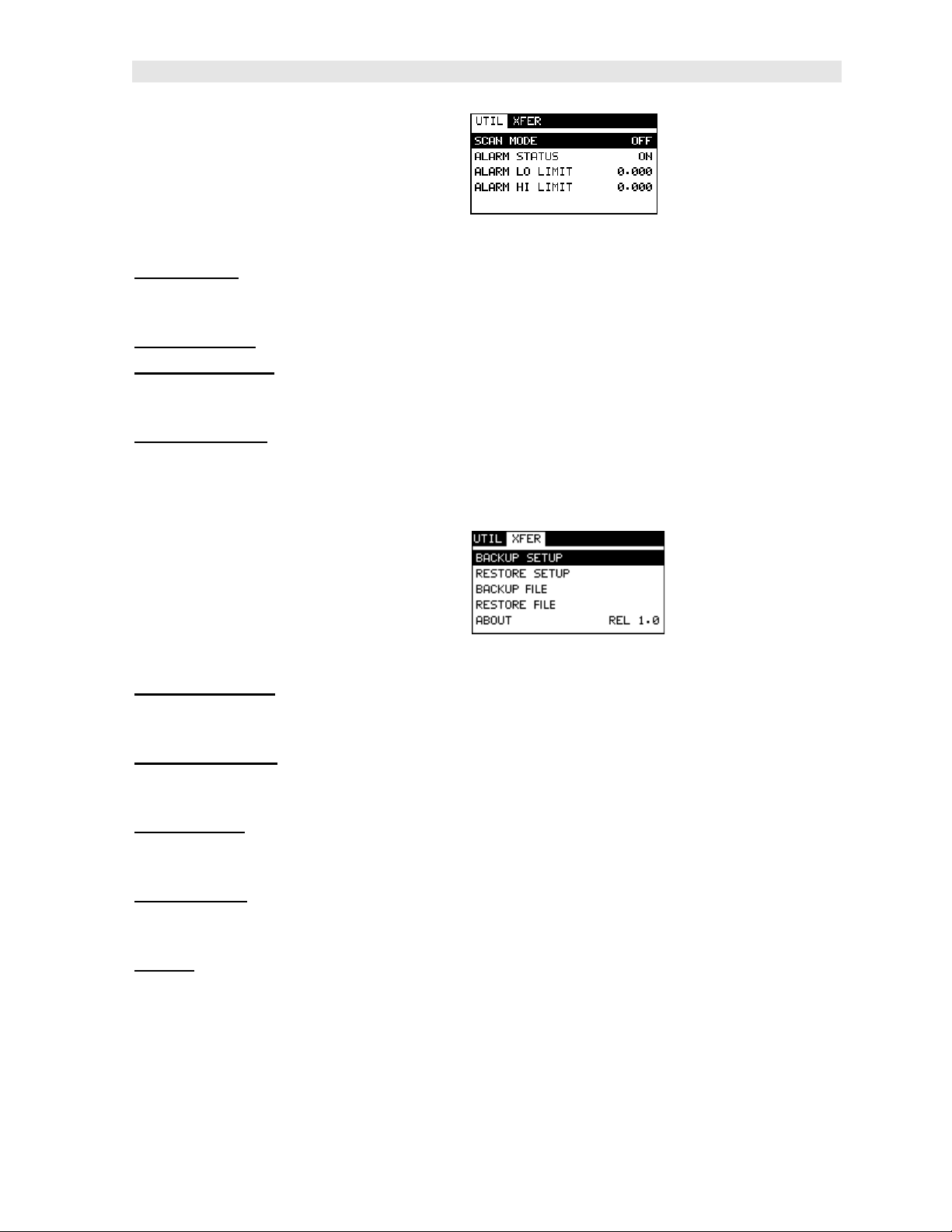

3.7 UTIL (utilities) – Menu

Scan Mode:

overall sample rate from the standard 4 measurements a second to 32

measurements a second. Refer to page 52 for further info.

Alarm Status: Toggles alarm mode on or off. Refer to page 54 for further info.

Alarm LO Limit:

measurement falls below this value, a red light will illuminate and sound the internal

beeper. Refer to page 55 for further info.

Alarm HI Limit:

measurement exceeds this value, a red light will illuminate and sound the internal

beeper. Refer to page 56 for further info.

This function enables a high speed scan mode that increases the

Gives the user the ability to set the LO limit parameter. If the

Gives the user the ability to set the HI limit parameter. If the

3.8 XFER (transfer) – Menu

Backup Setups: Enables the user the ability to backup the setups currently stored

in the PVX-B to a PC via RS232 port. Refer the help section of the DakView

software for a complete electronic manual.

Restore Setups: Enables the user the ability to restore the setups currently saved

on a PC to an PVX-B via RS232 port. Refer the help section of the DakView

software for a complete electronic manual.

Backup File: Enables the user the ability to backup grids currently stored in the

PVX-B to a PC via RS232 port. Refer the help section of the DakView software for a

complete electronic manual.

Restore File:

an PVX-B via RS232 port. Refer the help section of the DakView software for a

complete electronic manual.

About:

B software version. Refer the help section of the DakView software for a complete

electronic manual.

Provides the user with Dakota Ultrasonics contact information and the PVX-

Enables the user the ability to restore grids currently saved on a PC to

15

Page 20

Dakota Ultrasonics

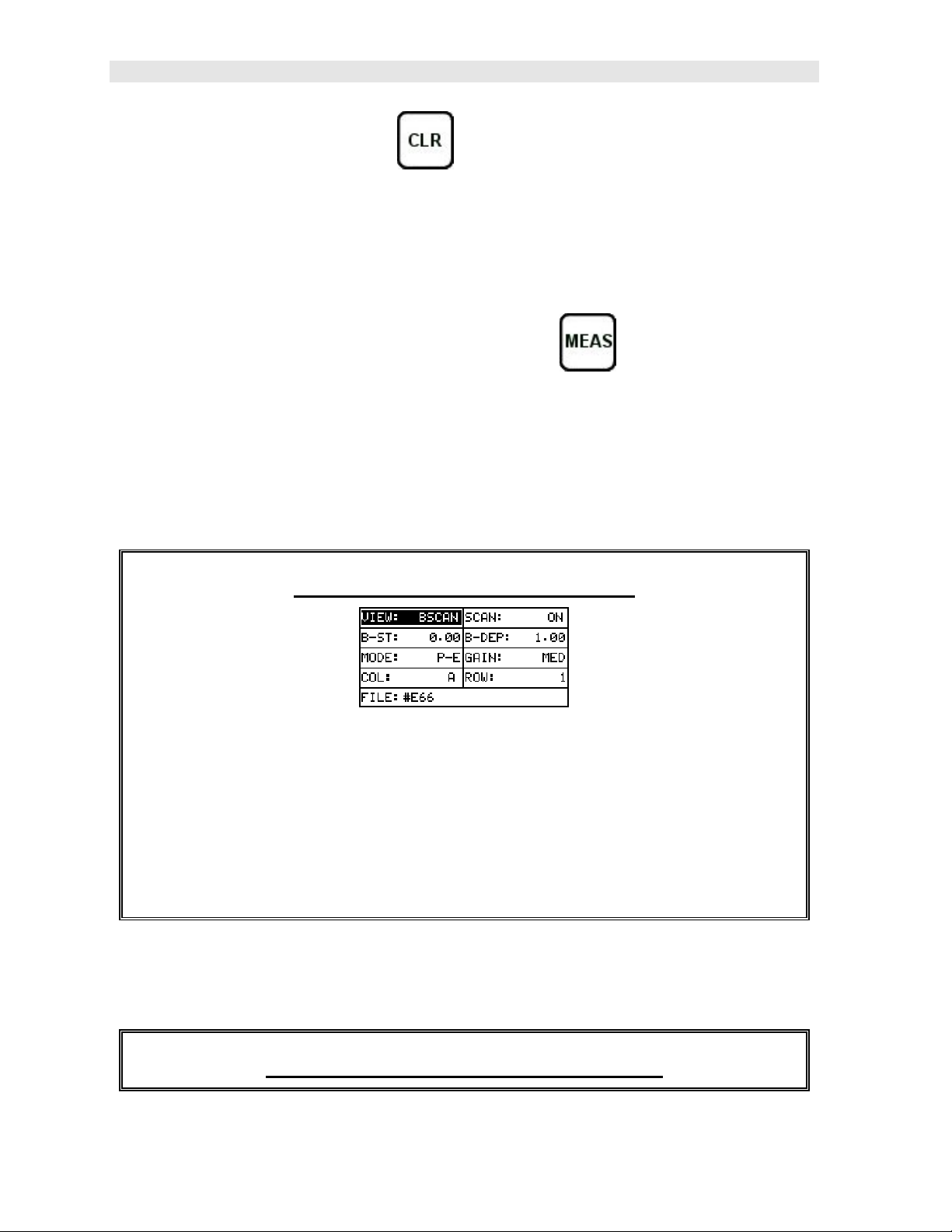

3.9 CLR (clear) Key

The primary functions of the CLR key, is to clear a measurement from a grid cell

location or set obstruct, and backspace in an Alpha Edit Box. If a user has already

saved a measurement and waveform to a cell location, use this key to clear the

measurement at any time.

3.10 MEAS (measurement mode) Key

The MEAS key puts the PVX-B into it’s primary mode of operation. In this mode, the

user has a complete view of the LCD, as well as control of the Hot Menu Functions.

These hot functions provide the user with the ability to make crucial adjustments to

the display, waveform settings, and grid storage locations without having to search

through the menu and sub menu items. It’s important to first get familiar with moving

around in the hot functions as follows:

Getting Around in the Hot Menus

1) Press the MEAS key at any time to return to the primarily measurement

mode.

2) Press the MEAS key multiple times to tab right through the menu fields, and

the ESC key multiple times to tab left through the menu fields, until the

desired hot function is highlighted.

Now that you’re familiar with activating and moving amongst the hot function fields,

let’s have a look at how to adjust or change the values of these fields:

Adjusting the Values of the Hot Menus

16

Page 21

PVX-B Precision Visual Thickness Gauge

1) Use the UP, DOWN, LEFT, and RIGHT arrow keys to increase and

decrease the values of the hot function fields.

2) Repeat step 1 until the desired value has been achieved.

Alternatively, the B-ST and B-DEP hot function fields can be changed using

the Digit Edit Box as follows:

1) Press the ENTER key to display the Digits Edit Box.

2) Press the UP and DOWN arrow keys to scroll the highlighted value.

3) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

4) Repeat steps 2 & 3 to adjust the other hot menu values.

5) Press the OK key to set and return to the measure screen, or ESC to cancel

entering the B-ST or B-DEP values.

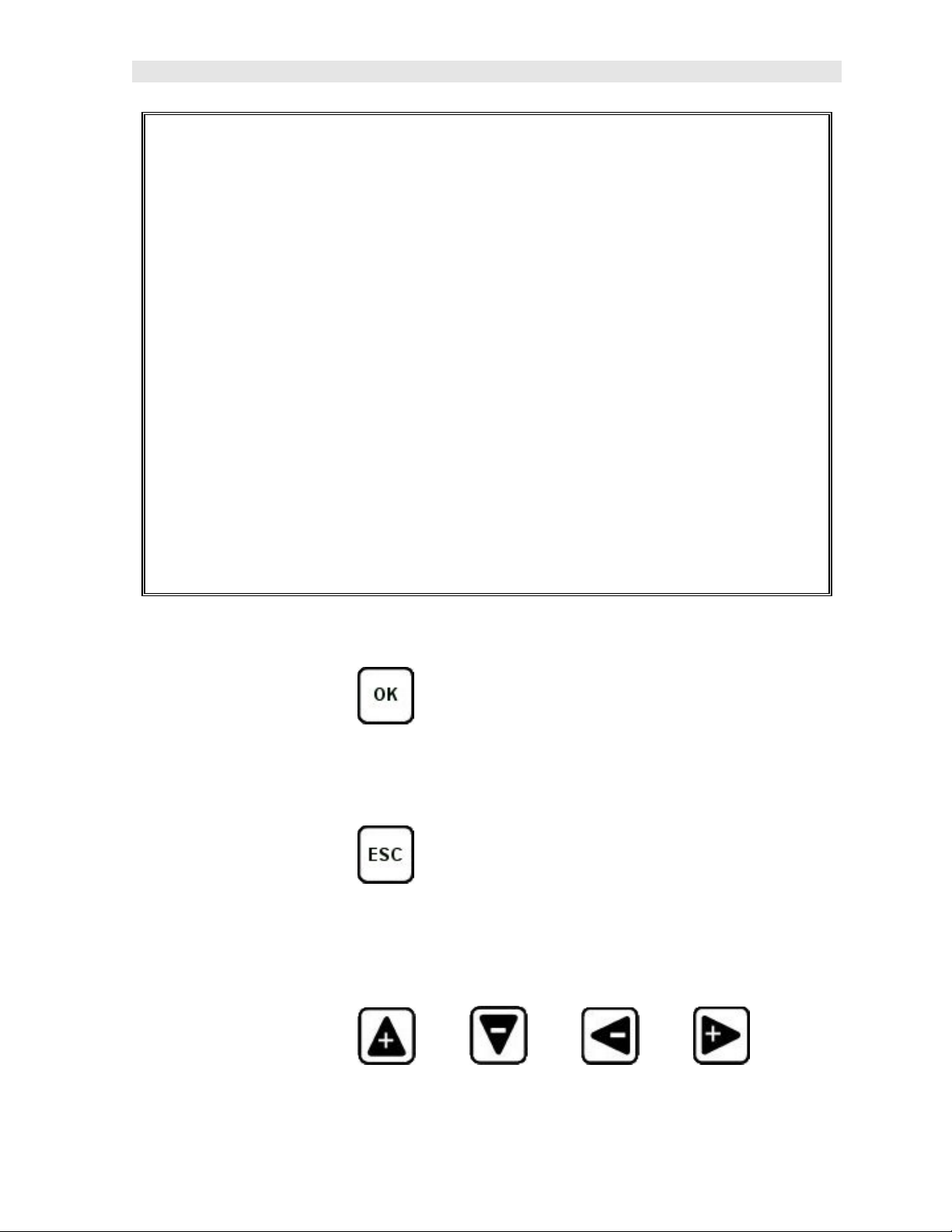

3.11 OK Key

The primary function of the OK key is confirmation of a change or selection. It also

toggles the view from B-SCAN to DIGITS in previously saved grid location.

3.12 ESC Key

The ESC key is used in the MENU, MEAS, and EDIT functions as a back or escape

function. It also toggles the view from B-SCAN to DIGITS in previously saved grid

location.

3.13 Arrow Keys

17

Page 22

Dakota Ultrasonics

The Arrow Keys are used to navigate through the menus, increase/decrease values,

and toggle specific function keys.

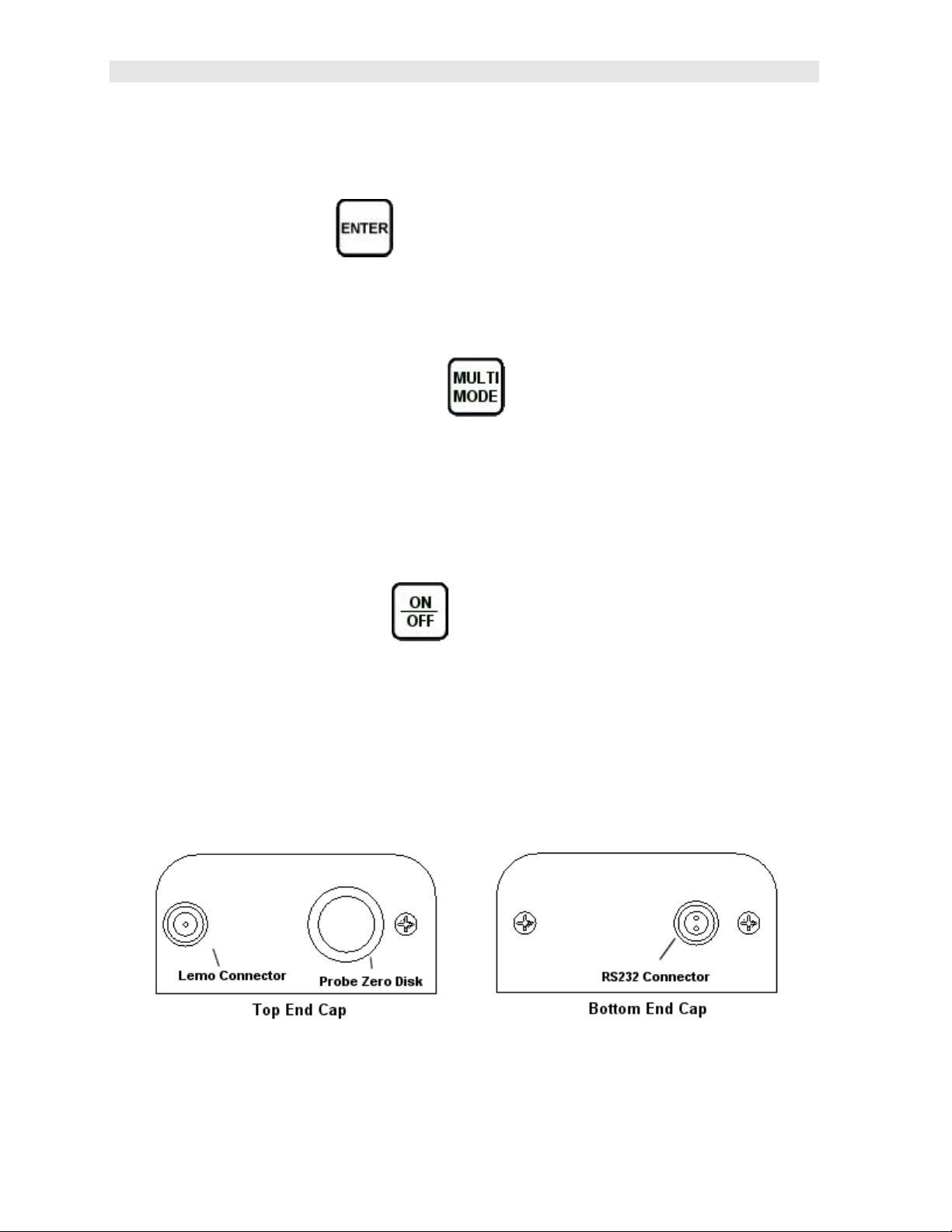

3.14 ENTER key

The ENTER key is used in the overall menu selection process, to activate list and

edit boxes, and save measurements to grid locations.

3.15 MULTI MODE Key

The MULTI MODE key activates the Load Setup List to select a factory or

previously saved user setup for a variety of different transducer types and settings.

This is a quick automatic preset mode that enables the user to change modes and

basic settings from the tabbed menus. The factory setups serve as the perfect

starting point for immediate use or further fine-tuning.

3.16 ON/OFF Key

The ON/OFF key simply powers the unit either ON or OFF. Note: Unit will

automatically power off when idle for 5 minutes. All current settings are saved prior

to powering off.

3.17 Top & Bottom End Caps

The top & bottom end panels are where all connections are made to the PVX-B. The

diagram above shows the layout and description of the connectors:

18

Page 23

PVX-B Precision Visual Thickness Gauge

Transducer Connectors

Refer to Diagram: The transducer connector and battery cover/probe zero disk are

located on the PVX-B’s top end cap. The transducer connector is of type Lemo “00”.

Probe Zero Disk & Battery Cover

Refer to Diagram: The Battery cover is the large round disk shown in the diagram.

Note: This same disk is also used as a probe zero disk. Simply remove the cover

when replacing the batteries (3 AA cells). When performing a probe zero function,

place the transducer on the disk making firm contact.

Important: Be sure to follow the polarity labels located on the back label of the PVXB. Note: Rechargeable batteries can be used, however they must be recharged

outside of the unit in a stand alone battery charger.

RS-232 Connector

Refer to Diagram: The RS-232 connector, located on the bottom end cap, is a 2 pin

female Lemo connector. It is designed to connect directly from the PVX-B to a

standard AT serial port on a PC. The cable supplied with the PVX-B is a Lemo to 9

pin serial cable. Note: This connector is also used to upgrade the PVX-B with the

latest version of firmware.

19

Page 24

CHAPTER FOUR

PRINCIPALS OF ULTRASONIC MEASUREMENT

4.1 Time versus thickness relationship

Ultrasonic thickness measurements depend on measuring the length of time it takes

for sound to travel through the material being tested. The ratio of the thickness

versus the time is known as the sound velocity. In order to make accurate

measurements, a sound velocity must be determined and entered into the

instrument.

The accuracy of a thickness measurement therefore depends on having a consistent

sound velocity. Some materials are not as consistent as others and accuracy will be

marginal. For example, some cast materials are very granular and porous and as a

result have inconsistent sound velocities.

While there are many different ultrasonic techniques to measure thickness, which will

be discussed below, all of them rely on using the sound velocity to convert from time

to thickness.

4.2 Suitability of materials

Ultrasonic thickness measurements rely on passing a sound wave through the

material being measured. Not all materials are good at transmitting sound.

Ultrasonic thickness measurement is practical in a wide variety of materials including

metals, plastics, and glass. Materials that are difficult include some cast materials,

concrete, wood, fiberglass, and some rubber.

4.3 Range of measurement and accuracy

The overall measurement capabilities, based on the wide variety of materials, is

determined by the consistency of the material being measured

The range of thickness that can be measured ultrasonically depends on the material

as well as the technique being used and the type of transducer. Thickness

measurements can be made from a minimum of 0.010 inch to 9.999” in steel.

However, the maximum attainable thickness is much less for more attenuative

materials (materials that absorb sound).

Accuracy, is determined by how consistent the sound velocity is through the sound

path being measured and, is a function of the overall thickness of the material. For

example, the velocity in steel is typically within 0.5% while the velocity in cast iron

can vary by 4%.

4.4 Couplant

All ultrasonic applications require some medium to couple the sound from the

transducer to the test piece. Typically a high viscosity liquid is used as the medium.

The sound frequencies used in ultrasonic thickness measurement do not travel

20

Page 25

PVX-B Precision Visual Thickness Gauge

through air efficiently. By using a liquid couplant between the transducer and test

piece the amount of ultrasound entering the test piece is much greater.

4.5 Temperature

Temperature has an effect on sound velocity. The higher the temperature, the slower

sound travels in a material. High temperatures can also damage transducers and

present a problem for various liquid couplants.

Since the sound velocity varies with temperature it is important to calibrate at the

same temperature as the material being measured.

Normal temperature range

Most standard transducers will operate from 0F to 180F.

High temperature measurements

Special transducers and couplants are available for temperatures above 180F up to

650F with intermittent contact. It is necessary to cool the transducer, by submerging

the transducer in water between readings, when measuring high temperatures.

Modes and temperature errors

In addition to errors caused by velocity changing with temperature, some modes

(measurement techniques) are affected more than others. For example, dual

element mode has larger errors due to changes in temperature of the delay line.

However, multi-echo techniques help to minimize these errors. The PVX-B operates

in multi-echo modes for a variety of transducer types.

4.6 Measurement Modes

In this section we will discuss the different measurements modes the PVX-B is

capable of operating in, the transducers required, and the reasons for using specific

modes:

Pulse-Echo Mode

Pulse-echo mode measures from the initial pulse (sometimes referred to as an

artificial zero) to the first echo (reflection). In this mode, the transducer is placed on a

reference disk, located on top of the PVX-B, and a key is pressed to establish a zero

point for the particular transducer.

In pulse-echo mode errors result from surface coatings and temperature variations.

This mode is only used with single element contact style transducers.

Echo-Echo (Interface-Echo) Modes

The echo-echo modes measure between two reflections. This technique is

commonly used to eliminate errors from surface coatings in echo-echo mode, as well

as make measurements in multiple layered materials. The disadvantage is that two

21

Page 26

Dakota Ultrasonics

echoes are needed which requires a much stronger echo (reflection). In interfaceecho mode, it moves the interface further out in time eliminating any noise that’s

close to the initial pulse.

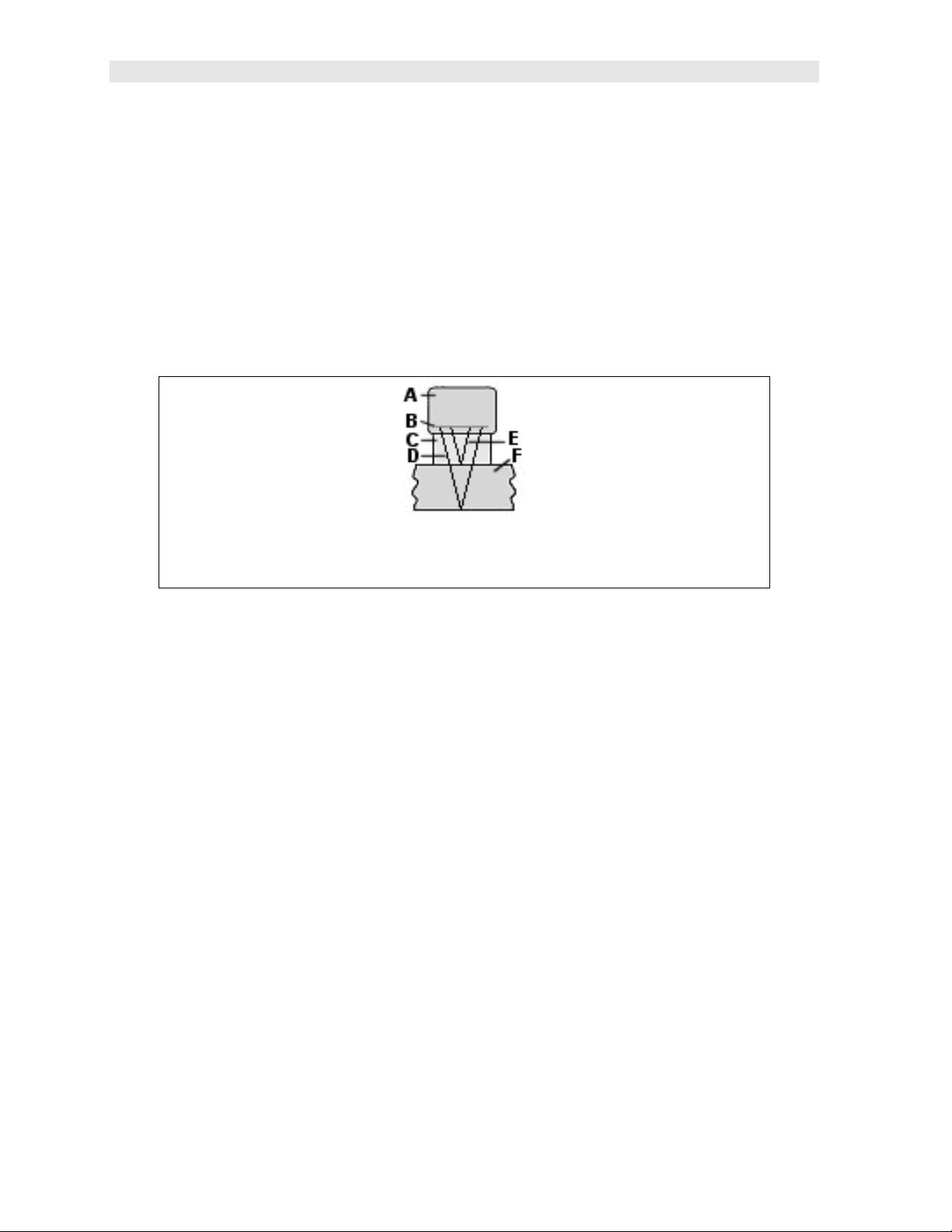

Important: The primary difference between interface-echo and echo-echo mode, is

interface-echo mode measures from the end of an interface (delay line), to the first

return reflection of the test material. However, in echo-mode, the measurement is

made between two return reflections (echoes). Although both modes use two gates

and virtually look the same on the scope, they are measuring in different ways and

are used to accomplish different application tasks. The diagrams below will offer an

additional explanation of the differences in these modes as follows:

Delay Line Single Element Transducer in Interface-Echo mode

Diagram 1

Refer to diagram 1. This diagram illustrates the sound path being measured in

interface-echo mode. (A) is the transducer. Point (B) is the piezoelectric crystal that

emits the sound wave. (C) is the delay line, most commonly made of acrylic or

graphite. The delay tip will act as the interface and the measurement will be made

starting from the difference of the reflection off the end of the delay tip (E). The

sound will also travel through the delay tip (C) and test material (F), and reflect back

to the piezoelectric crystal off the back wall of the test material. The measurement

will be made from the reflection off the end of the delay tip and back wall of the test

material.

4.7 Glossary of terms

Repetition Rate & Display Update

The repetition rate is how often the PVX-B generates a burst of ultrasound.

The PVX-B has a fixed repetition rate of 1 kHz, or 1000 times per second. The PVX-

B updates the display 4 times per second in regular measurement mode and 32

times a second in hi speed scan mode. Therefore, the scan mode is most suitable

for fast scans of a test piece at a lower resolution.

22

Page 27

CHAPTER FIVE

SELECTING THE MEASUREMENT MODE

5.1 The setup library

The PVX-B contains 18 factory setups and 46 user definable preset locations to store

custom setups for easy recall. These setups can be optimized for the user’s specific

application needs and can also be stored on a PC and transferred bi-directionally

using Dakota’s PC interface software included with the instrument.

The setups supplied with the instrument are optimized for specific transducer types

and serve as a starting point for some of the typical applications commonly used with

this type of instrument. These setups can be recalled, modified, and overwritten to

one of 46 setup locations. The PC software includes a default setup file that can be

uploaded to the gauge at any time to restore factory settings. Note: The first 18

setups cannot be overwritten. Once again, these factory settings are excellent

starting points for custom setups.

5.2 Which mode & transducer do I use for my application?

High penetration plastics and castings

The most common mode for these types of applications is pulse-echo. Select a low

frequency transducer. Depending on the thickness of the material, use a 2.25MHz or

lower frequency transducer. Larger diameters offer greater penetration power

because of the crystal size, for difficult to measure materials.

Thin Materials & Tough Access Areas

Use any of the delay-line transducers for materials under 1 inch. Tough access

areas with minimal clearances, are perfect applications for our pencil style

transducers. However, the pencil transducer have a very small thickness range and

are only suitable for thin materials less than .300”.

Thru Paint & Coatings

Often time users will be faced with applications where the material will be coated with

paint or some other type of epoxy material. Since the velocity of the coating is

approximately 2.5 times slower than that of steel, pulse-echo mode will induce error if

the coating or paint is not completely removed. By using echo-echo mode, the user

is able to successfully measure through both, the coating and steel, and completely

eliminate the thickness of the paint or coating. Therefore, the steel can be measured

without having to remove the coating prior to measuring.

Both the delay-line and contact transducers will work fine for thru coating

measurements. When using contact style transducers, it’s best to consider a high

damped model for thinner materials to minimize the potential ring down noise of the

transducer.

23

Page 28

Dakota Ultrasonics

Plastics

The PVX-B works extremely well on thin plastics using a delay line transducer and

special graphite tip. Because the velocity of the standard acrylic tip has a similar

velocity to most plastics, the PVX-B is unable to measure the material because it

simply can't see it. By using the graphite tip in place of the acrylic tip, the velocity of

the graphite tip allows an impedance mismatch to occur between materials, hence

the plastic can successfully be measured.

When measuring thicker plastics, a lower frequency contact transducer should be

used – typically 1 - 2.25MHz. Larger crystal diameters offer greater penetration

capabilities. Therefore, for thicker and hard to penetrate plastics, use larger diameter

transducers if possible.

High temperature

High temperature applications require a special delay line transducer using a high

temperature delay tip with a very low temperature coefficient. In other words, the

delay tip is not absorptive at high temperatures.

Noisy Material

Materials such as titanium, stainless steel, and aluminum may have inherent surface

noise issues that appear close to the initial pulse, or near the surface. This can be

avoided by using a delay style transducer in either echo-echo or interface-echo

modes. However, when using a contact style transducer in pulse-echo mode, it’s

best to consider a higher frequency transducer.

Restricted access

In order to measure materials with lots of curvature or restricted access, the use of a

delay line transducer with a cone delay tip or a pencil style transducer, can provide

additional access.

24

Page 29

PVX-B Precision Visual Thickness Gauge

5.3 Factory Setup Chart

Num Name Comment 1 Gn/AGC Velocity

1 E-E DELAY LINE 3/8 3 0.2330 in/uSec

2 I-E DELAY LINE 3/8 3 0.2330 in/uSec

3 E-E DELAY LINE 1/2 3 0.2330 in/uSec

4 I-E DELAY LINE 1/2 3 0.2330 in/uSec

5 E-E GRAPHITE STEEL 7 0.2330 in/uSec

6 I-E GRAPHITE STEEL 5 0.2330 in/uSec

7 I-E GRAPHITE PLASTIC 3 0.0920 in/uSec

8 E-E PENCIL 1/16T THN 7 0.2330 in/uSec

9 E-E PEN 1/16 THNPLAS 12 0.0923 in/uSec

10 I-E PENCIL 1/16T STD 17 0.2330 in/uSec

11 E-E PENCIL 1/8T STD 3 0.2330 in/uSec

12 E-E PEN 1/8T THNPLAS 9 0.0923 in/uSec

13 I-E PENCIL 1/8T STD 13 0.2330 in/uSec

14 E-E CONT 5M STL 1/4 6 0.2330 in/uSec

15 P-E CONT 5M STL 1/4 35 0.2330 in/uSec

16 P-E CONT 5M PLAS 1/4 35 0.0920 in/uSec

17 P-E CONT 5M STL 1/2 29 0.2330 in/uSec

18 E-E CONT 10M STL 1/4 48 0.2330 in/uSec

25

Page 30

CHAPTER SIX

MAKING MEASUREMENTS

The steps involved in making measurements are detailed in this section. The

following sections outline how to setup and prepare your PVX-B for field use.

In pulse-echo modes, the probe zero must be measured on the reference disk

(battery disk) attached to the top of the instrument. This compensates for variation in

the transducer. In all modes the sound velocity must be determined. The sound

velocity is used to convert the transit time to a physical length. The sound velocity

can be selected from a material chart in the manual, selected from a material list in

the PVX-B, or for greater precision, determined from a sample of the test material

that has been mechanically measured. To enter the velocity from a table, look up the

material on the chart in the appendix of this manual and refer to the section below on

Calibration to a Known Velocity. To determine the velocity of a single sample, refer

to the Material Calibration section on page 33.

When measuring curved materials, it is more accurate to calibrate from two test

points, one at the minimum limit of the target thickness and one at the maximum limit.

In this case the reference disk mounted to the PVX-B is not used. This is called twopoint calibration and is described on page 34.

6.1 Selecting the Transducer Type

The first step in using the PVX-B is to select setup according to the type of

transducer, and or delay tip length from the list of factory setups. There are delay tip

lengths of 3/8” and ½”. There are also two different pencil style transducer options:

spherical focused (PTR-100E) and flat (PTR-300E). The PTR-100E is the most

common and popular option available. This option offers both a .060” and .125”

diameter contact area tip. By selecting the setup associated with a specific

transducer type, all the scope settings will also be loaded and setup. This will give

the user an excellent place to start, requiring only minor adjustments of the delay and

width, if any. Note: Once the setup has been selected, the PVX-B will store and

recall this setup every time the PVX-B is powered on/off. If changes are made to the

setup, they must be saved in a setup location in or to recall them at a later time. The

setup will only change if the user physically selects another setup from the list.

Therefore, if you have previously gone through this section and selected a setup,

proceed to the next section:

Selecting the Transducer Type & Setup

26

Page 31

PVX-B Precision Visual Thickness Gauge

1) Press the MULTI MODE key once to activate the load setup list containing

the transducer types and settings.

2) Use the UP and DOWN arrow keys to scroll through the setup list until the

target setup is highlighted.

3) Press the ENTER key to display the confirmation screen.

4) Press the OK key to select the setup and return to the measure screen, or

ESC to cancel the selecting a setup.

27

Page 32

Dakota Ultrasonics

1) Alternately, the setups can be selected from the menu items manually.

Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the SETUP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until OPEN is highlighted.

3) Press the ENTER key to display the list of stored setups.

4) Press the UP and DOWN arrow keys to scroll through the list of setups until

the appropriate setup is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to select the setup and return to the menu screen, or ESC

to cancel the selection process.

7) Press the MEAS key to return to the measurement screen.

Finally, in an effort to be sure that the user is aware of this option, the measurement

mode can be manually selected from the menu items and all additional settings

adjusted manually. The measurement mode can be selected from the menu items as

follows:

28

Page 33

PVX-B Precision Visual Thickness Gauge

Selecting Measure Mode - Tabbed Menus

Note: The E-E mode should also be selected for setting up the PVX-B in I-E

mode.

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the GATE menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MEASURE MODE is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the mode options. Once the

mode is displayed, press the MEAS key to return to the measurement mode

screen.

6.2 Probe zero

The probe zero feature should only be used if a contact style transducer is connected

to the PVX-B in pulse-echo mode. As noted in chapter 3, the probe zero function is a

very important and necessary function that must done prior to calibration. It should

also be done on a regular basis. If the PVX-B is not zeroed correctly, all of the

measurements taken may be in error by some fixed value. In order to perform a

probe zero, the PVX-B must be in pulse-echo mode. If echo-echo mode was

previously selected in the last section, skip this section and continue on to the next.

Note: If you intend to switch between measurement modes simultaneously, setup

the PVX-B in pulse-echo mode, perform the probe zero as necessary, and save the

setup to one of the empty setup locations. Once this is completed, the user can

switch between modes toggling between two setups. The following steps outline the

procedure for performing a probe zero:

29

Page 34

Dakota Ultrasonics

Performing a Probe Zero

1) Clean the surface of the Probe Zero Disk, located on top of the PVX-B

(battery cover).

2) Apply a drop of couplant to the end of the transducer, or probe disk, and

hold the transducer in steady contact with the reference disk.

3) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the PROBE menu is highlighted and displaying the submenu items.

4) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ZERO TRANSDUCER is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to zero the transducer and return to the menu screen, or

ESC to cancel the zeroing process.

7) Remove the transducer from the probe zero disk.

8) Press the MEAS key to return to the measurement screen.

6.3 Material Calibration

In order for the PVX-B to make accurate measurements, it must be set to the correct

sound velocity of the material being measured. Different types of materials have

30

Page 35

PVX-B Precision Visual Thickness Gauge

different inherent sound velocities. For example, the velocity of sound through steel

is about 0.233 inches per microsecond, versus that of aluminum, which is about

0.248 inches per microsecond. If the gauge is not set to the correct sound velocity,

all of the measurements the gauge makes will be erroneous by some fixed

percentage.

The One Point calibration is the simplest and most commonly used calibration

method - optimizing linearity over large ranges. The Two Point calibration allows for

greater accuracy over small ranges by calculating the probe zero and velocity. The

PVX-B provides four simple methods for setting the sound-velocity outlined below:

Calibration to a known velocity

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VELOCITY is highlighted.

3) Press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the velocity number is correctly displayed.

31

Page 36

Dakota Ultrasonics

7) Press the OK key to set the velocity and return to the menu screen, or ESC

to cancel entering the velocity.

8) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

32

Page 37

PVX-B Precision Visual Thickness Gauge

One Point Calibration

Note: Be sure that a probe zero has been done prior to performing this

calibration procedure if a contact transducer in pulse-echo mode is being used.

1) Physically measure a location on the sample to be measured using a set of

calipers or a digital micrometer. Note: It’s always best to calibrate on

thickest location on the sample, rather than on the thinnest location, as the

percentage error is much less with respect to the PVX-B’s resolution of +/.0001” (0.001mm).

2) Apply a drop of couplant on the transducer. Place the transducer in steady

contact on the known thickness location. Be sure that the reading is stable

and the repeatability indicator, located in the top left corner of the display, is

fully lit and stable. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the ESC key multiple

times to tab left until the CAL menu is highlighted and displaying the

submenu items.

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ONE POINT is highlighted.

33

Page 38

Dakota Ultrasonics

4) Press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the known thickness value is correctly displayed.

8) Press the OK key to calculate the velocity and return to the menu screen, or

ESC to cancel entering the velocity.

9) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Note: CHECK YOUR CALIBRATION! Place the transducer back on the

calibration point. The thickness reading should now match the known

thickness. If the thickness is not correct, repeat the steps above.

Two Point Calibration

Note: Be sure that a probe zero has been done prior to performing this

calibration procedure, if a contact transducer in pulse-echo mode is being used.

34

Page 39

PVX-B Precision Visual Thickness Gauge

Note: If the user opted to do a setup from scratch for interface-echo (I-E)

mode, a two point calibration must be performed to set the probe zero.

1) Using a set of calipers, physically measure two known thickness locations

on the sample of material. Note: The two locations should represent the

desired thickness range being measured. If the range is from .050” - .200”,

then the two known locations should represent this range, or be slightly

outside or inside of this range. A typical example would be to find two

locations at .063” and the other at .247”. These thickness points will satisfy

the required thickness range noted above.

2) Apply a drop of couplant on the transducer. Place the transducer in steady

contact on thickest known location first. Be sure that the reading is stable

and the repeatability indicator, located in the top left corner of the display, is

fully lit and stable. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right, and the ESC key multiple

times to tab left, until the CAL menu is highlighted and displaying the

submenu items.

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ONE POINT is highlighted.

4) Press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the known thickness value is correctly displayed.

8) Press the OK key to calculate the velocity for the ONE POINT calibration

and return to the CAL menu screen, or press ESC to cancel entering the

velocity.

35

Page 40

Dakota Ultrasonics

9) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material on the thinnest, or

second known thickness location. Be sure that the reading is stable and the

repeatability indicator, located in the top left corner of the display, is fully lit

and stable.

10) Use the UP and DOWN arrow keys to highlight the TWO POINT calibration

submenu item.

11) Press the ENTER key to display the Digits Edit Box.

12) Press the UP and DOWN arrow keys to scroll the highlighted value.

13) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

14) Repeat steps 12 & 13 until the known thickness value is correctly displayed.

15) Press the OK key to calculate the velocity for the TWO POINT calibration

and return to the CAL menu screen, or press ESC to cancel entering the

velocity.

16) Finally, press the MEAS key to return to the measurement screen and

begin taking readings.

Note: CHECK YOUR CALIBRATION! Place the transducer back on both

calibration points. The thickness readings should now match the known

thickness locations. If they are not correct, repeat the steps above.

36

Page 41

PVX-B Precision Visual Thickness Gauge

Built in Material Selection

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the CAL menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATERIAL is highlighted.

3) Press the ENTER key to display the list of Material Types.

4) Press the UP and DOWN arrow keys to scroll through the material list until

the appropriate material is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to select the material and return to the menu screen, or

press ESC to cancel the material selection.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

37

Page 42

CHAPTER SEVEN

USING THE DIGITS & B-SCAN DISPLAYS

A key feature of the PVX-B is the ability to toggle between two different display

options, Digits and B-Scan. The Digits view provides the user with a large digital

readout of the thickness. The Digits view also includes a scan bar features that uses

a bar graph to indicate thickness. The scan bar can be very handy while scanning a

tank or pipe wall by graphically displaying deflections from pits or internal flaws,

rather than having to constantly watch for changes in the digital readout. The scan

bar is just another visual tool to alarm the user when something out of the ordinary is

detected.

The B-Scan display is also very useful when scanning surfaces and viewing the

cross section of the test material. It provides a convenient way of profiling the blind

surfaces during a scan. The B-Scan display is also equipped with a scan bar

representing the overall thickness. The scan bar gives the user a visual indication

when a flaw or defect is passed over during the scan process. The scan bar will

deflect off of the defect and return back to the overall thickness. Visually, this is

much easier to notice than watching for changes in the digital value displayed.

Note: The following chapter outlines some of the fine adjustment features of the

PVX-B. The PVX-B has two different display options (Large Digits and B-Scan).

We’ll take a better look at these options in this chapter. Note: In order to recall and

use the new adjustments made to the PVX-B at a later time, the user must save the

modified settings in one of the setup locations prior to powering off the unit. Refer

page 74 for more information on setups.

7.1 Selecting a Display Option

The following procedure outlines how to select or toggle display options:

Changing Display Options

38

Page 43

PVX-B Precision Visual Thickness Gauge

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VIEW is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the view options. Once the

appropriate view is displayed, press the MEAS key to return to the

measurement screen.

39

Page 44

Dakota Ultrasonics

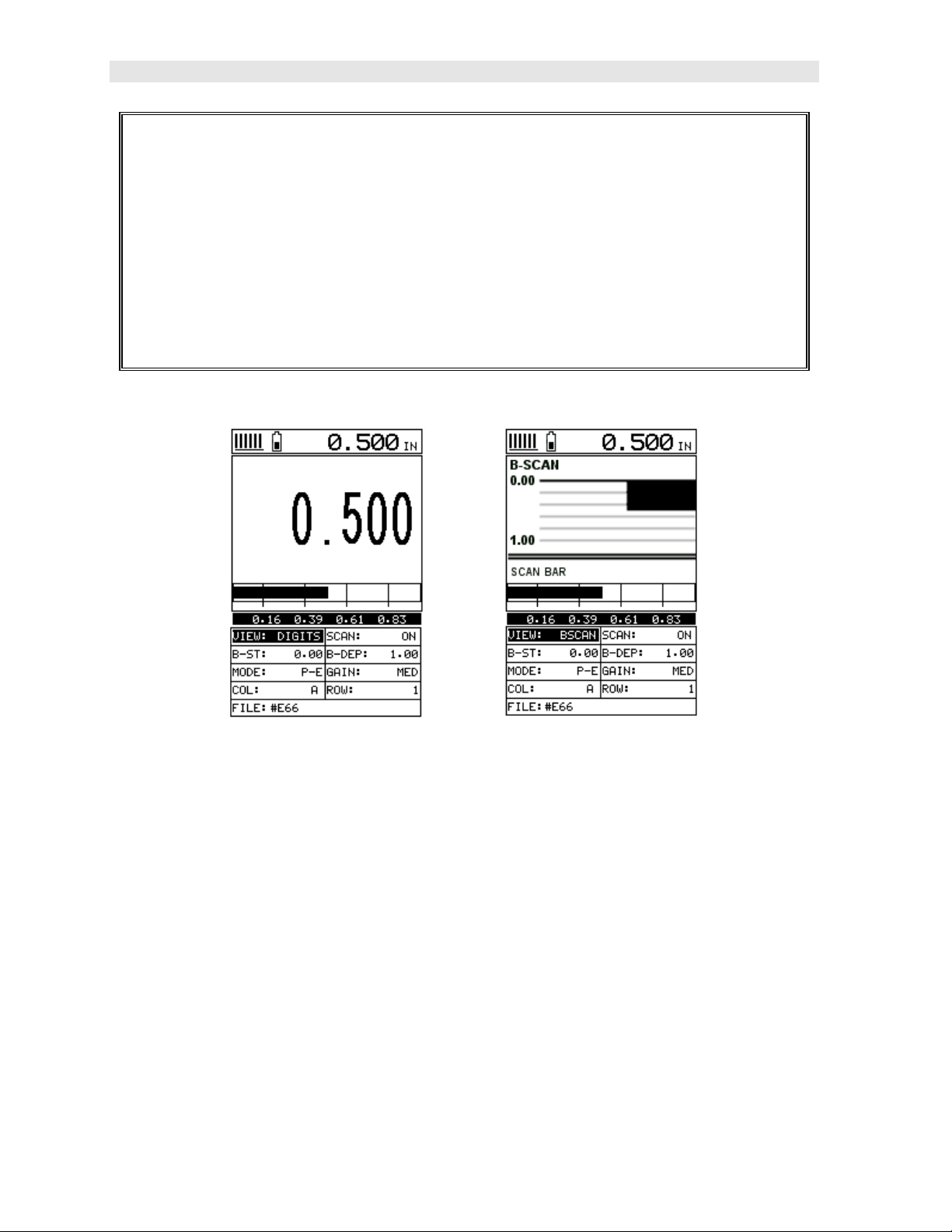

7.2 Display Views

DIGITS VIEW

DIGITS

The Digits view is a basic digital thickness gauge look and feel. The larger digits

make it much easier for the operator to monitor the thickness readings. The Scan

Bar has also been added to the Digits view to provide the user with yet another visual

tool for easily monitoring changes in thickness readings due to internal flaws or

defects.

The following is a list of the viewable features on the display:

A) Stability of Reading Indicator – Indicates the stability of the return echo on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the PVX-B is displaying a reading from memory, the repeatability

indicator will be replaced by the text “MEM”.

B) Battery life indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness reading – Digital readout of thickness (inche s or millimeters).

D) Large Digits – Large readout of thickness (inches or millimeters).

E) Units Label – Display’s the current unit of measurement (inches or millimeters).

F) Measurement Labels – The measurement labels are calculated and displayed

based on where the left side of the display has been set (B-ST), and the overall

viewable area (B-DEP) of the display. Note: The gray hash marks break the

40

Page 45

PVX-B Precision Visual Thickness Gauge

display up into 5 segments, or quadrants. The measurement labels correspond to

the measurement at each hash mark.

G) Scan Bar – The scan bar corresponds directly with thickness represented by the

horizontal labels on the on the display. As you can see from the diagram above,

the filled horizontal bar is displayed at .500”. This display can be very useful

when scanning materials in either B-Scan or Digits display views. It is much

easier to watch and notice deflections from flaws and general changes in

thickness using the scan bar, rather than trying to notice changes in the digital

value. If the user is scanning a material, for instance, and passes over a flaw

during the process, the scan bar will quickly deflect and alarm the user to go back

and search for the defect.

H) Hot Menus - Each of the fields located under the display are called the Hot Menu

Fields. These fields allow quick control of some of the fine adjustments needed

to control the display settings, measurement modes, and grid memory control.

All of these fields can be adjusted without having to activate the tabbed menu

items and searching through a variety of menus to make adjustments.

B-Scan View

B-Scan

The B-Scan displays a time based cross section view of test material. This view is

commonly used to display the contour of the blind, or underside, surface of the

material being tested. It is very similar to a fish finder. If a flaw is located during a

scan, the B-Scan will draw the flaw on the screen. The solid black rectangle in the

diagram at location E represents the cross section, or side view of the material. You

will notice that the overall thickness of the material is .500”, and the display range is

0.00” to 1.00” respectively. The B-Scan view draws at a rate of 15 seconds per

screen from right to left. Also notice at location J, the contour thickness changes of

the bottom surface of the material.

41

Page 46

Dakota Ultrasonics

It’s important to note that the measurement range on the display be set wide enough,

so that the maximum thickness of the material can be viewed on the display. Using

the diagram above, if the material thickness was actually 1.75”, the underside of the

material would not be viewable according to the current range at 0.00” – 1.00”. All

the user would see is a black screen from 0.00” – 1.00” with no view of the bottom

contour at 1.75”.

The following is a list of the viewable features on the display:

A) Stability of Reading Indicator – Indicates the stability of the echo signal on a

scale of 1 to 6 – the solid bars displayed in the figure above indicate a repeatable

signal. If the PVX-B is displaying a reading from memory, the repeatability

indicator will be replaced by the text “MEM”.

B) Battery life indicator – Fully charged batteries will appear filled in solid. Note:

The diagram shows the batteries at approximately 50%.

C) Thickness reading – Digital readout of thickness (inche s or millimeters).

D) B-Scan Display Area – This is the area representing where the B-Scan will be

drawn. Notice the range of the area in the diagram at 0.00” – 1.0” respectively.

E) Displayed B-Scan – Graphical presentation of the cross section, or side view of

the test material. The top, or accessible side of the material represented as 0.00”,

and the bottom, or blind surface at .500”. You will notice the contour in the B-

Scan, indicating a very irregular bottom surface. The B-Scan is displayed from

right to left at a rate of 15 screens per second.

F) Measurement Labels – The measurement labels are calculated and displayed

based on where the left side of the display has been set (B-ST), and the overall

viewable area (B-DEP) of the display. Note: The gray hash marks break the

display up into 5 segments, or quadrants. The measurement labels correspond to

the measurement at each hash mark.

G) Units Label - Display’s the current unit of measurement (inches or millimeters).

H) Hot Menus - Each of the fields located under the B-Scan display are called the

Hot Menu Fields. These fields allow quick control of some of the fine

adjustments needed to control the display settings, measurement modes, and grid

memory control. All of these fields can be adjusted without having to activate the

tabbed menu items and searching through a variety of menus to make

adjustments.

I) Scan Bar – The scan bar corresponds directly with thickness represented by the

horizontal labels on the on the display. As you can see from the diagram above,

the filled horizontal bar is displayed at .500”. This display can be very useful

when scanning materials in either B-Scan or Digits display views. It is much

easier to watch and notice deflections for flaws and pits using the scan bar, rather

than trying to notice changes in digital values. If the user is scanning a material,

for instance, and passes over a flaw in the process, the scan bar will quickly

deflect and alarm the user to go back and search for the defect.

42

Page 47

PVX-B Precision Visual Thickness Gauge

J) Contour (blind surface) – A view of the B-Scan displaying the blind side surface

contour of the material.

7.3 Adjusting the B-Scan Start (B-ST) & Depth (B-DEP)

In order to use the B-Scan and Scan Bar features of the PVX-B effectively, the

starting depth and overall depth must be setup correctly. This can be adjusted using

the B-ST (start) and the B-DEP (depth) features of the PVX-B. The B-ST refers to

the starting depth or thickness value displayed. Example: If you want your B-Scan

or Scan Bar to start at a zero thickness value, then B-ST must be set to 0.000”. If

you want the B-Scan and Scan Bar to start displaying at .125”, then B-ST must be

set to .125”. B-DEP represents overall viewable thickness range being tested.

Example: If your measuring tank walls with a total thickness of .300”, and your B-ST

has been set to 0.000”, you might consider setting your B-DEP value to something

like 0.400” to cover the entire thickness range being tested. You might also consider

B-DEP as a zoom feature for both the B-Scan and Scan Bar. Why? Because the

larger the overall thickness range view (B-DEP), the smaller the noticeable shifts in

the Scan Bar and B-Scan presentation. Therefore, it’s best to set the B-ST and B-

DEP to reasonable values that zoom in and optimize your graphic representations.

Overall range (B-DEP)

Once again, just to reiterate, B-DEP is the overall viewable thickness range being

tested. This should be set to a value slightly larger than the expected maximum

range being measured. The procedures to adjust the overall thickness range viewed

(B-DEP) are outlined below:

Adjusting the Depth (B-DEP) using the Hot Menus

43

Page 48

Dakota Ultrasonics

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the B-DEP cell is highlighted.

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the B-DEP value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the B-DEP.

The user can also access and adjust the B-DEP range from the tabbed menus.

However, this method is a more tedious than making the adjustments using the Hot

Menus. The procedure using the tabbed menus is outlined below:

Adjusting the Overall Depth (B-DEP) using the Tabbed Menus

44

Page 49

PVX-B Precision Visual Thickness Gauge

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until BSCAN DEPTH is highlighted.

3) Press the LEFT and RIGHT arrow keys to scroll the value. When the

correct width is being displayed, proceed to step 8.

4) Alternatively, press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the Bscan Depth value is correctly displayed.

8) Press the OK key to set the Bscan Depth and return to the menu screen, or

ESC to cancel entering the Bscan Depth.

9) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

Starting depth (B-ST)

The starting B-ST, or starting depth, is the starting thickness value. Often times this

value will simply be set to zero in order to start measuring at 0.000”. The only time

this value will be set to something other than zero, is if the user needs to zoom in

even closer. When will this be the case? If the user is testing a material that’s 1 inch

in thickness and knows that the potential corrosion is only on the back surface of the

material and not possibly deeper than .200”. In this case, the user may wish to set

the B-ST at .700” to zoom in closer to the actual area being tested. In turn, the B-

DEP might be set at 1.100” in order to cover the entire range respectively. This will

offer the user better resolution for both the B-Scan and Scan Bar graphical

presentations.

Note: Once the range is set, it will remain the same for all the views respectively.

45

Page 50

Dakota Ultrasonics

The procedures to adjust the starting depth (B-ST) are outlined below:

Adjusting the Starting Depth (B-ST) using the Hot Menus

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the B-ST cell is highlighted.

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the B-ST value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the B-ST.

The user can also access and adjust the B-ST from the tabbed menus. However,

this method is more tedious than making the adjustments using the Hot Menus. The

procedure using the tabbed menus is outlined below:

46

Page 51

PVX-B Precision Visual Thickness Gauge

Adjusting the Starting Depth (B-ST) using the Tabbed Menus

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the DISP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until BSCAN START is highlighted.

3) Press the LEFT and RIGHT arrow keys to scroll the value. When the

correct BSCAN START is being displayed, proceed to step 8.

4) Alternatively, press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the BSCAN START number is correctly displayed.

8) Press the OK key to set the BSCAN START and return to the menu screen,

or ESC to cancel entering the BSCAN START.

9) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

47

Page 52

Dakota Ultrasonics

7.4 Gain

The gain, or amplification of the return echoes, can be adjusted in the PVX-B to

accommodate a variety of applications. The setting of the gain is crucial in order to

obtain valid readings during the measurement process. Too much gain may result in

erroneous measurements, by detecting on noise rather than the actual material back

wall itself. Not enough gain may result in intermittent detection. It may also result in

lack of detection on internal flaws, pits, or porosity. The gain can easily be compared

to the volume control of a home stereo system. If you turn it up too much, you can’t

hear the music clearly. If it’s turned down too much, you can’t hear it at all.

The PVX-B has three gain settings LOW, MED, HIGH). Note: The PVX-B has been

optimized for the MED gain setting for all common performance racing applications.

It should be operated in this mode as standard. However, some applications may

require the low or high gain setting. When? The low set ting may be necessary for

certain cast aluminum materials, or very extremely granular cast iron materials. How

do I know when to lower the gain? If the reading becomes sporadic and won’t settle

down or resolve on a thickness value, the user can assume that the material is either

very noisy aluminum, or granular cast iron. This would be a good time to change the

PVX-B to low gain setting and see if the reading settles down and become stable.

How do I know when to increase the gain? Often times the user will be trying to

measure a material that is hard to penetrate or pass sound through. This may be

due to the material type, or overall thickness of the material. When a material is hard

to pass sound through because of the thickness or general make-up, it would be a

good time to consider switching the PVX-B into a high gain setting. In any case, the

selectable gain settings offer the user some additional options to resolve application

issues.

Note: When the echo-echo thru-paint measurement mode is selected, the gain

manual gain feature is disabled and grayed out in the menu items. In this mode, the

PVX-B switches to an automatic gain mode (AGC) that optimizes the gain setting

automatically in the hardware of the PVX-B.

The procedures to adjust the Gain are outlined below:

Adjusting the Gain using the Hot Menus

48

Page 53

PVX-B Precision Visual Thickness Gauge

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right, and the ESC key multiple times to

move left until the GAIN cell is highlighted.

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the GAIN value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the GAIN.

The user can also access and adjust the gain from the tabbed menus. However, this

method is more tedious than making the adjustments using the Hot Menus. The

procedure using the tabbed menus is outlined below:

Adjusting the Gain using the Tabbed Menus

1) Press the MENU key once to activate the menu items tab. Press the

MENU key multiple times to tab right, and the ESC key multiple times to tab

left, until the PROBE menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until GAIN is highlighted.

49

Page 54

Dakota Ultrasonics

3) Press the LEFT and RIGHT arrow keys to scroll the value. When the

correct Gain is being displayed, proceed to step 8.

4) Alternatively, press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the Gain value is correctly displayed.

8) Press the OK key to set the Gain and return to the menu screen, or ESC to

cancel entering the Gain.

9) Finally, press the MEAS key to return to the measurement screen and

begin taking readings.

50

Page 55

CHAPTER EIGHT

THRU PAINT MEASUREMENT TECHNIQUE

8.1 Introduction to Thru Paint Measurement

The principle behind thru paint measurement is by measuring the time between two

back wall echoes returning from the test material. Since both of these back wall

echoes travel the same path through the paint or coating, the thickness of the coating

is subtracted out of the measurement so that only the actual material thickness can

be measured. This feature saves the user a great deal of time scraping and

removing the coating from materials during the inspection process.

The primary purpose of thru paint measurement is to determine actual or overall

material thickness by eliminating the coating thickness. The PVX-B has general

factory setups that have been adjusted according to the transducer type and for

overall optimization. Since the PVX-B doesn’t have a scope for fine adjustments,

these setups cannot be altered. For specific applications where the standard factory

setups are not successful, contact Dakota Ultrasonics to send samples to the factory

to create a custom setup. The PVX-B can be programmed with custom setups

created with our PVX scope.

8.2 Using Thru Paint Mode

The first thing to note in this section is that by selecting the transducer types labeled

I-E & E-E from the factory setups stored in the PVX-B, a basic echo-echo thru paint

configuration is recalled from memory. Each of the transducers in the setup list

contain pre-configured interface-echo (I-E) and echo-echo (E-E) settings. Test the

feasibility of your application. If you’re not having any luck, have samples sent in to

factory for our evaluation.

51

Page 56

CHAPTER NINE

ADDITIONAL FEATURES OF THE PVX-B

9.1 Language Selection

The PVX-B is equipped with a multi language selection feature. This is an added

feature for to accommodate everyone. The procedures are outlined below:

Selecting the Language using the Tabbed Menus

1) Press the MENU key once to activate the menu items tab. Press the

MENU key multiple times to tab right, and the ESC key multiple times to tab